Your Guide to Partnering with a Skullcap Herb Private Label Contract Manufacturer

Find your ideal Skullcap herb private label contract manufacturer. This guide covers quality, custom formulas, pricing, and how to choose the right partner.

Get a Free Quote Today!

Get a Free Quote Today!Partnering with a Skullcap herb private label contract manufacturer is your fastest route to launching a premium supplement brand. You get to skip the massive overhead and operational headaches of building your own facility and jump right into the market with a trusted partner.

Think of it as leveraging our entire operation—our cGMP-certified infrastructure, advanced extraction technologies, and vetted supply chain—from day one. As your R&D partner from concept through launch, we become a true extension of your team, guiding you from a simple idea to a fully realized, market-ready product with speed and reliability.

Launching Your Skullcap Supplement Brand The Right Way

The wellness market is buzzing, and consumers are actively looking for natural ways to manage stress and find calm. Skullcap (Scutellaria lateriflora), with its long history of use for easing nervous tension, is perfectly positioned to meet that need. For an e-commerce founder or product manager, this is a golden opportunity to create a brand that truly connects with health-conscious buyers.

This isn't just a fleeting trend; the numbers back it up. The market for Scutellariae Extract, which includes skullcap for supplements, was valued around USD 143 million. It's projected to hit USD 279 million by 2031, growing at a healthy 10.3% each year. This isn't just a niche product; it's a rapidly expanding market with serious potential for innovative brands.

Key Takeaway: Partnering with a private label manufacturer isn't just outsourcing production. It's a strategic move that slashes your time-to-market, minimizes risk, and gives you instant access to formulation experts and regulatory know-how.

Understanding Your Manufacturing Partnership Options

When entering the manufacturing world, you'll hear "private label" and "contract manufacturing" a lot. While often used together, they represent two distinct paths for bringing your skullcap supplement to life. It's crucial to understand which model fits your vision and business goals.

Here's a quick comparison to clarify the two main partnership models.

| Feature | Private Label Manufacturing | Contract Manufacturing |

|---|---|---|

| Concept | You choose a pre-existing, market-tested formula from the manufacturer and apply your branding. | You provide a unique, custom formula that we produce exclusively for you. |

| Speed to Market | Extremely fast. The formula is already developed, tested, and ready for production. | Slower. Requires R&D, custom formulation, rigorous testing, and pilot batches. |

| Upfront Cost | Lower. No development costs, and MOQs are often smaller for existing formulas. | Higher. You're investing in R&D, custom ingredient sourcing, and proprietary testing. |

| Uniqueness | Low. Other brands could be selling a similar or identical formula. | High. Your product is one-of-a-kind and proprietary to your brand. |

| Best For... | Brands wanting to enter the market quickly, test consumer demand, or add a proven product to their line. | Brands focused on innovation, with a unique selling proposition and a desire for a proprietary product. |

Ultimately, many modern manufacturers offer a hybrid approach, allowing you to start with a private label product and then develop a custom formula as your brand grows. Knowing the difference helps you ask the right questions and find a partner who can support you now and in the future.

The Partnership Mindset

Choosing a manufacturer is less like hiring a vendor and more like finding a business partner. You need a collaborator who not only understands your brand vision but also has the technical expertise to execute it flawlessly. This means looking far beyond basic production capabilities.

Your ideal partner should feel like your in-house R&D team. They should be proactively offering services like:

- Custom Formulation: Collaborating with you to develop a unique skullcap tincture that stands out—perhaps by blending it with other synergistic herbs or creating a specific flavor profile.

- Flexible Production Runs: Offering the flexibility to handle small pilot batches for market testing, with the proven capacity to scale to full production runs as your brand takes off.

- Compliance Guidance: Ensuring your product and its labeling meet all FDA regulations for dietary supplements right from the start, preventing costly delays.

Of course, a great product is only half the battle. You need to know how to sell it. As you finalize your supplement, you should already be thinking about your go-to-market plan. For example, it’s worth exploring strategies for supplement brands to thrive on platforms like TikTok Shop. This holistic approach—from formulation all the way to sales—is what turns a great idea into a profitable business.

Ensuring Quality and Regulatory Compliance

In the supplement industry, trust is everything. Your brand's reputation is built on delivering safe, effective products that customers can rely on, and that regulators demand. When you're evaluating a potential Skullcap herb private label contract manufacturer, their credentials aren't just paperwork—they're the foundation of your brand's credibility.

Those certification logos on a manufacturer's website represent a deep commitment to a documented, audited system ensuring quality from raw material intake to the final sealed bottle. This isn't something to gloss over. Partnering with a facility that lacks the right credentials is a massive, unnecessary risk.

Decoding the Essential Certifications

When you're vetting potential partners, a few key certifications are non-negotiable. Think of them as the bedrock of product safety, consistency, and your peace of mind.

Here are the absolute must-haves:

- cGMP Certified: Standing for Current Good Manufacturing Practices, this is the FDA's gold standard. It means the manufacturer adheres to strict procedures for everything—from staff training and facility sanitation to equipment verification and meticulous record-keeping.

- FDA-Registered Facility: This is the baseline. It confirms the manufacturer is on the Food and Drug Administration's radar and is subject to inspection. Any legitimate supplement producer in the US will have this. For more details, explore the nuances of FDA regulations for dietary supplements in our detailed guide.

- UL Certified: A UL certification (or a similar one from an accredited body like NSF) adds another powerful layer of trust. It means an independent third party has audited the facility and processes, verifying they meet or exceed cGMP standards.

Seeing these certifications tells you one thing: this manufacturer has invested heavily in a controlled environment designed to prevent contamination, mix-ups, and inconsistencies. It's the difference between a professional operation and a risky gamble.

Beyond the Certificate: The Power of Third-Party Testing

While strong in-house quality control is a great start, verifiable third-party testing provides unbiased proof of your product's quality. A top-tier manufacturer will have a rigorous protocol for sending samples from every single batch to an independent lab for analysis.

Pro Tip: Don't hesitate to ask for a Certificate of Analysis (CoA) for a recent batch of a similar product. This document is your proof. It details the lab's findings on the product's identity, purity, strength, and composition, confirming it's free of contaminants like heavy metals, microbes, and pesticides.

A transparent partner won't just provide this; they'll welcome the request. They know their quality control process is a huge part of the value they deliver. This commitment to verification is what allows you to confidently stand behind your skullcap supplement, knowing it is exactly what the label says it is.

Crafting Your Unique Skullcup Formula

A generic, off-the-shelf product simply won't make an impact in today's crowded wellness market. To stand out, you need a unique, high-quality supplement that delivers on its promise. This is where the right manufacturing partner evolves from a supplier into your dedicated R&D team, helping you build a standout skullcap product from the ground up.

This collaborative process is where your vision becomes reality. A skilled Skullcap herb private label contract manufacturer doesn't just fill bottles. They bring deep formulation expertise, turning your concept into a tangible, shelf-ready supplement that perfectly captures your brand's unique mission.

Dialing in Potency and Synergistic Blends

One of the first, most important decisions is the core of your formula. Are you envisioning a potent, single-herb skullcap tincture? Or a more complex blend designed for a specific outcome, like promoting relaxation or better sleep? This choice defines your product's place in the market.

A partner with deep botanical knowledge can be a game-changer, helping you explore powerful synergistic combinations. For instance, you could pair skullcap with:

- Passionflower: A classic combination to amplify skullcap’s calming properties for powerful relaxation support.

- Valerian Root: A popular pairing aimed squarely at promoting deep, restful sleep.

- Lemon Balm: This gentle herb can complement skullcap’s effects while adding a pleasant, subtle flavor to your final product.

The conversation will get into the nitty-gritty of precise ratios and extraction strengths to create a formula that’s both balanced and effective. For a deeper look into this process, our guide on how to create a supplement formula is a fantastic resource.

Protecting Potency with Advanced Processing

How your supplement is made is just as important as what's in it. Skullcap contains delicate volatile compounds that are easily destroyed by heat. A manufacturer's technical capabilities, like their extraction and filling methods, can give your brand a serious competitive edge.

Look for modern methods like cold-fill technology and temperature-controlled extraction. These innovative processes are vital for preserving the herb's fragile compounds, resulting in a more potent and effective final product. This commitment to quality processing translates directly into a better customer experience and a stronger brand reputation.

A top-tier manufacturer will have the scientific expertise to recommend the best extraction methods to maximize the bioavailability of skullcap's active constituents. This ensures your final product is not just unique, but also highly effective.

The demand for high-quality herbal extracts is booming. The global Baical Skullcap Extract market is set for serious growth, with revenue projected to climb from around USD 373 million to an estimated USD 649.5 million by 2034. This trend makes it clear: consumers want potent, well-made herbal products. Discover more insights about the Baical Skullcap Extract market on oganalysis.com.

Ultimately, your goal is to find a partner with the flexibility and technical skill to support your growth. They should be equipped to handle everything from small pilot batches for market testing to full-scale production runs as your sales take off—all without ever compromising the integrity of your custom formula.

Getting From Formula to Finished Product: Timelines and Logistics

You can have the most incredible skullcap formula in the world, but it means nothing until it’s bottled, labeled, and in your customers' hands. This is where a solid partnership with your Skullcap herb private label contract manufacturer proves its value. Reliable production and on-time delivery are the engine that drives your inventory management, marketing launches, and sales.

An experienced manufacturer knows you need total transparency. They should provide a clear, detailed production schedule. This isn't a ballpark guess; it's a roadmap that outlines every key step, from the moment you approve your formula to the day your product ships from their warehouse.

What to Expect From the Production Timeline

For a liquid supplement like a skullcap tincture, a realistic production cycle is typically 8 to 12 weeks. Understanding what's happening during this time allows you to plan your business activities accordingly. This timeline isn't arbitrary; each week is packed with precise, quality-focused tasks.

Here’s a practical breakdown of what goes on behind the scenes:

- Sourcing Raw Materials (2-4 weeks): First, your partner secures high-quality skullcap and any other ingredients. This involves obtaining and verifying Certificates of Analysis (CoAs) to prove the purity and potency of every raw material before it enters the facility.

- Pilot Batch & Final Testing (1-2 weeks): Before a full run, a small "pilot" batch is often produced. This confirms the formula behaves as expected on a smaller scale. This batch undergoes both in-house and third-party lab testing to ensure it meets all specifications.

- Full-Scale Production (2-4 weeks): Once all tests are passed, it's go-time. Your full order is produced under strict cGMP protocols, covering everything from extraction and blending to bottling and capping.

- Final QA & Release (1-2 weeks): The finished products are quarantined. They cannot be shipped until the final third-party lab results for the completed batch are received and verified. Once confirmed, your product is officially released and ready for shipment.

A manufacturer with a deep supply chain and strong vendor relationships is invaluable. Ask them about their primary and secondary suppliers for critical ingredients. It’s a great indicator of how well they can navigate unexpected supply chain challenges.

Dodging Common Production Delays

Delays can happen, but most are avoidable with foresight and clear communication. The two most common hurdles are label compliance and material availability. A great manufacturing partner will help you anticipate these issues.

For example, by submitting your label designs early, their compliance team can screen them for FDA requirements. This proactive step can save you from a costly and time-consuming redesign right when you’re scheduled for production.

The same applies to materials. Providing your manufacturer with sales forecasts allows them to secure raw ingredients in advance. This ensures everything is on-site and ready for your production run. This kind of collaborative planning separates an order-taker from a true partner invested in your success.

Understanding Pricing Models and Scalability

Let's talk about the numbers. This is where your skullcap supplement idea transforms into a profitable brand. Understanding the pricing structure is key, but it’s more than a single cost-per-unit. A true Skullcap herb private label contract manufacturer will provide a transparent quote that shows the total value they bring, not just a bottom-line price.

When you compare quotes, look beyond the price tag. Several factors directly impact your final cost, and a good partner will walk you through each one.

What Determines Your Cost Per Unit

The price you pay reflects the quality and complexity of your product. Here are the main drivers that will shape your quote:

- Raw Material Quality: This is the most significant factor. The source, potency, and grade of your skullcap herb will heavily influence the cost. Sourcing high-potency, verified raw materials costs more than generic botanicals, but it’s essential for an effective product.

- Formula Complexity: A simple, single-herb tincture will be more cost-effective than a complex blend with multiple botanicals. Each additional ingredient requires its own sourcing, quality verification, and testing.

- Order Volume: This is the most significant variable in your per-unit cost. Larger production runs almost always result in a lower price per unit due to economies of scale in sourcing, machine setup, and labor.

Your packaging choices also play a major role. Custom-printed boxes, specialized dropper caps, or unique bottle shapes will add to the final cost compared to standard, off-the-shelf options. As you navigate this, it's wise to explore different e-commerce pricing strategies to find the sweet spot for your market.

Key Insight: Your cost per unit is directly tied to your Minimum Order Quantity (MOQ). This is the smallest order a manufacturer will accept for a production run. It’s a critical number for both new and growing brands.

Finding Flexibility for Growth

The best partner offers the flexibility to start small but has the capacity to scale with you. For a new brand, a manufacturer with a low MOQ—perhaps in the 500 to 1,500 unit range—is a game-changer. It allows you to test the market, gather customer feedback, and manage cash flow without being buried in inventory.

As your brand grows, your needs will change. That same partner should be able to efficiently scale your production to runs of 5,000, 10,000, or even 50,000 units without sacrificing the quality or consistency you built your brand on. This scalability is the hallmark of a true growth partner.

This is especially important given market trends. The global Baical Skullcap Extract market is currently valued at around USD 250 million and is projected to grow at a CAGR of about 7% through 2033. You need a partner who can keep pace as demand increases.

Finding the Right Manufacturing Partner: Your Vetting Checklist

Choosing the right Skullcap herb private label contract manufacturer is the single most critical decision you'll make for your brand. Get this right, and you build your business on a solid foundation. Get it wrong, and you'll face operational headaches for years.

This isn't about finding a supplier; it's about finding a true partner. Here are the key questions and green flags to look for when vetting potential manufacturers.

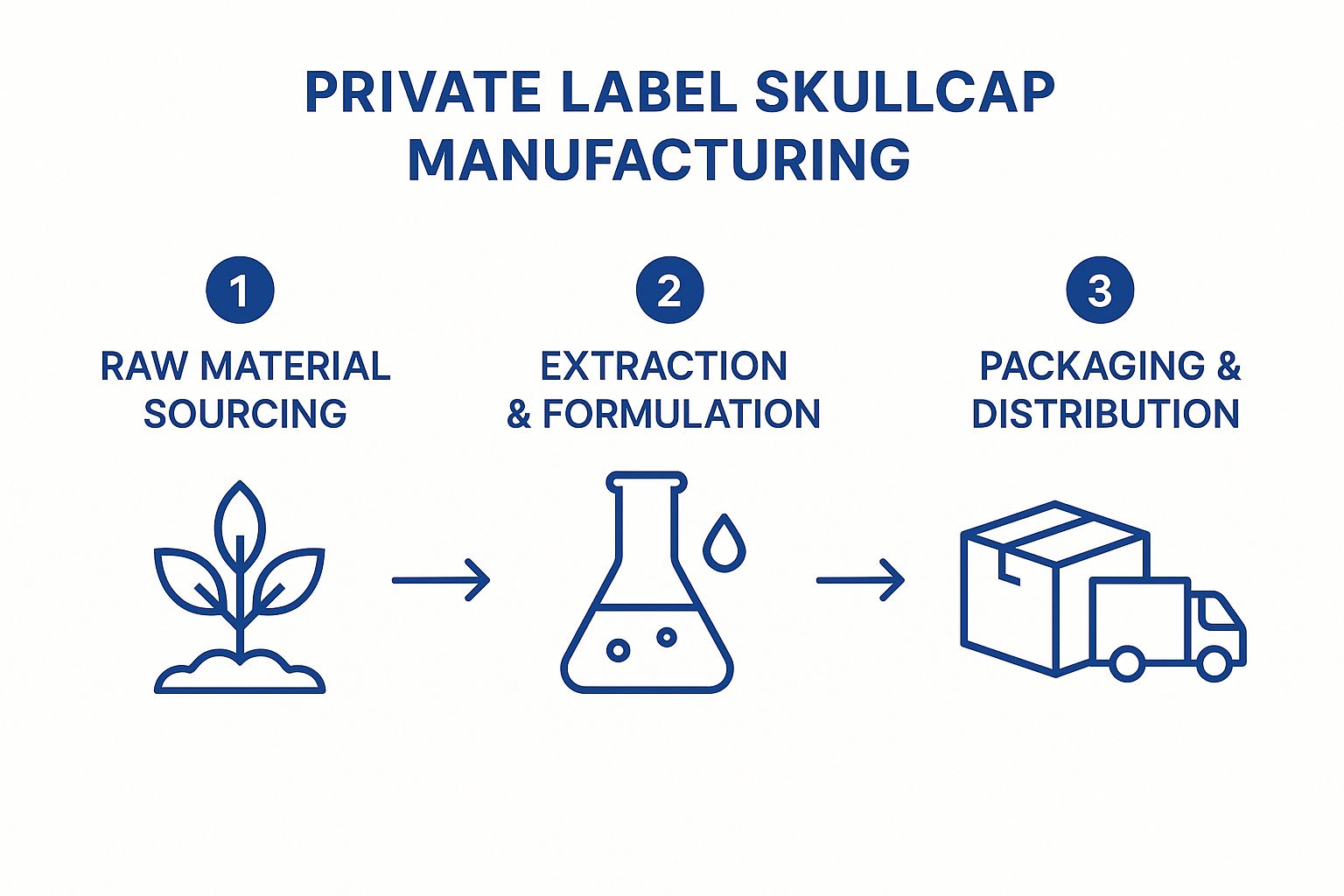

First, let's look at the big picture. The journey from raw skullcap herb to a finished product on a shelf involves many moving parts. A great partner makes this process look seamless.

This entire flow, from sourcing to shipping, needs to be seamless. Quality control isn't a single step; it's a thread that must run through the whole process. When you talk to potential partners, use the questions below as your guide.

Certifications and Compliance

Start with the non-negotiables. These credentials are the bedrock of your product's safety, legitimacy, and your brand's reputation. Ask these questions directly.

- Are you an FDA-registered and cGMP-compliant facility?

- Do you hold third-party certifications like UL or NSF?

- Can you share a recent Certificate of Analysis (CoA) for a similar herbal liquid you've produced?

A confident "yes" to all of these is the absolute minimum. Any hesitation is a major red flag. You want a partner who is proud of their compliance, not one who treats it as a chore.

Key Takeaway: A manufacturer that readily provides compliance documents sees quality as a selling point, not just a box to be checked. That's the kind of partner you want.

Formulation and Production Capabilities

Once you've established their credentials, dig into their technical skills. Can they create the high-quality product you envision? And can they grow with you?

Here’s what to ask:

- What are your capabilities for creating custom formulations? Can we explore synergistic blends with other botanicals?

- What extraction and processing methods do you use? Do you employ techniques like cold-fill processing to preserve botanical integrity?

- What are your Minimum Order Quantities (MOQs) for a first production run?

- How do you handle scaling up? Can you walk me through the process from a pilot batch to a full-scale order?

Finding a manufacturer who can support your brand from a small test run all the way to a large-scale launch is invaluable. This is especially true for herbal products where specialized knowledge is key. Many brands find that partnering with a dedicated herbal tincture contract manufacturer provides the focused expertise needed to create a truly premium skullcap supplement.

To help you keep track of conversations and compare partners side-by-side, use this simple but effective checklist.

Manufacturer Vetting Checklist

| Evaluation Area | Key Questions to Ask | Ideal Response / Green Flags |

|---|---|---|

| Regulatory Compliance | Are you FDA-registered and cGMP-compliant? Can I see your certifications? | Immediate "yes" and willingness to provide documentation. Bonus points for UL or NSF certs. |

| Quality Control | Can you walk me through your QC process, from raw materials to final product? | Detailed explanation of multi-stage testing protocols (identity, purity, potency). |

| Skullcap Sourcing | Where do you source your skullcap? What are your supplier standards? | Transparency about sourcing regions and supplier vetting. Provides COAs for raw materials. |

| Technical Skill | What are your formulation capabilities? Do you use methods that preserve botanical integrity? | Experience with custom herbal blends and modern techniques like cold-fill processing. |

| Scalability | What are your MOQs? How do you handle scaling production for a growing brand? | Flexible MOQs for startups and a clear, established process for increasing order volume. |

| Communication | Who would be my main point of contact? What is your typical response time? | A dedicated account manager is assigned. Clear communication channels and a responsive team. |

This checklist covers the most critical areas you need to investigate. A good potential partner will welcome these questions and have confident answers. A great partner will be enthusiastic about showing you why they're the right choice.

Common Questions About Skullcap Manufacturing

When you're ready to bring a skullcap supplement to market, questions are inevitable. Here are direct answers to the most common things we hear from brand managers and e-commerce founders looking to partner with a Skullcap herb private label contract manufacturer.

What Is a Typical Minimum Order Quantity?

Minimum Order Quantities (MOQs) vary significantly between manufacturers.

For a new brand, finding a partner who offers pilot runs as low as 500–1,000 units is a game-changer. It lets you test the market without a massive upfront investment.

More established manufacturers might require a commitment of 2,500 units or more for a fully custom run. The key is to find a partner whose scale fits your business now but who has the capacity to grow with you. Always ask how they handle scaling from a small initial order to much larger volumes.

How Long Does the Entire Process Take?

Realistically, from finalizing your formula to having a finished, ready-to-ship product, you should plan for 8–12 weeks. Be skeptical of anyone promising a faster turnaround, as it often means they're cutting corners on quality control.

Here’s a rough breakdown of that timeline:

- R&D and Formulation: This typically takes 2–4 weeks. It involves finalizing the details of your formula and getting your final approval.

- Production & Testing: The bulk of the time, around 6–8 weeks, is spent here. This covers raw material sourcing, the production run, and—most importantly—rigorous third-party quality testing.

A transparent partner will provide a clear schedule with all these milestones mapped out, so you know exactly what to expect.

Your brand is responsible for the label's marketing claims and visual design. However, a top-tier manufacturing partner will act as your compliance guide, reviewing your final design to ensure it meets all FDA requirements before it ever goes to print.

Who Handles Label Design and Compliance?

This is a team effort. You are in the driver's seat for branding and design—it's your vision. You'll provide the final design files that make your product stand out.

However, a great manufacturer won't just print what you send. Their in-house regulatory team will review everything. They’ll double-check your supplement facts panel, net contents statement, and other critical details to ensure compliance. Think of them as your regulatory safety net, helping you minimize risks and launch with confidence.

Ready to turn your vision into a market-ready skullcap supplement? The team at Triton Nutra Group is your dedicated R&D partner, from initial concept to final delivery. Request a free quote today and let’s build something exceptional together.