Your Expert Guide to Private Label Shelf-Stable Herbal Extracts

Discover how premium shelf-stable herbal extracts can elevate your brand. This guide covers formulation, preservation, and private label manufacturing.

Get a Free Quote Today!

Get a Free Quote Today!For ambitious brands in the booming herbal supplement market, shelf-stable herbal extracts are the key to delivering the potency and convenience today’s customers demand. Creating them is about more than just bottling herbs; it's about locking in a botanical's natural power at its absolute peak, so it’s ready whenever your customers need it.

This guide is your roadmap. It's built for e-commerce founders and brand managers ready to partner with an expert manufacturer and capitalize on the massive consumer shift toward natural, effective wellness solutions. As your R&D partner, we're here to guide you from concept through launch.

Why Shelf-Stable Extracts Are a Game-Changer for Your Brand

In a crowded market, product quality is non-negotiable. Customers expect supplements to work on day one and stay potent for months. Shelf-stable herbal extracts deliver on that promise, giving you a reliable, safe, and effective product that builds brand trust and drives repeat business.

This is about more than just preventing spoilage; it's about protecting the delicate, active compounds that make botanicals effective. A well-crafted extract ensures the last drop is just as powerful as the first. For your brand, this means a longer shelf life, simplified logistics, less waste, and a rock-solid reputation for quality.

The Growing Demand for Natural Potency

The market data is clear: consumers are actively seeking natural, reliable products. The global herbal extract market was valued at USD 29.9 billion in 2023 and is projected to nearly double, hitting USD 53.4 billion by 2030.

This incredible growth is fueled by consumers seeking products with natural ingredients—free from preservatives, gluten, and artificial additives. You can dive deeper into the trends behind this herbal extract market growth on Grandview Research.

For most brands, the smartest path to market is partnering with a manufacturer who lives and breathes this science. We position ourselves as your R&D partner, ready to cut through the complexity of creating top-tier, shelf-stable extracts. From initial concept to launch day, we bring the expertise you need to get a premium product to market with speed and confidence.

Our mission is to be your collaborator, not just a supplier. We combine our deep knowledge of botanical extraction and preservation with a commitment to your brand's success, ensuring your product stands out for its quality and reliability.

We handle the science so you can focus on building your brand. Our process is built on key pillars designed to help you succeed:

- Quality & Compliance: We operate in a cGMP, UL certified, and FDA-registered facility, ensuring your product meets the highest standards.

- Customization & Flexibility: We tailor formulas, flavors, and packaging, with run sizes from pilot to full scale.

- Speed & Reliability: You get rapid turnaround, transparent timelines, and an on-time delivery record you can count on.

Choosing a private label partner simplifies this entire journey, allowing you to bring a high-quality, shelf-stable product to market faster.

Key Advantages of Private Label Liquid Herbal Extracts

| Benefit | Impact on Your Brand | How We Deliver |

|---|---|---|

| Market-Ready Formulations | Launch proven, effective products quickly without the lengthy R&D phase. | We offer a portfolio of validated formulas ready for your branding. |

| Reduced Upfront Costs | Avoid major investments in manufacturing equipment, facilities, and specialized staff. | Our state-of-the-art, certified facility becomes your production hub. |

| Regulatory Peace of Mind | Navigate complex compliance landscapes with a partner who understands the rules. | Our cGMP, UL certified, and FDA-registered facility ensures your product meets all standards. |

| Scalable Production | Grow your brand seamlessly from small test runs to large-scale production without interruption. | We offer flexible run sizes to match your demand, from pilot batches to full production. |

| Expertise on Demand | Access a team of formulation scientists and quality control experts from day one. | Our team acts as an extension of yours, providing scientific and manufacturing support. |

Partnering with an experienced manufacturer takes the guesswork out of product development, ensuring you deliver a supplement that is safe, potent, and perfectly aligned with your brand's promise.

Understanding What Makes an Extract Shelf-Stable

Creating a shelf-stable herbal extract is a science. At its core, stability means protecting the formula from its three biggest enemies: microbial growth (like bacteria and mold), oxidation from air, and the natural breakdown of active botanical compounds.

The goal is to control the environment inside the bottle to create conditions where these threats can't survive. This is where the technical skill of an experienced manufacturing partner becomes your most critical asset.

The Core Pillars of Stability

Long-term stability isn’t achieved with one magic bullet; it's about balancing several key scientific principles. Each one works in concert to protect the formula's integrity from the day it’s bottled until the last drop.

Here are the three critical factors we manage in every batch:

-

Water Activity (Aw): This isn't about how much water is in a formula, but how much is available for microbes to use. By controlling water activity—often with ingredients like glycerin that bind to water molecules—we effectively "lock up" the water, making it impossible for bacteria and mold to grow.

-

pH Level: A liquid's acidity or alkalinity has a massive impact on what can live in it. Most microbes thrive in a neutral pH range. We carefully adjust the pH of each formula to create an environment that is inhospitable to unwanted organisms while keeping the active herbal compounds stable.

-

Preservative Systems: Think of preservatives as the formula's security guards. They actively shut down any potential microbial growth that might bypass the other defenses.

A successful shelf-stable formula is an ecosystem in balance. It’s not just about adding preservatives; it’s about engineering a foundation where contaminants can't survive, ensuring the product remains safe and potent for 24 months or more.

Natural vs. Synthetic Preservatives

The choice of preservative directly impacts your product's final profile and label claims. As your formulation partner, we guide you through this decision to select the ideal system for your brand.

Natural Preservatives Derived from botanical sources, these are a popular choice for health-conscious consumers.

- Examples: Rosemary extract, citric acid, and certain essential oils.

- Best For: Brands targeting a "clean label" or organic positioning.

- Considerations: They can sometimes affect the flavor profile and often require more formulation finesse to be effective.

Synthetic Preservatives These lab-created compounds are known for their powerful, broad-spectrum effectiveness and reliability.

- Examples: Potassium sorbate and sodium benzoate are common, safe, and widely used options.

- Best For: Complex formulas where robust, cost-effective preservation is the top priority.

- Considerations: While proven to be safe and effective, some consumer segments prefer to avoid them.

The methods used to extract botanicals in the first place also play a huge role. You can explore our complete guide on herbal extraction methods to see how these initial steps influence the final product's stability. Understanding these fundamentals empowers you to make strategic decisions that align with your brand's vision.

Modern Preservation for Maximum Botanical Potency

Creating a potent, shelf-stable herbal extract is a delicate dance between botanical wisdom and forward-thinking technology. The goal is simple: protect the delicate, active compounds in plants from the moment they’re extracted to the final drop a customer uses. This requires a strategic approach that begins long before the product is bottled.

As your R&D partner, we focus on innovative techniques that preserve the full spectrum of an herb’s benefits, ensuring your formula is both safe and powerful.

The Power of Cold-Fill Technology

Heat is a primary enemy of botanical potency. Many traditional "hot-fill" methods heat liquids to high temperatures for sterilization. While effective at killing microbes, this intense heat can also degrade or destroy the very compounds you want to preserve, like sensitive flavonoids and essential oils.

We champion a more advanced approach: cold-fill technology.

Hot-filling is like boiling fresh vegetables—you kill germs, but you also lose significant vitamins and flavor. Cold-filling is like flash-freezing those same vegetables, locking in their full nutritional value without destructive heat.

This method allows us to bottle your liquid supplement in a controlled, sterile environment at cool temperatures. By avoiding high heat, we protect the structural integrity of every active ingredient. The result is a final product as powerful as nature intended.

Choosing the Right Preservative System

Beyond the filling process, the preservative system is the formula's ongoing defense. The choice is strategic, balancing effectiveness with your desired label claims and target audience.

We collaborate with you to select from a range of options:

- Natural Preservatives: For "clean label" brands, natural options are ideal. We use ingredients like rosemary extract or citric acid that offer effective antimicrobial properties while aligning with consumer demand for all-natural products.

- Targeted Synthetic Options: For complex formulas, industry-standard preservatives like potassium sorbate or sodium benzoate provide robust, broad-spectrum protection. They are highly effective, cost-efficient, and have a long track record of safety.

Our role is to guide you to the choice that best aligns with your brand's vision, ensuring uncompromising safety and quality.

The Dual Role of Extraction Solvents

The preservation process actually begins during extraction. The solvent used to pull active compounds from the raw botanical—whether it's alcohol, glycerin, or water—plays a dual role. It not only captures the desired phytonutrients but also acts as the formula's foundational preservative. The choice of solvent directly impacts the final product's shelf life.

- Alcohol (Ethanol): A highly effective solvent and natural preservative, alcohol is excellent for extracting a broad range of compounds and ensuring long-term stability.

- Glycerin: A sugar alcohol, glycerin is a great non-alcoholic alternative. It acts as both a solvent and a preserver by binding to water, which inhibits microbial growth.

- Water: While essential for many extractions, water alone is not a preservative. Water-only infusions have a very short shelf life unless combined with a robust preservative system.

To highlight the advantages of these modern techniques, let's compare them to traditional methods.

Comparing Preservation and Filling Technologies

The manufacturing method you choose directly impacts your final product's quality, potency, and stability. This table breaks down the key differences.

| Technology | How It Works | Impact on Herbal Potency | Best For |

|---|---|---|---|

| Hot-Fill | Liquid is heated to 194°F (90°C) to sterilize, then bottled hot. | High Risk. Heat can degrade or destroy sensitive vitamins, flavonoids, and essential oils, reducing effectiveness. | Simple, heat-stable formulas where potency is not the primary concern. |

| Chemical Preservation | Preservatives like benzoates or sorbates are added to inhibit microbial growth at room temperature. | Low to Moderate Risk. Potency is maintained, but some consumers prefer "clean label" products without synthetic additives. | Complex formulas needing broad-spectrum protection and a long shelf life. |

| Cold-Fill | Product is processed and bottled in a sterile, temperature-controlled environment without high heat. | Minimal Risk. Preserves the full spectrum of active compounds, ensuring maximum potency and efficacy. | High-potency, heat-sensitive formulas where delivering the full benefit of the herb is critical. |

| Aseptic Filling | Both the product and the container are sterilized separately, then combined in a sterile environment. | Minimal Risk. Similar to cold-fill, this process avoids heat degradation and maintains the integrity of delicate ingredients. | Premium, sensitive products like dairy alternatives, juices, and high-end supplements. |

By mastering the interplay between extraction, preservation, and advanced filling technologies, we build shelf-stable herbal extracts from the ground up. This commitment to modern manufacturing ensures your product benefits from techniques that maximize both potency and longevity, giving your brand a distinct advantage.

Your Guide to Quality and Regulatory Compliance

In the supplement world, trust is the brand. You can create the most potent shelf-stable herbal extracts on the market, but ensuring they are pure, safe, and fully compliant is what protects your customers and secures your reputation.

This is where your partnership with a manufacturer obsessed with quality becomes your single greatest asset. Navigating regulations can feel complex, but it doesn't have to be. Think of quality control as the master checklist that turns premium raw botanicals into a final product your customers can count on.

Decoding the Alphabet Soup of Certifications

Acronyms like cGMP, UL, and FDA-registered are your brand's shield. They represent a deep commitment to safety and excellence that resonates with savvy customers and major retailers.

Here's what these critical credentials mean for your product:

-

cGMP (Current Good Manufacturing Practices): These are the FDA-enforced rules of the road. Being cGMP-compliant means we adhere to the highest standards for every step, from sourcing raw materials to final packaging, ensuring consistent quality every time.

-

UL Certified: UL is a global safety science leader. This third-party certification demonstrates that our facility and processes have been rigorously audited to meet strict safety, quality, and purity standards, adding a powerful layer of trust.

-

FDA-Registered Facility: This confirms we operate in a facility registered with and subject to inspection by the U.S. Food and Drug Administration. It’s a foundational requirement for any serious supplement manufacturer.

These certifications provide the peace of mind that your supplement is not just potent but also compliant, safeguarding your brand.

Our Multi-Stage Quality Assurance Process

A reliable product is born from relentless testing. We've built a transparent, multi-step process to guarantee your formula's integrity from concept to finished product.

This structured approach is our promise that what's on your label is exactly what's in the bottle.

Our Partnership Mindset: We view quality control as a collaborative effort to protect your brand. Your success is built on customer trust, and our rigorous processes are designed to fortify that trust from the ground up.

Our process is broken down into three critical phases. For a deeper dive, explore our complete guide to dietary supplement manufacturing requirements for the full picture.

From Raw Botanicals to Final Product

1. Raw Material Validation The moment raw botanicals arrive, the process begins. We verify everything in-house:

- Identity Testing: Confirming the exact plant species and part for your formula.

- Purity Screening: Testing for potential contaminants like heavy metals, pesticides, and microbes.

- Potency Analysis: Ensuring the raw material meets the required concentration of active compounds.

2. In-Process Checks During production, we continuously monitor critical parameters like temperature, viscosity, and pH. This ensures every batch is consistent and meets your formula's exact specifications.

3. Final Third-Party Testing Before any product is released, a sample from the finished batch is sent to an independent, third-party lab. This final, unbiased verification confirms the product's potency, purity, and safety, ensuring it meets all regulatory standards and lives up to your brand's promise.

Bringing Your Product From Concept to Launch

Turning a brilliant idea into a market-ready product is a journey of science, manufacturing expertise, and brand strategy. We don't just see ourselves as a manufacturer; we’re your R&D team and strategic partner, here to guide you every step of the way.

This collaboration is about bringing your concept to life, ensuring the final product is potent, stable, and a perfect reflection of your brand. Our entire partnership is built on flexibility and transparency, designed to support you from initial idea to successful launch.

From Your Vision to a Custom Formula

It all starts with your vision. You bring the idea—a unique herbal blend, a specific health benefit, or a flavor profile your customers will love. We bring the formulation expertise to make it a reality.

This is where true customization happens. We can tailor:

- Ingredient Profiles: Selecting the precise botanicals and active compounds to achieve your desired effect.

- Flavor and Sweetness: Crafting a taste your audience will love using natural flavors and sweeteners.

- Viscosity and Mouthfeel: Fine-tuning the liquid’s texture for the perfect customer experience.

Our goal is simple: create a unique product that stands out. For a deeper dive, check out our guide on private-label liquid supplements, which breaks down the formulation process.

Partnership in Practice: Think of us as an extension of your team, providing the scientific backbone to your creative vision. Every decision, from sourcing ingredients to perfecting the flavor, is made with your brand's success as the top priority.

Scalable Solutions for Brands of All Sizes

Every brand's journey is different. A startup has different needs than an established brand launching a new line. That’s why our manufacturing process is built to scale with you.

We set you up for confident growth by offering:

- Pilot Batches: We can start with small, cost-effective pilot runs. This lets you test your new formula and get market feedback without committing to a massive inventory.

- Full-Scale Production: When you're ready to grow, we seamlessly scale up to larger production runs to meet demand, all while maintaining the same strict quality standards.

This flexibility minimizes your risk and allows you to scale production as your sales grow. Of course, a great product is only half the battle; knowing how to build a brand strategy is just as crucial.

A Focus on Speed and Reliability

In the fast-paced world of e-commerce, speed and reliability are essential. Production delays mean missed sales and lost momentum. Our operation is engineered to deliver your product on time, every time, without compromising quality.

We provide transparent timelines from day one, so you know exactly what to expect. We’re proud of our on-time delivery record, built on efficient processes and clear communication.

This operational excellence is what it takes to compete. The Asia Pacific region, for example, represents a USD 22.99 billion herbal market powered by biodiversity and tradition—an industry that moves at lightning speed.

Partnering with a reliable manufacturer lets you plan your marketing campaigns and launch dates with confidence, knowing your inventory will be there when you need it. This is about building a solid foundation for your brand’s long-term success.

How Smart Packaging Protects Your Product

You've perfected a powerful, stable herbal extract. The formulation is precise, and the filling technology is state-of-the-art. But the final line of defense is the packaging.

More than just a container, the right packaging is a high-tech vault, safeguarding the formula’s integrity from our facility to your customer's hands.

The First Layer of Defense: Material Choices

The bottle itself plays a huge role in protecting sensitive botanical compounds from degradation. While options exist, some materials offer far better protection against environmental threats—especially UV light, which is notorious for destroying active ingredients and shortening shelf life.

This is why we champion amber glass.

Think of an amber glass bottle as high-quality sunglasses for your extract. It’s specifically designed to filter out harmful blue and ultraviolet light, preserving the delicate phytochemicals inside. While some plastics offer UV protection, amber glass provides a more complete and reliable barrier, ensuring maximum potency.

This single choice directly impacts your product's longevity. By blocking damaging lightwaves, we help ensure your extract is just as effective on the last day of its shelf life as it was on the first.

Sealing the Deal: Preventing Oxidation and Ensuring Safety

Even the best bottle is useless without a secure seal. The cap prevents oxidation—where oxygen degrades the product—and guarantees it’s safe and untampered with.

We rely on key mechanisms to create an airtight closure:

- Tamper-Evident Caps: These provide instant visual proof that the product has not been opened, building immediate consumer trust.

- Induction Seals: This is the foil liner you find sealed across a bottle's opening. We use an electromagnetic field to create a hermetic seal that locks out oxygen and moisture, offering one of the most effective barriers against contamination.

These details are non-negotiable. The food and beverage industry, which makes up about 70% of the herbal extract market, depends on these innovations to keep products stable across complex supply chains.

With indirect sales channels accounting for roughly 64% of market distribution, robust packaging is what protects your investment during shipping and storage. You can dive deeper into the market dynamics for herbal extracts at Future Market Insights. Every detail contributes to delivering a premium product your customers can trust.

Got Questions About Manufacturing Herbal Extracts? We Have Answers.

Stepping into the world of private-label supplements can bring up a lot of questions. As your R&D partner, we believe in total transparency.

Here are straightforward answers to the questions we hear most often from brand owners. Our goal is to give you the confidence you need to bring your vision for a premium, shelf-stable herbal extract to life.

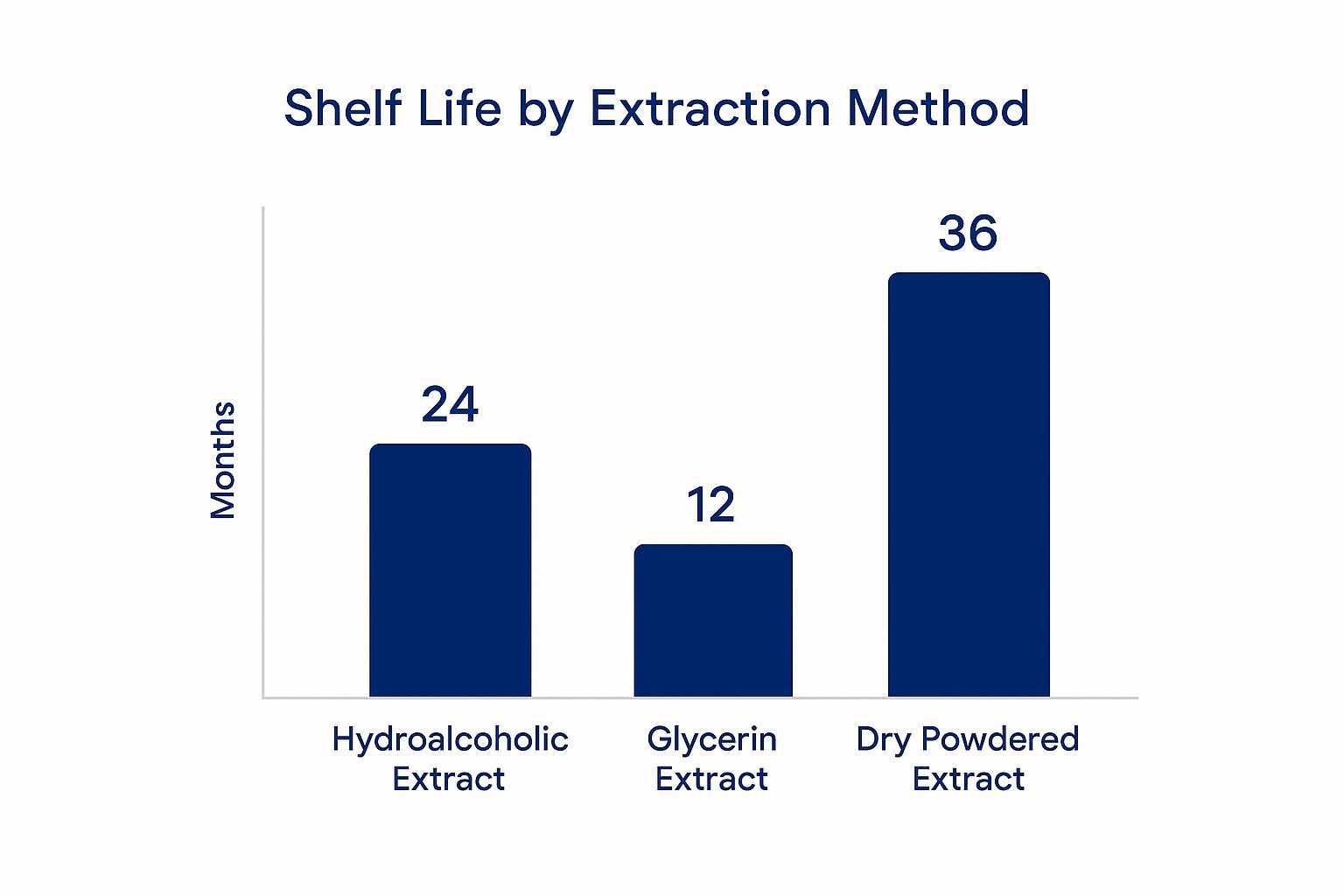

What Is the Typical Shelf Life of Your Extracts?

Our liquid herbal extracts generally have a shelf life of 24 to 36 months. The exact timeline depends on the specific ingredients and the final custom formulation we develop for you.

We achieve this stability through a combination of factors: advanced preservation methods, our innovative cold-fill process that protects delicate compounds, and high-barrier packaging. As part of our R&D process, we conduct rigorous stability testing to validate the shelf life for your specific product, ensuring it stays potent and safe until the expiration date.

What Are Your Minimum Order Quantities?

We are passionate about supporting brands at every stage, which is why our production is built for flexibility.

For new custom formulas, we often begin with small pilot batches. This allows you to test the market and gather feedback without a massive upfront investment. Our minimum order quantities (MOQs) for full production runs are competitive and designed to help you scale efficiently as demand grows. The best way to start is with a conversation—our team can walk you through the options to find a solution that fits your business goals.

Our Partnership Mindset: We're here to help you grow. Whether you're launching your first product or expanding a successful line, our scalable solutions align with your business strategy, providing a clear path from pilot batch to full-scale production.

How Do You Ensure Raw Ingredient Quality?

For us, quality starts with meticulous sourcing. We work with a global network of vetted suppliers who meet our demanding standards for botanicals.

But that's just the beginning. The moment raw materials arrive at our cGMP, FDA-registered facility, they undergo a comprehensive battery of in-house lab tests, including:

- Identity Testing: We use scientific methods to verify the correct plant species and part. No guesswork, only authenticity.

- Purity Screening: Every batch is screened for potential contaminants like heavy metals, pesticides, and microbes.

- Potency Analysis: We confirm that active compounds are present at the levels needed to make your product effective.

This rigorous validation ensures that only the absolute best ingredients make it into your product. This fanatical attention to detail is what builds trust and protects your brand’s reputation.

Ready to turn your vision for a high-quality, shelf-stable supplement into a market-ready reality? Partner with Triton Nutra Group and let our expertise guide you from concept to launch.

Request a free quote today and start your journey with a trusted manufacturing partner.