Nutraceutical Contract Manufacturing: The Complete Guide

Master nutraceutical contract manufacturing with proven strategies from industry experts. Learn how to choose partners, ensure quality, and scale success.

Get a Free Quote Today!

Get a Free Quote Today!Understanding Nutraceutical Contract Manufacturing

Imagine you have a brilliant idea for a new liquid vitamin C or a specialized herbal tincture. You’ve mapped out the brand, the vision, and the marketing strategy, but a massive hurdle remains: how do you actually produce it? Building a factory, buying specialized machinery, hiring chemists, and navigating complex regulations would require millions of dollars and years of work. This is where nutraceutical contract manufacturing comes in, offering a strategic partnership that lets your brand thrive without these immense burdens.

Imagine you have a brilliant idea for a new liquid vitamin C or a specialized herbal tincture. You’ve mapped out the brand, the vision, and the marketing strategy, but a massive hurdle remains: how do you actually produce it? Building a factory, buying specialized machinery, hiring chemists, and navigating complex regulations would require millions of dollars and years of work. This is where nutraceutical contract manufacturing comes in, offering a strategic partnership that lets your brand thrive without these immense burdens.

Think of it like being an architect designing a skyscraper. You create the blueprint, select the materials, and envision the final building. However, you don't personally pour the concrete or weld the steel beams. Instead, you partner with a construction company that has the heavy equipment, skilled labor, and operational knowledge to bring your vision to life safely and correctly. A contract manufacturer is your expert production partner, turning your supplement formula from a concept into a tangible, market-ready product.

What Does This Partnership Entail?

This relationship is much more than simple outsourcing. A great contract manufacturer acts as an extension of your team, providing a complete range of services that would be almost impossible for a new or growing brand to manage alone. They handle the complex details of the production process, freeing you up to focus on brand building, marketing, and customer connections. This is why everyone from ambitious startups to established global brands uses this model.

Key services often include:

- Sourcing Raw Materials: Gaining access to vetted, high-quality ingredients from a global network of trusted suppliers.

- Formulation and R&D: Working with expert chemists to refine your idea for stability, effectiveness, and taste.

- Production and Manufacturing: Using specialized equipment for blending, encapsulation, bottling, or creating liquid extracts.

- Rigorous Quality Control: Performing in-house and third-party testing to meet safety and purity standards.

- Regulatory Compliance: Making sure your product and its labeling follow cGMP and FDA guidelines.

The Driving Force of Industry Growth

The effectiveness of this model is clear from the market's rapid expansion. The global market for nutraceutical contract manufacturing services has grown significantly, climbing from $133.34 billion in 2022 to an estimated $174.09 billion in 2024. This impressive jump is fueled by a worldwide shift toward preventive health, a rising demand for personalized nutrition, and the growth of e-commerce. As more brands enter the market, the need for reliable, expert manufacturing partners becomes even more important. You can explore a full report on global nutraceutical services growth to understand these market dynamics better.

Ultimately, choosing to work with supplement contract manufacturers is a foundational business decision. It's about getting instant access to decades of accumulated knowledge, established supply chains, and advanced production technology. This partnership doesn't just save you money; it gives you a strong competitive edge, helping you bring better products to market faster than you ever could on your own.

Why Smart Brands Choose Contract Manufacturing

Successful supplement entrepreneurs learn a critical lesson early on: building your own manufacturing facility isn't just expensive—it's a massive distraction from the activities that actually grow your brand. Choosing nutraceutical contract manufacturing delivers much more than cost savings. It provides instant access to specialized expertise, proven quality systems, and the flexibility to respond to market changes. While your competitors are stuck dealing with production logistics, you are free to focus on what matters: understanding your customers, perfecting your formulas, and building a powerful brand.

The Strategic Edge: Beyond Cost Savings

The biggest benefit of working with a contract manufacturer is the immediate access to their deep well of knowledge. These partners have spent years, sometimes decades, perfecting their production methods, mastering complex regulations, and establishing reliable supply chains. For a new or growing brand, trying to build this level of institutional wisdom from scratch is an overwhelming and costly endeavor.

This partnership gives you a distinct competitive advantage, enabling your brand to:

- Accelerate Time-to-Market: Instead of dedicating months or even years to setting up a facility and buying equipment, you can go from a final formula to a market-ready product in a fraction of the time. This speed is essential for jumping on new consumer trends before they fade.

- Reduce Financial Risk: The investment needed for a cGMP-compliant manufacturing facility is huge. Contract manufacturing transforms this enormous capital expense into a manageable operational cost. This frees up your cash for what truly drives growth: marketing, inventory, and brand development.

- Access Advanced Technology: Leading manufacturers continuously invest in the latest production and testing equipment. This means your product benefits from top-tier technology without you having to pay for the purchase and upkeep yourself.

Focus on What Matters: Your Brand and Your Customers

Think of it like running a five-star restaurant. You wouldn't try to personally farm every vegetable and raise every animal yourself, would you? The quality of your dishes would decline because your attention would be divided. In the same way, managing manufacturing diverts precious time and resources from your core mission. By handing off production, you can pour all your energy into marketing, sales, and creating an amazing customer experience.

To make this choice clearer, let's look at a direct comparison between going it alone and partnering with an expert.

In-House vs. Contract Manufacturing: The Real Comparison

A comprehensive breakdown of costs, risks, and strategic implications to help you make the right decision for your business.

| Factor | In-House Manufacturing | Contract Manufacturing | Strategic Impact |

|---|---|---|---|

| Initial Cost | Extremely high (millions for facility & equipment) | Low (no capital expenditure on infrastructure) | Frees up capital for growth-driving activities like marketing and R&D. |

| Expertise | Built slowly over years, often through costly errors | Instant access to decades of production & compliance knowledge | Reduces errors, improves product quality, and ensures regulatory adherence from day one. |

| Speed to Market | Very slow (1-2+ years for facility setup) | Fast (weeks or months from formula to production) | Allows brands to be nimble and quickly respond to market opportunities. |

| Scalability | Limited by current facility and equipment capacity | Flexible, with the ability to scale production up or down as needed | Supports rapid growth without requiring another major capital investment. |

The takeaway here is clear: outsourcing manufacturing allows you to scale smarter and faster. You avoid the financial chains of a physical plant and gain a partner whose success is tied to yours.

Ultimately, choosing nutraceutical contract manufacturing is a strategic move that favors focus and agility. It empowers brands to leverage the experience of established experts, turning a great product idea into a market leader without the heavy burden and financial risk of building everything from the ground up. This path allows you to concentrate on creating a brand that customers know, trust, and love.

From Idea to Shelf: The Manufacturing Journey

Bringing a brilliant supplement idea to life—transforming it into a physical product customers can hold—is a fascinating, multi-stage journey. This process is much more than just mixing ingredients; it's a careful coordination of science, quality control, and logistics. A skilled nutraceutical contract manufacturing partner acts as your guide, taking your vision through each critical phase to ensure the final product is safe, effective, and ready for the market.

The journey usually starts with a deep dive into your concept. A manufacturer's research and development team becomes your scientific co-pilot, helping you sort through the details of formulation. They analyze how different active ingredients interact, work to improve taste and texture, and confirm the final blend will stay stable and potent throughout its shelf life. This initial stage is where your idea begins to take real shape, moving from a concept to a workable recipe.

The Core Manufacturing Phases

Once the formula is perfected, it moves into a structured production workflow. This is designed to make sure every single bottle is consistent with the last, upholding the quality your brand represents.

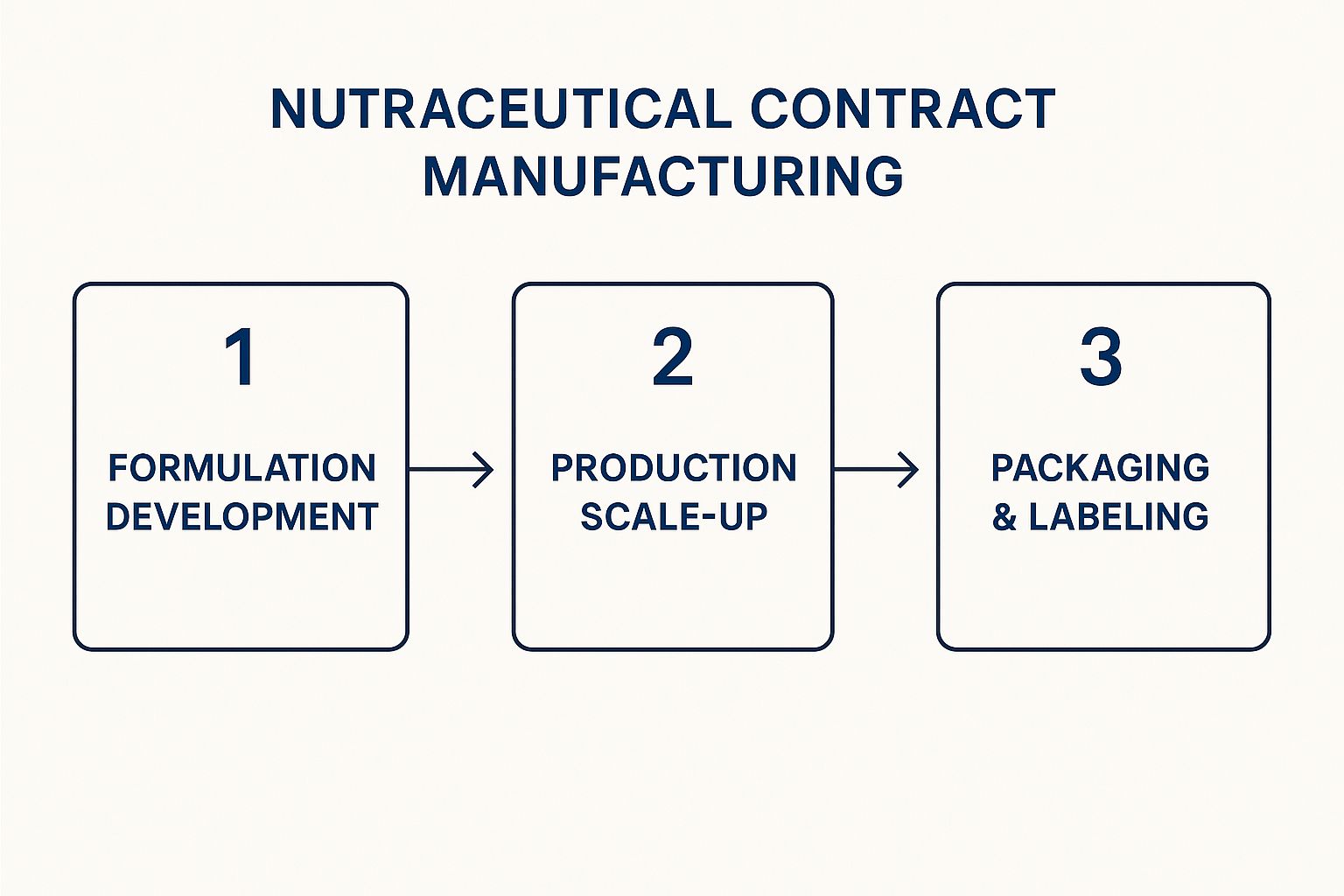

The infographic below shows the three fundamental stages that take your product from a blueprint to a reality.

This visual demonstrates that manufacturing is a step-by-step process. Each stage builds on the one before it, showing why it's so important to get each step right before moving on.

-

Formulation Development: This is where the initial magic happens. It involves sourcing high-quality raw materials, creating prototypes through pilot testing, and refining the formula for the best results and taste. A key decision here is the dosage form—whether it’s a capsule, liquid, or powder—as this choice affects everything from the customer experience to production costs. For instance, a liquid tincture requires very different stability testing than a powder blend.

-

Production Scale-Up: After a prototype is approved, the next challenge is to reproduce it on a commercial scale. This isn't as simple as just using a bigger mixer. Scaling up demands careful calculations to ensure a larger batch has the exact same properties as the small pilot batch. It involves precise material weighing, blending, and processing under strict cGMP (Current Good Manufacturing Practice) conditions to guarantee uniformity and prevent contamination. This stage requires specialized equipment and a deep understanding of the process.

-

Packaging & Labeling: The final step is getting the product ready for the customer. This goes beyond simply filling bottles. It includes applying labels that meet all regulatory guidelines, fitting tamper-evident seals, and preparing the finished goods for shipment. A solid nutraceutical contract manufacturing process is closely tied to effective supply chain management, ensuring a smooth flow from raw materials to finished products ready for retail or e-commerce fulfillment.

Every stage is underpinned by rigorous quality assurance. Testing happens at multiple points: raw materials are tested when they arrive, in-process samples are checked for consistency, and the final product undergoes demanding third-party analysis to confirm its potency and purity. This detailed attention ensures that the product on the shelf is exactly what you envisioned from the start.

Market Forces Driving Industry Growth

The nutraceutical contract manufacturing sector is riding a wave of growth, fueled by powerful shifts in consumer habits and global health awareness. For brand owners, grasping these forces is like a sailor understanding the wind and tides—it gives you a clear edge in the market. We are witnessing a fundamental change in how people manage their health, opening up massive opportunities for both veteran brands and new players.

This expansion isn't random. It’s driven by distinct market trends that are not only growing the customer base but also shaping the kinds of products people want.

Key Consumer and Market Drivers

Several key trends are behind the growing need for specialized supplement production. These forces are creating a larger pool of customers and dictating what they look for in a product.

- Proactive Health and Wellness: People are shifting from treating sickness to actively preventing it. They are now looking for supplements to support everything from their immune system to brain health. This creates a steady demand for high-quality, targeted nutraceuticals.

- The Rise of E-commerce: Online storefronts like Shopify and Amazon have democratized the market. Direct-to-consumer (DTC) brands can now connect with customers worldwide without needing a spot on a retail shelf. This has lowered the entry barrier, causing an explosion of new and specialized supplement brands that all need manufacturing partners.

- Personalization and Niche Markets: The era of one-size-fits-all supplements is over. Consumers want products designed for their specific needs, whether it's a vegan-friendly formula, a multivitamin for a particular gender, or a supplement to boost athletic recovery. A major influence here is the rising consumer demand for protein-enhanced beverages, a trend that directly shapes product development and manufacturing choices.

The Impact of Global Health Challenges

Beyond personal lifestyle goals, larger health issues are pushing consumers toward nutraceuticals. The growing rate of chronic diseases around the world is a major reason for the increased demand in nutraceutical contract manufacturing. As these long-term conditions become more common, people are seeking nutritional support to complement their health strategies.

For instance, in Australia, the death rate from chronic conditions climbed from 459 per 100,000 people in 2021 to 490 per 100,000 in 2022. This has boosted interest in supplements that can support heart health, help manage inflammation, or address metabolic issues. You can discover more insights about nutraceutical manufacturing drivers to understand the full picture.

These market forces are creating a more informed and selective consumer. People know more about ingredients, demand transparency in sourcing, and are happy to pay for premium products that offer real benefits. For brands that can rise to these new expectations, the potential is huge. Finding the right contract manufacturer is the key to transforming these market trends into a winning product line.

Choosing Your Manufacturing Partner: The Decision Framework

Picking a partner for nutraceutical contract manufacturing is one of the most important decisions you'll make for your brand. This isn't just about sourcing a vendor; it's more like choosing a co-pilot for a long and complex journey. The right partner helps you steer through turbulence and land safely, making the entire process feel smoother. The wrong one can cause critical failures, expensive delays, and reputational damage that's tough to fix.

This decision goes far beyond comparing price sheets. While cost is a factor, it can be misleading on its own. A low bid might hide issues like poor quality control, unreliable material sourcing, or unexpected fees that pop up later. A great partner delivers value that extends well beyond the per-unit cost. To find that partner, you need a structured way to evaluate them on the factors that truly matter.

Evaluating Technical Capabilities

First, you need to assess their technical skills and production capacity. Think of it as matching their workshop to your specific blueprint. Do they have deep experience in the dosage form you need, whether it's capsules, powders, or complex liquids? A manufacturer that excels at making simple capsules may not understand the nuances of stabilizing a liquid tincture or masking the taste of herbal extracts.

Here are some key questions to get the conversation started:

- What is your experience with our specific ingredients, such as botanical extracts or probiotics?

- Can you show us examples of similar products you've manufactured?

- What are your standard batch sizes, and can you handle our production needs as we scale?

- Do you manage raw material sourcing, and how do you qualify your suppliers?

Their answers will paint a clear picture of whether they are the right operational fit. If you're developing a sophisticated liquid formula, you need a partner with proven expertise in extraction methods and flavor systems, not just a basic blending operation.

Quality Systems and Communication

A manufacturer's dedication to quality is non-negotiable. This means more than just having a cGMP certificate hanging on the wall; it's about how deeply quality assurance is woven into their daily work. When you tour their facility or conduct an audit, look closely. Are the production areas spotless? Is the team following proper gowning and safety protocols? Is every step of the process clearly documented?

Just as important is the human element: communication and cultural fit. World-class technical skills are useless if your partner is impossible to work with. You need a responsive, transparent team that is genuinely invested in your success. Before signing anything, observe their communication style. Do they provide thoughtful answers to your questions? Are they proactive with updates? For more guidance, our article on choosing the right manufacturer offers more essential questions to ask.

To make this critical decision more objective, a structured evaluation tool can be incredibly helpful. This scorecard helps you weigh different factors and compare potential partners side-by-side, moving beyond gut feelings to a data-informed choice.

| Manufacturing Partner Evaluation Scorecard | | :--- | :--- | :--- | :--- | | Evaluation Criteria | Weight (%) | Scoring Guidelines | Red Flags | | Technical Capability | 30% | (5) Deep expertise in your specific dosage form and ingredients. (3) General experience but no direct specialization. (1) Limited or no relevant experience. | Vague answers about technical processes; inability to provide relevant case studies. | | Quality & Compliance | 30% | (5) Excellent cGMP adherence, robust in-house testing, clean audit history. (3) cGMP certified but with minor observations. (1) History of compliance issues or weak documentation. | Disorganized facility; staff not following protocols; recent FDA warning letters. | | Communication & Culture | 20% | (5) Proactive, transparent, and responsive communication. (3) Responsive but requires prompting. (1) Slow to respond, poor communication. | Ignoring emails or calls; defensive responses to questions; high employee turnover. | | Scalability & Sourcing | 15% | (5) Clear path to scale production; strong, vetted supplier network. (3) Can scale but with longer lead times. (1) Limited capacity for growth. | No clear plan for scaling; reliance on a single, unvetted raw material supplier. | | Cost & Value | 5% | (5) Transparent pricing with clear value-adds. (3) Competitive pricing but some unclear fees. (1) Lowest price but with significant hidden costs or quality risks. | Unusually low pricing compared to others; refusal to provide a detailed cost breakdown. |

A partnership built on clear, open communication is essential for navigating the inevitable challenges of product development and production. Ultimately, this scorecard helps you find a partner who doesn't just make your product, but actively contributes to your brand's growth and success. This collaborative spirit is often what separates a stressful, problematic relationship from a powerful, long-term alliance.

Mastering Regulatory Compliance And Quality Standards

Entering the world of nutraceuticals can feel like a high-stakes balancing act. One slip-up in regulatory compliance can cause your entire brand to falter. For supplement brand owners, a compliance failure is more than a simple mistake; it can undo years of effort, demolish customer trust, and lead to devastating business outcomes. In nutraceutical contract manufacturing, following the rules isn't just about checking a box—it's the bedrock that protects your business and your customers. Working with a seasoned manufacturer gives you instant access to compliance knowledge that would otherwise require years and a large investment to build on your own.

The Regulatory Landscape: cGMP and FDA

In the United States, the most critical standard is the Current Good Manufacturing Practice (cGMP), which is enforced by the Food and Drug Administration (FDA). You can think of cGMP as the official rulebook for manufacturing. It sets strict requirements for nearly every aspect of production, including:

- The design and upkeep of manufacturing facilities.

- The qualifications and ongoing training of the staff.

- The sourcing and testing of all raw ingredients.

- The detailed documentation of every step in the production process.

Following cGMP ensures your products are consistently made and managed according to strict quality standards. This system is designed to reduce the risks in production that can't be caught by just testing the final product. A top-notch manufacturer doesn't just meet these standards; their entire operation is built around them.

The FDA's website offers a wealth of information on the regulations for dietary supplements, clearly defining a manufacturer's responsibilities.

This screenshot shows the FDA's central role in monitoring the supplement market. It covers everything from product labeling and health claims to reporting adverse events, which highlights just how serious compliance is.

Beyond the Basics: Building a Culture of Quality

The best manufacturers go beyond basic compliance to foster a genuine culture of quality. This proactive mindset transforms regulatory requirements from a chore into a real competitive edge. It involves creating strong quality assurance (QA) programs that are much more demanding than the minimum standards. For instance, a manufacturer might perform extra third-party testing on every batch to confirm potency and purity, even when it's not officially required. This dedication provides another layer of assurance for both your brand and your customers. You can discover more about how a committed partner manages quality supplement production and how that commitment strengthens your final product.

Building this culture depends on several key actions:

- Supplier Qualification: Carefully vetting raw material suppliers through on-site audits and regular performance checks to guarantee ingredient quality.

- Rigorous Testing Protocols: Using a multi-stage testing approach—checking raw materials when they arrive, testing samples during production, and confirming the final product meets all specifications.

- Comprehensive Documentation: Maintaining detailed batch production records (BPRs) that track every ingredient and action, from the first measurement to the final packaging. This traceability is essential for regulatory inspections or product recalls.

- Audit Readiness: Staying prepared for FDA inspections or client audits at all times, with all documents organized and ready for review.

Ultimately, mastering regulatory compliance in nutraceutical contract manufacturing is about forging a partnership built on trust and openness. Your manufacturer should be your regulatory protector, making sure every product with your brand name is safe, consistent, and fully compliant. This watchfulness not only shields your business from legal and financial trouble but also builds the long-term consumer trust that is crucial for lasting success.

Future-Proofing Your Manufacturing Strategy

The supplement industry moves incredibly fast. Production methods that feel cutting-edge today could be the standard tomorrow. "Future-proofing" your manufacturing strategy isn't about having a crystal ball. It’s about choosing a partner for nutraceutical contract manufacturing who is actively building that future, not just reacting to it. This means looking beyond their current equipment and asking about their commitment to progress and long-term vision.

Think of it this way: a forward-thinking partner becomes a strategic asset. They prepare your brand for shifts in consumer taste, new regulations, and market trends before they even happen. They are already investing in the capabilities that will define the industry in the years to come, ensuring your products stay relevant and competitive.

The Rise of Technology and Sustainability

Two powerful forces are shaping the future of supplement production: technology and the demand for sustainability. A partner who ignores these trends is a partner who risks becoming obsolete. Forward-looking manufacturers are already using advanced analytics to make production runs more efficient and flexible manufacturing systems that can quickly switch between different products or batch sizes. This agility is vital for responding to fast-moving consumer demands.

Sustainability has shifted from a "nice-to-have" to a core expectation. Consumers want to know where their ingredients come from and that the brands they support use environmentally responsible practices. An advanced manufacturing partner is already addressing this by:

- Investing in sustainable packaging, such as biodegradable containers or recycled materials.

- Optimizing energy and water use in their facilities to shrink their environmental footprint.

- Building transparent supply chains that prioritize ethical and sustainable sourcing of raw ingredients.

Personalization at Scale

Another major development is the move toward personalized nutrition. More and more, consumers want products designed for their specific health needs. This creates a huge manufacturing puzzle: how do you produce custom formulas efficiently and at a reasonable cost? The solution lies in adaptable production systems and smart data management. A future-ready manufacturer is already figuring out how to achieve mass customization, allowing brands like yours to offer personalized supplements without the huge costs typically tied to small-batch production.

Choosing a partner with these capabilities means you're not just buying a production service; you're securing your brand's ability to grow and adapt. When you're vetting potential partners, ask them directly about their investments in new technology, their sustainability programs, and their plan for handling personalized products. Their answers will tell you if they are merely keeping up with the industry or actively leading it. This choice is fundamental to positioning your brand for lasting success.

If you're ready to work with a manufacturer built for what's next, let's connect. Triton Nutra Group combines decades of experience with a commitment to progress, offering flexible, transparent, and high-quality liquid supplement manufacturing. Turn your supplement vision into a market-ready success with us today!