Your Partner in Hawthorne Berries Private Label Manufacturing

Partner with a leading Hawthorne Berries private label contract manufacturer to create custom liquid supplements. We guide you from concept to market.

Get a Free Quote Today!

Get a Free Quote Today!If you're looking to break into the booming botanical supplement market, partnering with a Hawthorne Berries private label contract manufacturer is the smartest first move. This approach lets you launch a custom, high-quality liquid supplement under your own brand without the staggering overhead of building and certifying your own production facility. We act as an extension of your team—your R&D partner from concept through launch—handling everything from formulation to bottling and fulfillment.

Bringing Your Hawthorne Berry Supplement to Life

So you have a great idea for a Hawthorne Berry product, but the path from concept to shelf feels daunting. How do you navigate the maze of formulation, regulatory compliance, and production? That's where a manufacturing partner comes in. This guide breaks down exactly how to find and collaborate with the right one to make your vision a market-ready reality.

Forget thinking of us as just a supplier. We're your dedicated R&D and production crew. We’ll walk you through the entire journey, step by step, demonstrating why a collaborative partner is the single most critical decision for your brand's growth and speed to market.

Capitalizing on a Growing Market

The buzz around Hawthorne Berry isn't just hype; it’s backed by serious market growth. The global hawthorn berry extract market is on a steep upward trajectory, with some projections showing it could blow past $1.4 billion by 2032.

That's an impressive growth rate of around 7% annually. This surge in consumer interest creates the perfect opening for both new and established brands to innovate and capture a piece of the pie.

Choosing the right manufacturing partner is about more than just production. It's about finding a collaborator who understands your vision and has the technical expertise, quality systems, and flexible capabilities to execute it flawlessly.

This is your roadmap for starting your own custom liquid supplement brand, detailing the key steps from concept to creation. As you get ready to launch, remember that a strong online presence is non-negotiable. For that, you can reference this complete guide to small business website development to build out your digital storefront. Our process is built for clarity and speed, ensuring your product launch is as successful as it is efficient.

Crafting Your Custom Hawthorne Berry Formula

This is where the magic happens. Your idea for a Hawthorne Berry supplement is about to go from a concept on a whiteboard to a real, market-ready product. It all boils down to creating a standout formula, and that process starts with a deep dive into who your customer is and what kind of product you want to give them.

Are you picturing a high-potency tincture? Maybe a tasty daily syrup or a quick, convenient liquid shot? Whatever you've got in mind, the final formula has to deliver on your brand's promise. As your manufacturing partner, we jump into the R&D trenches with you to make that vision a reality.

From Ingredient Synergy to Flavor Profile

Let’s get practical. Imagine you want to create a tincture specifically for heart health. Hawthorne Berry is your star ingredient, of course, but you know you can make it even better by adding other synergistic herbs.

This is where our formulation experts come in. We’ll sit down with you and explore botanicals that complement Hawthorne. Maybe we add hibiscus for its well-known cardiovascular support or a little garlic extract to help with circulation. Every single ingredient is chosen for a reason, backed by solid research to make sure it’s both effective and safe.

This hands-on process looks at several key areas:

- Active Ingredient Sourcing: We source the absolute best Hawthorne Berry extracts and complementary herbs from our network of vetted, trusted suppliers, ensuring purity and consistency from the start.

- Flavor Masking & Enhancement: Let's be honest—herbal tinctures can taste pretty... earthy. Our R&D team excels at developing custom flavor profiles using natural sweeteners like stevia or monk fruit. The goal is a product people actually enjoy taking every day.

- Stability and Preservation: We leverage advanced techniques like cold-fill technology to protect the delicate bioactive compounds in every botanical. This is crucial for ensuring your supplement remains potent and stable for its entire shelf life.

Defining Your Product's Core Components

Every single drop in your formula needs to have a purpose. We break it all down into two simple categories: active ingredients (the ones doing the heavy lifting for health benefits) and inactive ingredients (the support crew that handles stability, texture, and taste).

Your formula is your brand’s unique fingerprint. The right manufacturing partner doesn’t just mix ingredients; they help you engineer a product that is effective, stable, and distinct in a crowded marketplace.

For example, your active ingredients might be Hawthorne Berry extract and hibiscus flower extract. The inactives could be purified water, organic vegetable glycerin to act as a solvent, and a natural berry flavor. We lay it all out for you, explaining what each component does so you’re in the driver’s seat. For a more detailed look, you can read our guide on how to create a supplement formula from scratch. We believe an informed partner is a successful one.

Our job is to guide you through every decision, from picking the perfect extraction method to getting the taste just right. This partnership approach takes the guesswork out of the equation, so you can put your energy into building your brand while we handle perfecting the product. The result? A custom, effective, and totally unique supplement that’s ready to fly off the shelves.

Navigating Quality and Compliance in Manufacturing

When you're building a supplement brand, your reputation is everything. It's built on trust. Your customers expect a product that's safe, effective, and has exactly what the label says it has—every single time. A single misstep can be incredibly damaging.

That’s why prioritizing quality and compliance isn't just about checking a box; it’s the bedrock of your brand. When you partner with a Hawthorne Berries private label contract manufacturer, their certifications and processes become your quality guarantee.

Choosing a partner who operates in a cGMP, UL certified, and FDA-registered facility means every step of the process is held to an incredibly high standard. It’s not about certificates on a wall; it’s about a daily, living commitment to quality that protects your product from the moment raw ingredients arrive until the finished bottle ships out.

From Raw Material to Finished Product

Real quality control is an active, hands-on process. It begins the moment raw Hawthorne Berries arrive at our facility.

Here’s a look at how those standards are put into practice:

- Strict Quarantine and Testing: Every batch of incoming raw material is immediately placed in quarantine. It doesn’t move to the production line until it has been rigorously tested for identity, purity, and potency.

- In-Process Checks: As your formula is blended and bottled, our technicians perform multiple checks along the way to guarantee consistency and ensure it perfectly matches your master formula.

- Final Product Verification: Before any product gets the green light for release, a final sample is sent for third-party testing to confirm it meets every one of your specifications.

This isn't overkill. It's the meticulous, step-by-step approach that ensures the Hawthorne Berry supplement you envisioned is exactly what lands in your customer's hands. Part of this process also involves securing the right global compliance certification, which is a must-have for brands looking to sell in domestic and international markets.

Decoding Manufacturing Certifications and What They Mean For Your Brand

It's easy to get lost in the alphabet soup of manufacturing certifications. But understanding what they represent is crucial for vetting a potential partner and protecting your brand. Each one is a promise of quality and safety.

Here’s a simple breakdown of the big ones and why they should matter to you.

| Certification | What It Guarantees | Why It Matters to Your Brand |

|---|---|---|

| cGMP | Adherence to the FDA's Current Good Manufacturing Practices for quality and consistency. | This is the foundation of a quality operation. It ensures your product is made in a clean, controlled environment. |

| UL | The facility meets stringent, globally recognized safety and quality standards. | Provides an extra layer of trust and verification, showing a commitment to safety beyond the bare minimum. |

| FDA Registered | The facility is known to the FDA and is subject to their inspections and oversight. | This is non-negotiable. It means the manufacturer is operating legally and transparently within the US. |

| Organic | Products are made with at least 95% certified organic ingredients and no prohibited substances. | If you're targeting the natural/organic market, this certification is essential for brand credibility. |

| NSF | Independent testing confirms that what's on the label is in the bottle, without contaminants. | A powerful marketing tool that builds consumer confidence and proves your commitment to transparency. |

These certifications aren't just for show; they are tangible proof that your manufacturing partner takes quality as seriously as you do.

Decoding the Certificate of Analysis (COA)

Transparency is absolutely non-negotiable. Once production is complete, every batch of your product should come with a Certificate of Analysis (COA) from an independent, third-party lab. This document is your concrete proof of quality, but it can look like a wall of technical jargon if you don't know what you're looking for.

A COA is more than just a piece of paper; it’s your guarantee that the product in the bottle matches the claims on your label. Think of it as the ultimate tool for accountability and brand protection.

When you get a COA for your Hawthorne Berry liquid supplement, you need to zero in on two key things: potency, which confirms the concentration of the active compounds, and purity, which screens for harmful contaminants like heavy metals and microbes. This third-party validation is what truly safeguards your brand and builds unwavering trust with your customers.

Understanding the full scope of dietary supplement manufacturing requirements is critical for any brand owner who wants to stay compliant and maintain a reputation for quality.

A Look Inside the Production Process

So, your custom formula is locked in, and the raw materials have all passed our tough quality checks. What happens next? This is where your product comes to life, but for many brand founders, it can feel like a black box. Our goal is to pull back the curtain and show you exactly how your Hawthorne Berry supplement gets made with precision and speed.

This isn't just about mixing ingredients; it's a meticulously crafted process designed for reliability and rapid turnaround. We turn your approved formula into a shelf-ready product, protecting the quality and reputation you're working so hard to build. Think of us as your dedicated production partner, handling all the complex moving parts so you can stay focused on your launch.

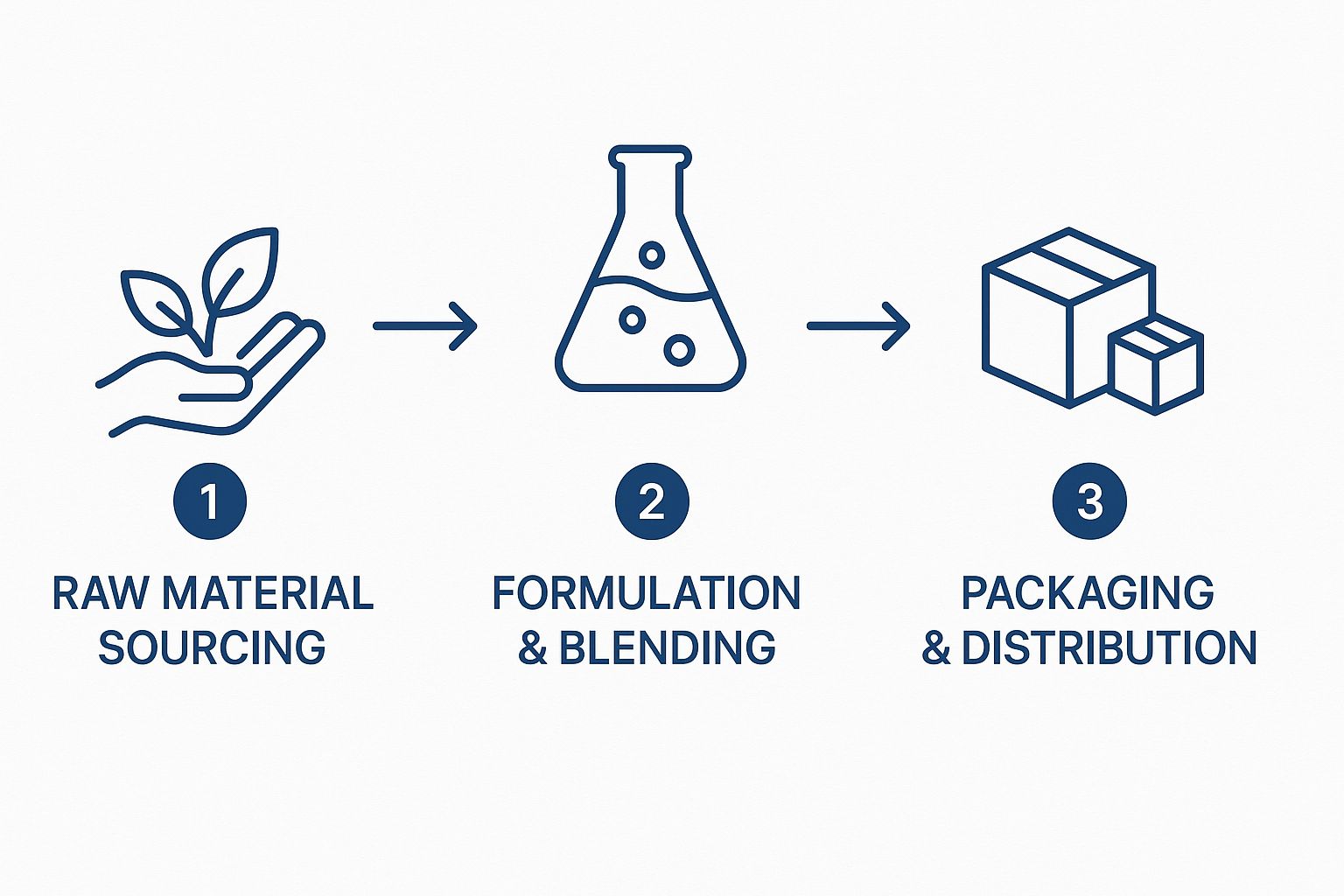

To give you a bird's-eye view, this infographic maps out the core stages of our manufacturing workflow, from sourcing all the way to final distribution.

As you can see, it’s a logical flow. Each step seamlessly feeds into the next, which is key to keeping the production cycle efficient and on time.

Blending and Filling with Precision

First stop on the production floor: the blending stage. This is where your specific Hawthorne Berry extract and any other synergistic ingredients get carefully combined in our state-of-the-art mixing vessels. It’s far more than a simple stir. We use a controlled process that ensures every single drop of the liquid is homogenous, guaranteeing consistent potency across every bottle.

From there, the blend moves to our filling line. This is where you’ll see our operational flexibility in action. Whether you've opted for 1 oz glass dropper bottles for a high-potency tincture or 2 oz single-serving shots for grab-and-go convenience, our automated equipment is calibrated for pinpoint accuracy. It dispenses the exact volume required, minimizing waste and ensuring your customers get the correct dosage every single time.

We use cold-fill technology, and this is a big deal. Unlike hot-fill processes that can actually degrade the delicate compounds in botanicals, our method preserves the full integrity and potency of your Hawthorne Berry extract. The result is a much more effective final product for your customers.

Capping, Labeling, and Final Checks

Right after filling, each bottle is immediately capped and sealed. This is a critical step that protects your supplement from oxidation and contamination, effectively locking in its freshness and extending its shelf life. We handle all kinds of closures, from standard screw caps to tamper-evident dropper tops.

Finally, your custom-designed labels are applied. Our machinery ensures perfect alignment and adhesion, giving your product that polished, professional look it needs to stand out on a crowded physical or digital shelf. Before anything gets boxed up, a final quality assurance check verifies that every single unit is correctly filled, capped, labeled, and coded with a batch number and expiration date.

As your Hawthorne Berries private label contract manufacturer, we manage this entire workflow from start to finish. This streamlined process allows for an incredibly rapid turnaround, whether you're starting with a small pilot run or placing a full-scale production order.

Going from Pilot Run to Full Production

Every brand dreams of growth, and your manufacturing partner needs to be ready to grow right there with you. A smart launch isn't about going all-in from day one. The best approach is a calculated pilot run to test the market, followed by a smooth ramp-up to full production once you know you've got a winner.

This method de-risks your launch and keeps initial costs down. You get to prove your product-market fit with actual sales data, not just hopeful forecasts, before committing to a warehouse full of inventory. It’s all about being nimble, learning fast, and making decisions based on what customers are actually doing.

The Pilot Run: Your Secret Weapon

Think of a pilot run as your first strategic move on the chessboard. For a new e-commerce brand launching a Hawthorne Berry tincture, starting with a 1,000-unit batch is the perfect way to test out marketing campaigns and see what real customers think. This initial order gives you priceless insights without the financial headache of a huge commitment.

Here’s what this approach lets you do:

- Validate Your Marketing: You can test ad copy, target different audiences, and try out promotional ideas on a small scale to see what resonates before investing heavily.

- Get Real Feedback: Early customer reviews are pure gold. They tell you if you need to tweak the formula, adjust the packaging, or change your marketing message for the next production run.

- Keep Financial Risk Low: A smaller first order means less cash is tied up in stock. That frees up capital for marketing, operations, and other activities that drive growth.

This is a fundamental way a modern Hawthorne Berries private label contract manufacturer helps new brands get off the ground. Our flexibility to accommodate small runs gives you a huge advantage in a competitive market.

A pilot run isn't just a "small order"—it's a market intelligence mission. It turns your launch from a blind gamble into a data-backed business strategy, paving the way for real, sustainable growth.

Scaling Up Without Skipping a Beat

Once your pilot run takes off and the sales numbers look solid, it's time to hit the accelerator. This is where having a flexible manufacturing partner really pays off. You can confidently jump from that initial 1,000 units to a 25,000-unit order to keep up with surging demand.

That transition feels seamless. We already have your formula, packaging specs, and all quality control checkpoints locked in. We simply scale the production schedule to handle the larger volume, ensuring the product that hits the market is the exact same high-quality formula your first customers loved. This reliability is key to building brand loyalty.

The upside of scaling is huge. Larger production runs bring your cost-per-unit way down, which goes straight to your bottom line. This efficiency means you can reinvest more into marketing, develop new products, or just enjoy healthier profit margins.

Hawthorne Berries private label contract manufacturing is built to be a scalable solution for brands at every stage. A typical pilot run starts around 1,000 units, but we have the capacity to support full-volume runs that can top 50,000 units as your brand becomes a household name. You can learn more about how these scalable manufacturing solutions work at Triton Nutra Group. Our goal is to be your partner for the long haul, supporting your journey from that very first sale to market leadership.

Common Questions About Private Label Manufacturing

Stepping into a partnership with a Hawthorne Berries private label contract manufacturer is a big move, and it's only natural to have a few questions. We get it. To give you some clarity, we've pulled together the most common things we hear from brand founders and product managers just like you.

This isn't just about logistics; it’s about understanding the real-world nuts and bolts of turning your vision into a product that lands on shelves. Let’s get into the details that truly matter.

What Is a Typical Minimum Order Quantity (MOQ)?

This is usually the first thing people ask, especially startups and e-commerce brands managing cash flow. While MOQs can vary across the industry, we pride ourselves on flexibility.

Our process is built to support brands at every stage. We can kick things off with pilot runs as low as 1,000 units. This lets you test the market, get crucial feedback from your first customers, and validate marketing channels—all without a massive upfront investment. Think of it as de-risking your launch, a core part of our partnership mindset.

How Long Does the Process Take from Start to Finish?

Getting to market quickly is crucial, but not at the expense of quality. We’ve streamlined our operations for efficiency without cutting corners. A reliable timeline—from finalizing your formula to having the finished product ready to ship—is between 8 to 12 weeks.

So, what happens during that time?

- Formula & Labeling Finalization: First, we lock in all the components and make sure your branding is compliant and ready for printing.

- Raw Material Sourcing & Testing: We then source and rigorously test every single ingredient. This is a critical quality and safety step.

- Production & Quality Control: This is where the magic happens—blending, filling, and bottling. It concludes with final third-party testing to generate your Certificate of Analysis (COA).

We provide a clear, transparent timeline from day one, so you're never left wondering where things stand. Our commitment is to deliver your high-quality Hawthorne Berry supplement on time, every time.

Do I Retain Ownership of My Custom Formula?

Absolutely, and this is non-negotiable for us. When we collaborate to create a custom formula for your Hawthorne Berry supplement, that intellectual property is 100% yours.

Your proprietary formula is one of your brand's most valuable assets. We protect it from the start with a Non-Disclosure Agreement (NDA), guaranteeing your unique blend remains exclusively yours. We're your manufacturing partner, not your competitor.

This commitment to protecting your IP is fundamental to how we do business. Our role is to execute your vision and produce it to the highest standard possible. You always keep full ownership and control over the very thing that makes your product unique. This way, you can build long-term brand equity without ever worrying about your formula being copied.

Ready to turn your Hawthorne Berry supplement idea into a market-ready reality? The expert team at Triton Nutra Group is here to be your dedicated R&D and production partner, guiding you from concept to launch with transparency and unmatched quality. Request a free quote today and let’s build your brand together.