Partnering with a Pumpkin Seeds Private Label Contract Manufacturer: A Brand Builder's Guide

Partner with a trusted Pumpkin Seeds private label contract manufacturer to create premium products. Discover quality and reliability now!

Get a Free Quote Today!

Get a Free Quote Today!You have a killer idea for a pumpkin seed product, but turning that vision into a shelf-ready item feels like a huge mountain to climb. The secret isn't just finding a supplier; it's about finding a true partner. For ambitious e-commerce founders and health brand managers, working with a top-notch pumpkin seeds private label contract manufacturer is the fastest, most effective way to launch. It gives you an instant leg up with industry certifications, production expertise, and a dramatically shorter path to market.

Launching Your Brand The Smart Way

Maybe you're dreaming up a unique seasoned pumpkin seed snack, a high-protein powder, or even a specialty liquid extract. The journey from that concept to a customer holding your product is paved with hurdles: sourcing raw ingredients, nailing the formulation, managing production runs, navigating compliance, and handling logistics. Trying to build that infrastructure from scratch costs a fortune and takes years—time and capital most new brands just don’t have.

This is precisely why partnering with a private label contract manufacturer is a game-changer. Forget spending months (and millions) building a factory. You get immediate access to a professional, FDA-registered facility that already meets cGMP standards from day one.

The Power of Partnership Over Production

Think of your manufacturer as your outsourced R&D team and operations department rolled into one. Their value goes way beyond simply mixing ingredients and bagging them. A true partner works with you on every detail, whether it’s perfecting a custom seasoning blend or choosing the right pouch material to keep your product fresh and make it pop on a digital shelf.

This collaborative approach gives growing brands a serious competitive edge.

- Speed & Reliability: You skip the painfully slow process of building a facility, buying equipment, and securing regulatory approvals. This means you can go from idea to launch in a fraction of the time, with transparent timelines and a partner committed to on-time delivery.

- Lower Risk & Cost: You avoid the massive upfront capital investment for manufacturing infrastructure. That frees up cash to pour into what actually grows your business: branding, marketing, and customer acquisition.

- Built-in Expertise: You instantly gain a team of food scientists, quality control pros, and regulatory experts. We become your R&D partner from concept through launch, ensuring your product is safe, compliant, and ready for retail.

When you align with an expert manufacturer, you're essentially leveraging their entire operational playbook. It lets you compete with established players right out of the gate, backed by proven quality and reliability, but without the crippling startup costs. Your brand’s reputation is built on their solid foundation.

Of course, launching the smart way also means having your marketing dialed in. Once your product is ready to go, getting a free ad account audit can be a great way to ensure your advertising dollars are working as hard as possible from the start.

This guide will walk you through the entire process, step by step, to help you make the right choices and hit your goals.

Vetting a Manufacturer for Quality and Compliance

The success of your brand rests squarely on the quality and safety of your product. One recall or compliance issue can wipe out years of hard work. This is why vetting a potential pumpkin seeds private label contract manufacturer isn't just a box to check—it’s the single most important decision you'll make. You're not just buying a service; you're safeguarding your investment and protecting your customers.

A true partner doesn't just talk about quality. They prove it with tangible certifications and transparent processes. Your job is to know what to look for and what questions to ask. When you get on that first discovery call, it's time to dig deep into their operations.

Decoding Key Certifications

You'll see a lot of acronyms on a manufacturer's website. They aren't just for show. Each one represents a serious commitment to specific standards, and understanding them is your first line of defense.

These are the absolute must-haves:

- cGMP (Current Good Manufacturing Practice): This is the gold standard, enforced by the FDA. cGMP certification is an all-encompassing system governing everything from staff training and facility cleanliness to equipment verification and meticulous record-keeping. Its entire purpose is to prevent contamination, mix-ups, and errors.

- FDA-Registered Facility: This is the bare minimum for any US-based operation. It means the facility is known to the FDA and is subject to their inspections. If a manufacturer isn't registered, that's a major red flag.

- UL Certified: While many associate UL with electronics, they also provide rigorous safety and quality audits for food and supplement facilities. A UL certification demonstrates an extra layer of commitment to safety protocols that often go above and beyond basic requirements.

When a manufacturer proudly displays these credentials, it’s a strong signal they’ve invested serious capital into their infrastructure and processes. It tells you they take quality and compliance as seriously as you do.

Finding a manufacturer who meets these standards is essential. For more guidance on what to look for, our guide on finding a reputable supplement manufacturer offers key considerations for your business.

The Critical Role of Third-Party Testing

In-house quality control is important, but independent verification provides true peace of mind. Third-party testing is where product samples are sent to an unaffiliated, accredited laboratory for a full analysis. This unbiased review confirms that what’s on the label is actually inside the package.

At a minimum, this testing must screen for:

- Potency and Purity: Verifies the active ingredients are at the levels specified and that the product is free from cheap fillers or undeclared substances.

- Microbiological Contaminants: Checks for harmful bacteria, yeast, and mold to ensure the product is safe for consumption.

- Heavy Metals: Screens for lead, arsenic, mercury, and cadmium. These can accumulate in botanicals like pumpkins, depending on the soil and environment where they're grown.

Always ask a potential partner for a recent Certificate of Analysis (CoA). This is the lab report detailing what they tested for and the results. If they hesitate to provide one, consider it a deal-breaker.

Scrutinizing Raw Material Sourcing

The quality of your finished product can only be as good as your raw ingredients. Any top-tier manufacturer will have a rock-solid supplier verification program and be able to trace their ingredients from farm to facility. You need to know where their seeds are coming from.

Global market dynamics are a big deal here. China, for instance, is the dominant player, producing about 70% of the world's pumpkin seeds and recently shipping over 160,000 tons in a single year. On the other hand, European growers in places like Austria are famous for high-quality GWS (Grown Without Shell) seeds, even if their output is much smaller. A manufacturer worth their salt will understand the nuances of these different sources, from quality variations to potential supply chain headaches.

As you move toward a formal partnership, applying strong contract formation principles is crucial for protecting your interests. This legal framework ensures all the quality and sourcing standards you discussed are clearly defined and contractually binding.

Bringing Your Custom Product Vision to Life

Let's be honest: your product’s unique formulation is what will make it stand out in a crowded market. Simply launching "another" pumpkin seed product won't cut it. The real magic happens when your manufacturing partner acts less like an order-taker and more like your personal R&D team.

You need a collaborator who is excited to explore creative possibilities beyond just roasting and salting seeds. The right pumpkin seeds private label contract manufacturer will get in the trenches with you, helping to transform a basic idea into a memorable product that customers seek out again and again.

Moving Beyond the Basics of Formulation

This is where your brand's personality starts to shine. The product development stage is a creative playground to experiment with different formats, flavors, and ingredients to carve out your unique selling proposition. Push your potential partner to show you what they're capable of.

A truly skilled manufacturer should have the equipment, botanical extraction advances, and expertise to help you create a diverse product line.

- Seasoned Snack Blends: Think far beyond sea salt. What about a smoky chili lime, a sweet cinnamon spice, or a savory everything bagel seasoning? The goal is to land on a flavor profile that becomes your signature.

- High-Protein Powders: Pumpkin seeds are a powerhouse of plant-based protein. A great partner can mill them into a fine powder and create custom blends with other trending ingredients like adaptogens or probiotics for a premium wellness product.

- Pumpkin Seed Oil Softgels: This format is perfect for the supplement aisle, delivering a concentrated dose of omega fatty acids. We use innovative technologies like cold-fill to preserve the delicate nutrients during the highly technical encapsulation process.

The formulation stage is a true collaboration. You bring the vision for your brand; your manufacturer brings the technical expertise to make it a reality. Together, you should be able to create something that’s not just sellable, but remarkable.

Diving deeper into the specifics of formulation is a smart move. For a more detailed look, check out our guide on how to create a supplement formula to get a head start.

The customization possibilities are vast. From the base ingredient to the final packaging, every choice helps define your product's place in the market.

Pumpkin Seed Product Customization Options

| Customization Area | Example Options | Key Considerations for Your Brand |

|---|---|---|

| Product Format | Whole Seeds, Powder, Oil, Softgels, Seed Butter | Who is your target customer? A gym-goer might want powder, while a snacker wants whole seeds. |

| Flavor Profile | Sweet (Cinnamon, Maple), Savory (Chili, Garlic), Unflavored | Does the flavor align with your brand's identity (e.g., "all-natural" vs. "bold & spicy")? |

| Texture | Roasted & Crunchy, Raw & Chewy, Finely Milled Powder | Texture is a huge part of the user experience. A crunchy snack is very different from a smooth butter. |

| Functional Add-Ins | Probiotics, Adaptogens (Ashwagandha), Antioxidants (Cacao) | Adding functional ingredients can create a new product category and justify a premium price. |

| Packaging | Stand-up Pouches, Jars, Tubs, Single-Serve Packets | Is your packaging designed for pantry storage, on-the-go convenience, or bulk use? |

Making thoughtful decisions in each of these areas is what separates a generic product from one that builds a loyal following.

Mastering Flavor, Texture, and Ingredients

It’s the small details that elevate a product from good to great. Flavor and texture aren't afterthoughts; they are central to the customer experience. A skilled food scientist on your partner's team is invaluable in helping you strike the perfect balance.

For example, are you after a super crunchy, roasted texture or a softer, more natural feel? Do you want to use natural sweeteners like monk fruit, or stick to savory spices? These choices define how customers perceive your product and who it appeals to.

This is also your chance to get innovative with ingredients to create a unique value proposition. Think about adding turmeric for its anti-inflammatory properties or cacao nibs for an antioxidant boost. These additions can transform a simple snack into a functional food that commands a higher price.

The timing couldn't be better. The global pumpkin seed protein market, valued at around USD 1.4 billion, is expected to hit USD 2.2 billion within the next decade. As detailed by market research from Future Market Insights, this growth is fueled by consumer demand for clean-label, allergen-free ingredients—a perfect sweet spot for private label brands.

Understanding MOQs for a Smart Market Entry

For many new brands, one of the scariest acronyms is MOQ, or Minimum Order Quantity. This is the smallest order a manufacturer will agree to produce. High MOQs can be a massive barrier, forcing you to invest tens of thousands of dollars before making your first sale.

This is why finding a partner with customization and flexibility in their run sizes is so important. A manufacturer who thinks long-term understands you need to test the waters and will offer different production tiers.

- Pilot Runs: These are small-batch runs, sometimes just a few hundred or a couple of thousand units. They're perfect for testing your product with a small audience, gathering real-world feedback, and validating your idea without betting the farm.

- Full-Scale Production: Once you have proof of concept and are ready for a full launch, you can move to larger runs. These bigger orders almost always come with a lower per-unit cost, which directly improves your profit margins as you grow.

A partner offering flexible run sizes from pilot to full scale shows they're invested in your success, not just in landing the biggest possible first order. This approach allows you to grow your brand intelligently, making decisions based on data instead of guesswork.

Your Packaging Is Your First Sales Pitch

Think of your packaging as the silent salesperson on the front lines. It's the first thing a customer sees, whether they're scrolling online or walking down a store aisle. For a product like pumpkin seeds, where what's inside can look similar from brand to brand, your packaging is your secret weapon. It has to do the heavy lifting—communicating your brand's story, hinting at the quality inside, and ultimately, convincing someone to give you a try.

A great pumpkin seeds private label contract manufacturer gets this. They know their role isn't just about filling bags. It's about giving you access to packaging that works on every level: it looks amazing, keeps the product fresh, and meets all legal requirements. Tapping into their expertise and supplier network can save you from a world of logistical headaches.

Finding the Perfect Packaging Format

The container you choose affects everything—shelf life, shipping costs, and even how your customer feels when they use your product. There's no single "best" option; it's all about what makes sense for your brand and who you're selling to.

-

Stand-Up Pouches: You see these everywhere for a reason. They're light, which helps keep shipping costs down, and they provide a large canvas for your branding. We recommend options with a resealable zipper for freshness and high-barrier films to lock out moisture and air.

-

Glass or PET Jars: Jars have a premium feel. They signal quality and are fantastic for protecting the product. The downside? They're heavier and more fragile, which means higher shipping costs. But if you’re targeting a gourmet foodie audience, the high-end feel can be worth it.

-

Single-Serve Packets: Perfect for today’s on-the-go lifestyle. These are a home run for subscription boxes, sample giveaways, or grabbing a quick, healthy snack. The cost per unit is higher, but they are an incredible tool for getting people to try your product for the first time.

You'll want to have a real conversation with your manufacturer about these choices. They should be able to show you samples and help you decide what works best for your specific product, whether you're selling roasted seeds, a fine powder, or even softgels.

Getting the Brand and Label Design Just Right

Once you’ve locked in the format, it’s all about what goes on the outside. This is your chance to make a real connection with your customer. A true manufacturing partner won't just source the bags; they might have in-house designers or refer you to someone who truly knows the food and supplement industry.

The material finish can completely change the vibe of your product:

- Matte Finish: This gives off a modern, natural, earthy feel. It doesn't reflect light, which can make it easier to read in a brightly lit store.

- Gloss Finish: If you want colors that pop and a look that screams for attention, gloss is your go-to. It's vibrant and eye-catching.

But design isn't just about looking good. Your label must be 100% compliant with FDA regulations. This is not a place to cut corners. A seasoned manufacturer’s guidance here is worth its weight in gold. They'll make sure your label has all the required elements, formatted correctly:

- Statement of Identity: What the product is.

- Net Quantity of Contents: How much is in the package.

- Nutrition Facts Panel: Using the latest FDA format.

- Ingredient List and Allergen Declaration: In the correct order.

- Name and Place of Business: Of the manufacturer or distributor.

Navigating FDA labeling rules is a minefield for new brands. One small mistake can trigger a recall, which is both expensive and damaging to your reputation. Leaning on your manufacturer's compliance expertise is one of the smartest things you can do to reduce risk and ensure you’re ready for market from day one.

Managing Logistics for a Seamless Product Launch

You can have the most incredible product and sharpest packaging, but it all means nothing if it isn't produced correctly and delivered on time. A bungled logistics plan can torpedo a product launch, causing stockouts, wasting marketing dollars, and leaving you with angry customers. This is where a top-notch pumpkin seeds private label contract manufacturer proves their worth—by turning your vision into a real product that shows up exactly when and where you need it.

Think of a solid supply chain as the engine of your business. A true partner lays out a clear, realistic project timeline the moment you sign on, taking the mystery out of the process so you’re never left wondering what’s next. This is a core part of our commitment to speed and reliability.

Mapping the Journey From Quote to Delivery

That production timeline is your roadmap. It details every milestone, from initial approvals to the final shipment rolling out of the warehouse. While every project has its own quirks, you can expect a few key phases that will need your sign-off to keep things moving. A great partner will be in constant contact, ensuring you’re never caught off guard.

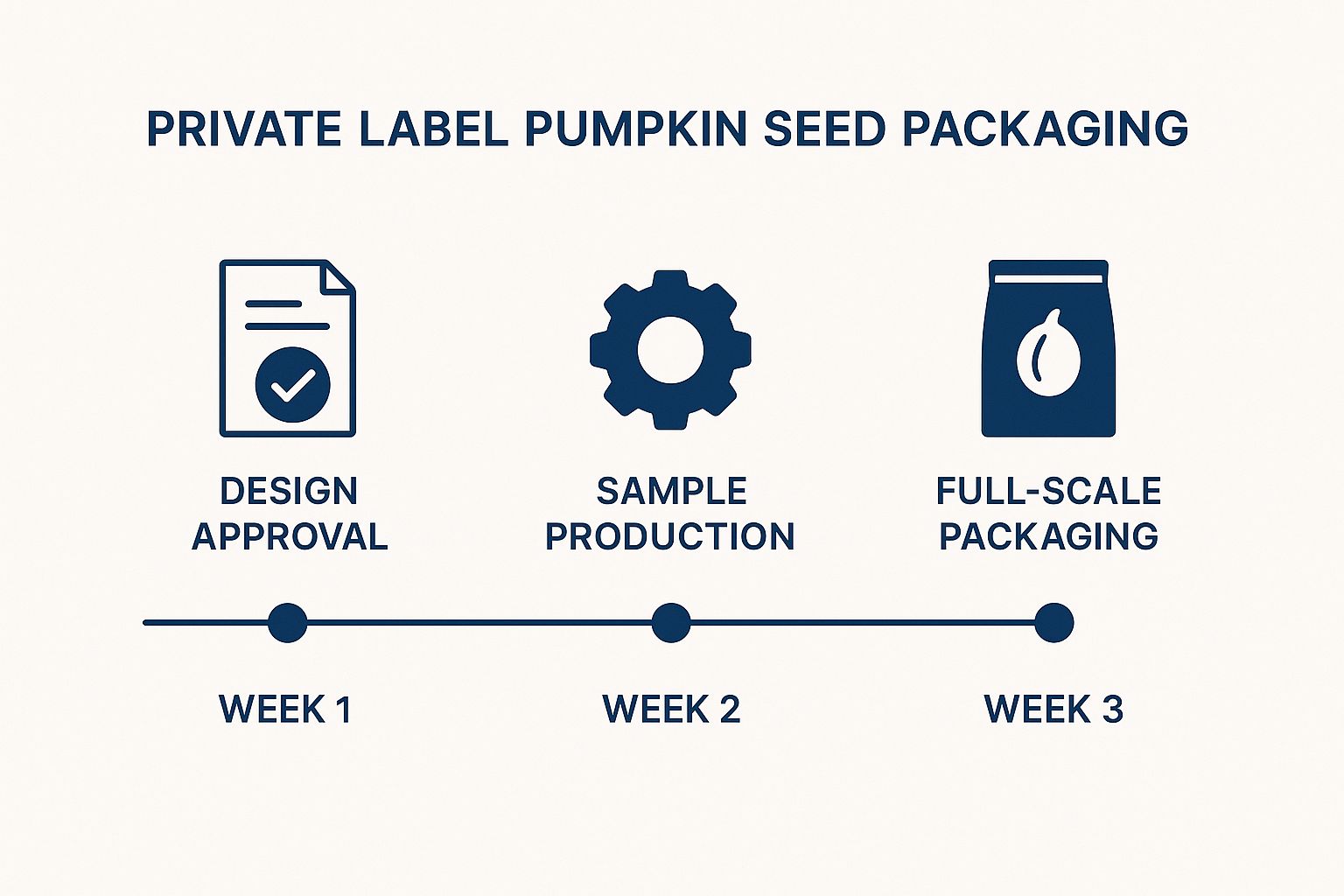

Here’s what those key milestones usually look like:

- Sample Approval: Once the formula is locked in, you’ll get a production-quality sample. This is your final chance to approve the taste, texture, and look before committing to a full production run.

- Sourcing Materials: As soon as you give the green light, your partner starts ordering all raw ingredients and packaging. Lead times on custom-printed pouches or jars can often be the longest part of this stage.

- Production Scheduling: Your project gets its official spot on the manufacturing calendar. A reliable manufacturer will give you a firm production window and stick to it.

- Final Quality Checks: After your product is made, it goes through one last round of rigorous quality assurance and third-party testing to ensure it meets every specification.

It’s important to understand the market pressures at play. The global pumpkin seed market is massive, recently valued at around USD 956.7 million and projected to grow at an explosive 13.4% annually. This boom, largely fueled by production in places like China and India, puts a huge strain on supply chains. This is why you need a manufacturer with strong, established sourcing relationships who can navigate the demand and lock down high-quality ingredients for your product. You can explore the full pumpkin seed market analysis to get a better handle on these global trends.

To give you a clearer picture, here is what a typical timeline might look like from start to finish.

Sample Private Label Project Timeline

This table outlines the estimated phases and durations for getting a private label pumpkin seed product off the ground.

| Phase | Typical Duration | Key Activities and Decisions |

|---|---|---|

| Concept & Formulation | 2–4 Weeks | Finalizing your product formula, selecting ingredients, and defining packaging specifications. |

| Quoting & Agreement | 1 Week | Receiving and approving the final project quote and signing the manufacturing agreement. |

| Sample Approval | 1–2 Weeks | Reviewing and providing feedback on the initial production sample. Your approval is critical here. |

| Material Sourcing | 4–8 Weeks | Ordering all raw ingredients and custom packaging. This is often the longest lead-time phase. |

| Production Run | 1–2 Weeks | The manufacturer produces and packages your full order according to the approved specifications. |

| QA & Testing | 1 Week | Final quality assurance checks and any required third-party lab testing are completed. |

| Shipping & Delivery | 1 Week | The finished product is shipped from the facility to your designated warehouse, 3PL, or Amazon FBA. |

Keep in mind that these are just estimates. A good manufacturing partner will provide a custom timeline tailored to your specific project.

The Power of Transparent Communication

Clear, consistent communication is the glue that holds this whole process together. You should never have to chase someone down for an update. A first-rate manufacturer will give you regular status reports, warn you about potential hiccups, and work with you to find solutions before they become crises.

This visual gives you a simplified look at the packaging phase, which is a make-or-break part of any launch.

As you can see, the stages—from design sign-off to full-scale production—are sequential. Making timely decisions is absolutely essential to keeping things moving forward.

Your manufacturer isn't just a supplier; they are your operational partner. Their ability to deliver on time, every time, reflects their process integrity and respect for your business. This reliability is what allows you to manage your inventory with confidence and scale without fear.

If you really want to get into the weeds of logistics, I highly recommend reading our guide on supply chain management best practices.

Navigating Fulfillment and Final Delivery

The last piece of the puzzle is getting your product from the manufacturing facility to your customers. Your partner needs to be flexible enough to work with your fulfillment strategy, whether you're shipping from your own warehouse or working with major retailers.

Here are the most common options:

- Ship to Your Warehouse: If you handle your own fulfillment, your manufacturer can arrange for freight to be sent directly to you.

- Deliver to Amazon FBA: This is a go-to for e-commerce brands. An experienced partner will already know Amazon’s strict rules for packaging and labeling, ensuring your inventory gets checked in smoothly.

- Send to a 3PL: Outsourcing warehousing and shipping to a third-party logistics (3PL) provider is a smart move for scaling brands. Your manufacturer should have no problem coordinating directly with your 3PL for a seamless handoff.

Common Questions About Private Labeling Pumpkin Seeds

Jumping into a partnership with a pumpkin seeds private label contract manufacturer is a big step, so it's natural to have questions. Getting straight answers from the start demystifies the process and lets you move forward with confidence.

Over the years, we've heard the same key questions from entrepreneurs and brand managers. Knowing the answers ahead of time means you can have more productive conversations, budget accurately, and turn unknowns into a clear, actionable plan.

What Is a Typical Minimum Order Quantity (MOQ)?

This is almost always the first thing people ask, and for good reason—it directly impacts your startup costs. Minimum Order Quantities, or MOQs, can vary dramatically depending on your product's complexity.

For a simple roasted and salted pumpkin seed product using stock packaging, you might see MOQs as low as 1,000 to 2,500 units. It’s a great way to enter the market.

However, for a custom formula with unique seasonings, functional ingredients, or specialized printed packaging, that number will climb. For more complex projects, you're realistically looking at 5,000 to 10,000 units. This is because the manufacturer has to buy raw materials in bulk and justify setting up a production line for your specific product.

A good manufacturer understands that you need to test the market first. Always ask if they offer smaller pilot runs. This lets you produce a limited batch to validate your concept before committing to a major investment. Our flexible run sizes are designed for this exact purpose.

How Long Does the Private Label Process Take from Start to Finish?

A realistic timeline to launch a new private label pumpkin seed product is between 12 and 20 weeks. This period is a series of interconnected phases, and a delay in one can easily push back your launch date. Our rapid turnaround times are built on a foundation of clear communication and efficient processes.

Here’s what that timeline generally looks like:

- Formulation & Quoting (2–4 weeks): Nailing down your product idea and getting a detailed cost breakdown.

- Sample Development (3–5 weeks): Your manufacturer creates a physical sample for you to approve that matches your vision perfectly.

- Packaging Design & Sourcing (4–8 weeks): This is often the longest part of the process, especially for custom-printed bags or pouches.

- Production & Quality Control (3–6 weeks): The actual manufacturing run, followed by final testing before the product is released.

The two biggest variables are lead times for custom packaging and formula complexity. A transparent partner will provide a detailed project timeline from the start so there are no surprises.

Can I Supply My Own Ingredients or Packaging?

This question gets to the heart of supply chain control. The short answer is: it depends entirely on the manufacturer’s quality systems. While some partners are flexible, those with strict cGMP protocols insist on managing the entire supply chain to guarantee full traceability and compliance.

If you want to provide your own pumpkin seeds, for instance, the manufacturer will require a Certificate of Analysis (CoA) for them and will likely run their own internal tests to verify identity and purity. If you’re bringing your own packaging, it must be compatible with their machinery. It’s crucial to get their policy on this nailed down in your first conversation.

Think of it from their perspective: their reputation and certifications are on the line with every product that leaves their facility. Controlling the supply chain is the best way for them to guarantee the quality and safety that you—and your customers—are counting on.

What Kind of Quality Control and Testing Is Performed?

Any manufacturer worth partnering with will have a multi-stage quality process that is non-negotiable. It’s not a one-time check; it's a continuous system of checks and balances from start to finish.

This process should always involve these three key stages:

- Raw Material Inspection: As soon as ingredients arrive, they are tested for identity, purity, and to ensure they meet all specifications.

- In-Process Checks: While your product is being made, technicians constantly monitor variables like temperature, mixing times, and fill weights to ensure consistency across every unit.

- Final Product Testing: The finished goods are then sent to an independent, third-party lab for a full analysis. This is where they screen for microbiological contaminants (like yeast and mold), heavy metals (lead, arsenic), and verify that the nutritional panel on your label is 100% accurate.

Don’t be shy about asking to see quality assurance procedures or a sample lab report. This documentation is concrete proof of their commitment to making a safe, high-quality product for your brand.

Ready to turn your pumpkin seed product vision into a market-ready success? At Triton Nutra Group, we act as your dedicated R&D and manufacturing partner, guiding you from concept through launch with transparency and expertise.

Request your free quote today and let's build your brand together.