Your Guide to Finding the Best US Supplement Manufacturers

A complete guide for founders on how to vet and choose US supplement manufacturers. Learn about cGMP compliance, private label processes, and MOQs.

Get a Free Quote Today!

Get a Free Quote Today!For brand managers and e-commerce founders in the health and wellness space, choosing the right US supplement manufacturer is one of the most critical decisions you'll make. This isn't just about finding a vendor to fill bottles; it's about securing a strategic partner who can transform your vision for a liquid herbal supplement into a compliant, market-ready product that customers trust.

Choosing Your Partner In Growth

The U.S. dietary supplement market is absolutely exploding. It’s already hit a staggering USD 67.09 billion and is on track to grow at a compound annual growth rate (CAGR) of 7.9% through 2034. You can dig into more of those numbers over at polarismarketresearch.com.

This growth is driven by a massive consumer shift towards health and wellness, especially with an aging population and a younger generation focused on preventative health. It’s a huge opportunity, but it also means the stakes are higher than ever. Your manufacturer's reliability and quality standards are a direct reflection of your brand. The wrong partner can sink you with production delays, compliance headaches, or a product that just doesn't deliver.

Why Your Manufacturer Is More Than Just A Supplier

You need to think of your manufacturer as an extension of your own team—they are your outsourced R&D department, your operations engine, and your guide through the tricky world of supplement production. A true partner doesn't just take orders; they collaborate with you, offering their expertise and finding solutions that fit your needs as you grow.

As you start looking, it's critical that you conduct thorough due diligence to make sure they’re the right fit for your brand's future. You’re not just signing a contract; you’re building a relationship.

Choosing a manufacturer is a foundational decision that influences everything from product efficacy to your bottom line. It's about finding a collaborator who is as invested in your success as you are.

This guide is your roadmap for vetting potential manufacturing partners. We'll break down the essentials for choosing a manufacturer that will help you scale from day one, giving you an inside look at making a confident, informed decision.

We'll be covering our three brand pillars:

- Quality & Compliance: Ensuring your product is safe, effective, and meets all regulatory standards.

- Customization & Flexibility: Tailoring formulas, flavors, and packaging to build a standout brand.

- Speed & Reliability: Getting to market faster with rapid turnarounds and transparent timelines.

The Private Label Journey From Concept To Launch

Launching a private label liquid supplement can feel like a huge undertaking, but it doesn't have to be. The right manufacturing partner acts as your R&D partner from concept through launch, guiding you from a raw idea to a polished, market-ready supplement.

This journey is a team effort. Your vision and brand identity are the foundation. Your manufacturer brings the technical skill, regulatory know-how, and production muscle to make it real. The entire process hinges on clear communication and well-defined roles to ensure a smooth, predictable launch.

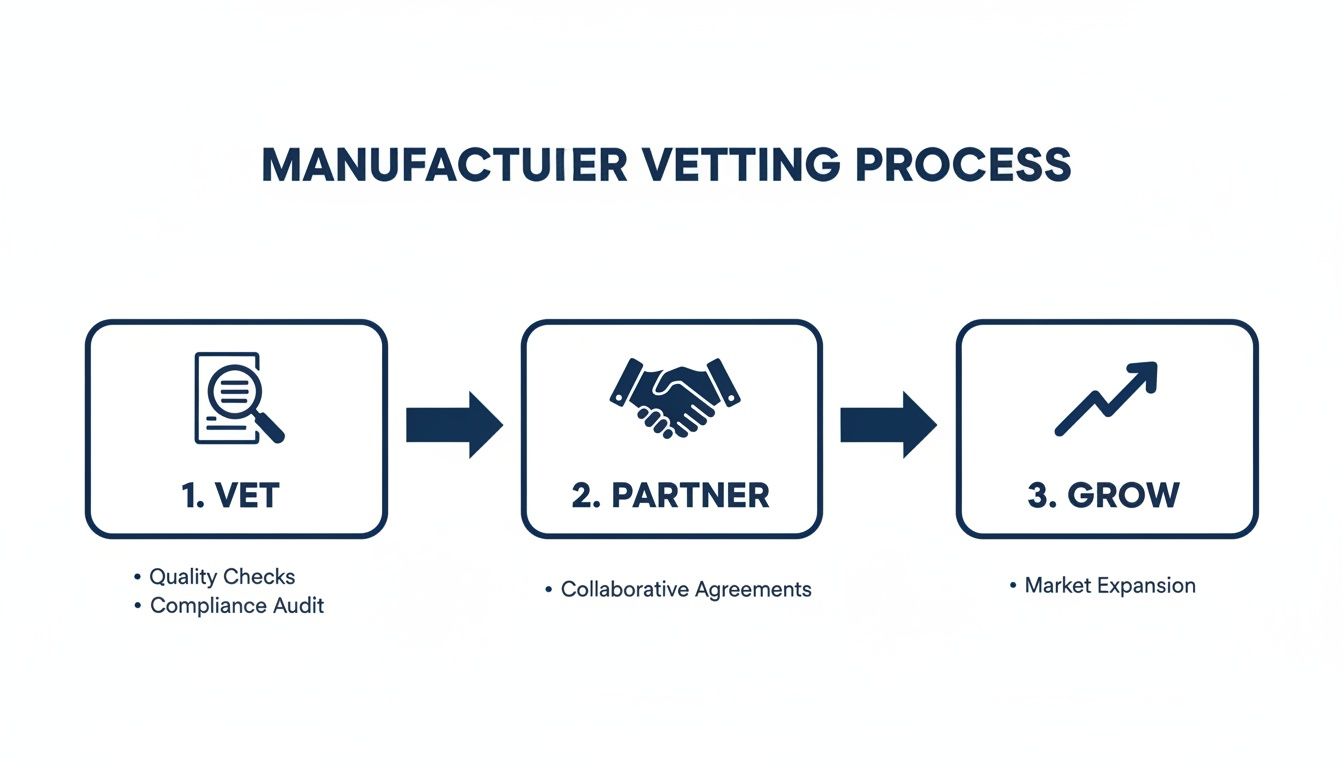

This visual below breaks down our simple, three-phase approach to building a successful partnership.

The key takeaway is that a successful product launch starts long before the production line runs. It begins with careful vetting that blossoms into a true partnership, setting you up for sustainable growth.

Phase 1: The Blueprint and Formulation

It all kicks off with an in-depth consultation where you lay out your vision. What problem is your supplement solving? Who are you trying to reach? What specific ingredients, flavors, or benefits are non-negotiable? This is the strategic planning stage where we map out the entire project.

From there, our R&D team gets to work. Using deep expertise in botanical extraction and nutraceutical science, they develop a formula that hits all your targets for efficacy, stability, and taste. This phase is highly collaborative—your feedback guides every single tweak, ensuring the final product aligns perfectly with your brand.

Phase 2: Sourcing and Small-Batch Prototyping

Once the formula is locked in, we source from our network of trusted, high-quality raw material suppliers. Every single component is quarantined and put through rigorous in-house and third-party testing for identity, purity, and potency before it gets near our production facility.

Next up is the pilot batch. This is a small-scale production run—from pilot to full scale—designed to perfect the flavor profile and consistency of your liquid supplement. It’s your chance to taste the product firsthand and request any final adjustments before committing to a larger run.

A pilot batch is the most critical quality gate in the process. It's the bridge between a formula on paper and the final product your customers will experience, ensuring everything is perfect before committing to a full-scale run.

This step is crucial for de-risking the full production run. By nailing the sensory aspects in a small, cost-effective batch, we guarantee the final product meets your exact expectations—a testament to our partnership mindset.

Phase 3: Full-Scale Production and Final Delivery

With your sign-off on the pilot batch, we scale up. Our state-of-the-art, FDA-registered facility kicks into high gear, strictly adhering to cGMP standards. Our team carefully compounds, blends, and fills each bottle with precision. We leverage forward-thinking innovations like our cold-fill technology to preserve delicate botanical compounds, ensuring maximum potency in the finished product.

The final steps involve packaging and quality assurance. Your chosen bottles, labels, and seals are applied, and the finished goods go through one last round of comprehensive testing. We then prepare all necessary documentation, like Certificates of Analysis (CoAs), to ensure your product is compliant. This transparent, step-by-step process demonstrates our commitment to speed and on-time delivery.

Understanding Quality And Compliance Standards

In the world of dietary supplements, "quality" and "compliance" aren't just industry jargon. They are the bedrock of a trustworthy brand. For any e-commerce founder, understanding these standards is non-negotiable—it's what separates a reputable, scalable product from a potential liability.

When you partner with a US supplement manufacturer, you’re trusting them with your brand's integrity. Their commitment to rigorous standards protects your customers, your reputation, and your ability to grow.

The Vitamin & Supplement Manufacturing industry in the US is a massive $16.9 billion market with roughly 1,200 manufacturers. With that kind of scale, regulatory oversight is intense. The FDA is ramping up inspections to keep consumers safe, making your choice of a compliant partner more critical than ever. You can explore the market research from IBISWorld to see just how big this space has become.

What cGMP Really Means For Your Product

You'll hear the term cGMP a lot. It stands for Current Good Manufacturing Practices, a set of FDA-enforced protocols designed to ensure every bottle is produced with consistency, purity, and safety. This isn't just a certificate on a wall; it's a living system a quality partner integrates into every step of their operation.

Adherence to cGMP covers a huge range of operational details, including:

- Facility & Equipment: Keeping production areas impeccably clean and calibrating machinery to prevent cross-contamination and ensure accuracy.

- Raw Material Handling: Quarantining and rigorously testing all incoming ingredients for identity and purity before they are used in your formula.

- Employee Training & Hygiene: Ensuring every person involved in production is thoroughly trained and follows strict hygiene protocols.

- Documentation: Keeping meticulous batch records that track every ingredient, procedure, and quality check, creating a complete history of your product from start to finish.

This intense documentation is your safety net. If a question ever arises about a specific batch, a cGMP-compliant manufacturer can trace its entire lifecycle in minutes.

The Roles Of The FDA And Third-Party Certifiers

It’s crucial to understand the different players who ensure quality. The FDA is the federal regulatory body that writes the cGMP rules and inspects manufacturing facilities. A manufacturer that is "FDA-Registered" has notified the FDA of its existence and is subject to those inspections.

Think of the FDA as the government agency that writes the laws and patrols the highways of supplement manufacturing. Third-party certifiers are like the independent mechanics who conduct in-depth inspections to verify a vehicle is not only street-legal but also built to the highest performance standards.

This is where third-party certifications come in. Independent organizations like UL or NSF act as impartial auditors. They perform deep-dive inspections to verify that a manufacturer not only meets but often exceeds baseline cGMP requirements.

Earning a UL Certified seal is a powerful signal of trust. It means a manufacturer has voluntarily opened its doors to intense scrutiny and passed, giving you an invaluable layer of confidence that your partner is truly committed to excellence. It’s proof they invest in quality. For a deeper look, you can learn more about these dietary supplement manufacturing requirements and how they protect your brand.

Choosing The Right Supplement Format

The delivery format you choose is just as critical as the formula inside. How your customers take your product shapes their entire experience, from consistency of use to the results they get. For brand owners, the choice between liquids, capsules, powders, or gummies impacts everything from manufacturing complexity to your bottom line.

Picking the right format is a strategic balancing act between bioavailability, ease of use, and dosage flexibility. This single decision will define your product's place in the market. As you speak with US supplement manufacturers, understanding these differences is key to building a product that delivers a standout user experience.

The Power Of Powders

Powders are a powerhouse in the supplement world, especially in sports nutrition. Their biggest draw is dosage flexibility. Customers can easily scoop a precise amount to fit their needs—a huge selling point for products like pre-workouts or collagen.

Powders also deliver large doses of active ingredients that would be impossible to fit into capsules. Just look at the U.S. protein supplements market, valued at $9.88 billion. Protein powders command a 55% share of those sales because they offer a convenient way to get a significant amount of protein. You can discover more insights about the U.S. protein supplements market and its future growth.

Capsules And Gummies: A User-Friendly Choice

For sheer convenience, nothing beats a capsule. They’re tasteless, easy to swallow, and deliver a perfectly pre-measured dose every time. This precision makes them a top pick for daily vitamins, minerals, and herbal extracts.

Gummies have exploded in popularity by turning a daily supplement routine into a treat. They're the perfect answer for "pill fatigue" and are fantastic for reaching customers who dislike swallowing capsules. The trade-off is that their formulation potential can be limited by sugars and binders, which restricts how much active ingredient you can pack in.

The Liquid Advantage: Bioavailability And Innovation

Liquid supplements, especially for complex herbal formulas, offer unique advantages. The single biggest benefit is superior bioavailability. Because the body doesn't have to break down a capsule, the active ingredients in a liquid are absorbed faster and more efficiently.

This rapid absorption is a potent marketing tool, as customers often feel the effects sooner. Liquids also offer unparalleled dosage flexibility—a simple dropper or measuring cap makes it easy for consumers to adjust their intake.

Liquid formats aren't just a delivery system; they are a platform for innovation. Advanced extraction and cold-fill technologies allow for the creation of potent, full-spectrum herbal formulas that simply aren't possible in a powder or capsule.

Modern US supplement manufacturers specializing in liquids are pushing the envelope with forward-thinking technology.

- Advanced Botanical Extraction: We use proprietary, temperature-controlled methods to capture a plant's full spectrum of beneficial compounds without damaging delicate phytonutrients.

- Cold-Fill Technology: By avoiding high-heat pasteurization, our process preserves the integrity and potency of heat-sensitive ingredients, delivering a more effective final product.

This commitment to innovation allows us to partner with you to create truly unique liquid supplements that stand out in a crowded market.

Supplement Format Comparison Bioavailability Dosing And Manufacturing

| Format Type | Bioavailability | Dosage Flexibility | Manufacturing Complexity |

|---|---|---|---|

| Liquids | Highest; rapid absorption as ingredients are already in solution. | Excellent; easily adjusted with droppers or measuring cups. | High; requires specialized equipment for stabilization and filling. |

| Powders | Good; absorption is relatively quick once mixed with a liquid. | Excellent; users can easily adjust scoop size for custom doses. | Moderate; requires blending, flavoring, and anti-caking agents. |

| Capsules | Moderate; requires digestion to break down the shell and release contents. | Poor; dosage is fixed per capsule, limiting user customization. | Low to Moderate; straightforward encapsulation process. |

| Gummies | Good; chewed and absorbed efficiently, but can vary. | Poor; dosage is fixed per gummy, difficult to adjust. | High; involves cooking, setting, and coating, with ingredient limits. |

Ultimately, the best format depends on your formula, your target audience's lifestyle, and the brand experience you want to create.

Decoding MOQs, Pricing, And Production Timelines

Let's get down to the questions every brand founder wants answered: How much will this cost, and when will I have my product? Getting straight, transparent answers on Minimum Order Quantities (MOQs), pricing, and timelines is a huge green flag when vetting US supplement manufacturers.

This isn’t just about crunching numbers; it's about aligning your business goals with a manufacturer's capabilities. A great partner works with you to find a smart path forward, whether you're a startup launching your first product or an established brand ready to scale.

Unpacking Minimum Order Quantities (MOQs)

The Minimum Order Quantity, or MOQ, is the smallest order a manufacturer can produce efficiently. Setting up machinery, ordering raw materials, and scheduling a production run has fixed costs, and MOQs ensure each run is financially sustainable for them and cost-effective for you.

But an MOQ shouldn't be a barrier. The best manufacturers offer customization and flexibility to help brands get off the ground. To learn more, it's worth your time to understand optimizing Minimum Quantity Orders (MOQs).

- Pilot Runs: Perfect for new brands. A small pilot run of 500-1,500 units lets you test your formula and validate your concept without risking significant capital.

- Full-Scale Production: Once you have a proven seller, larger runs of 5,000+ units bring your per-unit cost down, directly boosting your profit margins.

The ability to start small and scale up is what a true partnership looks like. We actually wrote a whole guide on this, which you can check out here: low minimum supplement manufacturer.

What Drives Your Per-Unit Pricing

So, what goes into that final price? A transparent manufacturer will happily walk you through this breakdown so you know exactly where your money is going.

Think of your product’s cost like building a custom car. There's a base price for the frame, but the final sticker price depends on the engine you pick, the quality of the leather seats, and any high-tech features you add. Every single choice adds value and shapes the final investment.

Here are the biggest factors that influence your price:

- Formula Complexity: A simple Vitamin C liquid is cheaper to produce than a complex blend with 15 rare botanical extracts. The number and type of ingredients are the biggest cost drivers.

- Raw Material Sourcing: The quality, purity, and market price for your ingredients have a direct impact. Certified organic, patented, or trademarked ingredients command a premium.

- Packaging Choices: Your per-unit cost will vary based on whether you choose a simple plastic bottle or go for custom-printed boxes, glass dropper bottles, and full-body shrink sleeves.

- Third-Party Testing: While non-negotiable for ensuring quality, running extensive lab panels for purity and potency adds to the overall production cost.

Mapping a Realistic Production Timeline

From deposit to shipment, a typical production timeline for a new liquid supplement runs between 8 to 12 weeks.

This timeline ensures every step—from sourcing and testing raw materials to blending, bottling, and final quality control—is done right. A reliable partner will provide a clear, phase-by-phase schedule, empowering you to plan your marketing and launch with confidence. That commitment to a transparent timeline is a huge part of our promise of speed and reliability.

Your Vetting Checklist: Questions To Ask Any Manufacturer

Picking the right partner out of a sea of US supplement manufacturers is the single most important decision you'll make for your brand. To feel confident, you need to walk into those first conversations armed with the right questions. This isn't about setting up a "gotcha" moment; it's about opening an honest dialogue that builds a long-term relationship.

Think of this checklist as your toolkit for due diligence. We've broken these questions into the three pillars of a great manufacturing partnership: Quality, Capabilities, and Support. We encourage you to bring these very questions to us—it’s the best way to see how a truly transparent partner responds.

Quality and Compliance Questions

Your brand's reputation rides on the safety of your product. These questions get to the heart of a manufacturer's commitment to quality.

- Can you provide your cGMP certificate and FDA registration number? This is non-negotiable. Any legitimate manufacturer will have this ready.

- What third-party certifications do you hold (e.g., UL, NSF)? Voluntary certifications like these show a manufacturer is proactively exceeding industry standards.

- Can you walk me through your raw material sourcing and testing process? Get specific. How do they vet suppliers? What tests are performed on ingredients before production?

- What does your final product testing protocol look like? Do they issue a Certificate of Analysis (CoA) for every batch? Do they test for identity, purity, potency, and contaminants?

For a deeper look into this, our guide on finding a reputable supplement manufacturer unpacks even more key considerations for your business.

Production and Capabilities Questions

Once you've confirmed their quality standards are solid, ensure their operation can handle your brand's needs—not just today, but as you scale.

A manufacturer's flexibility is a huge tell. Their ability to support a small pilot run for a startup is just as important as their capacity to handle a massive production order for an established brand.

Here are the key capability questions to ask:

- What are your MOQs for pilot runs versus full-scale production? This tells you a lot about their flexibility and willingness to support brands at different growth stages.

- What is your typical lead time for a new product, from deposit to shipment? A transparent partner will give you a clear, realistic timeline—usually 8-12 weeks.

- Can you describe your R&D and custom formulation process? How collaborative is it? Who on their team will be working on your formula?

- What packaging and labeling options do you offer? Understand what they can do in-house versus what must be outsourced, as this impacts both cost and timeline.

Partnership and Support Questions

Finally, get a feel for what it will actually be like to work with them. A great manufacturer is more than a vendor; they're an extension of your team, invested in your success.

- Who will be my dedicated point of contact? You need a single, accountable person you can call—not a generic customer service inbox.

- How do you handle communication and project updates? Find out if you'll get regular, proactive updates or if you'll be the one chasing them for information.

- What documentation support do you provide for selling on platforms like Amazon or Walmart? An experienced partner knows exactly what’s needed for FBA compliance.

- Can you provide references from other brands you've worked with? A confident manufacturer with happy clients will have no problem connecting you with them.

Frequently Asked Questions

When you're diving into the world of private label supplements, a lot of questions pop up. As your potential manufacturing partner, we believe in giving you clear, straight-up answers from the start. Here are a few of the most common things brand owners ask us.

What Is The Difference Between Private Label And Contract Manufacturing

Great question. This is the first big decision you'll make.

Think of private label like choosing from a portfolio of proven, market-ready formulas. We handle the R&D, and you get a stable, effective product with your brand's label on it. It’s a faster and more affordable way to get to market.

Contract manufacturing is a fully custom process. We work side-by-side with you to create a completely unique formula from scratch, based on your vision. We act as your R&D partner, building something truly one-of-a-kind. We offer both paths to give you the flexibility to either launch quickly or innovate.

How Do You Ensure My Product Is Compliant For Sale On Amazon

A huge portion of the products leaving our facility are headed for platforms like Amazon and Walmart. For us, compliance isn't an afterthought; it's baked into our process.

Here’s how we make sure you’re ready to sell:

- We operate in an FDA-registered, UL Certified facility and follow cGMP standards to the letter.

- We provide all critical paperwork, including a Certificate of Analysis (CoA) for every single batch, which marketplaces often demand.

- We ensure your packaging and labels meet all platform-specific requirements, so they’re ready for FBA right out of the gate.

Essentially, we act as your compliance partner. Our goal is to ensure your documentation is buttoned up, clearing the path for a smooth online launch.

Can You Help Source Unique Botanical Ingredients

Absolutely. Sourcing high-quality, specialized ingredients is one of our core strengths. Our R&D and sourcing teams have built a global network of raw material suppliers vetted to meet our demanding quality standards.

We specialize in botanical extracts and love collaborating with brands to find unique, high-potency ingredients that make a custom formula stand out. Before any raw material enters our facility, it undergoes intense third-party testing to verify its identity, purity, and potency. This is how we guarantee the integrity of your final product.

In the rare case a production batch doesn't meet our strict quality assurance specs, it's immediately quarantined and never sees the light of day. We then do a full root-cause analysis and restart production on a new batch—at our own expense. We guarantee you will only ever receive a product that meets every single safety and quality standard.

This uncompromising commitment to quality is how we protect your brand, your customers, and your reputation.

Ready to turn your vision for a liquid herbal supplement into a product customers love? The experts at Triton Nutra Group are here to be your dedicated R&D and manufacturing partner, guiding you from concept to launch with transparency and expertise. Request a free consultation and quote today.