A Guide to Lab Testing for Supplements

Our expert guide to lab testing for supplements covers choosing a lab, understanding test types, and ensuring your product's safety and quality.

Get a Free Quote Today!

Get a Free Quote Today!When you’re in the supplement business, lab testing isn’t just a good idea—it’s the scientific process of proving your product’s identity, purity, potency, and safety. This kind of third-party verification is an absolute must for any brand that takes itself seriously. It moves you past just checking a compliance box and becomes a true cornerstone of customer trust.

Honestly, it's the only real way to prove that what's on your label is what's actually in the bottle.

Why Supplement Testing Is a Brand Imperative

In a market that’s more crowded than ever, rigorous third-party lab testing is what separates the trustworthy brands from the rest of the pack. Think of it less as a chore and more as a fundamental investment in your brand’s reputation and future. Cutting corners here is a massive gamble, one that can lead to costly product recalls, legal nightmares, and a loss of customer confidence that’s almost impossible to win back.

This proactive mindset is becoming more and more critical. The global market for nutraceutical product testing is on a rocket ship trajectory, projected to more than double from $2.93 billion to an estimated $7.33 billion by 2035. This isn't a fluke; it's a direct response from consumers demanding products that are proven to be high-quality and safe. You can explore additional insights into this expanding market to see what it means for your brand.

The Pillars of Product Integrity

I like to think of lab testing for supplements as building the foundation of your product. Each type of test is a pillar holding up its quality and the claims you make. If one of those pillars is weak, the whole structure could come crashing down.

Here's a breakdown of the core pillars that support every great supplement product. Each one answers a very specific question about what you're selling.

| Testing Category | What It Verifies | Example Test |

|---|---|---|

| Identity | Is the ingredient what we say it is? | Confirms you have Echinacea purpurea and not a different, less effective species. |

| Purity | Is the product free of harmful junk? | Screens for heavy metals (like lead), microbes (E. coli), pesticides, and other contaminants. |

| Potency | Is the dose correct? | Verifies that if your label says 500 mg of Vitamin C, that's exactly what's inside. |

| Safety | Is it safe for consumption? | A comprehensive assessment combining data from the other tests to confirm overall safety. |

Ultimately, these tests culminate in a Certificate of Analysis (COA), which is your definitive proof of due diligence.

A Certificate of Analysis (COA) from a qualified lab isn't just a piece of paper—it's your proof. It's how you show customers, retail partners, and regulators that you’re all-in on transparency and quality.

Your Roadmap to Quality Assurance

Seeing lab testing as just another recurring expense is a classic, short-sighted mistake. A much smarter way to look at it is as a critical investment that protects your customers and shields your brand from massive liability. I’ve seen it happen: a single batch of a contaminated or mislabeled product can wipe out years of hard work, causing financial and reputational damage that’s devastating.

This guide is designed to be your actionable roadmap for building a solid testing strategy. We’ll walk through every crucial stage, from picking the right lab and understanding the key tests to making sense of your results and navigating the regulatory landscape.

By the end, you'll have the practical knowledge to build a quality assurance program that not only fosters trust but sets your brand up for real, long-term success.

How to Select the Right Testing Laboratory

Choosing a lab partner isn't just about finding the lowest bidder; it's one of the most critical relationships you'll build for your brand. Think of your lab as a partner in quality, an independent validator of your product's integrity. The right choice gives you unshakeable confidence in every batch, while the wrong one can inject massive risk and uncertainty into your business.

Your search should always start with one non-negotiable requirement: ISO/IEC 17025 accreditation. This isn't just a certificate to hang on the wall. It’s the international gold standard for the technical competence of testing and calibration laboratories. It proves the lab has a robust quality management system and can produce consistently valid results.

Without this accreditation, you’re essentially gambling on the lab’s internal processes. It’s the first and most important box to check.

Look Beyond Basic Credentials

Once you've confirmed a lab holds ISO/IEC 17025 accreditation, the real vetting process begins. Not all accredited labs are created equal, especially when it comes to the unique challenges of dietary supplements.

Consider your product line. If you're selling a single-ingredient Vitamin D3, your testing needs are fairly straightforward. But if your flagship product is a complex multi-herb blend for stress support, you need a lab with deep expertise in botanical testing. They must understand the nuances of different plant parts, extraction methods, and potential adulterants.

A lab's true value is in its specific expertise. Ask potential partners to share case studies or examples of how they've tested products similar to yours. Their answer will reveal their depth of knowledge far better than any marketing brochure.

To help you understand the landscape of lab certifications, here's a breakdown of what to look for and why it matters.

Lab Accreditation and Certification Comparison

| Certification/Accreditation | What It Signifies | Why It Matters for Supplements |

|---|---|---|

| ISO/IEC 17025 | The international standard for technical competence of testing labs. Verifies both the quality management system and the ability to produce valid results. | This is the foundational requirement. It ensures the lab's data is reliable, accurate, and scientifically defensible, which is critical for regulatory compliance and product safety. |

| cGMP Compliant | The lab follows Current Good Manufacturing Practices as outlined by the FDA. This applies to their handling, testing, and documentation procedures. | For supplements, cGMP is the law. Partnering with a cGMP-compliant lab ensures they understand and operate within the same regulatory framework you do, reducing compliance risk. |

| FDA Registered | The facility is registered with the U.S. Food and Drug Administration. It allows the FDA to be aware of the facility and its activities. | While registration itself doesn't imply endorsement, it's a basic requirement for any lab involved in the U.S. supplement supply chain. It shows they are on the regulatory radar. |

Choosing a lab with the right combination of these credentials ensures they are not only technically competent but also fully aligned with the specific regulatory demands of the supplement industry.

The Critical Questions to Ask

Creating a shortlist of potential labs is just the start. You need to interview them as you would a key employee. Your goal is to understand their processes, communication style, and how they handle problems—because problems will inevitably arise.

Here are some essential questions to guide your conversations:

- Methodology: What specific testing methods do you use for potency (e.g., HPLC, GC-MS) and contaminants (e.g., ICP-MS)? Can you explain why you choose a particular method for a specific ingredient?

- Turnaround Time (TAT): What is your standard TAT from sample receipt to the final Certificate of Analysis? What are the options and costs for expedited service?

- Out-of-Specification (OOS) Policy: What is your exact process when a sample fails testing? How do you conduct an investigation, and what are the steps for re-testing?

- Sample Requirements: What are your submission guidelines regarding sample size, type (e.g., finished product vs. raw material), and shipping?

When evaluating potential partners, it's also smart to consider what comprehensive test services they offer. A lab that can handle all your needs—from identity to stability—can become a more efficient, long-term partner.

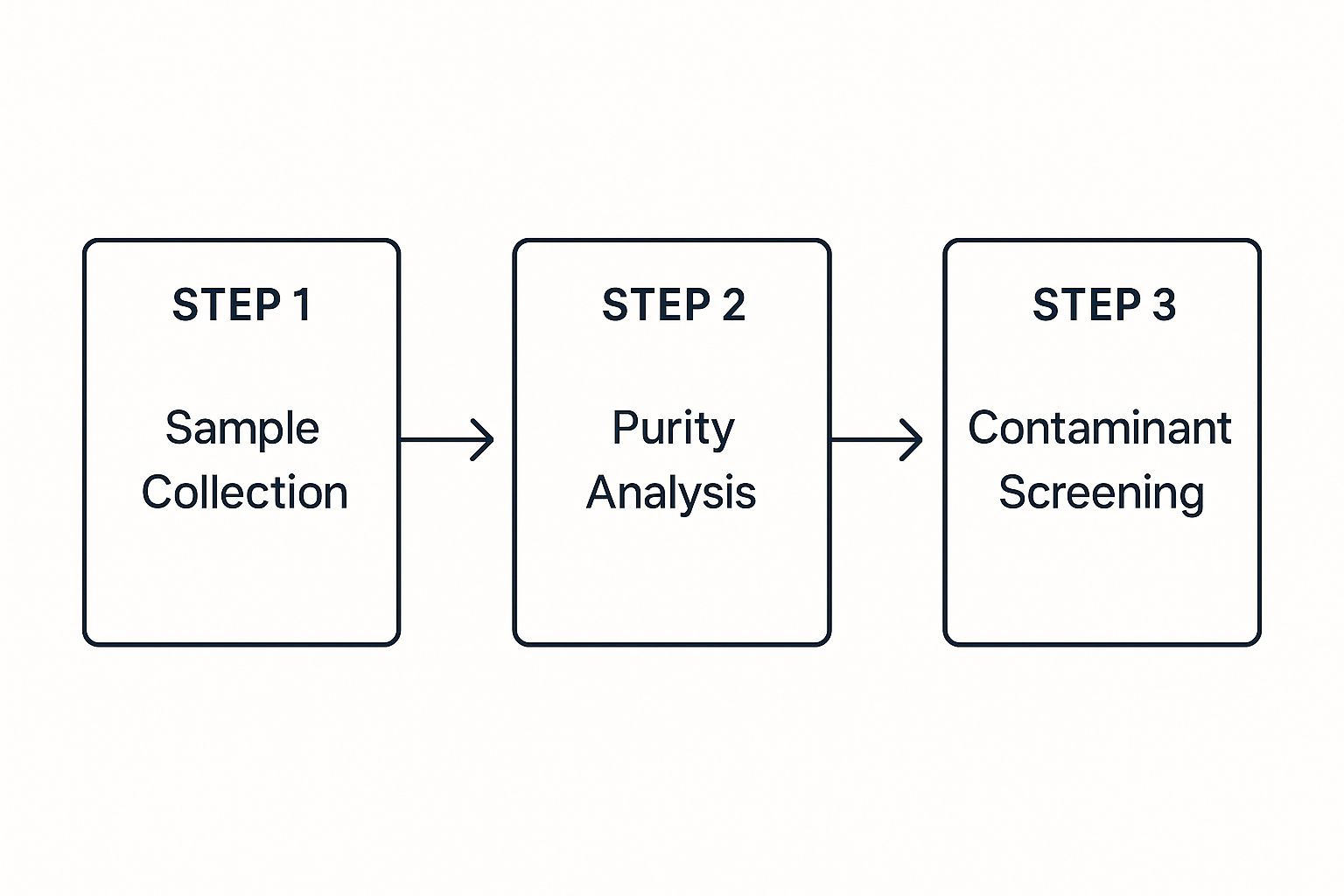

The path a sample takes from receipt to final report is a detailed one, as shown below.

This workflow highlights the journey from simple collection to detailed analyses for both the good stuff (active ingredients) and the bad (unwanted contaminants).

Finding a True Partner

Ultimately, you aren't just buying data points; you're looking for a true partner who is invested in your brand's quality. This is someone who will call you to discuss an unusual result, not just email a failing COA and move on. The best lab relationships are collaborative.

This partnership approach is a core principle in the manufacturing process as well. For those working with a partner for production, understanding the connection between manufacturing and testing is key. You can discover more about the benefits of working with an expert in our guide to nutraceutical contract manufacturing. A great manufacturing partner will already have established relationships with reputable labs, streamlining the entire quality assurance process for your brand.

Finding a lab with a collaborative spirit is just as important as finding one with the right equipment.

Understanding the Most Important Supplement Tests

Stepping into the world of lab testing for supplements can feel a bit like learning a new language. You'll hear a lot of acronyms—HPLC, ICP-MS—and terms like "microbial load" or "potency assay." But don't let the jargon intimidate you. Behind it all are simple, critical questions every responsible brand has to answer to make sure its products are safe, effective, and honest.

This isn't just about checking a regulatory box. This process is the scientific foundation of your product's quality. Each test gives you a vital piece of the puzzle, confirming that the product you designed on paper is exactly what your customers get in the bottle.

Identity Testing: What Is It, Really?

The first and most fundamental question is always: "Is this ingredient what we think it is?" That’s the entire job of identity testing. It’s about verifying the authenticity of your raw materials and, later, your finished product. It’s how you make sure you haven’t been sent a cheaper, less effective, or completely different substance.

For something simple like Vitamin C (ascorbic acid), this is pretty straightforward. But for a complex botanical blend? It gets much more complicated. A good lab needs to be able to tell the difference between Echinacea purpurea and other, less desirable species of the same plant.

Here are a few common methods used for identity testing:

- Organoleptic Analysis: A trained expert uses sight, smell, and even taste as a first-pass check. It’s an old-school method, but it should always be followed up with hard science.

- Microscopy: This involves looking at the material under a microscope to identify its unique cellular structure. It's especially useful for whole herbs and powders.

- High-Performance Thin-Layer Chromatography (HPTLC): This technique creates a distinct chemical "fingerprint" for a botanical, which is then compared to a verified reference sample.

Frankly, without solid identity testing, every other quality check is pointless. If you don't even have the right ingredient, who cares about its potency or purity?

Potency Testing: Does It Match the Label?

Okay, so you've confirmed you have the right stuff. The next logical question is, "Is the dose correct?" This is where potency testing comes in. It measures the amount of active ingredients in your product to ensure it lines up perfectly with the claims on your label.

If your label promises 500 mg of turmeric extract standardized to 95% curcuminoids, potency testing is how you prove it. This is a big deal for both consumer trust and regulatory compliance. The FDA doesn't take label claims lightly, and if you consistently miss the mark on potency, you could face serious penalties.

Think of potency testing as your brand's promise, quantified. It's the hard data that shows your customers they are getting the exact dosage they paid for, every single time. It builds a level of trust that marketing alone can't achieve.

The specific lab method used often depends on the ingredient. High-Performance Liquid Chromatography (HPLC) is a real workhorse for quantifying things like vitamins, amino acids, and specific plant compounds. Other methods are used for minerals and enzymes.

Purity and Contaminant Screening: Is It Clean and Safe?

This might be the most critical piece of the puzzle. Purity and contaminant testing is all about making sure your product is free from anything that could cause harm. This is a broad category, covering everything from environmental toxins to microbial pathogens. All it takes is one contaminated batch to seriously hurt consumers and do irreparable damage to your brand's reputation.

This is exactly why having a comprehensive testing plan is non-negotiable. The global market for dietary supplement testing services is exploding—growing from $2.93 billion to an anticipated $3.2 billion—because brands and consumers are demanding higher safety standards. These services cover analytical and microbiological testing, plus the stability testing that ensures a product stays safe and effective throughout its shelf life. You can see detailed projections on this market's growth to get a feel for where the industry is heading.

Here are the key contaminant tests every brand should be running:

- Microbial Screening: This looks for nasty bacteria like E. coli and Salmonella, plus total yeast and mold counts. It’s a must-do to prevent foodborne illness.

- Heavy Metals Analysis: Typically done with Inductively Coupled Plasma Mass Spectrometry (ICP-MS), this test screens for dangerous heavy metals like lead, arsenic, cadmium, and mercury, which can sneak into raw materials from the soil and water.

- Pesticide Residue Testing: For any botanical ingredient, it’s crucial to test for pesticides left over from cultivation. Labs can run panels that screen for hundreds of different pesticides at once.

- Residual Solvents Analysis: If you’re using solvent-based extracts, this test makes sure no harmful chemicals like hexane or methanol are left behind in the final product.

By systematically tackling identity, potency, and purity, you build a complete quality profile for your supplement. This data isn't just for regulators; it’s the very foundation of a brand that people can trust with their health.

Making Sense of Your Certificate of Analysis (COA)

When your lab results land in your inbox, it's a big moment. But that document, the Certificate of Analysis (or COA), can look like a complex puzzle at first glance. Think of it less as a simple pass/fail slip and more as a detailed story about your product batch. Learning to read it properly turns this document from a regulatory checkbox into a powerful tool that proves your commitment to quality through lab testing for supplements.

Even before the COA is created, though, everything hinges on proper sample handling. You have to be certain the sample you send the lab is truly representative of the entire batch. This is where composite sampling comes in—we take small amounts from multiple locations within the batch and combine them. It’s a simple but critical step to avoid a "hot spot" of high potency or a single contaminated area from skewing the results for the whole run.

Breaking Down the COA, Section by Section

Once you have the COA, resist the urge to just scan for a "pass." A true quality pro knows the real value is in the details. A standard COA is usually broken down into a few key areas, and each one tells you something important.

Here's what I always look for, piece by piece:

-

Header and Sample Information: This is your first stop. The top of the document should clearly identify the lab, your company, and the specific product name. Most importantly, find the unique batch or lot number. Always, always cross-reference this with your own production records to make sure the report matches the correct batch. No exceptions.

-

Date of Analysis: Check the dates for both sample receipt and the actual analysis. A big gap between these dates can be a red flag. It might signal a backlog at the lab or that your sample just sat there untested for too long, which is a real problem for sensitive ingredients.

The Core Data: Analyte, Specification, and Result

This is the heart of the COA, usually laid out in a table. It’s where the lab shows what it tested for, what your acceptable limits are, and what it actually found.

Here’s how to decipher it:

-

Analyte: This column lists the exact substance being measured. It could be an active ingredient like "Vitamin C (as Ascorbic Acid)," a heavy metal like "Lead (Pb)," or a microbe like "Total Aerobic Count."

-

Specification (or Limit): This is your brand's own predefined acceptable range for that analyte. For an active ingredient's potency, you might set a specification of 100% to 110% of the label claim. For a contaminant like lead, the limit might be something like <0.5 parts per million (ppm).

-

Result: This is the lab’s actual measurement. It’s where you see if your product hits the mark.

-

Method: This tells you the scientific technique used for the test, like HPLC for potency or ICP-MS for heavy metals.

A rookie mistake is to only look at the "Pass" or "Fail" summary. The real insight comes from seeing where the result falls within your spec. A potency result that barely squeaks by at 100.1% might technically pass, but it could point to a potential problem with your formulation consistency that needs a closer look.

Responding to Out-of-Specification Results

Seeing an "Out of Specification" (OOS) or "Fail" result is always stressful, but it's a vital part of a functioning quality system. Don't panic. Investigate.

Your first move should be to contact the lab immediately and kick off an OOS investigation. They’ll review their own procedures, double-check their equipment, and may even re-test the original sample or ask for a new one.

If the failure is confirmed, you must quarantine the entire batch. That product cannot be released for sale. Period. This is how you protect consumers and uphold your brand’s integrity.

Remember, the data on your COA directly supports the claims on your product’s label. Making sure all your ducks are in a row is essential for compliance. You can learn more about how all these pieces fit together in our detailed guide to dietary supplement labeling guidelines.

Ultimately, a failed COA, while disappointing, is proof that your quality system is working. It’s catching problems before they can ever reach your customers.

Navigating Regulatory and cGMP Compliance

Staying on the right side of the FDA is about so much more than just dodging warning letters. In the supplement world, rock-solid compliance is a core business strategy that builds trust, protects your brand, and frankly, is just good business. The entire rulebook for this is the FDA's Current Good Manufacturing Practices (cGMP), laid out in 21 CFR Part 111. These aren't just suggestions—they're the law.

When you first look at the regulations, they can feel incredibly dense and overwhelming. But the principle at the heart of it all is quite simple: you need objective, scientific proof that your product is exactly what you claim it is, every single time. This is where the lab testing for supplements we've been talking about comes directly into play. It's the "how" behind your quality promises.

The cGMP Testing Checklist

Under cGMP, you have a legal duty to perform at least one identity test on every dietary ingredient that comes through your door. But that's just the starting line. The regulations also demand that you verify the identity, purity, strength, and composition of your finished supplement batches. This means you need a clear, documented testing plan.

Your plan absolutely must cover these key checkpoints:

- Raw Material Identity: Is every incoming ingredient what the supplier says it is? You have to verify this before it even thinks about entering your production line.

- Finished Batch Potency: Does the final product actually contain the active ingredients at the levels you proudly state on your label? Prove it.

- Purity and Contaminant Screening: Every batch needs to be screened for things you don't want, like microbes, heavy metals, or residual solvents.

- Composition Verification: Is the final product formulated correctly? This is especially critical for complex blends with multiple ingredients.

Cutting corners here isn't an option. These are the non-negotiable minimums for creating a product that's both safe and legally sound.

cGMP compliance is your operational playbook for quality. It forces you to document every step, from vetting suppliers to testing finished goods, creating a transparent and defensible quality system that protects both your customers and your brand.

Substantiating Your Marketing Claims

Beyond the foundational cGMP requirements, any specific marketing claims on your label—like "gluten-free" or "non-GMO"—have to be backed by solid scientific evidence. This is where targeted lab testing becomes your best friend, helping you steer clear of false advertising claims that can trigger class-action lawsuits and hefty regulatory fines.

Let’s look at a few real-world examples:

- "Gluten-Free" Claim: You can't just guess. You must use a validated method, like an ELISA assay, to prove your product contains less than 20 parts per million (ppm) of gluten.

- "Non-GMO" or "GMO-Free" Claim: This requires specific DNA testing. PCR (Polymerase Chain Reaction) testing is the standard for detecting the presence of genetically modified DNA.

- "Allergen-Free" Claim: If you claim your product is free from common allergens like soy, dairy, or nuts, you need the lab data from specific tests to back it up.

Failing to substantiate these claims with hard data is one of the biggest—and most avoidable—compliance risks a brand can take. You must have the evidence on hand, organized, and ready for inspection at a moment's notice.

Building a Compliant and Resilient Business

At the end of the day, cGMP and its testing requirements are a blueprint for excellence. Yes, following them ensures you make a high-quality product, but it also prepares you for the inevitable scrutiny that comes with building a successful brand. Having your documentation in order, with every Certificate of Analysis filed away, shows regulators you take your obligations seriously. For more on what this certification really means, check out our post on what a GMP certificate means.

Beyond the specific rules of cGMP, having a firm grasp of your broader legal obligations is vital for any growing supplement business. For a deeper look into general comprehensive business legal advice, external resources can offer valuable strategies for long-term stability. A proactive approach to both regulatory compliance and general business law isn't just smart—it's the mark of a truly mature and resilient brand.

The Future of Personalized Supplement Testing

If you want to lead in the supplement industry, you have to keep an eye on what’s coming next. The next big wave in lab testing for supplements isn't on the horizon—it's already here. And it’s all about personalization. Gone are the days of one-size-fits-all products. Today's consumers are smarter and more informed, and they demand supplements designed specifically for their unique biology.

This isn't just a hunch; it's a trend fueled by the explosion of at-home DNA and microbiome testing kits. People now have direct access to insights about their genetic makeup and gut health. This creates a powerful new expectation: supplements should be just as unique as they are. This isn't some niche corner of the market; it's a fundamental shift in consumer behavior.

The Rise of Data-Driven Nutrition

Personalized testing is absolutely booming as people actively hunt for health solutions that feel made for them. The global market for this niche, currently valued around $11.77 billion, is on a rocket ship trajectory, projected to hit nearly $28.73 billion by 2030. This incredible growth is coming from health-conscious consumers who want supplements that speak directly to their genetics and specific health data. You can dig into the full research on this personalized nutrition market to see just how massive this opportunity is.

For supplement brands, this is a golden opportunity to build a much deeper, more meaningful connection with customers. Just imagine it: you could create a custom liquid formula designed to support a specific person's gut microbiome based on their individual test results. That level of customization isn't just a product; it's a service that builds unshakable brand loyalty.

The future isn't about selling a product; it’s about providing a solution. Personalized testing allows brands to move from a general recommendation to a specific, data-backed protocol that feels uniquely designed for the individual customer.

To keep up, the analytical technologies we rely on are also getting a major upgrade. New methods are constantly emerging that promise faster, more precise, and more comprehensive test results. By getting ahead of these changes, you can position your brand as a true innovator, ready and equipped to meet the next wave of consumer expectations for truly personalized wellness.

Got Questions About Supplement Testing? We've Got Answers.

When you're wading through the world of supplement manufacturing, lab testing can bring up a ton of practical questions that feel pretty overwhelming at first. Let's cut through the noise and get you some direct, actionable advice on the most common hurdles brands face.

How Often Should I Be Testing My Supplements?

This is easily one of the biggest questions we get. Should you test every single batch? The most straightforward, risk-averse answer is a resounding yes. Testing every batch gives you the highest possible level of assurance for both you and your customers. More importantly, it creates a complete, unbroken data record for every single product that goes out the door.

However, cGMP regulations do offer a path called a scientifically valid skip-lot testing program. This is an advanced strategy where you might test every fifth or tenth batch, but—and this is a big but—you can only do this after you’ve built up a bulletproof history of quality with a supplier you trust implicitly. You need a rock-solid statistical justification showing that your supplier consistently hits every spec, time after time.

If you’re a new brand or working with a new supplier? Test every batch. No exceptions. It’s the only way to build the foundational data you’ll need to even consider a skip-lot program down the road.

What's a Realistic Budget for Supplement Lab Testing?

Cost is always a huge factor, and the truth is, it's not a one-size-fits-all answer. The final price tag depends on a few key things: how complex the test is, the technology needed to run it, and the number of samples you’re sending. A simple Vitamin C potency test, for instance, will be a fraction of the cost of a full heavy metals panel on a multi-ingredient herbal blend.

To give you a ballpark idea, here’s what you might expect for some common tests:

- Microbial Panels (E. coli, Salmonella, Yeast & Mold): $75 - $200

- Heavy Metals (Lead, Arsenic, Cadmium, Mercury): $100 - $250

- Potency/Identity (via HPLC or HPTLC): $150 - $400+

A quick tip from experience: These are just estimates. The best way to keep costs in check is to bundle your tests and, more importantly, build a real relationship with your lab. They often offer volume-based discounts for loyal partners. But please, don't let price be your only guide. The cost of a bad result—or worse, a recall—from a cheap, unreliable lab is always, always higher in the long run.

Can't I Just Use My Manufacturer's Certificate of Analysis (COA)?

This is a critical point where so many new brands stumble. While your manufacturer's COA is a useful document, you absolutely cannot rely on it exclusively. The FDA’s cGMP regulations are crystal clear on this: you, the brand owner, are the one ultimately on the hook for your product's quality.

You are required to independently verify your supplier’s results to officially "qualify" them. That means sending samples to your own third-party lab to confirm their data is accurate. Simply forwarding their COA is a massive conflict of interest and shows you haven't done your regulatory due diligence. Independent verification isn't just a good idea; it's your proof that you've done the work to guarantee what's in your bottle.

At Triton Nutra Group, we don't just talk about quality—we build it into every step of the liquid supplement manufacturing process. From formulation support to in-house quality control and coordinating third-party testing, we offer the transparent, expert partnership you need to bring a market-ready product to life with total confidence. Turn your supplement vision into reality with us.