Your Expert Guide to Choosing a Shavegrass Private Label Contract Manufacturer

Find your Shavegrass private label contract manufacturer. This guide covers custom formulas, cGMP compliance, and scaling for your brand. Let's build together.

Get a Free Quote Today!

Get a Free Quote Today!You have an idea for a standout Shavegrass (Equisetum arvense) supplement. That's a great start, placing you at the heart of the wellness industry. But an idea, even a brilliant one, is just the beginning. Your brand's success will be built by the manufacturing partner you choose.

Think of a top-tier Shavegrass private label contract manufacturer as more than just a supplier; they are your R&D partner from concept through launch. They bring the heavy-lifting expertise needed to transform your vision into a high-quality, shelf-ready liquid supplement.

Finding The Right Manufacturing Partner

The path to launching a successful supplement brand is paved with critical decisions, but none is more important than selecting your manufacturer. This isn't just about finding someone to fill bottles. It's about building a strategic partnership with a team that has deep technical know-how and a genuine stake in your success.

A truly capable partner won't just take your order. They become your R&D lab, your quality control department, and your compliance consultants, all under one roof. That distinction is everything in an industry where product safety and efficacy are non-negotiable.

The numbers don't lie. The nutraceutical contract manufacturing market was valued at around USD 134.66 billion in 2022 and is expected to rocket forward with an 11.8% compound annual growth rate through 2031. This explosive growth is driven by consumers actively seeking natural health products like Shavegrass. This makes it absolutely essential to find a partner who can grow right alongside you.

The Foundation Of A Great Partnership

The strongest partnerships are built on shared values and proven capabilities. When you're vetting a potential manufacturer, you need to dig for tangible proof of their expertise. This means looking past the slick marketing on their website and asking pointed, specific questions about their day-to-day operations.

For instance, don't just ask if they are cGMP certified. Instead, ask them to walk you through their exact quality control process for a botanical ingredient like Shavegrass. This active questioning gives you a much clearer picture of their commitment to quality. You can get more pointers by digging into our guide on choosing the right manufacturer for your brand.

A true partner offers guidance, not just production. They should be able to advise you on everything from flavoring systems that complement the earthy taste of Shavegrass to the best preservative options to ensure maximum shelf life. This collaborative spirit separates a simple supplier from a true, long-term partner who is invested in seeing you succeed.

The right manufacturer doesn’t just fill bottles; they fill the gaps in your own expertise. They act as your quality guardian, R&D specialist, and production strategist, ensuring your product is not only compliant but also competitive from day one.

Finding the right partner is about identifying specific strengths that align with your brand's needs. The table below breaks down the core pillars of a successful manufacturing relationship, helping you understand what to look for and why it matters.

Key Pillars of a Successful Manufacturing Partnership

| Partnership Pillar | What It Means For Your Brand | Key Indicators of Quality |

|---|---|---|

| Transparent Sourcing | You can confidently stand behind your product's purity and potency. | Provides clear Certificates of Analysis (COAs) for all raw materials. |

| Flexible Production | Your business can start lean and scale up smoothly as your demand grows. | Offers flexible MOQs and clear processes for both pilot and full-scale runs. |

| In-House Expertise | You gain access to deep scientific knowledge without hiring a full R&D team. | Employs chemists and formulators who understand botanical extraction and flavoring. |

| Robust Quality Control | Your brand is protected from recalls, building unwavering customer trust. | Is a UL Certified, FDA-registered facility that rigorously follows cGMP guidelines. |

These pillars are not just nice-to-haves; they are the essential components that will support your brand's growth and reputation in the market. A manufacturer who excels in these areas is one you can build a future with.

Key Indicators Of A Quality Manufacturer

To drill down even further, here are a few non-negotiable qualities you should be looking for when you assess a potential partner:

- Transparent Sourcing: They must be able and willing to provide detailed information on their raw material suppliers. This includes providing Certificates of Analysis (COAs) for every single batch of Shavegrass extract they use. No exceptions.

- Flexible Production Runs: A great partner is one who can support you at every stage. They should offer accessible minimum order quantities (MOQs) to help you get started without a massive upfront investment, but also have the capacity to scale up production as your sales take off.

- In-House Expertise: Look for a team that has actual formulators and chemists on staff. You want people who genuinely understand the science behind botanical extraction and liquid supplement formulation. Their knowledge is your competitive advantage.

Developing Your Custom Shavegrass Formula

Bringing your Shavegrass supplement from concept to a shelf-stable liquid product is where a great manufacturing partnership truly shines. This isn't about picking from a catalog. It’s a hands-on, collaborative process. Think of a top-tier Shavegrass private label contract manufacturer as your dedicated R&D department, guiding you through every step from idea to finished formula.

The process begins with the star ingredient: the Shavegrass itself. Not all Shavegrass is created equal. We work closely with our clients to specify the exact qualities they need, from which part of the plant to use (the aerial stems pack the most minerals) to the specific silica content, which is often the main active compound. Getting this right from the start ensures your final product is potent and, just as importantly, consistent from bottle to bottle.

From Earthy Herb To Enjoyable Elixir

Let's be direct—Shavegrass has a distinct, earthy taste that can be bitter. If you just put a raw extract in a bottle, you risk a flood of bad customer reviews. This is where the science of formulation becomes essential. An experienced partner has a toolbox of flavoring systems designed to either complement or mask those natural notes.

For example, if you want a "Berry Fusion" flavor, a good formulator won't just add a generic berry flavor. They will meticulously balance sweetness and tartness to create a profile that turns taking your supplement from a chore into a pleasant ritual. This often takes a few rounds of samples until you taste it and say, "That's the one." To explore the possibilities with liquid supplements, our comprehensive guide for starting your own brand is an excellent resource.

Beyond taste, we tackle the technical details that separate a good product from a great one:

- Preservative Systems: We help you choose the right preservative—whether it's a natural option like potassium sorbate or another stabilizer—to keep your product safe and stable without affecting its quality.

- Viscosity and Appearance: Do you envision a thin, water-like liquid or something a bit thicker, like a serum? We can adjust the texture and clarity to perfectly match your brand's aesthetic and customer experience.

A winning formula is about more than just the ingredients. It’s about the entire customer experience. The right flavor, color, and mouthfeel can elevate a simple supplement into a premium product that customers come back for again and again.

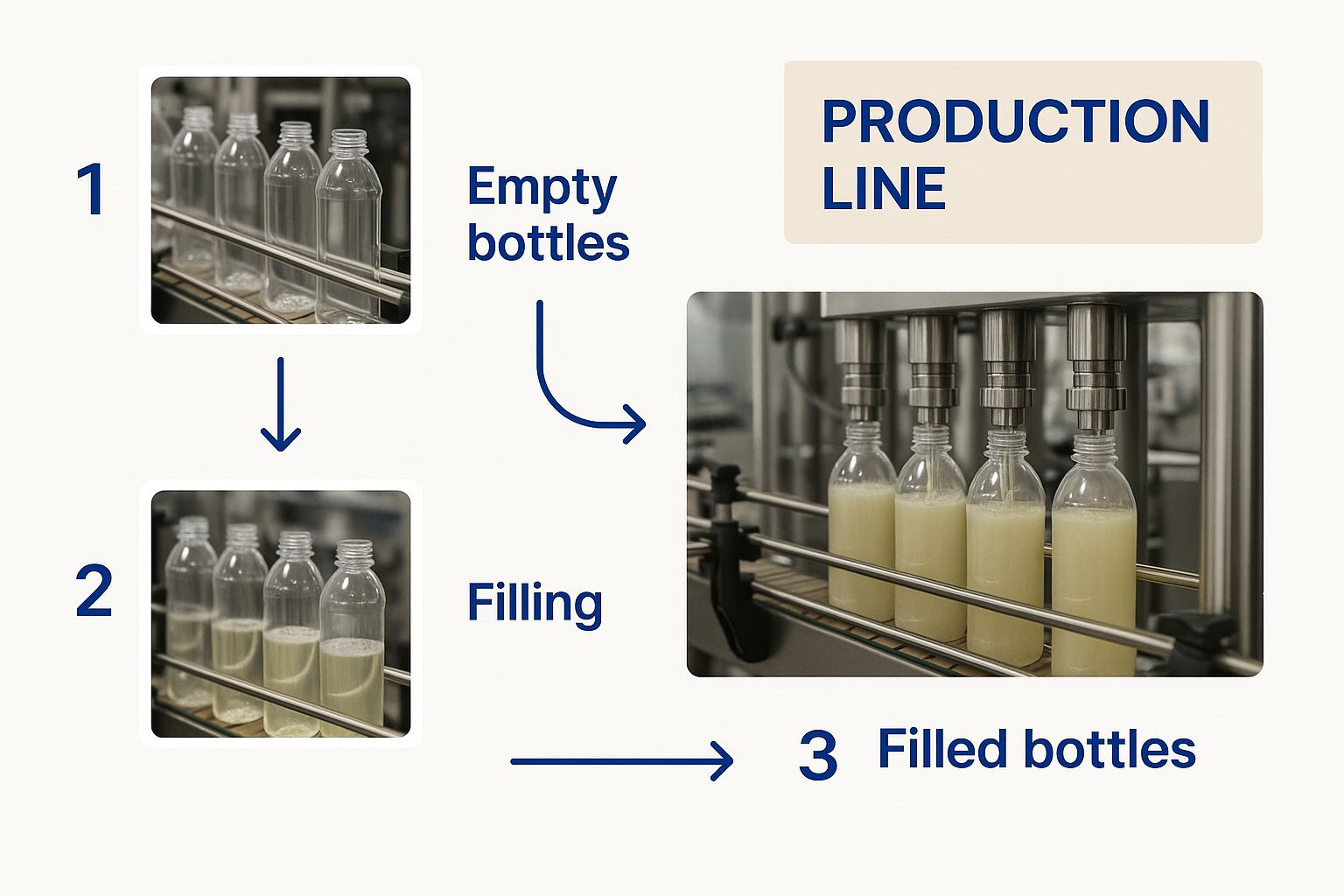

This graphic gives you a great visual of how a simple idea travels through the R&D and production pipeline to become a product ready for your customers.

It really highlights that the actual production line is just the final piece of a much larger, more intricate puzzle of development, testing, and quality control.

Creating Synergistic Blends And Perfecting The Formula

Many brands find success by creating unique blends that offer multiple benefits. With its high mineral content, Shavegrass makes an incredible base for these synergistic formulas. This is another area where having an expert formulator in your corner is a game-changer.

Let’s walk through a real-world example. Imagine a client wants to launch a "Beauty from Within" tincture, combining Shavegrass with two other powerhouse ingredients:

- Biotin: Known for supporting hair and nail health.

- Hydrolyzed Collagen: A go-to for skin elasticity.

You can't just mix these three ingredients and hope for the best. Our formulators must consider how soluble each ingredient is, any potential interactions, and the overall stability of the final blend. They might suggest a specific type of collagen that stays suspended in the liquid or adjust the pH to ensure every ingredient remains active and effective.

Before you commit to a full production run, we recommend a pilot batch. This is a small-scale run, typically 100-250 bottles, that perfectly mirrors the full-scale process. It gives you a chance to hold the final product, test it for taste and stability, and use it for marketing or stakeholder approval. It’s the ultimate way to reduce risk and ensure the product you launch is exactly what you envisioned, with no costly surprises.

Getting a Grip on Quality Control and Regulatory Compliance

In the supplement industry, your brand's reputation is built on trust. A single bad batch or regulatory misstep can tear down years of hard work. That's why quality control isn't just a box to check; it's the foundation of a durable business. When you partner with a Shavegrass private label contract manufacturer, you are placing your brand's future in their hands.

Their quality systems must be robust, transparent, and verifiable. Vague promises are not enough. You need a partner who provides hard proof of their commitment to safety and excellence at every stage. This diligence protects your customers and shields your business from significant legal and financial risk.

Decoding the Alphabet Soup of Certifications

When you enter the manufacturing world, you will encounter many acronyms. It is critical to understand what they actually mean for your product. These are not just logos for a website; they represent ongoing commitments to quality.

- cGMP (Current Good Manufacturing Practices): This is the non-negotiable industry standard. Enforced by the FDA, cGMP ensures that a manufacturer's processes and facility are properly designed, monitored, and controlled. It covers everything from raw material handling to final product release. To truly understand its impact, you can learn more about what a GMP certificate means for your supplement brand.

- FDA-Registered Facility: This confirms the manufacturer is on the FDA's radar and is subject to inspection. It is a mandatory first step for any facility making dietary supplements for the U.S. market.

- UL Certified: While cGMP is the baseline, certifications from organizations like UL signal a higher level of commitment. UL certification involves a third-party audit of a manufacturer's cGMP compliance, giving you an independent, unbiased stamp of approval on their quality systems. Think of it as an extra layer of confidence that they are exceeding minimum requirements.

A pro tip: The best manufacturing partners don't just get these certifications—they live and breathe them. Quality is part of their company culture. Ask potential partners how they maintain compliance day-to-day, not just when an inspector is scheduled.

The Make-or-Break Role of Third-Party Testing

Certifications tell you about the facility, but testing tells you about your actual product. Never rely solely on a manufacturer's in-house tests. Independent, third-party lab testing is the only way to get an unbiased look at what's really inside the bottle.

For a Shavegrass supplement, this testing needs to focus on three key areas.

First is Identity. This test confirms that the botanical ingredient is authentic Equisetum arvense (Shavegrass) and not a cheaper look-alike or a related but incorrect plant.

Second, you must verify Potency. This confirms that the active compounds are present at the levels you claim on your label. For Shavegrass, that often means checking the silica content to ensure your customers get the benefit you promise.

Finally, and most critically, is Purity. This is your safety check. A purity panel screens for contaminants that could harm your customers, including:

- Heavy metals (like lead, arsenic, and mercury)

- Microbes (like E. coli and salmonella)

- Pesticides and other chemical residues

Any reputable manufacturer will provide a Certificate of Analysis (COA) for every single batch, which details the results of these third-party tests. This document is your proof that the product is safe, pure, and potent. Do not be shy about asking for it and reviewing it closely. It’s your final checkpoint before that product gets to your customer.

A Look Inside The Modern Production Process

This is where your vision becomes reality. After meticulous formula development and compliance checks, your product is ready for the production line. It’s the moment your detailed recipe becomes a physical product your customers can hold.

For any brand owner, a look behind the curtain at a Shavegrass private label contract manufacturer is eye-opening. It demystifies the process and shows why a partner with a dialed-in operation is essential. The journey from raw botanicals to finished goods is a precise dance of technology, timing, and an obsessive focus on quality.

Preserving Potency From The Very Start

With a delicate botanical like Shavegrass, processing methods make all the difference. Traditional heat pasteurization is effective for sterilization but can destroy the very bioactive compounds you're paying for.

This is where a forward-thinking manufacturer sets themselves apart. We use advanced cold-fill technology, a method that bypasses high heat entirely. By handling your liquid supplement in a chilled, controlled environment, we protect the fragile silica and other key minerals in the Shavegrass extract. The result? Your final product has the full potency you designed, delivering maximum value to your customers.

This dedication to quality starts the moment a new batch is created. Everything is dictated by a master manufacturing record (MMR)—the single source of truth for your product.

- Precision Batching: Trained technicians weigh every single ingredient, from the Shavegrass extract to the last drop of flavoring, to exact specifications.

- Controlled Mixing: These ingredients are then blended in massive, stainless-steel tanks under tightly controlled conditions to create a perfectly uniform liquid.

- Homogenization: Next, the liquid is put through a homogenizer. This machine breaks down particles to ensure a smooth, stable suspension. It’s a critical step that prevents ingredients from settling at the bottom, guaranteeing that every drop of the product is identical.

A modern production process is built on one core principle: consistency. Bottle number 10,000 must be chemically and aesthetically identical to bottle number one. That kind of consistency is the direct result of rigorous process controls and state-of-the-art equipment.

The Final Steps to a Market-Ready Product

Once the bulk liquid is prepared and passes quality checks, the final sprint begins. This stage is a highly automated but closely watched sequence that turns the liquid into your branded product.

First, sterile bottles glide down a conveyor line, where they are filled with the perfect volume of your Shavegrass formula. They’re immediately capped and sealed, locking in freshness and preventing any contamination. Even a tiny deviation here could compromise a whole batch, which is why a partner’s investment in reliable, calibrated machinery is non-negotiable.

From there, the bottles head to labeling. Your carefully designed, FDA-compliant labels are applied flawlessly, giving the product its professional, retail-ready look. Finally, each unit gets a batch code and expiration date for full traceability before being packed into cases, ready for shipment.

Relying on specialized contract manufacturers isn't just for startups; it's a common strategy among the industry's biggest names. For instance, some of the leading private label companies lean heavily on third-party partners, with their primary manufacturer handling nearly 47% of their total output. This is a massive vote of confidence in the value of specialized expertise for managing production and meeting market demand—a trend you can read more about in these corporate filings and manufacturing insights.

The Unseen Advantage: Speed And Reliability

In the world of e-commerce, few things are as painful as a stockout or a blown launch date. This is where your manufacturer's operational excellence becomes your greatest competitive advantage. Speed and reliability aren't just about how fast a machine can fill bottles; they are the outcome of a masterfully managed supply chain.

A top-tier partner handles the procurement of every component—bottles, caps, droppers, labels, and boxes—so you don’t have to. They have deep relationships with multiple vetted suppliers, which minimizes the risk of a delay from a single source.

This allows them to give you a clear, realistic production timeline from day one and, more importantly, stick to it. On-time delivery isn't a "nice-to-have"; it's a core function of a dependable manufacturing partner. It’s what gives you the confidence to manage your inventory and plan your marketing campaigns without constantly looking over your shoulder.

Building A Standout Brand Beyond The Bottle

The liquid formula inside the bottle is the heart of your product, but the bottle itself is what your customer sees first. In a crowded market, your packaging and branding are what grab their attention, build trust, and drive that critical first sale.

A true Shavegrass private label contract manufacturer understands this. They are more than just a formulator; they are a partner in this final, crucial stage. Their design-for-manufacturing expertise is an invaluable resource, ensuring your branding vision is both possible to create and commercially viable. This collaboration delivers a polished, retail-ready product that is poised to stand out.

Strategic Packaging Choices For Your Shavegrass Supplement

The container you choose is more than a vessel; it is a direct statement about your brand's quality and values. A great manufacturing partner will walk you through the pros and cons of different options, ensuring your choice aligns with your product’s formula, target audience, and price point.

Think about the material itself. Glass often signals a premium, eco-conscious brand. Modern BPA-free plastics, on the other hand, offer durability and can significantly lower shipping costs. Color is another strategic decision. Amber or cobalt blue glass provides excellent UV protection, which is essential for preserving the sensitive compounds in your Shavegrass extract. Clear glass, however, lets you showcase a vibrant or uniquely colored liquid.

Beyond the bottle, the dispenser mechanism directly shapes the user experience.

- Graduated Droppers: Perfect for tinctures, these offer precise dosing that reinforces a sense of efficacy and control for the consumer.

- Pumps: Ideal for thicker, serum-like formulas, pumps provide a clean, consistent amount with each use. No mess, no fuss.

- Sprayers: A great choice for products designed for convenience or topical application, offering a fine, even mist.

Your manufacturing partner can source all these components for you, guaranteeing they fit and function correctly. This is how you avoid the nightmare of leaky caps or pumps that clog on the second use.

The most effective packaging is a seamless extension of the product itself. It should be intuitive, functional, and visually aligned with the promise your brand makes. A minor detail like a poorly designed dropper can sour the entire user experience.

Ensuring Your Label Is Both Beautiful And Compliant

Your label is your single most powerful marketing tool on the shelf, but it's also a legal document. While you and your designer focus on creating an eye-catching aesthetic, your manufacturer plays the vital role of compliance gatekeeper. They will review your final artwork to ensure it meets all strict FDA labeling requirements.

This review isn't just a friendly suggestion; it's a critical step that protects your business. Their quality team will scrutinize the supplement facts panel, confirm the net contents statement is accurate, and check for correct allergen declarations. This partnership ensures your beautiful design is also legally sound, preventing costly reprints or regulatory headaches down the line.

The private label market is booming. Consumers are increasingly turning to store brands they trust, and the numbers back it up. Recent data shows the unit market share for private labels has hit a record 22.9%, with dollar share reaching 20.4% of all retail sales. This surge highlights the massive opportunity for brands that present a professional, high-quality image right from the start.

Once your Shavegrass product is developed and manufactured, the next challenge is building a compelling brand and reaching your audience. For an excellent guide on this next phase, check out this article on Building a Powerful Ecommerce Digital Marketing Strategy.

Finally, a full-service partner can manage the entire final assembly process. This includes sourcing all packaging components, applying your labels with precision machinery, and even creating custom kits or multi-packs. This turnkey approach transforms your approved formula into a finished good, ready to be shipped directly to your warehouse, Amazon FBA, or a third-party logistics provider. It’s the final piece of the puzzle, delivering a product that looks just as good as the formula inside.

Answering Your Top Private Label Manufacturing Questions

Stepping into the world of private label supplements can feel like a big move, full of unknowns. You likely have a list of very practical, real-world questions that need straight answers. You need these details to budget properly, plan your launch, and understand your responsibilities.

Let's cut through the noise. Here are the most common questions we get from brands looking to create a Shavegrass private label supplement, answered with direct, actionable advice.

What’s a Realistic Minimum Order Quantity (MOQ)?

This is usually the first question on everyone's mind. The Minimum Order Quantity (MOQ) dictates your upfront investment and initial inventory. The answer depends on the complexity of your Shavegrass formula.

If you’re starting with a manufacturer's existing stock formula and making a minor tweak, like changing the flavor, you can often begin with a smaller run of 500 to 1,000 units. This is a great way to enter the market without a massive financial commitment.

However, if you're building a unique, custom formula from the ground up, the requirements change. Sourcing special ingredients and dedicating R&D time means the manufacturer needs a larger commitment. For these bespoke projects, expect MOQs to start around 2,500 to 5,000 units.

A pro tip: Ask a potential partner if they offer pilot runs. A small-batch run of 100–250 units is an incredible tool. It lets you test your concept in the real world, get customer feedback, and fine-tune everything before committing to a full production order. It's a smart way to de-risk your launch.

When discussing MOQs, always get clarity on whether it's a per-order minimum or tied to an annual commitment. Also ask for tiered pricing; a good partner will show you exactly how your per-unit cost drops as your order volume increases.

How Long Does This Whole Process Actually Take?

"When can I have my product?" is always a top concern. A realistic timeline is essential for planning your marketing, sales, and launch strategy. From signing off on a quote to the day finished bottles arrive at your warehouse, you should budget for 12 to 20 weeks for a custom liquid supplement.

Here’s a rough breakdown of that timeline:

- Formula & Quoting (3–6 weeks): This is the creative stage. We finalize your Shavegrass formula, make and approve samples, and lock in the final numbers.

- Sourcing Raw Materials & Packaging (4–8 weeks): This is often the longest phase. Your manufacturer orders every component—from the raw Shavegrass to the bottles, caps, and labels. Standard items are quicker, but custom packaging can extend this phase.

- Production & Testing (2–4 weeks): Once all materials are on-site and have passed quality control, production begins. This includes manufacturing, bottling, and third-party testing of your finished product.

- Shipping & Logistics (1–2 weeks): The final leg of the journey. Your product is carefully packed and shipped to your fulfillment center or warehouse.

A reliable manufacturer will provide a detailed project timeline with key milestones. You should never have to wonder about the status of your project.

Who’s on the Hook for FDA Label Compliance?

This is a critical point with no room for ambiguity. While your manufacturer is a vital partner, the ultimate legal responsibility for every word, number, and claim on your product’s label falls squarely on you, the brand owner.

However, a top-tier manufacturer won’t leave you to figure it out alone. They play a collaborative role. Here’s how it should work:

- You supply your finished label design.

- The manufacturer’s quality team performs a mandatory FDA compliance review.

- They will meticulously check your supplement facts panel, net contents statement, and all necessary allergen warnings.

- Most importantly, they will flag any marketing claims that could be considered disease claims, which are prohibited. This review is designed to protect you from costly regulatory trouble.

This partnership ensures your label is not only beautiful but also compliant before it ever goes to print.

Can I Just Supply My Own Shavegrass Ingredient?

It's a logical question. You might think supplying your own key ingredient is a smart way to control costs or use a specific source. In reality, reputable, cGMP-certified manufacturers almost always advise against it. It all boils down to one critical principle: maintaining an unbroken chain of custody.

A cGMP facility has an ironclad system for vetting suppliers and has complete documentation for every gram of material that enters their building. The moment you introduce an outside ingredient, you break that validated system. Your manufacturer would have to quarantine your Shavegrass, pay for extensive third-party testing to confirm its identity, purity, and potency, and then assume all liability for its quality.

This process adds so much time and expense that it almost always negates any potential savings. It is far more efficient and safe to leverage your manufacturer's trusted and thoroughly vetted supply chain.

Finding the right manufacturing partner takes the guesswork out of launching a supplement and gives you a clear, proven path from concept to market-ready product. At Triton Nutra Group, we act as your dedicated R&D and production partner, guiding you through every step. If you’re ready to bring your Shavegrass supplement vision to life, request a free quote today and let our expertise help your brand succeed.