Herbal Extraction Methods: A Complete Modern Guide

Learn effective herbal extraction methods with proven techniques. Discover modern approaches to maximize quality and yield today.

Get a Free Quote Today!

Get a Free Quote Today!Understanding What Makes Herbal Extraction Work

Think of herbal extraction like trying to open a treasure chest—you need the right key for the right lock. Simply crushing plants isn't a strategy; it’s a gamble. The true art and science lie in understanding how nature tucks its valuable compounds away inside complex plant cells and then choosing the perfect "key" to get them out. This idea is central to all modern herbal extraction methods, from brewing a simple tea to running advanced lab equipment.

Think of herbal extraction like trying to open a treasure chest—you need the right key for the right lock. Simply crushing plants isn't a strategy; it’s a gamble. The true art and science lie in understanding how nature tucks its valuable compounds away inside complex plant cells and then choosing the perfect "key" to get them out. This idea is central to all modern herbal extraction methods, from brewing a simple tea to running advanced lab equipment.

The practice of isolating plant compounds is far from new. Humanity's relationship with medicinal plants goes back roughly 60,000 years to the Paleolithic age. Ancient Sumerian records from over 5,000 years ago even list specific plants for particular uses. You can explore more about the deep history of herbal medicine on Wikipedia. This long-standing knowledge is the foundation for today's precise extraction techniques.

The Science of Separation and Solubility

At its core, herbal extraction is all about separation. Every plant holds thousands of chemical compounds, but we are usually only interested in a small group of bioactive constituents—the molecules that give the plant its health benefits. These compounds are locked inside the plant’s cellular structure, protected by a tough cell wall. The main goal of extraction is to dissolve these target compounds while leaving behind the unwanted material, like fiber.

Imagine trying to get sugar out of a teacup full of sugar cubes. You could try to pick them out, but a much better way is to pour in hot water. The water dissolves the sugar, separating it from the cup. In herbal extraction, the liquid we use is called a solvent. The type of solvent you choose determines which compounds it can pull from the plant material, following the simple chemical principle of "like dissolves like."

Key Factors That Influence Extraction Success

Several factors must work in harmony to produce a successful extraction. Getting this balance right is what separates a low-potency product from a high-quality, effective supplement. The relationship between these elements is complex, affecting everything from the final yield to the specific profile of the extracted compounds.

- Solvent Choice: Water is a polar solvent, making it great for pulling out water-loving compounds like some flavonoids and polysaccharides. On the other hand, non-polar solvents like certain alcohols or oils are better for dissolving oil-soluble compounds, such as resins and many essential oils.

- Temperature: Turning up the heat can often speed up extraction and make compounds more soluble, just like hot water dissolves sugar faster than cold water. But be careful—too much heat can damage or destroy delicate compounds, so precise temperature control is critical.

- Time: How long the plant material sits in the solvent directly affects the final result. A longer extraction might pull out more of the good stuff, but it could also start pulling out unwanted components that can affect the purity and taste.

- Plant Preparation: The physical form of the herb is very important. Grinding plants into a fine powder creates more surface area for the solvent to work on, leading to a more efficient extraction. However, if the powder is too fine, it can make filtering a challenge later in the process.

By carefully managing these factors, manufacturers can accurately target and capture the full benefits a plant has to offer. This is a fundamental part of creating powerful nutraceutical products. With this foundational knowledge, we can now look at the specific extraction techniques used today.

Water Extraction: Why This Ancient Method Still Dominates

Of all the herbal extraction methods, using water is the oldest and most familiar. It’s the simple process that gives you your morning coffee or tea. This very familiarity, however, often leads people to underestimate its power and complexity in a large-scale manufacturing environment. While making one cup of tea is straightforward, producing thousands of gallons of a consistent, potent herbal extract requires a precise blend of ancient knowledge and modern science. Its excellent safety profile, low cost, and ability to draw out specific water-soluble compounds like polysaccharides and certain flavonoids make it an essential tool for supplement producers.

Water's strength lies in its role as the "universal solvent." Because water is a polar molecule, it acts like a magnet for other polar molecules within a plant. This is why water-based methods are perfect for herbs where the target compounds are also "water-loving," such as the immune-supporting polysaccharides in echinacea or the soothing mucilage in marshmallow root.

The Three Pillars of Water Extraction

While all water-based methods use H₂O, the way heat and time are applied creates distinct techniques. Each is tailored for different parts of a plant, and understanding these differences is crucial for unlocking an herb's full potential.

- Infusion: This is the most delicate method, ideal for fragile plant parts like leaves and flowers. It involves steeping herbs in hot water, usually just below boiling, for a specific time. Think of making a cup of chamomile or peppermint tea. This gentle approach helps preserve volatile compounds that intense heat would otherwise destroy.

- Decoction: A more robust method reserved for tough, woody plant materials like roots, bark, and seeds. Here, the material is simmered in water for a longer duration. This process is necessary to break down the tough cellular walls and release the deeply embedded bioactive compounds.

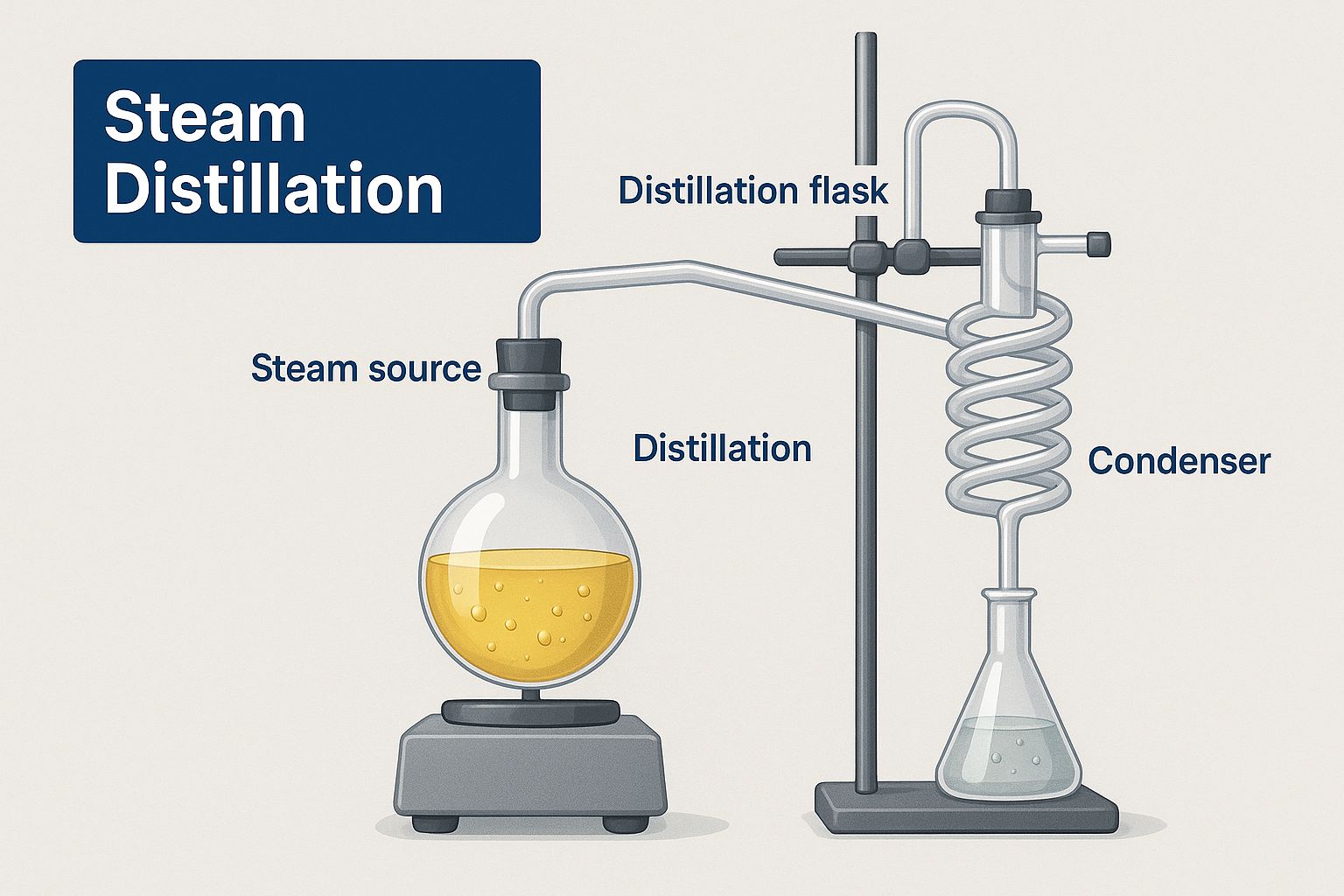

- Steam Distillation: This is a specialized technique used to capture volatile compounds, primarily essential oils. Steam is passed through the plant material, which vaporizes the volatile oils. This steam-and-oil mixture is then cooled in a condenser, allowing the essential oil to separate from the water.

This infographic shows a typical steam distillation setup, a key method for capturing volatile compounds from herbs.

The image illustrates the core components—the boiling flask, the container for plant material, and the condenser—that work in harmony to isolate essential oils.

The image illustrates the core components—the boiling flask, the container for plant material, and the condenser—that work in harmony to isolate essential oils.

To better understand which method to use, this table compares the key parameters of each water extraction technique.

| Method | Temperature Range | Extraction Time | Best For | Typical Yield |

|---|---|---|---|---|

| Infusion | 85-95°C (185-203°F) | 5-30 minutes | Delicate leaves, flowers, and soft aerial parts (e.g., chamomile, mint) | Varies greatly, focus is on quality |

| Decoction | 95-100°C (203-212°F) | 30 minutes to 2+ hours | Tough roots, bark, seeds, and woody stems (e.g., astragalus root) | Generally higher than infusion due to intensity |

| Steam Distillation | 100°C (212°F) | 1-6 hours | Aromatic plants rich in essential oils (e.g., lavender, peppermint) | Low (e.g., 0.1% to 2% for most essential oils) |

This comparison highlights that the choice of method is not random; it's a calculated decision based on the plant's physical structure and the chemical nature of the desired compounds.

Modern Challenges and Solutions

Despite its advantages, using water for large-scale extraction comes with its own set of challenges. Since water is a requirement for life, a water-based extract is an ideal environment for bacteria and mold to grow. Manufacturers must follow strict sanitation protocols and often use broad-spectrum preservatives to guarantee product safety and a stable shelf life.

Standardization is another significant hurdle. The potency of a water extract can change dramatically with small shifts in temperature, pH, or extraction time. Top-tier companies address this by using precision-controlled equipment that keeps these parameters consistent for every single batch. They also perform rigorous testing to confirm that each batch has the correct concentration of active compounds, ensuring the final product is both safe and effective. This careful approach is what turns a simple, ancient technique into a reliable manufacturing method.

Ethanol Extraction: The Versatile Powerhouse Method

If water extraction is the gentle specialist, then ethanol extraction is the versatile master key. Of all the herbal extraction methods, ethanol has a unique advantage because of its polarity. Think of it as a chemical diplomat, able to connect with both water-loving (polar) and oil-loving (non-polar) compounds. This dual-action ability lets it draw out a much wider range of a plant's active components in one go, making it a very efficient and popular choice in modern supplement manufacturing.

If water extraction is the gentle specialist, then ethanol extraction is the versatile master key. Of all the herbal extraction methods, ethanol has a unique advantage because of its polarity. Think of it as a chemical diplomat, able to connect with both water-loving (polar) and oil-loving (non-polar) compounds. This dual-action ability lets it draw out a much wider range of a plant's active components in one go, making it a very efficient and popular choice in modern supplement manufacturing.

This flexibility is why so many potent tinctures and full-spectrum extracts are made with ethanol. It can effectively dissolve alkaloids, glycosides, resins, and many other compounds that water would simply miss. However, this power demands careful management. It’s not just about soaking herbs in alcohol; it's a precise science where concentration and temperature are the main controls for shaping the final product.

Fine-Tuning with Concentration and Temperature

The true craft of ethanol extraction is in adjusting the solvent's concentration. Pure, 200-proof ethanol is fantastic for pulling out non-polar, oil-based compounds. On the other hand, a lower concentration, such as a 40-60% solution (80-120 proof), has enough water to also grab water-soluble compounds. This lets manufacturers create a custom solvent that perfectly matches the chemical makeup of the herb they're working with.

Temperature introduces another level of control. Cold ethanol extraction, often done at below-freezing temperatures, is a preferred method for protecting delicate compounds like terpenes. It also helps avoid pulling out unwanted materials such as chlorophyll and waxes, leading to a cleaner, more refined extract. In contrast, warm or room-temperature extractions are quicker and can produce a higher yield, but they might also extract more undesirable plant matter that needs to be filtered out later.

Pros and Cons of Ethanol Extraction

Just like any technique, ethanol extraction has its strengths and weaknesses. Its efficiency and scalability make it a go-to for many producers, but it also requires cautious handling and an investment in the right equipment.

| Pros of Ethanol Extraction | Cons of Ethanol Extraction |

|---|---|

| Broad-spectrum efficiency | Non-selective nature |

| Can pull a wide range of compounds. | Can also extract unwanted materials (e.g., chlorophyll, waxes). |

| Highly effective | Flammability concerns |

| Produces potent extracts and tinctures. | Requires explosion-proof equipment and strict safety measures. |

| Scalable process | Regulatory oversight |

| Works well for both small-batch and large-scale production. | The use of flammable alcohol is heavily regulated. |

| Food-grade safety | Post-processing needs |

| Ethanol is safe for consumption and can be left in tinctures. | Extracts often need more steps like winterization or filtration. |

Safety and Equipment Considerations

Working with ethanol requires a serious approach to safety. Since ethanol is highly flammable, facilities must use special, explosion-proof equipment and have powerful ventilation systems. Every electrical component in the extraction area must be rated to prevent sparks that could ignite ethanol vapor.

Beyond the safety gear, professional ethanol extraction involves more than a simple soaking tank. Operations use closed-loop systems that can recover and reuse a large amount of the ethanol—often over 95%. This not only lowers operating costs but also reduces the environmental footprint, making the process more sustainable. This blend of power, precision, and efficiency solidifies ethanol's place as a true powerhouse in the world of herbal extraction.

Supercritical CO₂: The Clean Technology Revolution

Stepping away from conventional solvents, we encounter a clean and precise approach: supercritical CO₂ extraction. Think of a solvent you can fine-tune with the delicacy of a dimmer switch, isolating specific plant compounds while leaving others behind. This is the reality of using carbon dioxide in its supercritical state, a unique phase where it possesses the properties of both a liquid and a gas at the same time. This technique is quickly becoming the benchmark among herbal extraction methods for crafting pure, premium products.

The method begins with ordinary carbon dioxide—the same gas we exhale. This CO₂ is then subjected to specific conditions: a temperature above 31.1°C and pressure above 1,070 psi. Under this pressure and heat, CO₂ enters its supercritical state. In this form, it can seep into plant matter like a gas but dissolve compounds like a liquid. By carefully adjusting the pressure and temperature, extractors can selectively pull out target molecules, such as specific cannabinoids or fragile terpenes, with impressive accuracy.

The Trade-Off: Purity Versus Cost

The most significant benefit of supercritical CO₂ is the remarkable purity of the final product. Once the extraction is finished, the pressure is released. The CO₂ turns back into a gas and simply evaporates, leaving behind a pristine extract with zero residual solvent. This is a major plus for health-conscious consumers and a key differentiator for high-end supplement brands. Since the process operates at low temperatures, it also protects heat-sensitive compounds that other methods might damage or destroy.

However, this exceptional quality requires a serious financial commitment. The equipment needed to manage such high pressures is specialized and expensive, making the initial setup cost quite high. Because of this, CO₂ extraction is usually reserved for high-value botanicals where consumers are willing to pay a premium for unparalleled purity and potency.

| Feature | Supercritical CO₂ Extraction |

|---|---|

| Solvent Residue | None; CO₂ fully evaporates. |

| Selectivity | Highly adjustable; can target specific compounds. |

| Operating Temperature | Low, preserving delicate molecules. |

| Initial Investment | Very high due to specialized equipment. |

| Best For | High-value, heat-sensitive botanicals; premium products. |

A Modern Application of a Long History of Precision

This push for precision in isolating plant compounds is rooted in a deep scientific history. The journey to understand plant anatomy for better extraction took a major leap in the 17th century. In 1682, Nehemiah Grew used the recently invented compound microscope to describe plant structures in incredible detail, creating a foundation for understanding how to access the compounds stored inside. You can discover more about the historical pursuit of herbal quality assessment and its evolution.

Today, CO₂ technology is the culmination of that centuries-long search for precision. It gives us a level of control that early scientists could only imagine. The outcome is an incredibly clean and potent product that justifies both the high initial cost and the premium price tag for consumers.

Alternative Solvents: Beyond Water And Ethanol

While water and ethanol are the true workhorses of herbal extraction, they don't have a monopoly on pulling valuable compounds from plants. Sometimes, the specific properties of a final product or the unique chemistry of a target compound require a different strategy. This is where alternative solvents come in, solving problems that traditional herbal extraction methods can't touch.

Think of it like a mechanic's toolbox. You have your standard wrenches (water and ethanol), but for certain jobs, you need specialized tools. These alternatives offer focused solutions, from creating alcohol-free products to capturing oily molecules that other solvents might leave behind. This specialized approach is essential for creating targeted, high-quality products.

Glycerin Extraction for Alcohol-Free Formulas

One of the most popular alternatives is vegetable glycerin. This is a thick, sweet-tasting liquid that comes from plant oils. It's the key to making glycerites—tinctures that are completely free of alcohol. This makes it a perfect choice for products aimed at children, people with alcohol sensitivities, or anyone who prefers an alcohol-free option. Its natural sweetness also improves the taste without needing to add sugar.

Glycerin works by drawing out a good variety of water-soluble compounds and even some alcohol-soluble ones, though it's generally not as potent as ethanol. The process is gentle, often involving a slow, low-heat infusion over several weeks. Because glycerin is also a humectant (it attracts and holds onto moisture), it adds a hydrating quality to formulas, a valuable benefit in topical products. This makes it an excellent choice for certain liquid supplements, which must often balance effectiveness with consumer preferences. You can see how these choices impact product development by exploring various wholesale liquid supplements offering a natural approach to wellness.

Capturing Lipids with Oil-Based Extraction

Another key alternative uses oils as the solvent. This method is specifically designed to capture lipophilic (fat-soluble) compounds. These are molecules that water can't touch and ethanol can only partially dissolve. Carrier oils like olive, coconut, or MCT oil are infused with herbs to pull out these valuable fat-soluble vitamins, resins, and other oily parts of the plant.

The process is quite direct: the plant material is steeped in the chosen oil, often with gentle heat applied over a long period. The oil effectively dissolves and holds onto these target compounds, creating a nutrient-dense, infused oil. This technique is fundamental for producing many topical salves, balms, and skincare items, as well as edible, oil-based supplements.

Emerging and Specialized Solvents

Beyond glycerin and oils, the industry is exploring other specialized solvents, each with distinct advantages.

- Propylene glycol (PG) is a synthetic organic compound that acts as a strong solvent, often used when high concentrations of specific compounds are required.

- "Green solvents" like ionic liquids and deep eutectic solvents are gaining traction due to a push for sustainability. They promise high efficiency with a smaller environmental footprint.

These developing options show how the field of herbal extraction is continually adapting, giving manufacturers an expanding set of tools to create more effective and specialized products.

Scaling From Lab To Manufacturing Success

Creating a powerful herbal extract in a lab is a huge win, but it’s just the starting line. Making the leap from a small, perfectly controlled batch to large-scale commercial production is like going from cooking a gourmet meal for two to running a high-volume catering company. The core ideas are the same, but the equipment, processes, and challenges are on a completely different level. This is the point where many promising herbal extraction methods can stumble without smart planning and the right investment.

Successfully making this jump means you need to be an expert on equipment, process validation, and the rules of the road for manufacturing. What worked beautifully on a lab bench can become incredibly inefficient or even unworkable when you try to scale it up.

From Benchtop to Industrial Systems

The path from a lab discovery to a product on the shelf involves distinct stages of equipment, each designed for a specific volume of production. A frequent error is trying to go straight from a small setup to a massive one, skipping the crucial middle step. This almost always leads to wasted raw materials, inconsistent product quality, and serious financial setbacks.

- Lab Scale (R&D): This is where it all begins, using small glassware and benchtop systems. The goal here is all about precision and experimentation to perfect the extraction parameters, not high output.

- Pilot Scale: Think of this as the essential dress rehearsal. Pilot systems are bigger versions of the lab equipment, able to make enough product for market testing and to prove the process works at a larger volume. This stage is key for spotting unexpected problems before you spend big on industrial machinery.

- Production Scale: This is the main event. These are large, industrial systems built for high-volume output, efficiency, and automation. They often handle hundreds or thousands of kilograms of plant material every day and need their own dedicated space and infrastructure.

To help visualize how these stages differ, the table below compares equipment across various scales, highlighting capacity, cost, and best-use cases.

Extraction Equipment Comparison By Scale

| Scale | Capacity Range | Equipment Type | Investment Range | Best Applications |

|---|---|---|---|---|

| Lab (R&D) | 10g - 1kg | Glassware, Rotary Evaporators, Soxhlet Extractors, Small-scale Presses | $500 - $20,000 | Method development, proof-of-concept, formula testing, small sample creation |

| Pilot | 5kg - 100kg | Small Stainless Steel Reactors, Pilot-scale Centrifugal Extractors, Short Path Distillation | $20,000 - $250,000 | Process validation, market sample production, GMP-compliant trial runs |

| Production | 100kg - 10,000kg+ | Large Industrial Reactors, Multi-stage Centrifuges, Falling Film Evaporators, Supercritical CO₂ Systems | $250,000 - $5,000,000+ | Full-scale commercial manufacturing, high-throughput processing, automated operations |

As the table shows, the investment and complexity grow substantially at each stage. The pilot scale is the critical bridge that ensures the process is repeatable and economically viable before committing to the significant costs of full production.

Critical Factors for Evaluating Equipment

Picking the right equipment is one of the most impactful decisions a supplement manufacturer will face. It’s about much more than the initial price tag; your choice affects long-term running costs, product quality, and ultimately, your bottom line. Even if you plan to outsource this step, knowing these factors is crucial for choosing the right partner. In fact, many brands opt to work with specialized supplement contract manufacturers to handle this complex scaling process.

When looking at equipment, focus on these key elements:

- Material Compatibility: The machinery must be built from materials, like 316L stainless steel, that won’t react with your solvent or the plant itself. This is non-negotiable for ensuring the final extract is pure and safe.

- Ease of Cleaning: Systems that are a nightmare to clean are a breeding ground for problems. They can lead to cross-contamination between different product batches and encourage microbial growth, creating a major safety hazard.

- Automation Potential: Automated systems cut down on labor costs, reduce the chance of human error, and deliver better consistency from one batch to the next. This consistency is vital for meeting quality standards and customer expectations.

- Maintenance and Support: Before you buy, think about what happens when something breaks. How easy is it to get spare parts? Is technical support readily available? Equipment downtime is expensive, so reliable support is a must.

Every extraction method comes with its own scaling puzzles. Expanding a water-based decoction involves handling huge volumes of liquid and the energy needed to heat it. Scaling up a supercritical CO₂ process, on the other hand, demands specialized high-pressure vessels and complex control systems. A successful transition requires a clear strategy that matches your chosen method with the right equipment and a realistic view of your long-term production ambitions.

Choosing Your Extraction Strategy For Real-World Success

Selecting the right combination of herbal extraction methods isn’t about finding a single “best” technique. It’s more like building a strategic plan tailored to your specific product goals. The decision is a balancing act, weighing the chemistry of the plants you're working with against the practical needs of production scale, quality, and how you want to position your product in the market.

This process starts by asking a few key questions. What specific compounds are you trying to pull from the plant? How much finished product do you need to make? What are the purity and quality standards for your target audience? The answers will point you toward the most suitable technology and operational setup.

A Practical Decision-Making Framework

A winning strategy begins with a clear vision for your product. You need to define what makes it unique and valuable to your customers, which will then determine the technical requirements for producing it.

Here’s a simple framework to guide your choices:

- Define Your Target Profile: Are you trying to create a full-spectrum extract that captures the plant's complete range of compounds, or do you need to isolate a single, high-potency molecule? A full-spectrum goal often works well with a versatile solvent like ethanol. In contrast, isolating a specific compound might lead you to a highly selective method like supercritical CO₂.

- Assess Production Volume: The amount of extract you need to produce is a major factor. Small-batch or pilot-scale production for a niche product can accommodate slower, more hands-on methods like glycerin maceration. However, mass-market production requires efficient, scalable systems, such as large-scale ethanol or water extraction facilities.

- Evaluate Economic Realities: It’s important to be realistic about your budget. While supercritical CO₂ can produce incredibly pure extracts, the initial equipment investment is significant, often costing hundreds of thousands of dollars or more. A well-managed water or ethanol extraction setup can produce excellent results for a fraction of that initial cost.

- Consider Regulatory and Market Demands: Your final product has to meet all legal standards. After you've picked the best extraction method, understanding the rules for distribution, such as CBD shipping policies, is vital for getting your product to market successfully. Consumer trends, like the demand for "clean label" or "alcohol-free" products, might also guide you toward water, glycerin, or CO₂ extractions.

The image below shows a basic liquid-liquid extraction. This helps visualize the core principle of separating components between two liquids that don't mix, like oil and water.

This visual demonstrates the idea of phase separation, which is fundamental to many herbal extraction methods where a solvent selectively pulls desired compounds away from the raw plant material.

The Growing Importance of Sustainability

Today’s consumers care about more than just what’s in their products; they also care about how they are made. This shift is making sustainability a critical part of any extraction strategy. The principles of green chemistry—which aim to minimize waste, reduce energy consumption, and use non-toxic solvents—are no longer just nice-to-haves. They are key factors that can set a brand apart.

Methods that allow for excellent solvent recovery are becoming the industry norm. For example, closed-loop ethanol or CO₂ systems can recycle over 95% of the solvent used in the process. Water extraction, when managed correctly, also has a very low environmental footprint. Choosing a method with strong sustainability credentials can significantly improve your brand’s reputation and attract a wider, more conscious customer base.

Ultimately, the best strategy is one that delivers a high-quality product while aligning with your budget and the values of the modern market.

For entrepreneurs and established brands ready to turn a strategic vision into a market-ready reality, expert guidance is key. Triton Nutra Group specializes in developing and manufacturing custom liquid supplements, using advanced, temperature-controlled extraction methods to create potent, high-quality products. Contact us today to start your project.

Article created using Outrank