How to manufacture protein powder: A Step-by-Step Private-Label Guide

Learn the essentials to manufacture protein powder—from formulation to packaging—and successfully launch your private-label line.

Get a Free Quote Today!

Get a Free Quote Today!Manufacturing protein powder begins with selecting high-grade protein sources and ends when you seal a shelf-stable, market-ready blend. Every choice—from ingredient ratios to on-site testing—shapes product performance and ensures compliance in our FDA-registered, UL-certified facility. With cGMP (current Good Manufacturing Practices) at the core, let’s walk through the private-label process so you can launch fast, hit your specs, and delight customers.

Assess Market Potential For Protein Powder

Before you scale equipment or launch a new line, map demand. Right now, global retail revenue for protein powder sits between USD 24.6–31.9 billion, growing at 6.8%–8.7% CAGR through 2030. North America alone commands ~37% of those sales, making it a key target for brands.

For full data, see GMInsights.

Key Takeaways:

- Global Revenue: USD 24.6–31.9 billion

- Projected CAGR: 6.8%–8.7%

- North America: ~37% share

Whey, casein, plant-based isolates, and specialty blends dominate retail. Use regional insights to guide your private-label formula, packaging, and marketing.

Global Protein Powder Market Overview

To set strategic priorities, compare today’s figures with 2030 forecasts:

| Region | Current Revenue (USD) | Projected CAGR | Forecasted Value (2030, USD) |

|---|---|---|---|

| North America | 9.1–11.8 billion | 7.0% | 16.0 billion |

| Europe | 6.5–8.2 billion | 6.5% | 12.5 billion |

| Asia Pacific | 5.0–6.3 billion | 8.2% | 11.4 billion |

| Latin America | 1.2–1.6 billion | 7.5% | 2.8 billion |

| Middle East & Africa | 0.8–1.0 billion | 6.8% | 1.5 billion |

Align production capacity and marketing spend to match these growth profiles.

Case Study Highlights

In Europe, a whey specialist expecting 8.0% CAGR upgraded to a larger spray dryer, boosting throughput by 30%. A plant-protein brand targeting Asia-Pacific shifted to pea and rice isolates, capturing vegan demand. In Latin America, ramping up drum packaging and regional warehousing cut lead times from six weeks to two—driving restocks and faster sales.

Practical Tips:

- Budget materials against precise demand forecasts

- Schedule pilot runs before full-scale production

- Reserve capital for key equipment upgrades

- Focus marketing on top territories

Note: Raw ingredients make up ~60% of COGS. Accurate forecasts cut spoilage and storage costs.

Craft Your Protein Powder Formula

Your base protein choice shapes texture, claims, and costs. Whether for athletes or plant-based consumers, each source adds unique value.

Comparison Of Common Protein Sources

| Protein Source | Protein Content per 100g | Allergen Notes | Ideal Applications |

|---|---|---|---|

| Whey | 80g | Dairy | Post-workout shakes |

| Casein | 75g | Dairy | Slow-release nighttime blends |

| Soy | 90g | Soy | DIY bars and protein snacks |

| Pea | 85g | None | Vegan protein formulations |

| Rice | 78g | None | Hypoallergenic mixes |

Use this table to forecast costs, flavor impact, and label positioning.

Enhance Mixability And Mouthfeel

Nobody likes clumps. A small dose of lecithin or soluble fiber can turn gritty powder into a silky pour. In one trial, 0.5% sunflower lecithin cut clumping by 30%.

- Lecithin: improves emulsification and reduces dust

- Inulin: adds creaminess and fiber

- Silica: protects against moisture, keeps powder free-flowing

These tweaks drive customer satisfaction and filling efficiency.

Learn more in our nutraceutical formulation development post.

Develop Flavor Profiles

Flavor blends science and art. Natural extracts—cocoa, freeze-dried fruit—deliver depth. Maltodextrin helps bind complex notes.

- Cocoa: rich chocolate note without masking protein

- Freeze-dried fruit: vibrant color and authentic taste

- Stevia/monk fruit + masking agents: control aftertaste

Switching maltodextrin for pea dextrin boosted stability by 25%.

“Tuning polysaccharide ratios improved taste and shelf life in just 8 weeks.”

Source Ingredients Strategically

High-quality inputs matter. Choose UL-certified, FDA-registered suppliers with transparent COAs (Certificate of Analysis).

- Negotiate annual volume for price breaks

- Request third-party testing for potency and contaminants

- Run pilots to confirm mix behavior and yield

This cuts surprises in scale-up and aligns forecasts with real performance.

Finalizing Your Blend

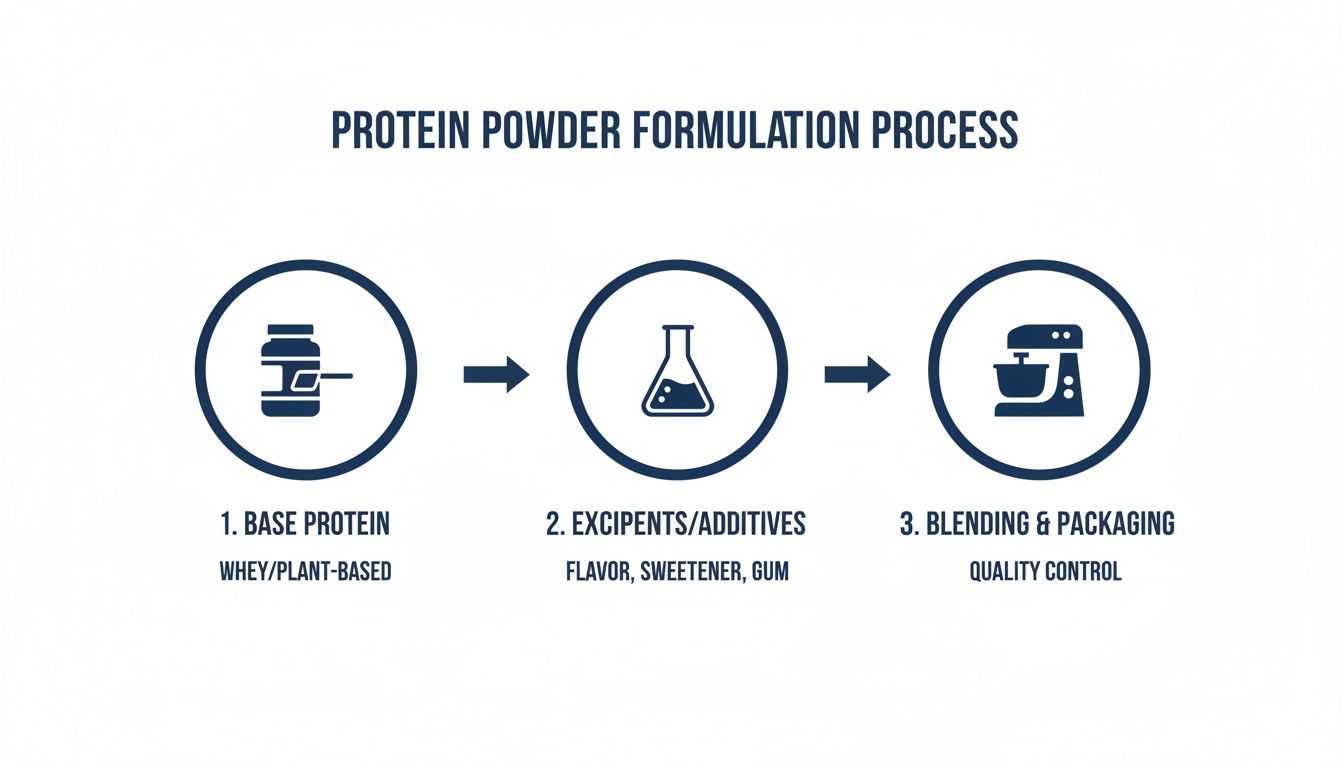

Moving from lab to line? Follow a clear roadmap:

- Confirm label claims meet regulatory standards

- Test small batches on high-shear mixers for uniform dispersion

- Use third-party labs to verify amino acid profiles and microbial safety

- Adjust excipients based on taste and stability studies

- Document details—from raw batches to process settings—for cGMP audits

Early collaboration with your contract manufacturer smooths bottlenecks and ensures on-time delivery.

Optimize Costs And MOQ

Ingredient choices drive costs. Swapping 10% whey for soy isolate cut COGS by 15% without diluting nutrition.

- Combine orders across SKUs for volume discounts

- Use pilot runs to negotiate lower MOQs on specialty flavors

- Explore modular packaging to tweak portion sizes without new tooling

Efficient MOQ strategies free up capital for marketing and R&D.

Rigorous data and collaboration put your protein powder on a fast track from development to shelf.

Optimize Processing Methods And Equipment

Scaling protein powder production means matching techniques with machines. Choices like high-shear mixing, spray drying vs. agglomeration, and micronization shape solubility and mouthfeel. Small pilot runs can save costly mistakes.

This visual shows why ingredient order and precise equipment settings are non-negotiable.

Compare Drying Strategies

Spray drying and agglomeration each have pros and cons:

| Technique | Particle Size | Energy Use | Mixability | Equipment Cost |

|---|---|---|---|---|

| Spray Drying | 20–100 μm | High | Instant | $$$$$ |

| Agglomeration | 100–300 μm | Medium | Cold-water | $$$ |

Align your investment with performance goals and budget.

Validate Processes With Pilot Runs

Run 10–50 kg trials to catch issues—sticking, uneven particles, filter clogs.

Document:

- Batch Size: 10–50 kg

- Moisture Target: 3–5% residual

- Key Params: mixer rpm, nozzle temp, airflow

This forms your SOP for scale-up.

Maintain Equipment Efficiency

Downtime cuts margins. Use vibration sensors and thermal imaging to spot wear.

Key steps:

- Quarterly calibrations: moisture probes, pressure gauges

- Scheduled filter swaps to preserve airflow

- Thermal scans for hot spots in pumps

These tactics keep drying cycles on spec.

Plan For Reliable Throughput

Hit output targets by planning capacity. Include cleaning cycles and unplanned holds when sizing mixers, dryers, and sieves.

Throughput = Batch Volume ÷ (Cycle Time + Cleaning)

Right-sizing avoids floor-space waste and overages.

Cutting downtime by 25% lifts annual output by 10%.

Optimize Extraction And Cold-Fill

Cold-fill blending (<40 °C) protects heat-sensitive botanicals and speeds cycles. Ethanol-free extraction bumped yield from 60% to 75% in one project.

Inline homogenizers keep extracts ready, ensuring batch-to-batch consistency.

Improve Particle Consistency With Micronization

Micronization shaves particles below 50 μm, boosting solubility up to 40%—vital for ready-to-drink mixes.

Benefits:

- Fast cold-liquid dissolution

- Lower dust levels

- Enhanced mouthfeel

A client cut mixing time by 25% after adding a micronizer.

Select Equipment Based On Scale

Lab setups: 20–100 kg high-shear mixers; production: 500–1,000 kg vessels. Scale impacts cleaning time, CIP (Clean-In-Place) schedules, and cGMP validation.

Layout tip: keep mixers, dryers, mills within meters to reduce transfers and contamination.

Plan Maintenance And Training

Equip operators with clear SOPs for sieves, nozzles, impellers. Use digital logs for traceability.

Regular training ensures swift changeovers and smooth operations.

Continuous process and equipment refinement is key to cost-efficient, scalable protein powder production.

Implement Quality Control And Labeling Compliance

Launching protein powder safely means airtight processes. Every sample test and label review protects your brand. Our FDA-registered, UL-certified, third-party tested workflow earns trust and prevents recalls.

See our dietary supplement manufacturing requirements guide.

Quality Control Workflows

QC starts before ingredients hit the hopper. Incoming audits verify each UL-certified supplier’s COA. On the line, operators track moisture, blend time, and granulation pressure.

QC roadmap:

- Raw Material Verification: match COAs to specs; screen for heavy metals, microbes

- In-Process Monitoring: mid-mix samples for pH and moisture; adjust cycles if needed

- Finished Product Analysis: microbial assays, heavy-metal screens, allergen tests before release

Tip: A quick fluid-bed re-dry can rescue a high-moisture batch, saving time and material.

In-House And Third-Party Testing

An in-house QC lab speeds routine assays by ~30%. For advanced tests—heavy-metal speciation or mycotoxin screens—use a USP- or ISO-accredited external lab.

- In-House: faster feedback and confidentiality

- Third-Party: high-end instrumentation and regulatory-grade reports

Example QC Testing Timeline

| Test Type | Turnaround Time | Notes |

|---|---|---|

| Microbial Screening | 3 days | In-house rapid PCR |

| Heavy Metals | 5 days | External USP-accredited lab |

| Allergen Panel | 4 days | Gluten, dairy, soy, nuts screening |

“A single missed microbial test can halt production and cost thousands.” — QA Director

Label Requirements And Templates

FDA rules dictate ingredients in descending weight order. Shoppers need clear allergen statements. Bold “Contains: Milk, Soy” to cut confusion and returns.

Essentials:

- Ingredient Declaration: full sources and excipients

- Nutrition Facts: FDA-compliant macro/micronutrient panel

- Allergen Statement: clear and prominent

- Claim Substantiation: link statements to research or internal data

Pro Tip: Use stability data to set a two-year shelf life and clear “Best By” dates.

Audit Documentation And FBA Compliance

Be audit-ready with organized SOPs, batch logs, and training records. Amazon FBA demands lot traceability and visible expiration dates.

Keep:

- Version-Controlled SOPs with effective dates

- Batch Records: lot numbers, weights, QC results

- Training Logs: operator qualifications and sign-offs

- Retention: store records for at least two years post-distribution

Certification Steps And Timelines

UL marks for equipment take 6–12 months—factory audits, safety checks, corrective actions. FDA facility registration (Form 356h) is ~15 days for initial review.

Milestones:

- Facility Registration (FDA 356h): FSVP confirmation

- cGMP Audit: internal gap analysis, external UL/NSF review

- Corrective Actions: resolve non-conformances, follow-up audit

- Annual Renewal: maintain registrations and certifications

Collaborate For Ongoing Compliance

Standards shift. Our partnership model includes a compliance dashboard with real-time alerts, quarterly reviews, and regulatory briefs.

We offer:

- Real-Time Alerts: test expirations and renewals

- Quarterly Strategy: sessions with QA experts

- Regulatory Watch: monthly FDA and industry updates

Stay proactive—avoid surprises and keep your line running.

Ready to build a QC and labeling framework that stands up to any audit? Contact Triton Nutra Group for a tailored compliance review and quote.

Design Packaging And Ensure Shelf Stability

Packaging shields your powder from moisture, oxygen, and light. It’s also your brand’s first impression. Options include single-serve sachets, stand-up pouches, and bulk drums.

- Sachets: precise portions, minimal waste

- Stand-up pouches: multilayer film for moisture and UV barriers

- Bulk drums: tamper-evident, cost-effective at scale

Most brands find pouches balance cost and performance. Drums lower unit costs but demand higher MOQs. Sachets work in food service and sampling.

Material Selection

Use multilayer films (PET, foil, PE) to block moisture and UV. One brand extended shelf life from six to nine months by switching to a five-layer pouch.

Five-layer film added 50% more protection—boosting shelf life to 9 months.

Vet materials by:

- Checking barrier ratings (MVTR, OTR)

- Reviewing accelerated aging data

- Verifying tamper-evident and UV inhibitors on samples

Negotiating MOQ And Costs

MOQs vary by format and thickness. Expect:

- Pouches: ~5,000 units

- Drums: ~500 units

Tips:

- Combine SKUs or use modular packaging to lower minimums

- Forecast annual demand to unlock volume tiers

- Run pilot batches for custom-film MOQs

- Explore mixed-format orders to leverage supplier creativity

Align pack sizes with pallets to trim freight and handling costs. Spell out lead times and change-control in your contract.

Sustainability Strategies

Consumers want eco-friendly packaging without quality loss.

- Films with recycled content to cut waste

- Compostable liners for non-refrigerated products

- Supplier take-back or recycling programs

Lightweight designs reduce shipping emissions and costs. One mid-size brand cut plastic use by 30% with recycled pouches.

Packaging Logistics

Packaging affects warehousing and freight.

- Match case counts to pallet heights

- Use barcodes and nested carton codes for FBA

- Coordinate with carriers on temp and humidity

Work closely with your contract manufacturer on specs and trials to avoid last-minute issues and ensure on-time launches.

With these insights, you’re ready to manufacture protein powder with quality packaging, cost control, and compliance.

Partner With Contract Manufacturers

Choosing a contract manufacturer is like choosing an R&D partner. Look for cGMP compliance, UL-certified equipment, FDA registration, and transparent third-party testing.

Evaluate:

- Certifications: cGMP, UL, FDA

- Capacity: pilot to commercial volume

- QC systems: in-house and third-party testing

- Communication: project tools, real-time updates

- MOQ flexibility and tiered pricing

Sample Evaluation Checklist

| Evaluation Criteria | What to Verify |

|---|---|

| Quality Certifications | cGMP audit reports, UL test records |

| Production Capacity | Monthly output, shift schedules |

| Communication Practices | Project management software, SLAs |

| Change Control | Version histories, approval logs |

| MOQ Flexibility | Tiered pricing, SKU bundling options |

This side-by-side helps you spot red flags and speed negotiations.

Tips For Smooth Scale Up

- Lock specs before your pilot run

- Run QC assays in parallel with blending

- Track modifications in change-control logs

- Engage third-party labs for critical tests

- Hold regular batch reviews to catch issues early

A collaborative relationship can cut time to market by 20% without sacrificing quality.

Negotiation is about aligning on quality checkpoints, tooling schedules, and R&D support. Flexibility in MOQs and packaging runs keeps you agile.

For a deeper dive into vetting, compliance, and partnership best practices, see our nutraceutical contract manufacturing.

Glad you’re here.

FAQ

What Is The Typical Lead Time For A Pilot Batch Of Protein Powder?

Expect 4–8 weeks from formula sign-off to finished samples. This covers ingredient sourcing, small-scale mixing, and lab testing. Align specs early and book trials in parallel to cut weeks off the timeline.

How Do Spray-Dried And Agglomerated Powders Differ In Performance?

Spray-dried powders produce fine 20–100 μm particles that dissolve instantly but need more energy. Agglomerates (100–300 μm) mix smoothly in cold water and generate less dust. One sports-nutrition line saw shaker-clumping complaints drop 40% after switching to agglomerates.

Common Challenges And Solutions

How Do You Substantiate Label Claims Under FDA Rules?

Collect peer-reviewed research, in-house assay data, and third-party analyses in a claims dossier. Track:

- Scientific evidence and lab results

- Claim wording reviewed by a regulatory advisor

- Archived files for audit readiness

“Detailed records are your best defense in an audit.” — Quality Director

How Can You Reduce Production Costs Without Sacrificing Quality?

Negotiate volume discounts on isolates and forward-buy when possible. Fine-tune excipient ratios—sometimes a cost-effective binder performs like a premium one. Run routine tests in-house, outsource specialized analyses to control external lab fees.

- Forecast volumes early for bulk pricing

- Apply lean batch planning

- Use real-time moisture monitoring to cut rework

Ready to overcome production hurdles? Request a quote from Triton Nutra Group at tritonnutragroup.com