Find a Reliable Low Minimum Supplement Manufacturer Today

Looking for a low minimum supplement manufacturer? Discover how to vet partners, manage costs, and successfully launch your supplement brand.

Get a Free Quote Today!

Get a Free Quote Today!So, what exactly is a low minimum supplement manufacturer? Think of them as a strategic partner who lets you produce small batches of your product—often somewhere between 500 and 1,500 units per run.

This approach is a total game-changer for startups and growing brands. It dramatically slashes the financial risk compared to the old-school manufacturing model, which often demanded you commit to 5,000 units or more right out of the gate.

Launching Your Supplement Brand Without Breaking the Bank

Trying to enter the supplement market used to feel like an all-or-nothing gamble. For years, the biggest barrier was a massive, upfront investment in inventory. New brands were forced to risk tens of thousands of dollars on a single product run, making it nearly impossible for innovative startups to even get off the ground.

Thankfully, the industry has evolved. The rise of the low minimum supplement manufacturer has completely leveled the playing field, specializing in smaller, more manageable batches and, in doing so, has opened the doors for a new generation of entrepreneurs.

This shift unlocks some serious advantages:

- Slash Your Financial Risk: Instead of ordering 10,000 units of a product you haven't even tested yet, you can start with just a fraction of that. This frees up precious capital for what really matters early on: marketing, branding, and other critical areas of your business.

- Validate Your Product: A smaller run is the perfect way to test your formula with real customers. You can gather honest feedback, look at the sales data, and make smart, informed decisions before you even think about scaling up.

- Stay Agile in the Market: Low Minimum Order Quantities (MOQs) give you the flexibility to move fast. You can launch new products, tweak your formulas based on feedback, or pivot your entire strategy without getting stuck with a warehouse full of inventory you can't sell.

I've seen firsthand how low MOQs can make or break a new brand. It's the difference between cautiously testing the waters and jumping into the deep end with your eyes closed. This flexibility is what allows smart, strategic growth.

Here's a quick breakdown of why this matters so much.

Why Low MOQs Are a Game-Changer for New Brands

| Benefit | Impact on Your Business |

|---|---|

| Lower Upfront Cost | Frees up cash for marketing and other growth activities. |

| Product Testing | Allows you to validate your formula with real customers before a big investment. |

| Market Agility | You can quickly launch new products or adapt to changing trends. |

| Reduced Waste | Minimizes the risk of being stuck with thousands of units of unsold inventory. |

| Easier Entry | Makes it possible for startups and niche brands to compete with larger companies. |

This isn't just a trend; it's a fundamental shift in how the supplement industry operates, empowering smart growth over risky bets.

A Market Built for Growth

This new manufacturing flexibility is a huge reason the market is expanding so rapidly. The global dietary supplement contract manufacturing sector was valued at around USD 59.63 billion in 2024 and is on track to more than double by 2030.

This incredible growth is being fueled by startups and niche brands that can now compete, bringing fresh ideas to consumers without the old financial handcuffs. You can dive deeper into the numbers with this detailed market analysis on dietary supplement contract manufacturing from Grand View Research.

Choosing a low MOQ partner isn't just about saving money upfront; it's a strategic decision that builds a more resilient, adaptable, and customer-focused brand from day one. It prioritizes smart growth over risky speculation.

Ultimately, this model empowers you to launch with confidence. It transforms the intimidating process from a high-stakes gamble into a calculated, strategic business move. By minimizing your initial outlay, you can focus on what truly matters: creating an amazing product and building a community of loyal customers.

If you're just getting started, our complete guide on how to start a supplement business walks you through a roadmap built on these very principles.

Alright, let's get your product idea and budget locked down. This is the foundational work you absolutely must do before you even think about contacting a manufacturer.

Nailing Down Your Product and Budget

Before you start your search, you need a crystal-clear vision. Trust me, showing up with a vague idea like "I want to sell a sleep supplement" is the fastest way to get a sky-high, inaccurate quote—or worse, not be taken seriously at all. You need to turn that concept into a concrete plan.

Start by getting laser-focused on your target customer. Who are they, really? What are their specific health goals and pain points? A formula for a 25-year-old biohacker trying to optimize cognitive function is worlds apart from a product for a 55-year-old looking for joint comfort. Getting this right guides every single decision from here on out.

Next up: the delivery format. Will it be a liquid, capsule, or powder? Each has its own manufacturing challenges and consumer benefits. Liquids boast faster absorption and are a godsend for people who can't stand swallowing pills. Powders offer flexible dosing. And capsules? They're convenient and tasteless.

Your choice here is critical because it will narrow your search for a low minimum supplement manufacturer significantly. Many facilities specialize in only one or two formats.

Creating a Realistic Budget

Once the product concept is solid, it's time to talk money. A well-researched budget isn't just a spreadsheet; it's your most powerful negotiation tool.

First, dig into the costs of your key ingredients. Are you leaning toward premium, patented ingredients like KSM-66® Ashwagandha, or are more standard, generic versions a better fit for your price point? The cost difference can be massive.

Your target cost per unit should be the anchor for your entire budget. You need to work backward from your planned retail price. For instance, if you want to sell a tincture for $30, what does your cost per bottle need to be for you to actually turn a profit after factoring in marketing, shipping, and marketplace fees?

And please, don't forget about the one-time expenses that can sneak up on you:

- Formulation & R&D: If you're not using a stock formula, expect to pay development fees to create your custom blend.

- Stability Testing: This is non-negotiable. It ensures your product stays potent through its shelf life and is almost always a separate charge.

- Third-Party Lab Testing: You must verify purity and potency with an independent lab. This is a recurring cost and a sign of a reputable brand.

The Power of a Detailed Product Brief

Now, pull all this thinking together into a professional product brief. This document is your first impression with potential manufacturing partners. It immediately shows them you're a serious, organized professional.

A great product brief is the blueprint for your product. It’s a clear, concise document that gives a manufacturer everything they need to know to provide an accurate, reliable quote right from the start.

A solid brief eliminates the back-and-forth and prevents costly misunderstandings down the road. It proves you've done your homework.

When a low minimum supplement manufacturer gets a detailed brief, they don't see a dreamer with a half-baked idea. They see a partner who is ready for a successful launch. This prep work is the first real step in building a profitable, long-term relationship.

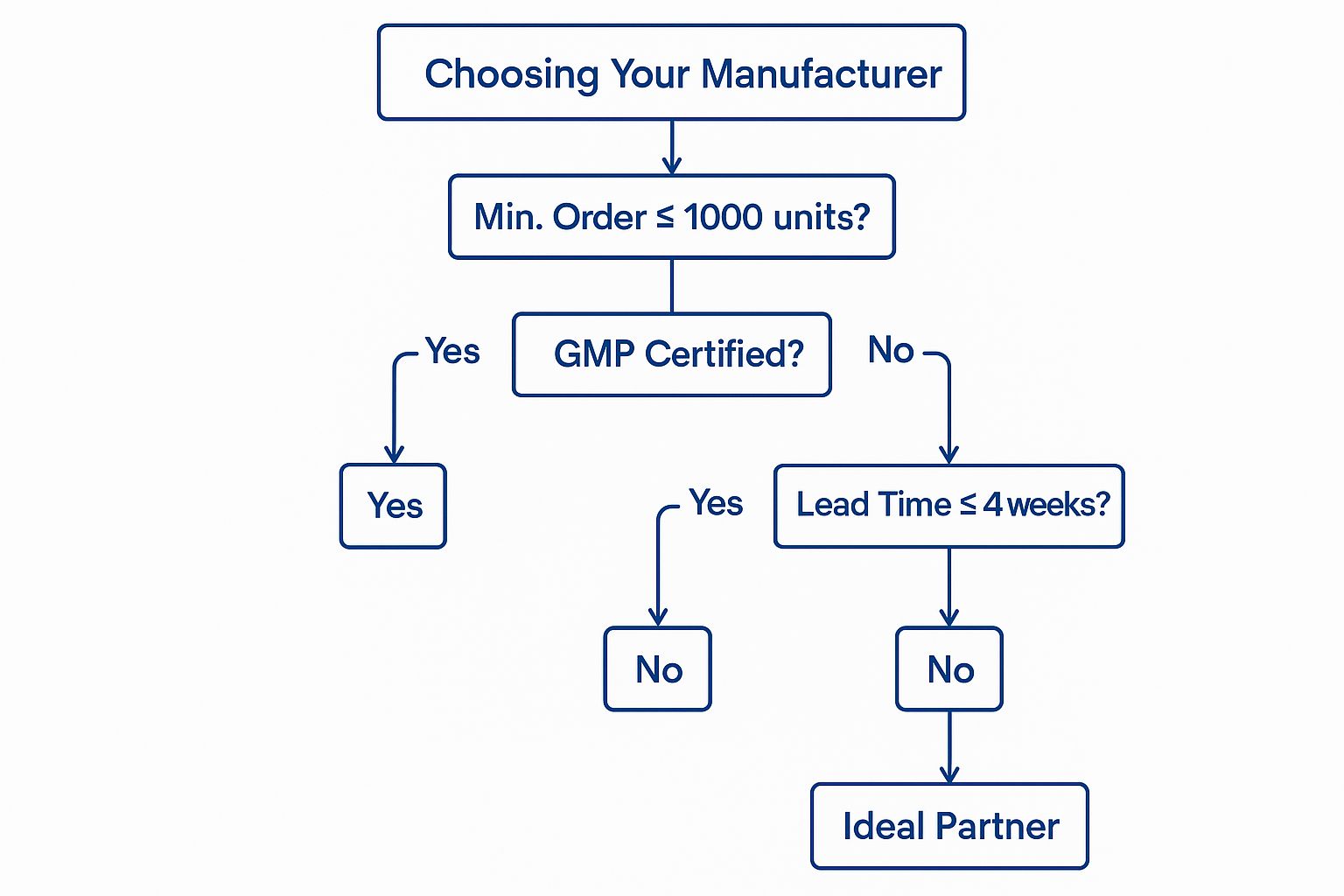

How To Properly Vet Manufacturing Partners

A low MOQ is a great starting point, but it means nothing if your partner cuts corners on quality. I can't stress this enough: vetting potential manufacturers is the single most important thing you'll do to protect your brand's reputation and your customers' safety. This means you have to dig deeper than their glossy sales pitches and marketing fluff.

Your first move? Verify their core credentials. Don't just take their word for it—ask for the paperwork. The two non-negotiables are FDA registration and cGMP (Current Good Manufacturing Practice) certification. An FDA-registered facility is legally allowed to make supplements, but cGMP certification—especially from a tough third-party auditor like NSF—proves they actually stick to strict quality standards day in and day out.

This is your first filter. It’s a simple yes or no question.

If a potential partner can't clear these basic hurdles, they're out. It doesn't matter how low their minimum order is; they aren't a viable option for a serious brand.

Digging Into Quality Control and Sourcing

Once you've confirmed the basic credentials, it's time to get into the nitty-gritty of their daily operations. This is where you separate the good from the great. A truly reputable low-minimum supplement manufacturer will be an open book about their quality control (QC) and sourcing.

You need to ask specific, probing questions. Things like:

- Ingredient Sourcing: Where do your raw materials come from? Do you have backup suppliers for key ingredients to avoid stockouts?

- Testing Protocols: What kind of testing happens when raw materials arrive? What about during production and on the final product?

- Third-Party Verification: Will I get a Certificate of Analysis (CoA) from an independent, third-party lab for every single batch?

A legitimate partner will happily show you a sample CoA. If they get defensive, hesitate, or make excuses, that’s a massive red flag. That document is your only real proof that what’s on your label is what’s in the bottle.

A manufacturer's willingness to openly discuss and document their quality control procedures is a direct reflection of their commitment to excellence. Secrecy isn't a sign of proprietary genius; it's a sign of weakness.

Assessing Communication and Compliance

Finally, get a feel for their communication style and how well they know the rules. If their team is slow and unresponsive while they're trying to win your business, just imagine how bad it will be after you've signed a contract. Pay close attention to how they answer your questions. Do you have a dedicated person to talk to?

This is so important, especially now. The global dietary supplements market was worth around $360.2 billion in 2022 and is expected to balloon to nearly $689 billion by 2032. All that growth attracts a lot of new, and sometimes inexperienced, players.

A little homework goes a long way. You can search the FDA's public databases for any past warning letters or issues. Our guide on finding a reputable supplement manufacturer dives deeper into this due diligence process. A clean record and clear, proactive communication aren't just nice-to-haves; they are essential for a successful, long-term partnership.

Manufacturer Vetting Checklist

To keep things organized, it helps to use a simple scoring system. This framework allows you to compare potential partners side-by-side on the factors that truly matter, moving beyond just the price quote.

| Evaluation Criteria | Manufacturer A | Manufacturer B | Manufacturer C |

|---|---|---|---|

| FDA Registered? (Y/N) | |||

| cGMP Certified? (Y/N) | |||

| Third-Party CoA Provided? | |||

| Sourcing Transparency (1-5) | |||

| Testing Protocols (1-5) | |||

| Communication Quality (1-5) | |||

| Dedicated Contact? (Y/N) | |||

| FDA Warning History? (Y/N) |

By filling out a table like this for each serious contender, you create a clear, objective picture. It quickly highlights which manufacturer not only meets the baseline requirements but also aligns best with your brand's commitment to quality and service.

Decoding Quotes and Finding Hidden Costs

Getting that first quote from a potential manufacturing partner is a huge moment. It feels real. But before you get too excited, let's talk about that cost-per-bottle number. It can be dangerously misleading.

To keep your budget intact and avoid painful surprises down the line, you need to learn how to dissect a quote like an industry pro. The goal is to sniff out the hidden costs that almost always catch new brands off guard.

A real quote isn't just a single number; it's a detailed breakdown of every service. A transparent partner will give you an itemized list. If you get a single "all-in" price, you need to push back. You have a right to know exactly what you’re paying for.

Breaking Down the Line Items

A solid quote from a trustworthy low minimum supplement manufacturer should clearly separate several key costs. Getting familiar with these line items is the first step toward understanding your total investment.

Here's what you should be looking for:

- Raw Materials: This should spell out the cost for every single ingredient in your formula. Don't be surprised if high-quality, patented ingredients cost more than their generic counterparts—they should.

- Blending and Manufacturing: This is the cost for the labor and machine time it takes to actually create your product. For liquids, this covers specialized processes like homogenization and extraction.

- Bottling and Packaging: The price of your chosen bottles, caps, seals, and all the labor involved in filling and sealing them up.

- Label Application: This is almost always a separate line item, whether it's done by a machine or by hand.

- Third-Party Lab Testing: This is non-negotiable. This fee covers the essential Certificate of Analysis (CoA) that proves your product's purity and potency are what you claim they are.

The single biggest mistake new brand owners make is assuming the initial quote is the final price. Hidden fees for development, testing, and shipping can easily bloat your total cost by 20-30% if you don't know what to look for.

Uncovering Common Hidden Fees

Beyond the usual production costs, a few other charges can sneak up and wreck your budget. The best defense is a good offense—ask about these potential fees upfront. It shows the manufacturer you’ve done your homework and are a serious partner.

Make sure you get clear answers on the costs for these items:

- Product Development Revisions: What’s the plan if that first sample isn't quite right? Most manufacturers will include one or two revisions in their initial R&D fee, but any tweaks beyond that will almost certainly cost you extra.

- Stability Testing: This is a critical, one-time fee for each new formula. It ensures your product maintains its quality and potency throughout its entire shelf life. It is rarely included in a standard production quote unless you ask for it specifically.

- Unexpected Shipping and Logistics: Does their price include freight shipping to your warehouse or fulfillment center? Are there extra charges for things like palletizing or special handling requirements?

Asking these direct questions is the only way to prevent expensive misunderstandings later. For a much deeper dive into this, especially for liquid products, check out our ultimate guide to choosing a liquid supplement manufacturer. It’s packed with a full checklist of questions that will help you ensure total cost transparency and negotiate like a pro.

Kicking Off Production: From Raw Materials to Your First Run

You’ve dotted the i's, crossed the t's, and signed the contract. This is the exciting part—where your concept finally starts becoming a real, tangible product your customers can hold. But getting from a signed agreement to a finished bottle involves a few critical steps. Knowing what to expect will make the whole process feel less like a mystery and more like a well-oiled machine.

The moment you give the green light, your low minimum supplement manufacturer should immediately get to work on a clear production timeline. First up: sourcing and verifying every single raw material. This isn't just a simple shopping trip; it's a foundational quality control checkpoint.

Every ingredient that arrives at the facility must be quarantined and rigorously tested for its identity, purity, and safety before it even thinks about getting close to your formula. This initial phase really sets the tone for your partnership. A good partner will keep you in the loop, letting you know as your ingredients arrive and pass their tests.

From a Test Run to Full-Scale Blending

Before your manufacturer commits to blending your entire order, they should run a small pilot batch. You can think of it as a dress rehearsal for the main event. It’s usually just a handful of bottles, but it’s incredibly important.

This small run confirms that everything—flavor, color, texture, and consistency—is perfect when produced with their equipment. It’s the final check to ensure the formula behaves exactly as planned.

Once you sign off on that pilot batch, your project gets its spot in the full-scale production queue. This is where your formula is blended in huge commercial mixers, filled into bottles, and prepped for labeling. Your biggest job here is giving the final, final approval on your label proofs. Seriously, triple-check every word, every claim, every tiny detail. Once those labels are printed, any changes become a costly headache.

Your Certificate of Analysis (CoA) isn't just a piece of paper—it's your non-negotiable proof of quality. It’s an independent, third-party lab report that verifies your final product is exactly what you say it is. Never, ever ship a product without reviewing and approving its batch-specific CoA.

The Final Gatekeeper: Third-Party Lab Testing

As the production run wraps up, the most crucial quality check of all takes place. A sample from your finished, bottled product is pulled and sent off to an independent, third-party laboratory. This lab puts your supplement through its paces to generate the Certificate of Analysis (CoA).

This document is your ultimate guarantee that what's inside the bottle perfectly matches what's on the label. It verifies the potency of your active ingredients and confirms the product is free from nasty stuff like heavy metals or microbial contaminants. Any transparent low minimum supplement manufacturer will provide this to you without you even having to ask.

Think about the booming Asia Pacific market, where health consciousness is driving massive growth. That market was valued at around USD 71.64 billion in 2024. Low MOQ manufacturers are game-changers in this region, giving smaller, nimble brands a chance to compete. This kind of accessibility allows new brands to innovate quickly and tap into local trends without a huge financial gamble—a model that works for startups everywhere. You can dive deeper into these global dietary supplement market trends from Precedence Research.

Clear, proactive communication through this entire process is what separates a smooth launch from a complete nightmare. By understanding these stages and your role in them, you can sidestep expensive delays and make sure your first production run is a success that sets your brand up for a bright future.

Got Questions About Low MOQ Manufacturing?

If you're just getting into the supplement game, the manufacturing side of things can feel like a whole new world. It's totally normal to have a long list of questions swirling around. Getting straight answers is the only way to move forward and feel good about your decisions.

So, let's break down some of the most common things brand owners ask when they start searching for the right partner.

So, What's a "Low" MOQ, Really?

This is usually the first question on everyone's mind. While the exact number can vary from one manufacturer to another, a "low" Minimum Order Quantity for a startup typically lands somewhere between 500 and 1,500 units per run.

That's a game-changer. It's a world away from the old industry standard, where you were often forced to commit to 5,000, 10,000, or even more units right out of the gate. These lower minimums are specifically designed to give new and niche brands a fighting chance without needing a massive, and often risky, upfront investment.

Balancing Cost and Risk

The next logical question is always about the money. "Will I pay more per bottle with a low MOQ?" The honest answer is, yes, the per-unit price is usually higher on smaller runs.

Think of it this way: every production run has fixed setup costs. That includes things like deep cleaning the equipment, calibrating all the machinery, and the labor it takes to get the line ready. When you spread those fixed costs over 1,000 units instead of 10,000, the cost baked into each bottle naturally goes up.

The real takeaway here is about risk. While your per-unit cost is a bit higher, your total upfront investment is dramatically lower. You're essentially paying a small premium for the flexibility to test the market and keep your cash flow healthy.

For a new brand, this trade-off is almost always the smart move. It's a strategic play that prioritizes validating your product and protecting your capital over chasing the absolute rock-bottom unit price on your first go.

Custom Formulas vs. Private Label

Finally, a lot of founders ask if they can develop a completely unique formula with a low minimum supplement manufacturer. The answer is a big, resounding yes. In fact, this is a specialty for many low MOQ partners—they thrive on helping startups create innovative products from the ground up.

Just be ready for this path to include some research and development (R&D) fees. It takes real time and expertise to create a formula that’s stable, effective, and tastes great. But it’s an investment in creating a product that is truly yours and can’t be easily copied.

On the other hand, some manufacturers might nudge you toward using one of their existing "private label" or "white label" formulas to hit the lowest possible MOQ. While these stock formulas are a fast track to market, they offer zero product differentiation. It's critical to be clear from the very beginning whether you want a truly custom formula or a private label product, as it will completely change your costs, timeline, and overall brand strategy.

Ready to turn your vision for a unique liquid supplement into a market-ready product? The team at Triton Nutra Group specializes in guiding brands through every step, from custom formulation to full-scale production, with the flexibility your business needs. Partner with us to build your supplement brand today.