Your Expert Partner: A Guide to Hawthorn Berries Private Label Contract Manufacturing

Partner with a leading Hawthrone Berries private label contract manufacturer to launch your supplement. Learn about formulation, production, and how to choose the right manufacturer.

Get a Free Quote Today!

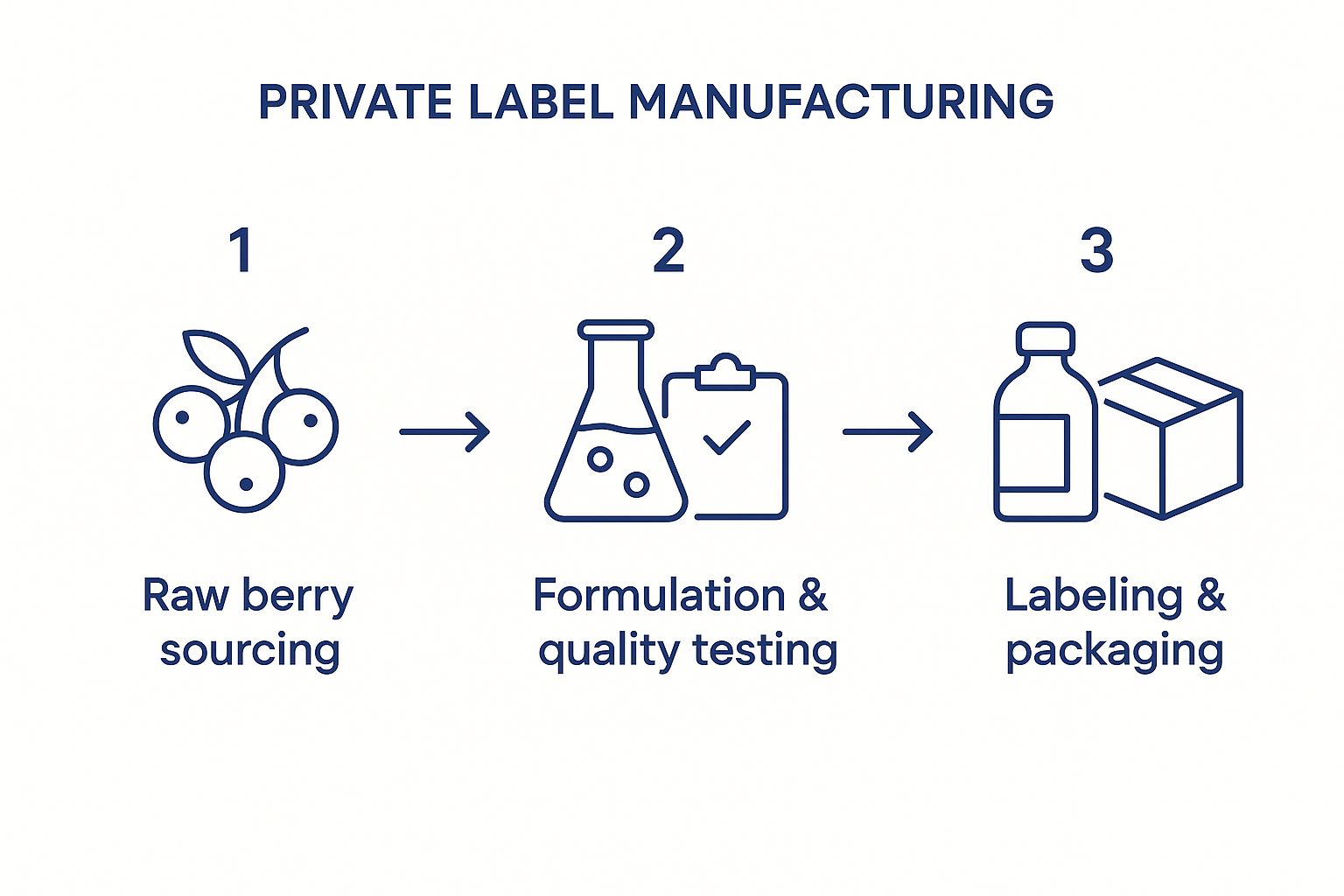

Get a Free Quote Today!You've identified a strong market opportunity with hawthorn berry supplements. That's a great first step, but your brand's success hinges entirely on who you choose to produce it. This is where a Hawthorn Berries private label contract manufacturer becomes your most critical partner. Partnering with an expert allows you to leverage their compliant facilities, advanced technology, and deep formulation know-how from day one.

Why Private Label Is Your Smartest Path to Market

Bringing a new supplement to life is a massive undertaking. You have a clear vision: a top-tier hawthorn berry liquid supplement that resonates with health-conscious consumers. The reality, however, involves navigating a maze of complex regulations, sourcing verified raw botanicals, and investing millions into a manufacturing facility.

A private label partnership is your strategic shortcut. Instead of building from scratch, you team up with an industry insider who has already mastered the operational complexities. You gain immediate access to our UL certified, cGMP, and FDA-registered facility without the crippling overhead costs, allowing you to focus on growth.

Private Label vs. In-House Manufacturing Snapshot

Choosing between a private label partnership and building your own facility is a critical decision. Each path has vastly different impacts on your capital, timeline, and business focus. This table breaks down the core differences in clear terms.

| Factor | Private Label Partner | In-House Manufacturing |

|---|---|---|

| Initial Investment | Low (no facility or equipment costs) | Extremely High (millions for facility, staff, etc.) |

| Time to Market | Rapid (weeks to months) | Slow (years) |

| Regulatory Burden | Handled by your manufacturing partner (us) | Your full responsibility (FDA, cGMP, etc.) |

| Expertise Required | Brand building, marketing, and sales | Formulation, operations, compliance, and QC |

| Flexibility | Start with pilot runs, test the market | Locked into high-volume production |

| Core Business Focus | Growing your brand and connecting with customers | Managing production and supply chain logistics |

The private label model is engineered for speed and capital efficiency. It empowers you to concentrate on what actually scales a brand: powerful marketing and authentic customer relationships. Building in-house offers total control but comes with immense financial and operational burdens that can sink a new company before it launches.

Accelerate Your Launch and Focus on Growth

The single greatest benefit is speed. A dedicated Hawthorne Berries private label contract manufacturer has the validated processes, advanced machinery, and reliable supply chains ready to go. Our streamlined approach can slash your time-to-market from years down to just a few months—a decisive advantage in today's competitive landscape.

This operational efficiency means you can invest your most valuable resources—time and capital—into what you do best:

- Building Your Brand: Focus your energy on compelling storytelling, smart marketing, and creating a loyal community around your product.

- Connecting with Customers: Engage directly with your audience and build loyalty without being bogged down by production logistics.

- Strategic Planning: Before launching, it's wise to get a clear picture of the market by performing a thorough SWOT analysis.

Tap Into a Booming Market with Confidence

The demand for hawthorn berry is strong and growing. The global hawthorn berry extract market was valued at approximately USD 597.2 million, demonstrating significant consumer interest in natural cardiovascular health support. Partnering with an expert manufacturer gives you a credible, compliant, and premium product to confidently enter this expanding market.

A partnership mindset is key. We function as your R&D partner, guiding you from concept through launch to ensure your vision becomes a market-ready reality.

Ultimately, private labeling de-risks your entire venture. Our flexible run sizes, from pilot to full scale, allow you to test your product without being buried under excess inventory. To understand this journey better, explore our comprehensive guide for starting your own brand. We help you launch smarter, not harder.

Vetting Your Future Manufacturing Partner

Choosing your hawthorn berry private label contract manufacturer is the single most important decision your brand will make. This isn't just about finding a supplier; it's about selecting a partner whose standards will define your product's quality, safety, and your brand's reputation.

Get this right, and you have a powerful engine for growth. Get it wrong, and your brand can stall before it ever gains momentum.

Your vetting process must go far beyond a website overview. You need to dig into certifications, processes, and real-world capabilities. Before making calls, familiarize yourself with essential vendor management best practices to build a framework for selecting a partner who aligns with your business goals.

First, demand proof of core certifications.

A true manufacturing partner will have their documentation ready and offer it proactively. If you have to press just to see a cGMP certificate or FDA registration, that’s a major red flag about their commitment to transparency.

From Paperwork To Practice

Certifications are the entry ticket—the absolute baseline, not the finish line. Any manufacturer you consider must provide current copies of their essential documents without hesitation. Once you have that paperwork, the real diligence begins.

Here are the key credentials you must verify:

- cGMP Certification: Don't just look at the certificate; verify it's from a reputable body like UL. A cGMP-certified facility adheres to the FDA's strict quality standards for manufacturing, packaging, and holding.

- FDA Registration: The FDA does not "approve" supplement facilities, but they must be registered. This is non-negotiable for legal compliance in the U.S.

- Third-Party Audits: Ask for other certifications, such as those from UL or NSF. These independent audits provide another layer of assurance that their quality systems are robust and consistently followed.

With the basics covered, probe their specific expertise with botanicals. Hawthorn berry is not a simple vitamin. Its quality depends on proper sourcing, precise botanical identification, and advanced extraction methods. You need a partner who understands the nuances of herbal manufacturing.

Think about each stage. Sourcing, formulation, packaging—every step is a control point where quality is either protected or compromised. Your job is to find out how they protect it.

Asking The Right Questions About Quality

How a manufacturer answers specific, technical questions reveals their true capabilities. Ditch generic inquiries and focus on details that directly impact your hawthorn berry supplement. You can get more ideas by exploring our guide on key considerations for finding a reputable supplement manufacturer for your brand.

Here are some of the most critical questions to ask:

- Raw Material Sourcing: "Walk me through your vendor qualification program for hawthorn berries. What specific documentation do you require from your raw material suppliers?"

- Identity Testing: "What specific methods, like HPTLC, do you use to confirm the botanical identity and purity of incoming raw hawthorn berry?"

- Extraction Technology: "What extraction methods do you offer? We're interested in innovative, temperature-controlled options to preserve delicate phytonutrients."

- Finished Product Testing: "Will my finished product be tested by an independent, third-party lab for potency, heavy metals, and microbes? Will I receive a copy of the Certificate of Analysis (CofA) for every batch?"

Their answers—or lack thereof—will tell you everything. A true partner will welcome these questions with confident, detailed answers.

Creating Your Unique Hawthorn Berry Formula

In a crowded supplement market, a generic product is an invisible one. Your brand's success hinges on creating a formula that stands out. This is where the right Hawthorn Berries private label contract manufacturer becomes your strategic R&D partner.

We are not just order-takers. Think of us as your outsourced R&D team, dedicated to translating your vision into a unique, effective, and marketable supplement. This is where we infuse your brand's DNA into the product itself. It’s the difference between a simple hawthorn extract and a thoughtfully crafted formulation designed for a specific customer.

A great manufacturing partner is your product development co-pilot. You set the destination—your brand vision and target customer—while we provide the technical expertise to navigate botanical synergy, flavoring, and bioavailability. Together, we create a winning product.

From Initial Brief To Pilot Batch

The process begins with your product brief. This is more than a list of ingredients; it's the blueprint for your product. Who is it for? What problem does it solve? What makes it different? A detailed brief empowers our formulation team to provide strategic, meaningful recommendations from day one.

From that brief, the journey unfolds in a few key stages:

- Formula Development: This is a core collaborative phase. Our experts work with you to dial in extract concentrations, suggest synergistic botanicals, and select the perfect delivery format—from potent liquid tinctures to convenient sprays.

- Flavor Profiling: For liquid supplements, taste is paramount. Our team develops flavor profiles that mask hawthorn's natural earthiness while aligning with your brand’s identity, whether that's a clean, minty finish or a sweet, berry-forward taste.

- Pilot Batch & Sampling: Before committing to a full production run, you get hands-on with pilot batches. This is your chance to taste, test, and provide feedback. This iterative loop ensures the final product is precisely what you envisioned.

This collaborative process is crucial for nailing every detail. If you're new to this side of the business, our guide on how to create a supplement formula offers a great primer on what to expect.

Two Scenarios, One Goal: Differentiation

To see this in action, let's imagine two different brands developing a hawthorn supplement.

Scenario A: The High-Potency Tincture

- Goal: A pure, powerful hawthorn berry liquid extract targeting knowledgeable consumers who demand maximum potency.

- Development Focus: The conversation centers on the science of extraction. We would recommend a specialized, cold-fill process to preserve delicate flavonoids and oligomeric proanthocyanidins (OPCs). The final product would be a high-concentration, single-ingredient tincture with minimal flavoring to signal its purity and strength.

Scenario B: The Comprehensive Cardio Blend

- Goal: A daily liquid supplement for broad cardiovascular wellness, aimed at a mainstream audience.

- Development Focus: Here, synergy is the goal. Our R&D team would suggest complementing hawthorn with other heart-supportive ingredients like CoQ10 for cellular energy, magnesium for muscle function, and hibiscus for blood pressure support. Flavoring becomes a top priority to ensure daily compliance and enjoyment.

In both scenarios, our partnership approach results in a product perfectly tailored to a specific market need—a world away from a generic stock formula. This level of customization is what turns a commodity into a trusted, must-have brand.

Going from Pilot Run to Full-Volume Production

You've perfected your unique hawthorn berry formula. That's a huge milestone. Now, the focus shifts from product creation to smart, strategic manufacturing. This is where many promising brands hit a wall—they get locked into a production agreement that can't scale with them.

The strategic move is to find a partner who values flexibility. You need the ability to start with a small, manageable pilot run. Think of this as your live market test. It lets you validate customer response, fine-tune marketing, and build early momentum without tying up all your capital in inventory.

As sales data comes in and demand climbs, the shift to full-scale production should feel seamless. This is where a top-tier Hawthorne Berries private label contract manufacturer proves its value, ensuring rapid, reliable scaling.

Making Sense of Production Timelines and MOQs

One of the biggest hurdles for new brands is the Minimum Order Quantity (MOQ). Many manufacturers won't engage unless you commit to tens of thousands of units—a non-starter for most launches. A true partner invested in your growth offers flexible MOQs, allowing you to start small and scale as your sales justify it.

Your production timeline is the other critical piece. A transparent partner provides a clear, realistic schedule upfront. Once you approve your pilot batch, the clock starts on a process that includes:

- Sourcing and Verification: Securing and testing the high-quality hawthorn berries for your formula.

- Production & Quality Checks: The core manufacturing phase, conducted under strict cGMP protocols.

- Third-Party Lab Testing: A sample from your finished batch is sent to an independent lab to confirm potency and purity. You will always receive a Certificate of Analysis (CofA).

- Bottling and Packaging: The final step before your product is ready for shipment.

For a full-scale run, this entire process typically takes 6-8 weeks after final formula approval. Clear, consistent communication from your manufacturing partner is non-negotiable; it's what ensures on-time delivery.

The ability to grow without switching partners is one of the most underrated assets for a new brand. Outgrowing your manufacturer just as you hit your stride creates massive disruptions in supply, quality control, and momentum. It's a costly and avoidable headache.

Scaling a specialized product like a hawthorn berry extract presents unique challenges. Industry research confirms that finding affordable, appropriately-sized manufacturing is a major pain point. This is why partnering with a contract manufacturer offering ‘right-sized’ production is such a powerful strategic advantage. You can dive deeper into these industry dynamics by reading about manufacturing capacity insights for specialized products on auri.org.

Ultimately, your goal is to find a partner who gives a 1,000-unit pilot run the same focus and precision as a 100,000-unit order. That flexibility is the foundation for smart inventory management, healthy cash flow, and scalable, long-term success.

Breaking Down Costs to Ensure Profitability

A fantastic product is only part of the equation. A profitable product is what builds a sustainable brand. Understanding the financials behind private label manufacturing is non-negotiable. It allows you to collaborate effectively with your partner and set a retail price that ensures healthy margins from day one.

As a dedicated Hawthorne Berries private label contract manufacturer, we believe in complete transparency. Your final per-unit price is a sum of several key parts. When you understand these components, you can work with us to identify efficiencies and build a solid financial foundation for your brand.

Dissecting the Core Cost Components

So, what exactly are you paying for? A clear quote from a reputable manufacturer should break this down to eliminate surprises. You need a complete picture of where every dollar goes.

Here are the primary costs that make up your final price:

- Raw Material Sourcing: The cost of high-quality, verified hawthorn berries can fluctuate based on harvest quality and global demand. A manufacturer with strong, long-term supplier relationships can help secure stable, competitive pricing.

- R&D and Formulation: For a fully custom formula, there may be a one-time fee. Consider this an investment in creating a unique, defensible product.

- Per-Unit Production: This is the core manufacturing cost. It covers blending, filling, and the continuous quality checks that occur during the production run.

- Packaging and Labeling: This includes your bottles, caps, seals, and the labor to apply your branded labels. Sourcing these components in bulk is a classic way to reduce per-unit costs.

- Third-Party Lab Testing: This is non-negotiable. This cost covers independent verification of every batch's potency and purity—a critical investment in your brand's credibility and your customers' trust.

Your first production run is a learning curve. The initial unit cost may be higher as processes are dialed in. Subsequent, larger runs almost always benefit from economies of scale, leading to a lower per-unit price and healthier margins for your business.

The Impact of Volume on Your Bottom Line

The relationship between production volume and unit cost is simple but powerful. A pilot run of 1,000 units will have a higher cost per bottle than a full-scale order of 50,000 units. This is because all setup, labor, and testing fees are spread across a much larger number of finished products.

For instance, manufacturers often see their own margins change over a contract's lifecycle. The first run has higher internal costs due to setup and calibration. Later, bigger runs become far more efficient and profitable for everyone. Understanding this dynamic is crucial for planning your financial strategy, especially when dealing with natural ingredients like hawthorn berries. You can get more insight into these revenue and margin considerations on bdo.com.

When you work with a partner who provides a transparent cost breakdown, you can make smarter decisions. You'll see exactly how ordering more packaging or increasing your run size impacts your Cost of Goods Sold (COGS). This collaboration is what enables you to strategically build a profitable product, from concept to launch.

Common Questions About Hawthorn Berry Manufacturing

As you move closer to launching your hawthorn berry supplement, big-picture ideas shift to practical details. You're moving past the "why" and focusing on the "how." For entrepreneurs and brand managers, getting clear answers to these questions is critical. It impacts your launch plan, budget, and choice of a Hawthorn Berries private label contract manufacturer.

Here are direct, no-jargon answers to the most common questions we hear from brands ready to move forward.

What Are the Typical Lead Times for a New Product?

This is often the first question asked, as it directly impacts your marketing calendar and launch strategy. While every project is unique, a good rule of thumb is a 12 to 16-week process from start to finish.

This timeline is built from critical phases that ensure a quality product and cannot be rushed:

- Formula Development & Approval (4-6 weeks): This is our collaborative stage. We finalize your unique formula, create and ship samples for your approval, and ensure your label design is compliant and production-ready.

- Production & Testing (6-8 weeks): Once you approve the formula and label, production begins. This window covers raw material sourcing and verification, the manufacturing run, third-party lab testing, and final bottling and packaging. Our commitment is to a transparent timeline and a reliable, on-time delivery record.

What Quality Documentation Should I Receive?

This question is a deal-breaker. For every single batch, you must receive a complete set of quality documents. Our commitment to quality and compliance means this is a standard part of our process.

The Certificate of Analysis (CofA) is the single most important document you will receive. It is your proof—and your customer's guarantee—that what's in the bottle is safe, pure, and delivers the potency claimed on your label. We never compromise on this.

You will always receive a finished product CofA detailing the results from an independent, third-party lab. This report confirms the product's identity and potency and verifies that it is free from contaminants like heavy metals or microbes. We can also provide the CofAs for the raw hawthorn berry used in your batch for complete traceability.

Can I Supply My Own Branded Packaging?

Yes, absolutely. As a flexible manufacturing partner, we can easily work with your custom-supplied bottles, caps, or other packaging components. The key to a seamless process is close collaboration.

We will provide die-lines—the exact digital templates for your labels. Using these ensures a perfect fit and smooth application on our automated machinery. We will also need to approve your chosen bottles and caps to confirm compatibility with our equipment and ensure they properly protect the integrity of your liquid supplement.

How Are Raw Hawthorn Berries Sourced and Verified?

The quality of the final product begins with the raw ingredient. We don't just shop for the cheapest materials; we operate a strict vendor qualification program.

This means sourcing only from trusted, pre-vetted suppliers who provide extensive documentation on the botanical’s origin and harvesting methods. When a new shipment of raw hawthorn arrives, it is quarantined and must pass a series of identity and purity tests before it is approved for use.

This always includes rigorous identity testing—often using advanced methods like HPTLC—to confirm it is the correct Crataegus species. It’s also screened for potential contaminants to guarantee purity from the very start.

Ready to turn your vision for a premium hawthorn berry supplement into a market-ready reality? At Triton Nutra Group, we act as your dedicated R&D and manufacturing partner, guiding you from concept to launch with transparency and expertise. Request your free quote today and let's build your brand together.