Your Partner in Launching a Premier Garlic Bulb Supplement

Learn how to choose the best Garlic Bulb private label contract manufacturer for quality, compliance, and reliable supply chain success.

Get a Free Quote Today!

Get a Free Quote Today!Launching a new supplement is a huge undertaking. When you're ready to bring a garlic bulb product to market, you'll need a "Garlic Bulb private label contract manufacturer." Simply put, this is a specialized company that handles all the heavy lifting—from formulation and production to bottling and labeling—so you can launch a premium product under your own brand name.

This partnership is a game-changer for entrepreneurs and established brands alike. It allows you to enter the market quickly, without the massive capital investment in manufacturing facilities, the headache of navigating complex FDA regulations, or the stress of managing a global supply chain. A true partner handles the operational complexities, freeing you to focus on what you do best: building your brand and connecting with your customers.

Why Your Manufacturer Is Your Most Important Partner

Let's be direct: choosing your private label contract manufacturer is the single most critical decision you'll make. This isn't just about finding a vendor to fill bottles. It's about finding a strategic partner who is deeply embedded in the world of botanical supplements. Your choice will directly impact your product’s quality, your regulatory compliance, and ultimately, your brand's reputation.

Think of your manufacturer as a true extension of your team. A great partner acts as your R&D lab, your quality control department, and your compliance experts, all rolled into one. Anyone can take an order, but a real partner brings deep industry expertise to the table—and that innovative, collaborative mindset makes all the difference.

The Difference Between a Supplier and a Partner

A supplier will give you exactly what you ask for. A partner, on the other hand, collaborates with you to create the best possible version of your product. That distinction is everything in the crowded health and wellness market.

Here’s where a true partnership shines:

- Formulation Expertise: We advise on the most effective forms of garlic extract, suggest synergistic ingredients, and ensure your final formula is stable, potent, and innovative.

- Regulatory Navigation: As a cGMP, UL-certified, and FDA-registered facility, we ensure your product is not just legal and safe to sell, but manufactured to the highest quality standards. This isn't a bonus; it's our baseline.

- Supply Chain Management: We leverage established relationships with premier raw material suppliers. This de-risks your launch by securing high-quality garlic and insulating you from supply shortages or price spikes.

- Speed & Reliability: We offer turnkey solutions with rapid, transparent timelines, from pilot runs to full-scale production, all managed through a system built for on-time delivery.

To really grasp how vital this relationship is, it's helpful to have a solid understanding of private labeling on Amazon, where quality and compliance can make or break a business.

Your manufacturer is the gatekeeper of your brand’s reputation. Our commitment to quality, transparency, and compliance directly translates into the trust consumers place in your products. A failure on their end becomes a failure of your brand.

Ultimately, choosing the right manufacturing partner does more than just get a product made. It builds the foundation for scalable growth. We provide the operational backbone that lets you market your garlic bulb supplement with total confidence, knowing it was built for success from concept to launch.

Mastering Quality Control and Compliance

In the supplement world, your brand's reputation is everything. It’s built on trust—the trust that your product is safe, effective, and precisely what the label claims. A brilliant marketing campaign can't save a brand from a quality failure. For any brand, from startup to enterprise, getting this right is non-negotiable.

When vetting a potential Garlic Bulb private label contract manufacturer, you'll encounter a series of acronyms and certifications. These aren't just industry jargon; they are the bedrock of a safe, compliant, and high-quality operation. Understanding what they truly mean is the first step to protecting your brand and your customers.

Decoding the Alphabet Soup of Quality

Let's cut through the noise and focus on the certifications that truly matter. Seeing these on a manufacturer’s site is a good start, but knowing what’s behind them empowers you to ask the right questions.

-

cGMP Certified: Short for Current Good Manufacturing Practices, this is enforced by the FDA. Think of cGMP as the master rulebook for manufacturing. It mandates documented procedures for everything—from how raw materials are received and tested to how final products are sealed and shipped. It's all about ensuring consistency and preventing contamination.

-

FDA-Registered Facility: This is straightforward but absolutely critical. It means the manufacturer is on the FDA's official register. While not an FDA endorsement, it is a 100% mandatory requirement for any facility producing supplements for the U.S. market. If a potential partner isn’t registered, walk away. It’s that simple.

-

UL Certified: Underwriters Laboratories (UL) is a globally respected safety certification company. When a facility is UL certified for dietary supplements, a trusted third party has audited their cGMP compliance with a fine-toothed comb. This is an extra layer of assurance that shows a manufacturer is deeply committed to quality, not just meeting the minimum requirements.

This trio of credentials forms a powerful trifecta of trust. They signal that a manufacturer has built an entire culture around quality and compliance.

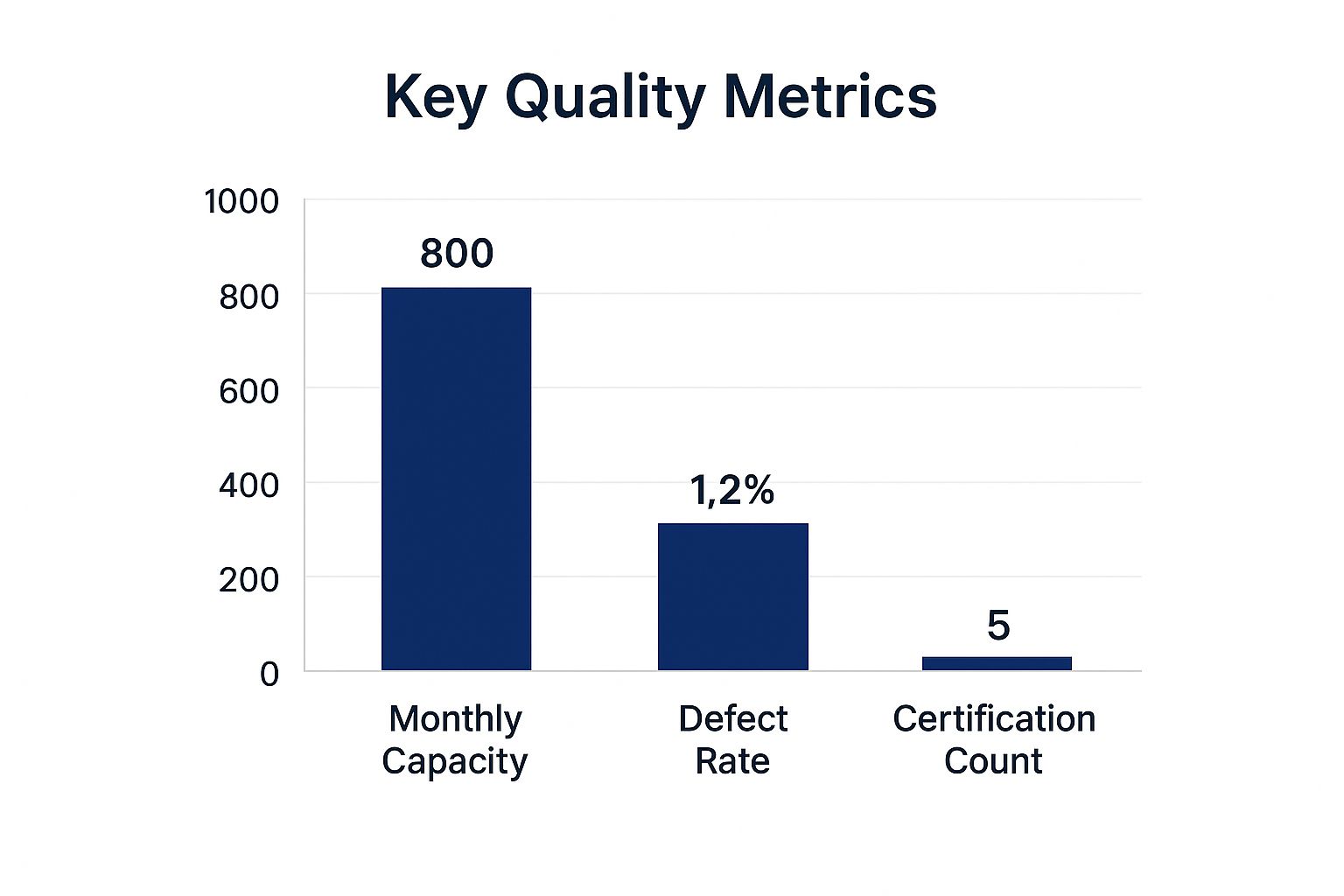

This infographic breaks down key figures that highlight a manufacturer's ability to balance large-scale production with precision.

As you can see, a high production capacity doesn't have to come at the expense of quality. The best partners manage both, with an impressively low defect rate and a strong portfolio of certifications backing up their robust systems.

Essential Quality and Compliance Checklist

Before you sign a contract, you must verify a potential partner's commitment to quality. This checklist covers the absolute non-negotiables.

| Certification or Practice | What It Guarantees | Why It's Critical for Your Brand |

|---|---|---|

| cGMP Certification | Consistent, controlled, and documented manufacturing processes from start to finish. | Protects against contamination, incorrect dosages, and inconsistent product quality, safeguarding your reputation. |

| FDA Registration | The facility is legally permitted to manufacture, pack, or hold supplements for the U.S. market. | This is a fundamental legal requirement. Partnering with an unregistered facility puts your entire brand at risk. |

| Third-Party Lab Testing | Independent verification of the product's potency, purity, and safety for every single batch. | Provides unbiased proof that your product meets label claims and is free from harmful contaminants. |

| Robust Traceability System | The ability to track a finished product all the way back to its specific batch of raw materials. | Crucial for quick and effective action in the rare event of a product recall or quality issue. |

| UL Certification | An extra, independent audit confirming that the manufacturer's cGMP practices meet rigorous global standards. | Demonstrates a proactive, top-tier commitment to quality that goes beyond basic regulatory compliance. |

This isn't just a list of "nice-to-haves." Think of it as your brand's insurance policy, ensuring every product you sell is safe, effective, and worthy of your customers' trust.

The Critical Role of Third-Party Testing

Certifications confirm a manufacturer has the right processes in place. Third-party testing proves the product itself is what you claim it is. This independent validation is your ultimate safety net. The best manufacturing partners don't just offer this—they insist on it as a core part of their quality promise.

Think of it this way: cGMP is the detailed recipe for baking a perfect cake every time. Third-party testing is when you have an independent food critic taste that cake to confirm it has exactly the right ingredients and is absolutely delicious.

This testing verifies a few key things:

- Potency: Does your garlic supplement actually contain the amount of allicin promised on the label?

- Purity: Is the product free from undeclared fillers or other additives?

- Safety: Has it been screened for contaminants like heavy metals (lead, mercury), pesticides, or microbes?

For every batch produced, your manufacturer should provide a Certificate of Analysis (COA) from an accredited lab. This document is your concrete proof of quality. To get a better handle on this, check out our guide on comprehensive supplement quality control.

Transparency in Sourcing and Traceability

A world-class quality system doesn't start at the factory door. It begins on the farm where the garlic was grown. Your manufacturer should have no problem showing you exactly where their raw materials come from and how they vet those suppliers.

Ask about their traceability systems. If there were ever a quality concern with a specific bottle, could they trace it back to the exact batch of raw garlic it came from? This capability, managed through detailed batch records, is absolutely vital for managing risk and demonstrates a true partnership mindset.

When you partner with an organization that obsesses over this level of detail, you’re not just buying a product. You’re investing in peace of mind.

Making Sense of the Global Garlic Supply Chain

The journey a garlic bulb takes from field to finished supplement is a complex global dance. For a brand owner, understanding this supply chain isn't just trivia—it's critical for managing risk. Your manufacturer's sourcing strategy directly impacts your product's cost, quality, and availability.

A top-tier Garlic Bulb private label contract manufacturer doesn't just place an order for garlic; they cultivate a diverse, resilient network of global suppliers. This strategic sourcing acts as a buffer for your brand, shielding it from market volatility. It’s what ensures a consistent supply of quality raw material, even when the global stage gets unpredictable. This deep supply chain expertise is a major, yet often overlooked, advantage of working with an experienced partner.

The Big Players in the Global Garlic Game

The global garlic market is massive, valued at around USD 38.15 billion in 2025 and projected to hit USD 44.04 billion by 2030. The Asia-Pacific region is the undisputed powerhouse, generating about 78% of the world's revenue.

This is largely thanks to China's staggering annual production of 21 million metric tons and India's 3.2 million metric tons. These two giants effectively set the global wholesale price. You can get a deeper look at the global garlic market dynamics over at Mordor Intelligence.

This concentration creates both opportunities and vulnerabilities. A drought in a key growing region or a sudden trade policy shift can send shockwaves through the industry, tightening supply and sending costs soaring. An expert manufacturing partner lives and breathes these dynamics. They don't just react to market shifts—they anticipate them.

A manufacturer with a multi-regional sourcing strategy is your best defense against supply chain disruption. If one region faces a poor harvest or logistical delays, they can pivot to another source, maintaining production continuity and protecting your inventory levels.

By building relationships with growers in different climates and on different continents, we create a stable foundation for your business. That foresight is invaluable for a growing brand trying to meet customer demand.

What Makes Garlic Prices Swing?

The price you pay for your finished product is directly tied to the cost and quality of raw garlic, and several factors can make those prices fluctuate. A good manufacturer constantly monitors these variables to protect its partners.

Here are the key elements we watch:

- Climate and Weather Patterns: Garlic can be a temperamental crop. A sudden drought, heatwave, or hailstorm can devastate a harvest, leading to immediate shortages and price hikes.

- Geopolitical and Trade Policies: Tariffs, trade agreements, or export bans can alter the cost and availability of garlic from major producers overnight.

- Logistics and Transportation Costs: The price of a shipping container, fuel costs, and port congestion all get factored into the final cost of the raw material.

- Currency Exchange Rates: As a global commodity, fluctuations between the U.S. dollar and the currency of the producing country can significantly impact costs.

Navigating these challenges requires a deep, nuanced understanding of global markets. A strong manufacturing partner uses their expertise to hedge against these risks, often locking in contracts far in advance to secure pricing and guarantee supply. We've shared more of our thoughts on supply chain management best practices. This proactive approach gives your brand the stability needed to manage inventory and protect your profit margins.

Bringing Your Custom Formulation to Life

Your product idea is the culmination of your market insight and unique brand vision. A true Garlic Bulb private label contract manufacturer doesn't just fill bottles. We act as your innovation partner, turning that vision into a tangible, shelf-ready supplement.

This is where the relationship transforms into a creative collaboration, blending your brand goals with our scientific and production expertise. The best partners can take your idea—whether a rough sketch or a detailed brief—and systematically engineer it into a standout product. We are an extension of your R&D team, providing the people, technology, and flexibility to guide you through the critical choices that define your product's effectiveness, appeal, and commercial success.

Choosing the Right Garlic Extract

At the heart of your supplement is the garlic itself. But "garlic" isn't a one-size-fits-all ingredient. The type of extract you choose dramatically impacts the product’s benefits, taste, and marketing story. A seasoned formulator is your essential guide here.

-

Aged Garlic Extract (AGE): A top choice for many brands, AGE is highly stable and has a much milder odor. The aging process makes it more palatable, a fantastic choice for consumers sensitive to garlic's potent scent and flavor.

-

Black Garlic Extract: Created through a meticulous heating and aging process, black garlic has a sweeter, more complex flavor profile. It’s also packed with specific antioxidants, providing a unique marketing angle that signals a premium product.

-

Standardized Allicin Content: If your brand is built on potency, this is your path. Standardizing for allicin—garlic's key active compound—guarantees a consistent, measurable dose in every serving. That's a powerful claim for savvy consumers.

This decision lays the groundwork for everything else. A quality manufacturer will have established supply chains for high-grade raw materials for each type. Many leverage key agricultural hubs—for instance, California is the undisputed leader in U.S. garlic production, producing around 4,587,000 units in 2022. This regional dominance ensures a steady, premium supply. You can dig into more of this data on U.S. garlic production by state.

Building a Synergistic Formula

Garlic is a powerhouse, but its effects can be amplified when paired with the right ingredients. This is where a manufacturer's formulation expertise truly shines. We can help you create a custom blend that targets a specific health concern or consumer demographic.

Your formula is your product’s unique fingerprint. A forward-thinking manufacturer helps you combine ingredients in a way that is scientifically sound, stable, and tells a compelling story to your target audience.

Here are a few powerful combinations:

- For Cardiovascular Support: Garlic plus CoQ10 or Omega-3s.

- For Immune Function: Blending garlic with Vitamin C, Zinc, and Echinacea.

- For Detoxification: Pairing garlic with potent antioxidants like N-Acetyl Cysteine (NAC) or milk thistle.

The right partner maintains a deep library of vetted raw materials and has the R&D capabilities to test for stability and efficacy when combining them. This is complex science, not simple mixing. You can get a better sense of what's involved by reading our guide on the nutraceutical formulation development process.

From Liquid Tinctures to Custom Capsules

How your customer takes the supplement is just as important as what's inside it. A flexible manufacturing partner will offer a full menu of delivery formats and packaging options, letting you perfectly tailor the product to your audience.

Common Delivery Formats

- Liquid Tinctures: Ideal for rapid absorption and easy dose adjustments. Our innovative, alcohol-free extraction methods and cold-fill technology preserve garlic's delicate compounds.

- Capsules: A convenient, tasteless, and odorless option for the on-the-go consumer.

- Powders: A great choice for customers who mix supplements into smoothies or drinks, offering dosage flexibility.

Packaging is the final piece of the puzzle. Your manufacturer should offer turnkey solutions, from amber glass dropper bottles that protect light-sensitive liquids to sealed pouches and classic supplement bottles. This all-in-one approach ensures your product looks professional and polished from day one.

The Power of Flexible Run Sizes

Finally, a truly valuable partner understands that brands need room to grow. They offer flexibility in production volume, supporting you from early R&D to market leadership. This scalability is non-negotiable.

- Pilot Batches: Small runs let you test a new formula with a real audience, gather feedback, and adjust without sinking a fortune into inventory.

- Launch Quantities: Moderate run sizes are perfect for your initial launch, helping you manage cash flow while still achieving a good cost-per-unit.

- Full-Scale Production: As your brand takes off, your manufacturer must be able to ramp up production seamlessly to meet surging demand. You can't afford to run out of stock.

This flexibility means you can stay with the same trusted partner as you scale, avoiding the massive headache of switching suppliers and freeing you to focus on marketing, sales, and building a loyal customer base.

Getting Real About MOQs, Pricing, and Timelines

You've perfected your custom formula and selected the ideal packaging. Now comes the business end of production. This is where your partnership with a Garlic Bulb private label contract manufacturer transitions from a creative project to a serious logistical operation.

Navigating quotes, projecting costs, and locking in timelines are skills that make or break your cash flow, profit margins, and ability to deliver on your brand promise. A transparent partner works with you to find a solution that fits, whether you're a startup or a seasoned brand launching a new line.

How MOQs and Pricing Really Work Together

The concept is simple: the more you produce, the lower the cost per unit. This is the principle behind Minimum Order Quantities (MOQs). Manufacturers need these minimums to cover the costs of raw materials, machine setup, labor, and quality control tests for your specific run.

However, a high MOQ can feel like an insurmountable barrier for a new brand. Tying up capital in inventory before you have sales data is a classic startup risk. This is precisely why finding a manufacturer with flexible MOQs is a game-changer.

-

Pilot Runs (Low MOQ): Your best friend for market testing. Launch with a smaller batch, gather real customer feedback, and see sales data without betting the farm. The cost per unit is higher, but your overall financial risk is significantly lower.

-

Scale-Up Runs (Medium MOQ): Once you have market traction, you can confidently increase your order size. This is where you start to see better per-unit pricing as volume increases.

-

Full-Scale Production (High MOQ): For proven products with predictable demand, larger runs provide the best economies of scale and maximize your profit margins.

A great manufacturing partner doesn't see your first small order as a one-and-done transaction. They see it as the start of a long-term growth story and are willing to invest in your success by giving you a clear path to scale.

Discussing MOQs and production timelines also involves effective inventory management for your small business. A reliable partner with on-time delivery helps you forecast accurately, which is crucial for avoiding the dreaded stockout or painful overstock situations.

Breaking Down Your Quote: What to Look For

A quote from a manufacturer should be more than a single number. A detailed, transparent quote is a sign of a professional operation. Scrutinize it for potential hidden costs and ensure you understand every line item.

Key Parts of a Manufacturing Quote:

| Item | Description | What to Ask |

|---|---|---|

| Per-Unit Cost | The price for each finished bottle or pouch at a specific quantity. | "Does this price change at different volume tiers?" |

| Setup Fees | A one-time charge for setting up the production line for your product. | "Is this fee waived for reorders of the same product?" |

| Component Costs | The cost for bottles, caps, labels, and boxes. | "Can I source my own packaging to potentially lower costs?" |

| Lab Testing Fees | Charges for third-party testing to verify potency and purity. | "Is a Certificate of Analysis (COA) provided for every single batch?" |

| Shipping & Freight | The cost to get the finished goods from their facility to you. | "What are my freight options, and can I use my own shipping account?" |

Don't forget to look at market trends, which can open up huge opportunities. The demand for convenience is skyrocketing. In 2023, the peeled garlic market was valued at around USD 4.2 billion and is on track to nearly double to an estimated USD 7 billion by 2032. This gives private label brands a golden opportunity to meet that demand. You can find more insights on 2025 peeled garlic market trends on spicesgarlic.com.

Setting Clear and Realistic Timelines

"How long will this take?" It’s one of the first and most important questions you’ll ask. A dependable manufacturer won’t just give you an answer; they will provide a clear, transparent production timeline and, most importantly, stick to it. That reliability is everything for planning marketing launches and managing customer expectations.

A typical timeline has several distinct phases:

- Sourcing Materials: Procuring and verifying all your ingredients.

- Production: The actual mixing, blending, and creation of your product.

- Quality Control: Time for both in-house and third-party lab testing.

- Packaging: Filling, labeling, and boxing everything up.

- Final Release: A final documentation review before it ships.

Clear communication is non-negotiable here. Your partner should provide regular updates, especially if there's an unexpected delay. A solid on-time delivery record isn't just a nice feature; it's a powerful advantage that lets you run your brand with confidence and build unshakable trust with your customers.

Your Top Questions About Choosing a Manufacturer Answered

Jumping into the supplement market means you’ll have questions, especially when choosing a manufacturing partner. As a seasoned Garlic Bulb private label contract manufacturer, we've guided countless brands through this exact process.

Here are direct, no-fluff answers to the questions we hear most often from entrepreneurs and brand managers. Getting these answers right is your most critical first step. They reveal a manufacturer's true capabilities and whether they are a partner who can support your vision for quality and growth.

How Much Leeway Do I Have with My Formula?

The only right answer is: "As much as you need." A true partner doesn’t push a generic stock formula. They should be ready to collaborate to create something that is uniquely yours. You should be in the driver's seat.

- Picking the Garlic Extract: Do you want aged garlic for its stability, black garlic for its unique antioxidant profile, or a formula standardized for allicin content to back your marketing claims? The choice should be yours.

- Mixing in Synergistic Ingredients: Thinking about an immune blend with Vitamin C and Zinc? Or a heart health formula with CoQ10? Your partner needs the R&D capabilities to ensure these combinations are effective and stable.

- Deciding on Flavor and Delivery: From capsules to custom-flavored liquid tinctures, the final form must align with what your target customer wants to buy.

Think of your manufacturer as your R&D partner from concept through launch. They provide the scientific guardrails while you steer the creative vision. That is how you build a product that stands out.

Customization isn't just a nice-to-have; it's the bedrock of a memorable brand. Your manufacturer should be your innovation engine, not a roadblock to your creativity.

What’s a Realistic Timeline for Production?

A reliable timeline is everything. It dictates your launch date, marketing campaigns, and inventory strategy. While every project is unique, a transparent manufacturer will provide a clear schedule broken into distinct phases.

From a locked-in formula to a shipped product, a typical run usually breaks down like this:

- Sourcing and Verifying Raw Materials (2-4 weeks): This involves rigorously testing all incoming ingredients to confirm their identity, purity, and potency. No shortcuts.

- Production and Blending (1-2 weeks): Your custom garlic formula is brought to life, blended precisely according to cGMP standards.

- Third-Party Testing and QA (1-2 weeks): The finished batch is sent to an independent lab for a final Certificate of Analysis (COA), while internal documentation is reviewed.

- Packaging and Labeling (1 week): Your product is bottled, sealed, labeled, and boxed for shipment.

All in, you're typically looking at a 5 to 9-week process. A partner worth their salt will keep you in the loop the entire time, providing real-time updates and hitting their deadlines to ensure on-time delivery.

How Are Costs Broken Down? Are There Hidden Fees?

Price transparency is non-negotiable. A vague quote is a red flag. A reputable partner provides a detailed, line-item quote so you know exactly where every dollar is going.

Your quote should clearly spell out:

- Per-Unit Cost: The price for each finished bottle, often tiered based on your order volume (MOQ).

- One-Time Setup Fees: This typically covers initial R&D, formula development, and configuring the production line.

- Component Costs: A separate breakdown for your chosen bottles, caps, droppers, and labels.

- Third-Party Lab Fees: The cost for crucial independent testing for potency and safety on every batch.

A true partner operates on a "no surprises" basis. They should be upfront about every potential cost from day one. This lets you budget accurately, protect your margins, and build the trust needed for a successful, long-term partnership.

Ready to turn your idea for a premium garlic bulb supplement into a market-ready reality? The experts at Triton Nutra Group are here to partner with you every step of the way, delivering the flexibility, speed, and quality your brand deserves.