Partner with the Top Maca Root Private Label Contract Manufacturer

Discover expert Maca Root private label contract manufacturer services. Custom formulas, quality assurance, and transparent pricing for your brand.

Get a Free Quote Today!

Get a Free Quote Today!Launching a maca root supplement is an exciting venture, but it throws you right into the deep end of a complex manufacturing world. Your single most critical decision? Picking the right Maca Root private label contract manufacturer.

This partner isn't just a supplier filling orders. Think of them as your R&D partner from concept through launch—your outsourced production facility, and your quality control experts, all rolled into one. Making the right choice here is the absolute foundation for building a brand that's not only reputable but also built to scale.

Choosing Your Maca Root Manufacturing Partner

To nail this, you need an insider's perspective—one that looks past shiny brochures and surface-level sales pitches. True success comes down to finding a partner who excels in three core areas: rock-solid quality and compliance, deep customization capabilities, and transparent, reliable operations.

Before you even start making calls, it’s worth taking a moment for a clear understanding what private labeling entails and how it’s different from other manufacturing models. This partnership is fundamental. Imagine working with a team that not only gets your vision but has the technical expertise to bring it to market safely and effectively. They're the ones ensuring every bottle meets the strictest standards while helping you innovate in a crowded space.

The Growing Demand for Maca Supplements

The market for maca isn't just holding steady; it's exploding. The global maca supplement powder market, a huge piece of this industry, was valued at around USD 1.2 billion in 2024. But here’s the kicker: it’s projected to grow at a CAGR of 8.1%, hitting an estimated USD 2.4 billion by 2033.

This massive growth is fueled by a surge in consumer awareness around maca's adaptogenic properties for stress resistance, energy, and fertility. As more people gravitate toward natural and organic supplements, the demand for high-quality, trustworthy maca products is only climbing.

This boom is a golden opportunity for new and existing brands. But it also means the competition is fierce, and customers expect—and deserve—unprecedented levels of quality and transparency. Partnering with a top-tier manufacturer has gone from a "nice-to-have" to a "must-have" for anyone serious about capturing market share.

Key Pillars of a Successful Partnership

When you start vetting potential manufacturers, you have to look beyond their sales pitch and focus on the real substance. A true partnership is built on non-negotiable pillars that will protect your brand and fuel its growth.

Think of it as your three-point checklist for success:

- Quality & Compliance: This is the bedrock of your brand, period. Does the manufacturer operate out of an FDA-registered, cGMP-compliant, and UL-certified facility? Will they provide transparent third-party testing results to prove purity and potency?

- Customization & Flexibility: Your product has to stand out. Can they help you tailor formulas, adjust extraction methods, or offer unique packaging? Do they support both pilot runs for testing and full-scale production for launch? For a closer look at what this involves, check out our guide on the essentials of nutraceutical contract manufacturing.

- Speed & Reliability: Time to market can make or break a launch. Do they offer rapid turnarounds? Is communication about timelines clear and consistent? Do they have a proven record of on-time delivery?

A great manufacturing partner doesn’t just take your order. They challenge and refine your concept, acting as a true collaborator from the initial idea all the way through a successful market launch. They are invested in your brand's long-term success, not just a single production run.

To help you organize your evaluation process, we've put together a quick-reference table. Use this checklist as you interview potential partners to ensure you're covering all the critical bases.

Manufacturer Vetting Checklist At A Glance

| Evaluation Pillar | Key Questions to Ask | What to Look For |

|---|---|---|

| Certifications & Compliance | Are you FDA-registered, cGMP-compliant, and UL-certified? Can I see your documentation? | An unhesitating "yes" to all. They should readily provide certificates and registration numbers. |

| Quality Control & Testing | What are your third-party testing protocols for raw materials and finished products? | A robust, multi-stage testing process. Look for transparency and a willingness to share lab results (COAs). |

| Ingredient Sourcing | Where do you source your maca root? Can you trace it back to the origin? | Reputable, vetted suppliers, preferably with direct relationships in Peru. Full traceability is a huge plus. |

| Customization & Formulation | Can you accommodate custom formulas, blends, and delivery forms (capsules, powders, liquids)? | A dedicated R&D team and flexibility. Avoid partners who only offer a limited, off-the-shelf menu. |

| MOQs & Scalability | What are your Minimum Order Quantities (MOQs)? Can you scale with us as we grow? | Reasonable MOQs for a startup, with clear evidence they can handle much larger production volumes later on. |

| Turnaround Times & Communication | What are your average lead times from PO to delivery? Who will be my main point of contact? | Clear, realistic timelines (6-12 weeks is common). A dedicated account manager for direct communication. |

This table isn't exhaustive, but it covers the absolute essentials. A potential partner who can confidently and transparently answer these questions is one worth keeping on your shortlist. Remember, you're not just buying a product; you're building a partnership.

Decoding Quality and Regulatory Compliance

In the supplement world, quality isn't just a buzzword you slap on your label—it’s the entire foundation of your brand. When you team up with a Maca Root private label contract manufacturer, you’re handing them the keys to your reputation, your customers’ health, and your legal standing.

One slip-up or regulatory misstep can trigger a product recall—a brand-killing nightmare that vaporizes customer trust in an instant.

This is where that alphabet soup of certifications comes into play. Understanding these credentials isn't optional; they are the objective measure of a manufacturer's commitment to quality. They’re what separates professional outfits from the corner-cutters.

The Core Certifications You Cannot Ignore

As you vet potential partners, three credentials must be at the top of your checklist. Think of these not as nice-to-haves, but as the absolute baseline for producing a safe and legal dietary supplement in the U.S.

-

FDA-Registered Facility: This simply means the manufacturer is on the Food and Drug Administration's radar. It confirms they are a legitimate operation subject to FDA inspections. While it’s not an official endorsement, a manufacturer operating without it is a gigantic red flag.

-

cGMP Compliant: Current Good Manufacturing Practices are the FDA's rulebook for supplement quality. Compliance means the facility has documented, repeatable processes for everything—from quarantining raw materials to employee hygiene, equipment sanitation, and keeping meticulous batch records.

-

UL Certified (or NSF): This is your proof. Third-party organizations like Underwriters Laboratories (UL) or NSF International perform tough, independent audits to verify a facility is actually following cGMP standards. It’s crucial because it provides unbiased validation of a manufacturer’s claims.

A manufacturer that willingly hands over their cGMP certificate from a third-party auditor like UL is showing you a culture of transparency. They're proud of their quality systems. If a potential partner gets cagey or hesitant about sharing this? That's your cue to walk away.

These certifications are your first line of defense. They ensure the partner you pick has the systems in place to consistently produce a high-quality product, protecting your business and your customers.

Going Beyond the Basics with Third-Party Testing

While facility certifications are a must, they're only half of the quality story. The other critical piece is rigorous, batch-by-batch third-party lab testing. For your maca root supplement, this should be non-negotiable.

The best manufacturers conduct comprehensive testing at multiple points in the process. This isn’t about ticking a box; it’s about creating a documented chain of custody for quality, from raw maca powder to the finished bottle on the shelf.

The global maca extract market is on a steady climb, projected to grow from USD 62.09 million in 2024 to over USD 106 million by 2037. This isn’t a fleeting trend; it’s driven by savvy consumers actively looking for natural performance boosters and demanding proof of what’s in their supplements. You can explore more on the growth of the maca market at researchnester.com.

This growing demand puts product integrity right under the microscope. Your manufacturing partner must be ready to provide clear, accessible testing results to meet this expectation.

What to Look For in a Testing Protocol

A solid testing program should verify several key things for every production run, and you should get the paperwork to prove it. For a deeper look into why this is so critical, check out our guide on the importance of comprehensive supplement ingredient testing.

Here’s exactly what you should expect to see on a Certificate of Analysis (COA) for your maca product:

| Test Category | Purpose | Why It Matters |

|---|---|---|

| Identity | Confirms the ingredient is genuine maca root (Lepidium meyenii). | Stops incorrect or contaminated botanicals from being used. |

| Potency | Measures the concentration of active compounds (like macamides). | Guarantees your product delivers the benefits you promise. |

| Purity/Microbials | Screens for yeast, mold, E. coli, and Salmonella. | Protects your customers' health and prevents product spoilage. |

| Heavy Metals | Tests for lead, arsenic, mercury, and cadmium. | Ensures the product is safe from toxic environmental contaminants. |

When you demand this level of documentation from your Maca Root private label contract manufacturer, you're doing more than just ensuring compliance. You are building a brand founded on trust and verifiable quality. It's the best way to protect your investment and create a product people will come back for again and again.

Bringing Your Custom Maca Formula to Life

This is where your idea for a killer maca supplement goes from concept to a tangible product. A truly great Maca Root private label contract manufacturer won’t just hand you a generic formula. They’ll work with you as an extension of your R&D team to build something unique to your brand.

Think of it this way: a basic white-label product is like buying a suit off the rack. It gets the job done, but it wasn't made for you. A custom private-label formula is a bespoke suit, tailored to fit perfectly. Every detail is yours to control.

That level of customization is what gives you an edge. It's how you carve out your space in a crowded market and create something that speaks directly to your audience.

From Stock Formula to Signature Blend

The journey starts by thinking beyond a simple maca extract. A true formulation partner will help you build a product with a distinct purpose.

Maybe you want to create an energy and focus blend. You could start with a high-potency gelatinized maca and then add Lion's Mane mushroom extract and a touch of natural citrus for a bright, clean flavor.

Or perhaps your brand is all about tackling stress and promoting hormonal balance. You might lean toward a liquid tincture that combines red maca with the calming effects of ashwagandha and the balancing properties of holy basil. The possibilities are endless, and the right partner will help you navigate the science to find botanicals that work together beautifully.

Your formula is your brand’s story in a bottle. Every ingredient choice, every potency adjustment, and every flavor note should be a deliberate decision that reinforces your brand’s promise to the customer. A great manufacturer helps you write that story.

This is an exciting, collaborative process. If you want to dive deeper into the nuts and bolts of it, our guide on how to create a supplement formula offers a comprehensive look at how these concepts become finished products.

Tailoring Every Aspect of Your Maca Product

A truly custom formula is about more than just the active ingredients. The best manufacturing partners give you a full suite of options to make the final product unmistakably yours. These details ensure your supplement not only works well but also delivers a premium experience from the moment a customer picks up the bottle.

Here are just a few of the key areas you can dial in:

- Extract Potency and Type: You can specify the exact concentration of your maca extract or choose between different types, like raw, gelatinized, or even specific color phenotypes (yellow, red, black), each with its own unique profile.

- Synergistic Ingredients: Want to add complementary vitamins, minerals, or other adaptogens? Go for it. Adding Vitamin B6, for example, can enhance the formula's support for energy metabolism.

- Flavor Profile: This is especially true for liquid supplements. You can develop custom flavor profiles ranging from earthy and natural to complex fruit or spice blends, all using high-quality, natural flavor systems.

- Delivery System: While liquid tinctures are a fantastic option, a flexible manufacturer can often discuss possibilities for powders or other forms, depending on their capabilities.

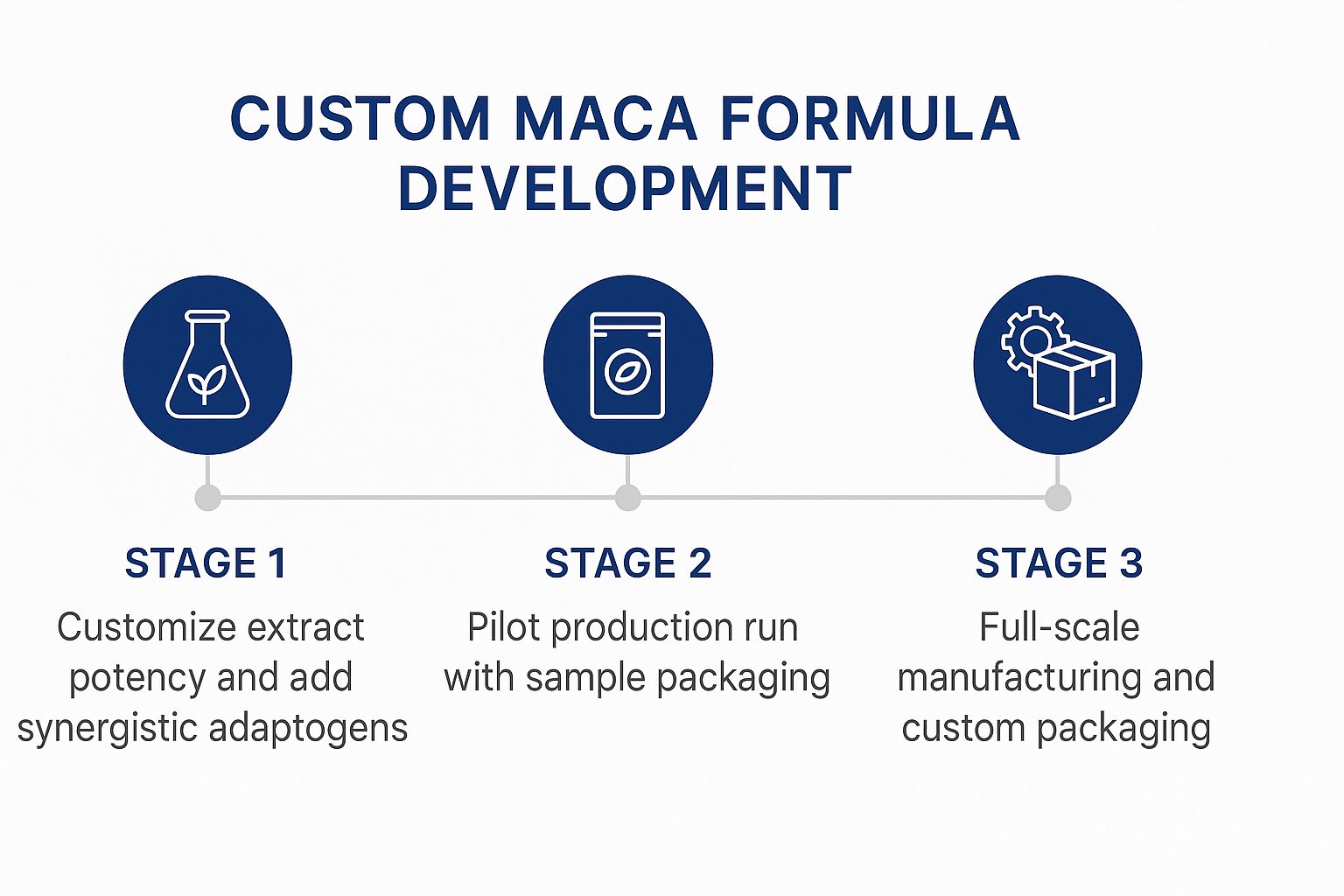

This infographic gives you a bird's-eye view of how a custom formula typically moves from an idea to full-scale production.

As you can see, it’s a structured process designed to perfect your unique formula before you commit to a massive production run.

Packaging and Presentation Matters

Let’s be honest: the bottle, the label, and the box are the first things your customer experiences. Your packaging needs to do more than just protect the product; it has to scream quality and communicate your brand's identity in a single glance. A seasoned manufacturer will have a whole catalog of choices to help you get the presentation just right.

Some key packaging customizations include:

- Bottle Selection: You can pick from different sizes, shapes, and materials, like amber glass to protect against UV light or recycled plastics if your brand has a sustainability focus.

- Dropper and Cap Styles: You can choose calibrated glass droppers for precise dosing, child-resistant caps for safety, or even spray tops for different delivery methods.

- Labeling and Boxing: You can work with their design team—or bring in your own—to create custom-printed labels and retail boxes that meet all FDA compliance standards while beautifully showcasing your brand.

The last piece of the puzzle is scalability. The best partners are with you from day one. They’ll offer small pilot runs, which let you test the waters with a minimal investment. Once you’ve got proof that your product is a winner, they can seamlessly scale up to full production to meet growing demand, ensuring the quality and consistency remain perfect every step of the way.

A Look Inside the Manufacturing Process

So, you’ve signed off on a formula and given the green light for production. What happens next? The journey from raw Peruvian maca root to a finished, shelf-ready supplement is a meticulous dance of science and precision.

Understanding this flow is crucial for any brand owner. It’s not just about mixing ingredients; it’s about appreciating the value and expertise a true manufacturing partner brings to the table. Let’s pull back the curtain and see how a simple botanical is transformed into a premium product.

Sourcing and Traceability

Everything circles back to the quality of the raw material. It's that simple. A top-tier Maca Root private label contract manufacturer doesn't just buy maca powder off the open market. They build real relationships with vetted suppliers who can trace the material right back to specific farming cooperatives in the Andes.

This traceability is your brand's first line of defense. It’s how you know the maca is authentic, sustainably harvested, and free from contaminants before it even hits the loading dock. Upon arrival, every single lot is quarantined and put through rigorous identity testing to confirm it’s the real deal—Lepidium meyenii—and that it meets our strict purity standards.

Advanced Botanical Extraction

Once the raw material gets the all-clear, the real magic begins. Creating a potent, bioavailable liquid extract is way more involved than just mixing powder and water. The best manufacturers use advanced extraction methods designed to capture the full spectrum of maca's active compounds, like macamides and macaenes, while leaving the inert plant material behind.

We use proprietary, temperature-controlled, alcohol-free extraction techniques. This gentle process coaxes the bioactive compounds from the plant’s cellular matrix without harsh solvents or high heat that could destroy delicate phytonutrients. The end result is a clean, powerful extract that truly reflects the plant's natural profile.

An exceptional extract is the heart of your product. The goal isn't just to concentrate the maca, but to preserve its natural synergy. The extraction method a manufacturer uses is a key differentiator that directly impacts the efficacy and quality of your final formula.

This careful process is becoming a major selling point as consumer demand skyrockets. The market for black maca extract alone is projected to grow from roughly USD 66.5 million to about USD 119.1 million by 2035. This trend underscores the growing appetite for high-quality, specialized products.

Precision Blending and Cold-Fill Technology

With a potent maca extract ready to go, the next step is blending it all together. This is where your custom formula comes to life inside a cGMP-controlled cleanroom. The maca extract is carefully combined with other synergistic ingredients, natural flavors, and stabilizers, all according to your approved recipe.

Every ingredient is weighed with absolute precision and added in a specific order to ensure a perfectly homogenous blend. To protect any heat-sensitive components, like certain vitamins, we use cold-fill technology. Unlike old-school hot-fill methods that can degrade nutrients, this innovative process keeps the liquid cool from start to finish, preserving the integrity and potency of your entire formula.

Of course, none of this happens without a solid operational backbone. A manufacturer’s strategy for managing supply chain finance is key to securing high-quality raw materials and keeping production running smoothly.

Final Quality Control and Shipment

We’re in the home stretch, but these last steps are just as critical as the first. Before any product leaves our facility, a sample from the finished batch is sent out for final third-party lab testing. This is the ultimate verification that the product meets every single specification for potency, purity, and safety. What’s on the label is exactly what’s in the bottle.

Once the batch gets the final green light, the bottles are labeled, coded with lot numbers and expiration dates for full traceability, and packaged up for shipment.

Here is a sample timeline to give you a clearer picture of how long this all takes.

Private Label Maca Production Timeline Example

This timeline provides a general overview of the production process, from finalizing your formula to shipping the finished product. Keep in mind that these are estimates and can vary based on raw material availability and testing requirements.

| Phase | Key Activities | Estimated Duration (Business Days) |

|---|---|---|

| Pre-Production | Finalize formula, approve quote, raw material sourcing, and initial testing. | 15-20 Days |

| Production | Botanical extraction, precision blending, and bottling in a cGMP facility. | 10-15 Days |

| Post-Production | Final third-party testing, labeling, packaging, and quality release. | 10-15 Days |

| Shipping | Product is prepared and shipped to your designated fulfillment center. | 3-5 Days |

From start to finish, the entire process is a carefully orchestrated sequence. It's all designed to guarantee a safe, effective, and high-quality product that you’ll be proud to put your name on.

Getting Down to Brass Tacks: Pricing, MOQs, and Timelines

Alright, let's talk about the big three questions every brand owner asks: What’s it going to cost? How many do I have to buy? And how fast can I get it? This is where your vision meets the realities of manufacturing and finance. A good Maca Root private label contract manufacturer won't shy away from these questions; they'll give you clear, direct answers.

The final price for your maca root supplement isn't a random number. It’s a direct result of the choices you make. Understanding these variables is key to creating a supplement that hits your target retail price and profit goals.

What Goes Into the Cost of Your Product?

The price-per-bottle is directly linked to your formula's complexity and your packaging choices. A straightforward maca extract in a generic bottle will cost less than a certified organic, multi-ingredient blend housed in a custom-printed box.

Here are the main cost drivers you'll discuss with your manufacturing partner:

- Raw Material Choices: Opting for USDA Organic or Non-GMO Project Verified maca root will increase your cost, but it's a powerful selling point that lets you command a higher retail price.

- Formula Complexity: A single-ingredient maca tincture is simple. But adding synergistic herbs like ashwagandha or specific vitamins will increase the cost of materials and the labor for precision blending.

- Extraction Method: Advanced, alcohol-free extraction methods are fantastic for preserving maca's full nutrient spectrum. They require specialized equipment and expertise, which costs more but delivers a much higher quality product.

- Packaging Selections: Custom-designed boxes, unique bottle shapes, or high-end calibrated droppers create an incredible customer experience but add more to your unit cost than standard options.

It’s all a balancing act. Your manufacturer should act as a consultant, helping you match your product vision with your budget to get the best possible supplement without cutting corners on quality.

Making Sense of Minimum Order Quantities (MOQs)

The acronym MOQ (Minimum Order Quantity) can cause stress for new brands, but it’s a standard part of manufacturing. MOQs exist so the manufacturer can operate efficiently—covering the cost of sourcing raw materials, setting up the production line, and running necessary quality control for your specific product run.

For liquid supplements like a maca root tincture, expect MOQs to start around 1,000 to 3,000 units for a custom formula. Any lower, and the per-bottle cost for setup and testing becomes too high. Think of this as your launch inventory—ready to go when your first customer clicks "buy."

A partner who gets it knows startups need to test the waters. You want a manufacturer who offers scalable options. They should be comfortable with a reasonable launch MOQ but also have the capacity to easily handle runs of 50,000 units or more as your brand grows. That kind of scalability is critical for long-term growth; you don't want to switch partners just as you're gaining momentum.

Setting a Realistic Timeline for a Flawless Launch

In the fast-paced world of e-commerce, speed to market feels like everything. But rushing the manufacturing process is a recipe for expensive mistakes. A reliable partner will give you a transparent and realistic timeline from the start, letting you plan your marketing campaigns and launch strategy without last-minute surprises.

For a new, custom private label product, plan for the entire process—from locking in your formula to having finished goods ready to ship—to take about 8 to 12 weeks. This window accounts for all the crucial steps that ensure your product is safe, compliant, and top-notch.

So, what’s happening during those weeks? Here’s a rough breakdown:

- Sourcing & Testing Raw Materials (2-3 weeks): Your specific maca root and any other ingredients are ordered. They undergo intense identity and purity testing before being allowed into the production facility.

- Pilot Batching & Flavor Approval (1-2 weeks): For custom formulas, the lab will create a small sample batch. You’ll get to personally approve the final taste, color, and feel before the main run starts.

- Full-Scale Production (2-4 weeks): This is the main event. Your product goes through extraction, blending, bottling, and labeling inside the cGMP-compliant facility.

- Final Quality Assurance (2-3 weeks): Before anything ships, the finished product goes through one last round of third-party lab testing to verify its potency and safety. All batch records are reviewed and signed off on for release.

Every brand wishes they had their product yesterday, but this methodical process is what protects you. It prevents costly recalls and ensures your launch is something to be proud of. An experienced Maca Root private label contract manufacturer doesn't see these quality checks as extra steps—they're just part of how things are done.

Answering Your Lingering Questions About Maca Manufacturing

Jumping into private label manufacturing can feel like learning a new language. You've done the research and you're close to a decision, but a few questions are probably still bouncing around in your head. That's completely normal.

Let's tackle some of the most common questions we hear from ambitious brand owners just like you.

What’s The Biggest Mistake New Brands Make?

Hands down, the single biggest misstep is choosing a partner based only on the lowest price per unit. We all have budgets, but an unusually low quote is almost always a red flag. It often means cut corners on raw materials, non-existent testing, or a surprise list of hidden fees that pop up later.

A real partnership is about value, not just cost. A slightly higher price tag usually points to superior ingredient quality, rigorous third-party testing, and a team that actually picks up the phone—all things that protect your brand’s reputation and save you from massive headaches down the road.

How Can I Be Sure Your Maca Is Actually High-Quality?

This is the question you should be asking any potential partner. The answer should always come back to two things: documentation and transparency. High-quality maca starts with ethical sourcing from trusted growers in Peru, but the proof is in the testing.

Here’s how we verify quality at every step:

- Raw Material Testing: Every single batch of incoming maca root is immediately quarantined. It doesn't get anywhere near our production floor until it's been tested for identity, purity, and potential contaminants.

- Finished Product Testing: Once your product is bottled, we send samples to an independent, third-party lab to verify its potency and safety one last time.

- Certificates of Analysis (COAs): You get a full COA for every single production run. This is your documented proof that what’s on your label is exactly what’s in the bottle.

Can You Help Me Create an Organic or Non-GMO Maca Formula?

Absolutely. This is one of the best parts of a custom private label partnership—the power to create products that meet specific consumer demands. We’ve built solid supply chains for sourcing certified USDA Organic and Non-GMO Project Verified maca root.

Getting these certifications for your final product involves a detailed documentation and verification process. We're here to guide you through that entire process, from start to finish. It’s what allows you to confidently put those valuable claims on your packaging and connect directly with health-conscious buyers.

Your manufacturer should be your compliance partner, not just a production line. They need the expertise to help you navigate certification requirements, ensuring your product isn't just effective, but also perfectly positioned for the market.

How Much Creative Control Do I Really Get?

You get 100% creative control. Think of us as your expert collaborators. We provide the scientific know-how and production muscle to bring your unique vision to life, but you're in the driver's seat.

You dictate all the core aspects of your product, including:

- The complete formula, from the specific type of maca extract down to every last synergistic ingredient.

- The flavor profile, which we can develop and tweak with you through as many sample iterations as it takes.

- All the packaging elements, including the bottle type, dropper style, label design, and even retail boxing.

Our job is to provide the technical guardrails—making sure the final product is stable, safe, and scalable. But the brand vision? That's all yours. We're here to empower you, not limit you.

Ready to turn your vision for a premium maca root supplement into a market-ready reality? At Triton Nutra Group, we act as your dedicated R&D and manufacturing partner, providing the quality, flexibility, and speed you need to succeed. Request a free quote today and let's build your brand together. https://tritonnutragroup.com