Your Complete Guide to FDA Regulations for Dietary Supplements

Learn everything about FDA regulations for dietary supplements. Stay compliant and informed with our comprehensive guide. Click to learn more!

Get a Free Quote Today!

Get a Free Quote Today!It's one of the biggest myths in the wellness industry: that the FDA gives every dietary supplement a stamp of approval before it can be sold. That couldn't be further from the truth.

Instead of acting as a gatekeeper, the FDA regulates dietary supplements more like a market watchdog. Its most significant actions happen after a product is already on store shelves, focusing on things like safety, honest labeling, and quality manufacturing.

How The FDA Actually Regulates Supplements

Think of the FDA's role here like a traffic cop on a busy highway. The cop doesn't inspect every car before it gets on the road. That would be impossible. Instead, they patrol the streets, watching for reckless driving, speeding, or broken taillights, and pull over anyone who violates the rules of the road.

That’s a post-market surveillance system, and it’s the very foundation of how supplements are regulated in the United States.

This entire framework was put in place by a landmark piece of legislation: the Dietary Supplement Health and Education Act (DSHEA) of 1994. Before DSHEA, supplements were basically treated like regular foods. This act carved out a special category just for them, establishing the rules that allow brands to bring products to market without the pre-approval required for prescription drugs. You can get more background on this pivotal shift over at NewHope.com.

A Shift to Post-Market Oversight

DSHEA handed the FDA the authority to monitor the market for unsafe products, bogus claims, and shoddy manufacturing after they are already for sale. The key takeaway? The responsibility falls squarely on the brand to ensure its product is safe and fully compliant from day one.

The core idea behind DSHEA is that supplement manufacturers are responsible for evaluating the safety and labeling of their products before marketing to ensure they meet all FDA requirements.

This entire system is built on a few key regulatory pillars. These are the areas where the FDA focuses its enforcement power to protect consumers. A misstep in any one of these can bring serious consequences, from official warning letters to product seizures and even legal action.

To give you a clearer picture, we've broken down these core pillars of FDA regulation. Think of these as the main chapters in the FDA's rulebook for supplements.

To give you a clearer picture, we've broken down these core pillars of FDA regulation. Think of these as the main chapters in the FDA's rulebook for supplements.

Key Pillars of FDA Supplement Regulation

| Regulatory Area | What It Covers |

|---|---|

| Labeling & Claims | Ensures all information on the label is truthful, not misleading, and follows strict rules about health-related claims. |

| Good Manufacturing Practices (cGMP) | Requires manufacturers to follow quality-control standards to prevent contamination, incorrect dosages, and other safety issues. |

| Ingredient Safety & NDI Notifications | Mandates that any "new" dietary ingredient (not sold before 1994) must be proven safe before it can be marketed. |

| Adverse Event Reporting | Legally requires brands to report any serious health problems linked to their products directly to the FDA. |

These pillars form the backbone of the regulatory landscape. Throughout this guide, we’ll dive deep into each one, exploring exactly what you need to know to stay compliant and build a trustworthy brand.

Decoding Supplement Labels and Marketing Claims

Think of your product label as more than just packaging. In the eyes of the FDA, it’s a legal document. It's your direct line of communication to both your customers and the regulators, and every single word, number, and symbol on it is under scrutiny. This makes getting your label right one of the most critical parts of your entire compliance strategy.

Your label is your product’s resume. It needs to be accurate, honest, and formatted perfectly to make the right impression. If it’s not—if it has errors or makes misleading statements—the FDA can, and absolutely will, take action. This is a minefield where many brands, especially those just starting out, make some very expensive mistakes.

The Five Mandatory Label Elements

Before you get into fancy marketing copy, you have to nail the basics. Every single dietary supplement label must display five specific pieces of information. These aren't suggestions; they're the non-negotiable foundation of consumer transparency.

- Statement of Identity: This is simply what the supplement is (e.g., "Vitamin C" or "Herbal Sleep Blend"). It has to be front and center on the main display panel.

- Net Quantity of Contents: This tells your customer exactly how much product they’re getting (e.g., "60 Capsules" or "8 fl oz").

- Supplement Facts Panel: This is the nutritional blueprint of your product. It’s similar to the Nutrition Facts on food, detailing the serving size, ingredients, and the amount per serving.

- Ingredient List: You have to list everything in the bottle—both the dietary ingredients and the "other" ingredients like fillers or the capsule material. The list must be in descending order by weight.

- Name and Place of Business: The label has to state the name and address of the company responsible for the product, whether that’s the manufacturer, packer, or distributor.

Getting these five elements right is square one. For a much more detailed walkthrough, you can check out our complete dietary supplement labeling guidelines, which digs into the nitty-gritty of each requirement.

Understanding Permissible Marketing Claims

Once you have the essentials locked down, you enter the most complex area of labeling: marketing claims. The FDA has incredibly strict rules about what you can and cannot say your product does. Getting this wrong is the single fastest way to get a warning letter in your mailbox.

There are three main types of claims you’re allowed to make:

- Structure/Function Claims: These are the most common. They describe how a nutrient or ingredient affects the body's normal structure or function.

- Nutrient Content Claims: These use specific, FDA-defined terms to describe the level of a nutrient, like "high," "good source," or "free."

- Health Claims: These are the most heavily regulated claims. They link a substance to a reduced risk of a disease or health condition and require a massive amount of scientific agreement to be used—many are pre-approved by the FDA.

Most brands will live in the world of structure/function claims. For instance, saying "Calcium helps build strong bones" is a perfectly compliant claim. It describes what calcium does in a normal, healthy body.

But there’s a huge catch.

Any time you make a structure/function claim, you must include the "DSHEA Disclaimer" on your label. It's the one that says: "This statement has not been evaluated by the Food and Drug Administration. This product is not intended to diagnose, treat, cure, or prevent any disease."

Forgetting this disclaimer is a direct violation and an easy penalty for regulators to spot. It’s a bright, shining line that tells consumers, "This is a supplement, not a drug."

The Bright Red Line: Disease Claims

There is one line you can never cross: making a disease claim. This means you cannot state or even imply that your product can diagnose, treat, cure, or prevent any disease. That is the exclusive territory of FDA-approved drugs. Period.

The distinction can be subtle, but it's critically important. Let’s look at how you can talk about the same idea in a compliant versus a non-compliant way.

| Claim Type | Example Statement | Compliance Status |

|---|---|---|

| Structure/Function (Compliant) | "Helps maintain healthy cholesterol levels already within the normal range." | Legal |

| Disease Claim (Illegal) | "Lowers high cholesterol." | Illegal |

| Structure/Function (Compliant) | "Supports a healthy immune system." | Legal |

| Disease Claim (Illegal) | "Prevents the flu." | Illegal |

See the difference? Compliant claims focus on supporting a normal, healthy state. Illegal claims promise to fix or prevent a medical problem. Sticking to this rule isn't just about following the FDA regulations for dietary supplements—it’s about being an ethical brand and protecting the long-term health of your business.

Mastering Good Manufacturing Practices (cGMP)

If your supplement label is the product's public resume, then Current Good Manufacturing Practices (cGMP) are the internal rulebook for your entire operation. This isn't just about ticking boxes on a checklist. It's a living, breathing system designed to guarantee the purity, strength, and consistency of every single bottle that leaves your facility. These are the fundamental quality standards laid out by the FDA regulations for dietary supplements.

Picture a high-end restaurant kitchen. The executive chef doesn't just cross their fingers and hope the line cooks get the recipes right. There are strict, documented procedures for every dish, precise temperature logs for every cooler, and rigorous hygiene protocols for every single staff member. This is how they ensure a diner gets the exact same delicious, high-quality, and safe meal every time.

That's precisely what cGMP, as detailed in 21 CFR Part 111, does for the supplement world. It's a complete set of requirements that govern every step of your process, from raw ingredients to finished goods.

Core Components of a cGMP System

A solid cGMP system is built on several key pillars. It covers everything from the physical building to the people working inside it, creating a web of controls that prevents mix-ups, contamination, and costly errors that could put your customers at risk.

You'll need to focus on a few key areas for cGMP compliance:

- Personnel: Are your employees properly trained for their specific roles? Do they follow strict hygiene procedures?

- Physical Plant and Grounds: Is your facility clean and organized? Are temperature and humidity controlled to protect both raw materials and finished products?

- Equipment and Utensils: Is all your equipment properly designed, maintained, and calibrated to do its job without contaminating the product?

- Production and Process Controls: Do you have a master manufacturing record for each unique product formula and a batch production record for every single batch you produce?

These controls are designed to work together, creating a system where quality is built into the process from the very beginning—not just tested for at the end. For example, a well-maintained facility prevents airborne contaminants, while properly trained personnel make sure the right ingredients are added in the right amounts, every time.

The Importance of Documentation

At the very heart of cGMP is meticulous record-keeping. It's simple: if you didn't write it down, then in the eyes of an FDA inspector, it never happened. Two documents are absolutely critical here: the Master Manufacturing Record (MMR) and the Batch Production Record (BPR).

The Master Manufacturing Record is the master recipe for your product. It details every single specification, from where you get your ingredients to the final packaging. The Batch Production Record is the real-time diary of a specific batch, proving that the master recipe was followed to the letter.

This paper trail provides a complete, traceable history for every unit you sell. It’s your proof that you have full control over your processes and can thoroughly investigate any issue that might come up.

Building a Compliant Supply Chain

Your cGMP responsibilities don't end at your own factory door. You are also on the hook for the quality of the raw materials you get from your suppliers. This means you must have established procedures for qualifying your vendors and for testing incoming ingredients to verify their identity and purity.

This quality-first mindset needs to run through your entire business process. To make sure your dietary supplements meet all the necessary standards from production to delivery, it's vital to understand every compliant aspect of your supply chain, including supplement fulfillment. A compliant fulfillment partner ensures your products are stored and handled correctly right up until they land on your customer's doorstep.

Ultimately, sticking to cGMP is non-negotiable. While the FDA itself doesn't issue certifications, third-party audits can be a powerful tool for verifying that your systems are sound. Taking the time to learn what a GMP certificate means can give you a much deeper understanding of how these independent assessments show a real commitment to quality. Complying with cGMP not only keeps you on the right side of the law—it builds a powerful foundation of trust with your customers.

Navigating The New Dietary Ingredient (NDI) Process

For the most part, FDA oversight of dietary supplements is a post-market game. The agency typically steps in after a product is already for sale. But there's one huge exception where you absolutely must deal with the FDA before you even think about launching: the New Dietary Ingredient (NDI) notification.

This process gets triggered anytime you plan to use a brand-new ingredient in your formula.

So, what exactly counts as "new"? The FDA has a very specific cutoff date: October 15, 1994. Any dietary ingredient that was already on the U.S. market before that date is considered an "old" or "grandfathered" ingredient and is exempt from this pre-market notification. If your ingredient showed up after that date, you’ve got an NDI on your hands, and a formal notification to the FDA is required.

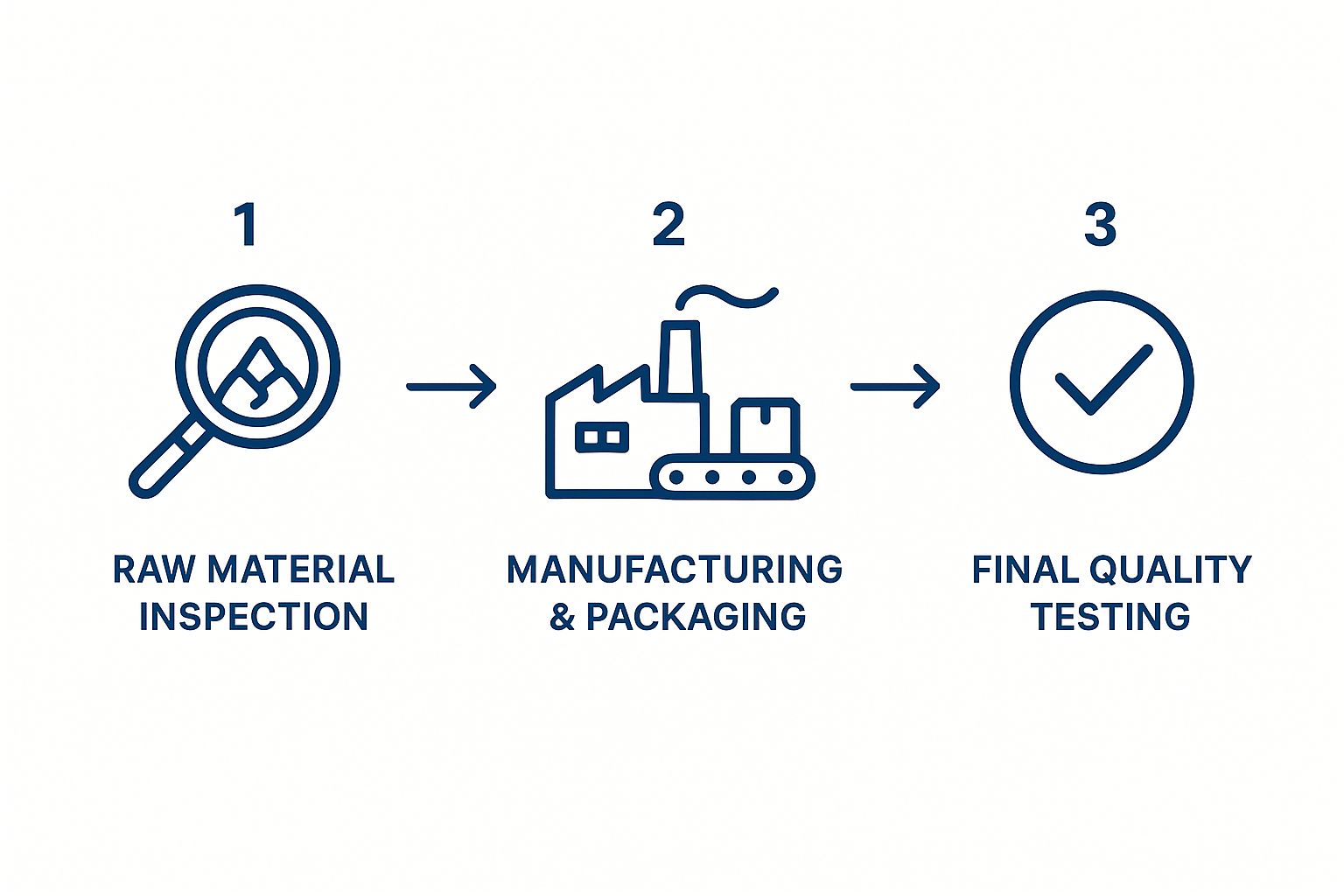

This quality control flow is essential for any ingredient, whether it's been around for decades or is fresh on the scene.

As you can see, every ingredient, grandfathered or not, has to run the same gauntlet of rigorous quality checks from start to finish.

The 75-Day Pre-Market Notification

The NDI process involves a formal submission you must send to the FDA at least 75 days before your supplement is scheduled to hit the market. Now, the goal here isn't to get "approval" like a new drug would. Instead, you're providing the FDA with a dossier of evidence showing your new ingredient is reasonably expected to be safe for use as directed on your product's label.

Think of it like this: you've designed a new type of seatbelt. You wouldn't just start selling it. You'd first submit all your safety data—stress tests, material analysis, and performance reports—to the transportation authorities. You aren't asking for an endorsement, but you are proving it won't fail when it matters most. Your NDI notification is that safety file for your ingredient.

The heart of your NDI notification is the safety data. You have to build a convincing case that your dietary supplement, with the new ingredient, will be reasonably expected to be safe.

This is a high bar. Your submission needs to be a detailed scientific story backed by solid, credible evidence. This could include toxicology studies, data on how it's been consumed elsewhere, or a well-documented history of safe use in other countries. Simply saying your ingredient is "natural" won't cut it.

What Must Be In Your NDI Submission

The FDA has a checklist of required information for evaluating an NDI's safety. If you miss any of these pieces, you can expect the agency to object to your submission, sending you back to the drawing board.

Your complete NDI package must include:

- A detailed description of the new dietary ingredient, covering its identity and the specifics of how it's manufactured.

- The conditions of use for the supplement, including the serving size, how often it should be taken, and who it's for.

- A comprehensive history of use or other evidence of safety, which is the core of your argument.

- Supporting scientific data, like published studies or toxicology reports that directly back up your safety claims.

Pulling all this together is a heavy lift, requiring deep scientific and regulatory expertise. It's why many brands find that teaming up with an experienced partner is the only way to get it right. For anyone looking to bring a novel formula to market, understanding ingredient documentation is non-negotiable. Exploring nutraceutical contract manufacturing can give you direct access to teams who navigate these exact waters every day.

Trying to sidestep the NDI process is one of the most serious mistakes a supplement brand can make. It's illegal to launch a product with an un-notified NDI, and the consequences are swift and severe, ranging from warning letters and product seizures to a full-blown injunction shutting you down.

Of course. Here is the rewritten section, crafted to sound completely human-written and natural, following the provided style guide and examples.

Your Responsibilities After the Sale

Think your job is done once the customer clicks "buy"? Think again. In the world of FDA-regulated dietary supplements, some of your most important work starts after the sale. This is where post-market surveillance comes in, and it's a non-negotiable part of running a compliant supplement brand.

It's a lot like a car manufacturer's recall system. If they find out a batch of cars has a faulty brake line, they have a legal and ethical duty to track down the issue, investigate it, and report it to keep people safe. Your role is no different. You absolutely must have a solid system in place to handle any health concerns that could be linked to your products.

This whole framework is the result of decades of regulatory tug-of-war in the U.S. Before the landmark DSHEA act of 1994, the FDA and the supplement industry were constantly at odds over everything from ingredient safety to potency claims. Those debates eventually forged the unique system we have today—one that balances consumer access with serious post-market oversight. You can get more of the backstory on how these rules came to be over at the NPA's resource page.

Understanding Adverse Event Reporting

The core of your post-market duties is Adverse Event Reporting (AER). This is the official process for documenting and reporting any negative health experiences your customers have after taking your supplement. The law, specifically the Dietary Supplement and Nonprescription Drug Consumer Protection Act, makes this mandatory.

You are legally required to collect and look into any adverse event report you get, no matter how it comes to you—an email, a phone call, or even a comment on social media. These reports can be anything from a minor stomachache to something much more serious. While you need to log every single report, the law is very specific about which ones have to be escalated to the FDA.

The Mandate for Serious Adverse Events

The FDA requires you to report any "Serious Adverse Event" (SAE) through its MedWatch program. This isn't just a good idea; it's a legal requirement with a firm deadline. You have just 15 business days from the moment you receive the information to get your report filed.

So, what counts as "serious"? The FDA doesn't leave it up to interpretation.

An adverse event is considered "serious" if it results in death, a life-threatening experience, inpatient hospitalization, a persistent or significant disability or incapacity, or a congenital anomaly or birth defect.

Failing to report an SAE is a major violation. The FDA sees this reporting system as the primary safety net protecting consumers, and it expects every single brand to take it seriously.

Record-Keeping Requirements

Your job doesn't end with filing a report. You also have to keep meticulous records of every adverse event report you get, whether it’s serious or not.

Here are the key record-keeping rules you need to live by:

- Comprehensive Files: You must keep all records related to each report. This means the original customer communication, your follow-up notes, and any documents from your investigation.

- Six-Year Retention: All of these adverse event records must be kept on file for a minimum of six years.

- FDA Inspection Access: You must be able to provide these records to an FDA inspector if they ask for them.

This long-term record-keeping is what allows the FDA to spot potential safety patterns across the entire market over time. It’s a vital piece of the data-gathering puzzle that makes post-market surveillance work. Building a reliable AER system isn't just about compliance—it's a foundational part of running a trustworthy and sustainable supplement business.

Your Essential FDA Compliance Checklist

We've walked through the dense forest of FDA regulations for dietary supplements, covering everything from labels and manufacturing to new ingredients and post-market duties. Now, let's distill all that information into a practical tool you can start using right away.

Think of this less as a simple summary and more as your go-to internal audit checklist. It's designed to help you proactively catch any compliance weak spots before they balloon into expensive, brand-damaging problems. After all, treating compliance as an ongoing process is how you build a rock-solid foundation of trust with both your customers and the regulators.

Labels And Marketing Materials

Your product label isn't just a piece of paper; it's a legal document and the first thing an inspector will scrutinize. Even a single mistake here can be enough to trigger a warning letter. Run through these questions to make sure everything your customer sees is fully compliant.

- Is your Supplement Facts panel 100% accurate and formatted precisely according to 21 CFR 101.36?

- Have you combed through every piece of marketing copy—websites, social media, ads—to ensure there are no disease claims, either direct or implied?

- For any product making a structure/function claim, is the mandatory DSHEA disclaimer present and worded correctly?

Manufacturing And Quality Control

Current Good Manufacturing Practices (cGMP) are the operational heart of your entire business. These questions cut right to the core of whether your quality system is truly robust and, just as importantly, properly documented.

A strong cGMP system demonstrates that quality is not just tested at the end but is built into every step of the process, from raw material sourcing to finished product packaging.

- Do you have a unique and complete Master Manufacturing Record (MMR) for every single product formula? No exceptions.

- Is a comprehensive Batch Production Record (BPR) meticulously filled out for every batch, proving that the MMR was followed to the letter?

- Are your procedures for qualifying new suppliers and testing all incoming raw materials fully documented and consistently followed every single time?

Ingredient And Formula Safety

Ingredient safety is an absolute cornerstone of FDA oversight, especially when you're bringing new components into the market. This is one of the few areas that demands pre-market interaction with the agency, so you have to get it right.

- Have you verified the regulatory status of every ingredient in your formulas to pinpoint any potential New Dietary Ingredients (NDIs)?

- If you've identified an NDI, do you have a documented history of use or the hard scientific evidence needed to back up a safety notification to the FDA?

Post-Market Surveillance

Your job isn't done once a product leaves the warehouse. Having a well-oiled system for handling customer feedback isn't just good practice—it's a legal requirement and your most critical safety net.

- Is your adverse event reporting system fully tested and ready to capture, document, and report any Serious Adverse Event to the FDA within the strict 15-business-day deadline?

- Do you have a secure, organized, and easily accessible system for holding onto all adverse event records for the required six-year period?

Frequently Asked Questions About Supplement Regulations

Let's be honest, trying to make sense of FDA supplement rules can feel like you're wading through legal quicksand. It's complex, and a lot of brands and consumers end up with the same practical questions. So, let's cut through the noise and tackle some of the most common ones with direct, clear answers. The goal is to get you feeling confident about your compliance strategy.

Does The FDA Approve Supplement Labels?

No, they don’t. This is a huge point of confusion for new brands. The FDA does not pre-approve dietary supplement labels before they hit the market. That responsibility falls squarely on your shoulders as the manufacturer or brand owner. It's up to you to ensure every label is truthful, not misleading, and follows all the rules laid out in DSHEA.

So, what does the FDA do? Their role is all about post-market enforcement. This means they take action—like sending out a warning letter or worse—against a product with a non-compliant label after it’s already being sold to consumers.

Key Takeaway: Think of yourself as the gatekeeper for your own label compliance. The FDA is the watchdog, not the pre-market approver.

This system puts a massive emphasis on getting your label right from the very start. There are no do-overs once a product is in circulation.

What Is The Difference Between A Drug Claim And A Structure/Function Claim?

This is arguably the most critical line to understand in supplement marketing. A drug claim is any statement suggesting a product can diagnose, treat, cure, or prevent a disease. An example would be "lowers high blood pressure." These are completely illegal for supplements and are the fastest way to get your product classified as an unapproved new drug.

A structure/function claim, on the other hand, describes the role an ingredient has in supporting the body's normal, healthy operations. For example, "calcium helps build strong bones" is a classic structure/function claim. These are perfectly fine to use, as long as they are truthful and you include the mandatory DSHEA disclaimer on your label.

Can I Get My Facility GMP Certified By The FDA?

This is another common misconception. The FDA does not issue "cGMP certifications" or hand out an official "approved facility" plaque to hang on your wall. What they do is conduct inspections to see if your facility is compliant with the cGMP regulations detailed in 21 CFR Part 111.

It’s the manufacturer's job to be in a constant state of compliance. While you can (and should!) get cGMP certification audits from respected third-party organizations, these are valuable for demonstrating your commitment to quality but are not a substitute for passing an actual FDA inspection.

Navigating the complexities of FDA regulations for dietary supplements demands real-world experience and an unwavering commitment to quality. Triton Nutra Group partners with brands to make sure every formula, from raw ingredient sourcing to the final bottled product, meets the highest standards of cGMP and regulatory compliance. Let our 25+ years of experience guide your next project. Turn your vision into a market-ready success by visiting us at https://tritonnutragroup.com.