10 Supply Chain Management Best Practices for 2025

Discover 10 essential supply chain management best practices for supplement and e-commerce brands. Boost efficiency, cut costs, and improve resilience now.

Get a Free Quote Today!

Get a Free Quote Today!Why Your E-Commerce Success Hinges on Mastering the Supply Chain

In the competitive world of supplement manufacturing and e-commerce, a product's journey from concept to customer is filled with complexity. Every step, from sourcing raw ingredients to final delivery, presents an opportunity for either costly error or strategic advantage. For brands aiming to scale, especially those navigating the rigorous demands of Amazon FBA, Shopify, and Walmart, a reactive supply chain is no longer sufficient. Proactive optimization is the key to survival and growth.

This article moves beyond generic advice to provide a detailed roadmap of 10 essential supply chain management best practices. We will dissect each strategy, offering actionable insights and real-world examples tailored for supplement and e-commerce businesses. You will learn how to implement proven strategies in areas like:

- Demand Forecasting and Planning

- Supplier Relationship Management (SRM)

- Lean Methodologies

- Supply Chain Visibility and Transparency

- Risk Management and Contingency Planning

- Digital Transformation

- Collaborative Planning (CPFR)

- Sustainable Practices

- Agile Supply Chain Management

- Performance Measurement and Analytics

Adopting these practices will not only streamline your operations but also build the resilience needed to thrive in a competitive market, ensuring you can deliver on your brand promise every single time. Let's explore the strategies that separate market leaders from the rest.

1. Demand Forecasting and Planning

For supplement brands, especially those with seasonal products like immunity boosters or summer wellness formulas, accurately predicting customer demand is paramount. This is a core tenet of effective supply chain management best practices. Demand forecasting is the systematic process of using historical sales data, market trends, and predictive analytics to optimize inventory. It’s about knowing what your customers will want before they do.

For instance, a vitamin D supplement brand can analyze sales spikes during winter months and layer that quantitative data with qualitative insights from social media about new health trends. This dual approach prevents costly overstocking of ingredients with limited shelf lives and avoids stockouts during peak demand, which can lead to lost sales and negative reviews on platforms like Amazon.

Why It's a Top Practice

Effective forecasting allows a manufacturer to schedule production runs efficiently, ensuring they have the capacity to support your brand's growth without tying up capital in excess inventory. Companies like Walmart and Zara leverage sophisticated forecasting to manage massive, fast-moving inventories, demonstrating its power at scale. For a growing supplement brand, this means better cash flow, higher customer satisfaction, and a more resilient operation.

Actionable Implementation Tips

- Start Simple, Then Scale: Begin with basic statistical methods like moving averages before investing in complex AI-driven software. This builds a foundational understanding of your sales cycles.

- Combine Data Types: Don't rely solely on historical sales (quantitative data). Integrate qualitative intelligence from your sales and marketing teams regarding upcoming promotions, competitor activities, and emerging health fads.

- Review and Refine: Your forecast is a living document. Regularly measure its accuracy against actual sales and adjust your models accordingly. A quarterly review is a good starting point.

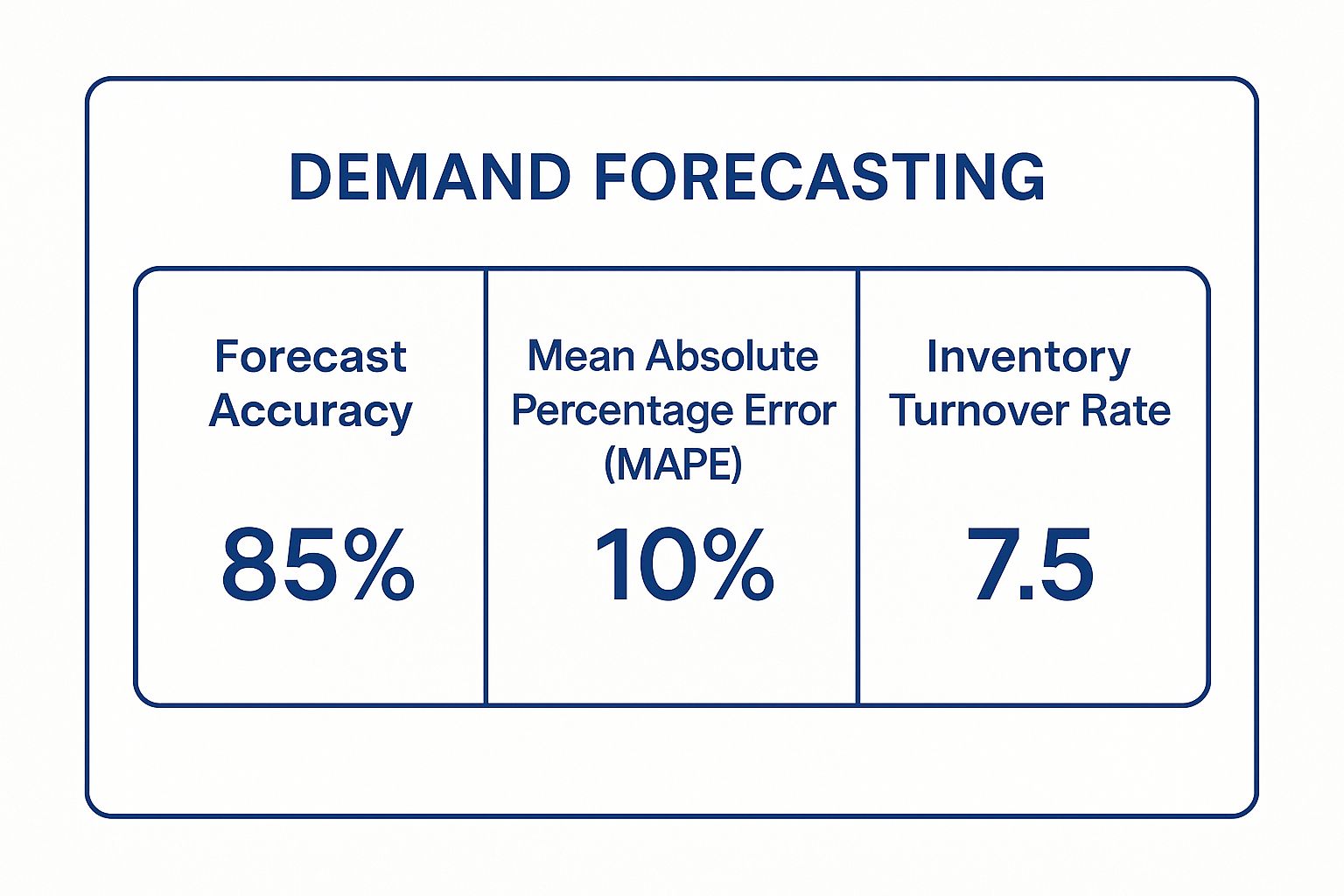

To gauge the effectiveness of your forecasting efforts, tracking a few key metrics is essential.

Tracking these key takeaways reveals the health of your inventory strategy, showing how accurately you predict demand (Forecast Accuracy), the magnitude of your prediction errors (MAPE), and how efficiently you are moving product (Inventory Turnover).

2. Supplier Relationship Management (SRM)

In the supplement industry, where quality control and raw material consistency are non-negotiable, your suppliers are more than just vendors; they are strategic partners. This is where Supplier Relationship Management (SRM) becomes a critical component of your overall supply chain management best practices. SRM moves beyond transactional, price-focused interactions to build collaborative, long-term partnerships that drive mutual value and resilience.

For a supplement brand, this means working closely with a raw ingredient provider to get early access to a new, clinically-backed botanical or partnering with a packaging supplier to develop more sustainable bottling solutions. This collaborative approach ensures a stable supply of high-quality materials and can unlock innovations that give you a competitive edge.

Why It's a Top Practice

A strong supplier relationship provides stability in a volatile market. When supply chain disruptions occur, partners are more likely to prioritize your orders and work with you to find solutions. Companies like Toyota built their legendary production system on deep, decades-long supplier partnerships, fostering continuous improvement and shared success. For a supplement brand, this translates to better ingredient quality, reliable lead times, and a more agile response to market changes.

Actionable Implementation Tips

- Segment Your Suppliers: Categorize suppliers based on their strategic importance. Your primary creatine monohydrate supplier is more critical than your office supply vendor. Focus your deepest partnership efforts on the most strategic relationships.

- Establish Clear Metrics: Define and track key performance indicators (KPIs) for your key suppliers, such as on-time delivery rates, quality compliance, and cost-effectiveness. Hold regular business reviews to discuss performance.

- Invest in Collaboration: Share your sales forecasts and new product development roadmaps with trusted partners. This transparency allows them to align their production and inventory planning with your needs, preventing future bottlenecks.

3. Lean Supply Chain Management

Adopting a lean methodology is a powerful way to streamline operations by relentlessly focusing on eliminating waste. For supplement brands, this translates into a more agile and cost-effective system. This is one of the most transformative supply chain management best practices because it shifts the focus from simply moving products to creating value for the customer with maximum efficiency. It involves systematically identifying and removing non-value-added activities, from excessive ingredient storage to inefficient production steps.

Toyota's production system is the classic example, where just-in-time principles ensure parts arrive exactly when needed, minimizing inventory costs. For a supplement brand, this could mean scheduling raw material deliveries to align precisely with manufacturing runs for a new batch of protein powder. This prevents capital from being tied up in materials and reduces the risk of spoilage for sensitive ingredients like probiotics.

Why It's a Top Practice

A lean supply chain is inherently more responsive and resilient. By removing waste, you reduce lead times, lower operational costs, and improve overall quality. Dell’s direct-to-consumer model famously cut out intermediary inventory, allowing for greater customization and faster delivery. For supplement e-commerce brands, applying lean principles means you can react quickly to market shifts, launch new products faster, and operate with a lower cost base, leading to better margins and a stronger competitive edge.

Actionable Implementation Tips

- Map Your Value Stream: Begin by visually mapping every step of your supply chain, from raw material sourcing to customer delivery. This helps identify bottlenecks, delays, and wasteful activities.

- Embrace a "Pull" System: Instead of producing based on forecasts (a "push" system), aim to produce based on actual customer orders. This is the core of just-in-time delivery and drastically reduces overproduction.

- Standardize Workflows: Create clear, documented procedures for key processes like order fulfillment and quality control checks. Standardization reduces errors, improves consistency, and makes it easier to train new team members.

- Foster Continuous Improvement: Encourage everyone, from the warehouse floor to the executive office, to constantly look for small, incremental improvements. This culture, known as "Kaizen," is the engine of a successful lean transformation.

4. Supply Chain Visibility and Transparency

For supplement brands, knowing where your raw ingredients are sourced and where your finished product is at any given moment is no longer a luxury; it’s a necessity. This is a critical component of modern supply chain management best practices. Supply chain visibility is the ability to track materials, components, and products in real-time as they move from supplier to manufacturer to consumer. It provides a clear, end-to-end view of your entire operational network.

For a brand selling organic ashwagandha, for example, visibility means tracing a specific batch back to the farm in India, verifying its organic certification, and tracking its journey through customs and into your warehouse. This level of transparency builds consumer trust and allows you to respond swiftly to disruptions, like a delayed shipment, by proactively communicating with customers. It's the standard set by companies like Amazon, whose detailed package tracking has shaped consumer expectations for all e-commerce brands.

Why It's a Top Practice

Enhanced visibility empowers you to manage risks, improve efficiency, and ensure compliance. When you can see every step, you can identify potential bottlenecks or quality control issues before they escalate into costly recalls or stockouts. Major companies like Walmart leverage blockchain to provide unparalleled food traceability, while logistics giants like Maersk offer platforms for complete shipping transparency. For a supplement brand, this means stronger quality assurance, better inventory management, and a more resilient business model.

Actionable Implementation Tips

- Start with High-Risk Areas: Focus your initial efforts on critical products or suppliers with a history of variability. Implement tracking for your most valuable or volatile ingredients first.

- Invest in Integration: Utilize technology platforms that connect disparate systems (e.g., your supplier's ERP, your 3PL's WMS, and your own e-commerce platform) into a single, unified dashboard.

- Establish Data-Sharing Agreements: Work with your key partners to create clear agreements on what data will be shared, how often, and in what format. This fosters collaboration and mutual accountability.

- Focus on Actionable Insights: Don't just collect data; analyze it to find patterns and make informed decisions. Use the visibility to improve lead times, reduce safety stock, and enhance supplier performance.

5. Risk Management and Contingency Planning

The global supply chain is inherently volatile, with potential disruptions ranging from raw material shortages to geopolitical events. An essential component of supply chain management best practices is a systematic approach to identifying, assessing, and mitigating these risks. This involves creating a comprehensive risk management framework and developing contingency plans to ensure operational continuity when disruptions inevitably occur.

For a supplement brand, a single point of failure, such as a sole supplier for a critical botanical extract, can halt production entirely. Johnson & Johnson famously demonstrated resilience during the COVID-19 pandemic by leveraging its diversified supplier base to maintain production. Similarly, a proactive risk strategy means anticipating potential logistics failures. Within effective risk management, considering robust protection strategies is key; for instance, understanding how car shipping insurance can protect assets during transit is crucial for brands that might move vehicles or high-value equipment between facilities.

Why It's a Top Practice

A robust risk management plan transforms a company from being reactive to proactive. Instead of scrambling when a crisis hits, you have a pre-defined playbook to execute, minimizing downtime, financial loss, and brand damage. Companies like Apple and Zara have institutionalized this by building flexible, multi-source networks that can adapt quickly to market shifts or supplier issues. This foresight builds a resilient business that can withstand shocks and maintain customer trust even in turbulent times.

Actionable Implementation Tips

- Conduct Regular Risk Assessments: Assemble a cross-functional team (including procurement, logistics, and quality control) to brainstorm and map potential risks. Use a matrix to rate them by likelihood and impact.

- Develop Scenario Plans: Don't just plan for the most likely disruption. Create distinct contingency plans for different scenarios, such as a key supplier going out of business, a shipping lane closure, or a sudden regulatory change.

- Establish Backup Relationships: Identify and vet alternative suppliers or logistics partners before you need them. Having these relationships in place can drastically reduce your recovery time during an emergency.

- Maintain Strategic Safety Stock: For mission-critical ingredients or packaging components with long lead times, hold a calculated amount of safety stock to buffer against unexpected supply interruptions.

6. Digital Supply Chain Transformation

Moving beyond spreadsheets and manual tracking is essential for modern brands; this is where digital transformation becomes one of the most crucial supply chain management best practices. This involves integrating advanced technologies like the Internet of Things (IoT), AI, and analytics into every step of your operation. The goal is to create a smart, connected, and highly visible supply chain that can react in real-time.

For a supplement brand, this could mean using IoT sensors to monitor the temperature and humidity of raw ingredients during transit, ensuring potency is never compromised. It could also involve AI-powered analytics to predict potential logistics bottlenecks before they disrupt customer deliveries. Companies like Amazon have mastered this, using robotics and AI in their fulfillment centers to achieve unprecedented speed and accuracy, demonstrating the immense competitive advantage of a fully digitized system.

Why It's a Top Practice

A digital supply chain provides unparalleled visibility and control. It replaces guesswork with data-driven decision-making, allowing brands to be proactive rather than reactive. This leads to reduced operational costs, enhanced efficiency, and greater resilience against disruptions. Schneider Electric, for example, leveraged digital tools to reduce its inventory by 30% while improving customer satisfaction, proving the tangible ROI of this strategic shift.

Actionable Implementation Tips

- Start with Pilot Projects: Don’t attempt to overhaul your entire system at once. Begin with a small, high-impact area, like digitizing your warehouse receiving process or implementing a route optimization tool for deliveries.

- Invest in People: Technology is only as good as the people using it. Prioritize employee training and effective change management to ensure your team can leverage the new tools effectively.

- Focus on Integration: Select technologies that can integrate seamlessly with your existing systems (like your ERP or WMS). Data quality and interoperability are keys to avoiding information silos and maximizing benefits.

7. Collaborative Planning, Forecasting and Replenishment (CPFR)

True optimization in the supply chain doesn't happen in a silo. Collaborative Planning, Forecasting, and Replenishment (CPFR) is a sophisticated business practice that formalizes cooperation between trading partners, like a supplement brand and its key retailers or raw material suppliers. This approach combines the intelligence and data from multiple points in the supply chain to create a single, shared demand forecast. This is a powerful application of supply chain management best practices that moves beyond internal forecasting.

For example, a supplement brand selling on Amazon can share its promotional calendar and sales data directly with its primary contract manufacturer. In return, the manufacturer shares its production schedule and potential lead time issues for critical ingredients. This shared visibility allows both parties to anticipate demand spikes and supply constraints together, preventing stockouts during a major sale or overproduction based on faulty assumptions.

Why It's a Top Practice

CPFR breaks down the walls between trading partners, turning a series of independent forecasts into one cohesive and more accurate plan. This reduces the "bullwhip effect," where small changes in consumer demand get amplified into major inventory errors further up the supply chain. Pioneers like Walmart and Procter & Gamble used CPFR to dramatically improve product availability while cutting inventory costs, proving its effectiveness at the highest level of retail. For a supplement brand, this translates to stronger retail relationships, lower safety stock requirements, and a more agile response to market changes.

Actionable Implementation Tips

- Start Small with a Willing Partner: Don't try to implement CPFR with all your partners at once. Select one trusted, high-volume retailer or critical supplier and a limited number of SKUs to pilot the process.

- Establish Clear Governance: Before sharing any data, create a formal agreement that outlines what information will be shared, how frequently, and who is responsible for each step of the process. Define the key metrics for success together.

- Focus on Exception Management: The goal isn't a perfect forecast but a better process for managing deviations. Use the collaborative framework to quickly identify and resolve potential stockouts or overstocks, rather than chasing flawless predictions.

8. Sustainable and Green Supply Chain Practices

For supplement brands aiming to connect with a health-conscious and ethically-minded consumer base, integrating environmental considerations into operations is no longer optional. This is a crucial element of modern supply chain management best practices. A green supply chain involves intentionally designing and managing processes to reduce waste, minimize carbon footprint, and conserve resources, from raw material sourcing to final product delivery.

For example, a supplement manufacturer can prioritize suppliers who use regenerative farming for their botanicals or switch to lightweight, recycled packaging materials. This not only appeals to eco-conscious buyers but can also create operational efficiencies. Companies like Patagonia have built their brand identity around such principles, demonstrating that sustainability and profitability can be mutually reinforcing goals.

Why It's a Top Practice

Adopting sustainable practices enhances brand reputation, reduces long-term operational costs through resource efficiency, and mitigates risks associated with environmental regulations. As consumers increasingly scrutinize a brand's ecological impact, a transparently green supply chain becomes a powerful market differentiator. This forward-thinking approach future-proofs the business against resource scarcity and shifting consumer preferences.

Actionable Implementation Tips

- Set Measurable Targets: Go beyond vague commitments. Establish specific goals, such as reducing packaging waste by 20% or sourcing 50% of ingredients from certified sustainable suppliers within two years.

- Engage Your Suppliers: Your supply chain's sustainability is only as strong as its weakest link. Collaborate with suppliers on their environmental performance, share your goals, and incentivize improvements.

- Focus on Transportation: Optimize shipping routes and consolidate shipments to reduce fuel consumption. To truly embrace green practices, businesses should explore dedicated resources outlining effective strategies for reducing supply chain carbon emissions to make a tangible impact.

- Communicate Transparently: Share your sustainability journey, including both successes and challenges, with your customers. This builds trust and authenticates your brand's commitment to the planet.

9. Agile Supply Chain Management

In the volatile supplement market, where new health trends can emerge overnight and consumer preferences shift rapidly, an agile supply chain is a critical competitive advantage. This approach prioritizes flexibility, responsiveness, and rapid adaptation over traditional, cost-focused efficiency. Embracing agility is a fundamental aspect of modern supply chain management best practices, allowing brands to thrive amidst uncertainty. It means building a system that can pivot quickly to new ingredient demands or sudden spikes in online orders.

For example, if a new study highlights the benefits of a specific botanical extract, an agile supplement brand can quickly source the ingredient, adjust production schedules, and launch a new product to meet burgeoning demand. This contrasts with a rigid, cost-optimized chain that might be locked into long-term contracts for other ingredients, unable to adapt. Companies like Zara have mastered this in fashion, responding to trends in weeks, a model that directly translates to the fast-paced wellness industry.

Why It's a Top Practice

An agile supply chain enables a brand to capitalize on market opportunities and mitigate risks far more effectively than a traditional, lean-only model. While lean focuses on cutting waste, agile focuses on responding to market volatility. For a supplement brand, this means reducing the risk of obsolescence for trend-based products and capturing sales from emerging health fads before competitors. It builds resilience, ensuring your operations can withstand unexpected supplier disruptions or changes in consumer behavior without collapsing.

Actionable Implementation Tips

- Develop a Multi-Supplier Strategy: Avoid single-sourcing critical raw materials like whey protein or specialized botanical extracts. Cultivating relationships with multiple, vetted suppliers provides flexibility and a buffer against regional disruptions.

- Implement Postponement: Delay final product assembly or labeling until an actual order is received. For instance, you can hold bulk, unflavored protein powder and add flavorings or package it into different-sized containers only after a sales trend becomes clear.

- Foster Cross-Functional Collaboration: Create small, empowered teams with members from procurement, marketing, and operations. This allows for rapid, informed decision-making when a new market opportunity or supply chain challenge arises, cutting through bureaucratic red tape.

10. Performance Measurement and Analytics

You cannot improve what you do not measure. For supplement brands navigating complex global supply chains, a systematic approach to performance measurement is a non-negotiable supply chain management best practice. This involves establishing key performance indicators (KPIs), benchmarking against industry standards, and using analytics to transform raw data into actionable intelligence. It’s the process of making your supply chain transparent and accountable.

For example, a brand selling probiotics with strict temperature-control needs can use real-time sensor data to track the "perfect order rate" - orders delivered on-time, complete, damage-free, and at the correct temperature. This goes beyond simple delivery confirmation. It ensures product efficacy and customer safety. Companies like UPS use their ORION (On-Road Integrated Optimization and Navigation) system, which leverages advanced analytics to optimize delivery routes in real-time, saving millions in fuel and improving delivery times.

Why It's a Top Practice

Consistently measuring performance reveals hidden inefficiencies, highlights opportunities for cost reduction, and improves partner accountability. It allows you to move from reactive problem-solving to proactive, data-driven decision-making. McDonald's, for instance, uses meticulous supply chain metrics to ensure that a Big Mac tastes the same in Boston as it does in Beijing, a testament to the power of standardized performance measurement in maintaining quality and consistency at a massive scale.

Actionable Implementation Tips

- Focus on Outcome-Driven Metrics: Don't just track everything. Select KPIs that directly impact business goals, such as cash-to-cash cycle time, on-time in-full (OTIF) delivery, and landed cost per unit.

- Balance Indicator Types: Use a mix of lagging indicators (like historical inventory turnover) to evaluate past performance and leading indicators (like supplier lead time variability) to predict future challenges.

- Use Visualization Tools: Implement dashboards using tools like Tableau or Power BI. This makes complex data accessible and understandable for all stakeholders, from the warehouse floor to the executive suite, fostering a culture of continuous improvement.

Best Practices Comparison Matrix

| Item | Implementation Complexity | Resource Requirements | Expected Outcomes | Ideal Use Cases | Key Advantages |

|---|---|---|---|---|---|

| Demand Forecasting and Planning | High - requires advanced analytics | Significant investment in technology & talent | Improved forecast accuracy; reduced inventory costs | Inventory optimization; production planning | Proactive decision-making; reduces bullwhip effect |

| Supplier Relationship Management (SRM) | Medium to High - involves collaboration and governance | Time and resource-intensive supplier management | Cost reduction; improved quality; risk mitigation | Strategic supplier partnerships; innovation focus | Enhances resilience; drives supplier collaboration |

| Lean Supply Chain Management | Medium - cultural change needed | Moderate to high, involving process redesign | Waste reduction; increased efficiency; better quality | Industries prioritizing efficiency and waste elimination | Reduces inventory; improves productivity |

| Supply Chain Visibility and Transparency | High - needs technology integration | High technology and partner cooperation | Real-time tracking; improved risk management | Complex supply chains needing end-to-end visibility | Proactive issue resolution; compliance support |

| Risk Management and Contingency Planning | Medium - requires comprehensive frameworks | Moderate to high for monitoring and planning | Reduced disruption impact; increased resilience | Businesses facing volatile supply risks | Ensures continuity; protects brand reputation |

| Digital Supply Chain Transformation | Very High - complex technology adoption | High capital and skilled workforce | Increased efficiency; real-time optimization | Companies seeking automation and smart tech integration | Enhances accuracy; reduces human error |

| Collaborative Planning, Forecasting and Replenishment (CPFR) | High - multi-partner coordination | High technology and trust investments | Better forecast accuracy; reduced inventory | Collaborative supply chains with multiple partners | Strengthens partnerships; reduces bullwhip effect |

| Sustainable and Green Supply Chain Practices | Medium to High - involves new policies and technologies | Moderate, with higher upfront costs | Lower environmental impact; regulatory compliance | Companies focused on sustainability and brand value | Cost savings through efficiency; enhanced reputation |

| Agile Supply Chain Management | High - requires organizational change | High due to flexibility and rapid response capabilities | Faster market response; improved customization | Dynamic markets requiring rapid adaptation | Competitive advantage; faster innovation |

| Performance Measurement and Analytics | Medium - requires data systems and analytics | Significant investment in analytics tools | Objective performance insights; continuous improvement | All supply chains aiming for data-driven management | Supports strategic decisions; identifies inefficiencies |

Building a Resilient Supply Chain for Tomorrow's Market

Navigating the complexities of the modern marketplace requires more than just a great product; it demands a sophisticated, resilient, and agile operational backbone. We've explored ten foundational supply chain management best practices that serve as the blueprint for building such a system. From the data-driven precision of demand forecasting and performance analytics to the collaborative power of Supplier Relationship Management (SRM) and CPFR, each practice offers a distinct lever for enhancing efficiency and driving growth.

The journey toward supply chain excellence is not a one-time initiative but a continuous cycle of improvement and adaptation. Embracing lean principles eliminates waste, while fostering an agile mindset allows your business to pivot swiftly in response to market shifts. Crucially, integrating digital transformation and ensuring end-to-end visibility are no longer optional luxuries; they are essential for survival and scalability in the competitive supplement and e-commerce sectors. These strategies collectively empower you to build a supply chain that is not only cost-effective but also robust enough to withstand unforeseen disruptions.

From Theory to Actionable Strategy

The true value of these principles is realized through their practical application. Your immediate next steps should involve a candid assessment of your current operations. Identify your weakest links and prioritize the practices that will deliver the most significant impact.

- Start with an Audit: Begin by mapping your existing supply chain. Where are the bottlenecks? Where do you lack visibility? Use this as your baseline for measuring improvement.

- Prioritize and Implement: You don't have to implement all ten practices at once. Perhaps your most pressing need is to strengthen supplier partnerships or improve inventory accuracy through better forecasting. Select one or two key areas to focus on first.

- Leverage Technology: Investigate and adopt the right technology stack. This could range from inventory management software to comprehensive ERP systems that unify data and provide a single source of truth.

- Optimize Logistics: A resilient supply chain depends on efficient transportation and delivery. To build a truly resilient supply chain, optimizing every component, including transportation, is essential. Explore these key fleet management best practices for 2025 to enhance logistical robustness.

By systematically integrating these supply chain management best practices, you transform your operations from a simple cost center into a powerful competitive advantage. A well-managed supply chain directly translates into improved customer satisfaction, higher profit margins, and a brand reputation built on reliability and trust. This strategic foundation is what enables a startup to scale into a market leader, capable of seizing new opportunities with confidence.

Ready to implement these best practices with a partner who understands the unique demands of the supplement industry? Triton Nutra Group specializes in providing flexible, compliant, and transparent manufacturing solutions that align with your growth strategy. Visit Triton Nutra Group to learn how our expertise can become the cornerstone of your optimized supply chain.