Choosing the Right FDA-Registered Supplement Manufacturer: A Guide for Brand Builders

Find the right FDA-registered supplement manufacturer. This guide offers actionable steps to vet partners on cGMP compliance, quality, and reliability.

Get a Free Quote Today!

Get a Free Quote Today!When you see "FDA-registered supplement manufacturer" on a website, what does that really mean for your brand? As an entrepreneur in the health and wellness space, understanding this is your first step toward launching a successful product. But it's just the starting point, not the whole story.

Let's get the basics straight. "FDA-registered" simply means the manufacturing facility has registered with the U.S. Food and Drug Administration. This is a mandatory step for any facility that makes, processes, packs, or holds dietary supplements for the U.S. market. Think of it as getting on the FDA's radar so they know you exist and can conduct inspections.

What FDA Registered Really Means for Your Brand

Navigating the supplement industry's regulatory maze can be daunting, especially for a growing brand. One of the biggest points of confusion is the difference between an "FDA-registered" facility and an "FDA-approved" product. Getting this right is fundamental to protecting your brand and, more importantly, your customers.

Here's the critical takeaway: The FDA does not approve dietary supplements or their labels before they hit the market. This isn't like the pharmaceutical world where drugs undergo years of pre-market approval. For supplements, the legal responsibility for ensuring a product is safe and that its claims are truthful falls squarely on the manufacturer and the brand owner—that’s you.

The True Benchmark of Quality: cGMP

So, if FDA registration isn't a stamp of approval, what should you look for? The real measure of a manufacturer's commitment to quality is their strict adherence to Current Good Manufacturing Practices (cGMP). These are the actual, enforceable regulations laid out by the FDA in a document called 21 CFR Part 111.

cGMP provides the entire framework for ensuring your products are made correctly, every single time. It covers everything from facility design and raw material sourcing to process monitoring, guaranteeing the identity, strength, quality, and purity of your supplements.

A top-tier manufacturing partner doesn't just "meet" these standards; they live and breathe them. Their entire operation is built around cGMP principles. This looks like:

- Raw Material Verification: Every ingredient that comes through their doors is rigorously tested for identity, purity, and potential contaminants before it gets anywhere near your formula.

- Airtight Process Controls: They have strict, documented procedures for every step of production. From weighing and mixing to bottling and labeling, nothing is left to chance.

- Finished Product Testing: After your product is made, it's sent to a third-party lab to verify that what's on the label is exactly what's in the bottle.

A manufacturer's FDA registration is the cost of entry. Their obsession with cGMP compliance—backed by third-party certifications from respected bodies like UL or NSF—is what shows they're a true partner dedicated to excellence.

Beyond the Basics: Finding a Forward-Thinking Partner

Finding the right FDA-registered supplement manufacturer means looking past the registration number. You're looking for a partner who sees compliance not as a chore, but as a competitive advantage. This means they're proactive, staying on top of regulatory changes and investing in new technologies that improve product integrity, like advanced botanical extraction methods or innovative cold-fill processing to protect sensitive ingredients.

As you start your search, it helps to know the different kinds of partners you can work with. To get a better handle on your options, you can learn more about the different types of supplement contract manufacturers and how they operate.

Ultimately, choosing a manufacturer is one of the most critical decisions you'll make. It directly shapes your brand's reputation and potential for long-term success.

Your Vetting Checklist for Manufacturing Partners

Picking the right FDA-registered supplement manufacturer is more than just checking a box. It’s a strategic decision that will define your brand’s reputation for years to come. With so many options out there, you need a clear way to distinguish the truly great partners from those doing the bare minimum. You're not just finding a supplier; you're finding your R&D partner from concept through launch.

First, verify the essentials. Don't just take their word for it—ask to see their FDA registration number and cGMP documentation. A transparent partner will provide this without hesitation. Remember, the gold standard isn't just saying they follow cGMP; it's proving it with third-party certification from a respected body like UL or NSF. This independent stamp of approval shows they've invested in their processes and passed a tough audit.

Any hesitation to share these documents is a huge red flag. If a potential partner gets cagey about providing certifications, inspection reports, or their quality control procedures, it’s your cue to walk away. Your brand’s future is on the line, and you need a manufacturer who operates with total transparency.

Verifying Quality From Raw Materials to Finished Goods

A manufacturer’s commitment to quality goes way beyond paperwork. You need to get into the details of their daily operations, especially when it comes to testing. Real quality control is a two-part process, covering both the beginning and the end of the production line.

Start by asking for their raw material testing protocols. Every ingredient should have a Certificate of Analysis (CoA) and then be independently tested for identity and purity upon arrival. This is non-negotiable. It’s the only way to ensure your formula starts with clean, potent ingredients, free from contaminants like heavy metals or microbes.

Just as critical is finished product testing. After your liquid supplement has been mixed and bottled, a sample must go to an independent, third-party lab. This final check verifies that the product in the bottle matches your formula, meets every claim on the label, and is safe for your customers. Always ask to see examples of these final reports.

A partner genuinely dedicated to excellence will be proud to show you their multi-stage testing process. They understand that rigorous verification isn't just a cost—it's a critical investment in product integrity and consumer trust.

Understanding the Bigger Picture

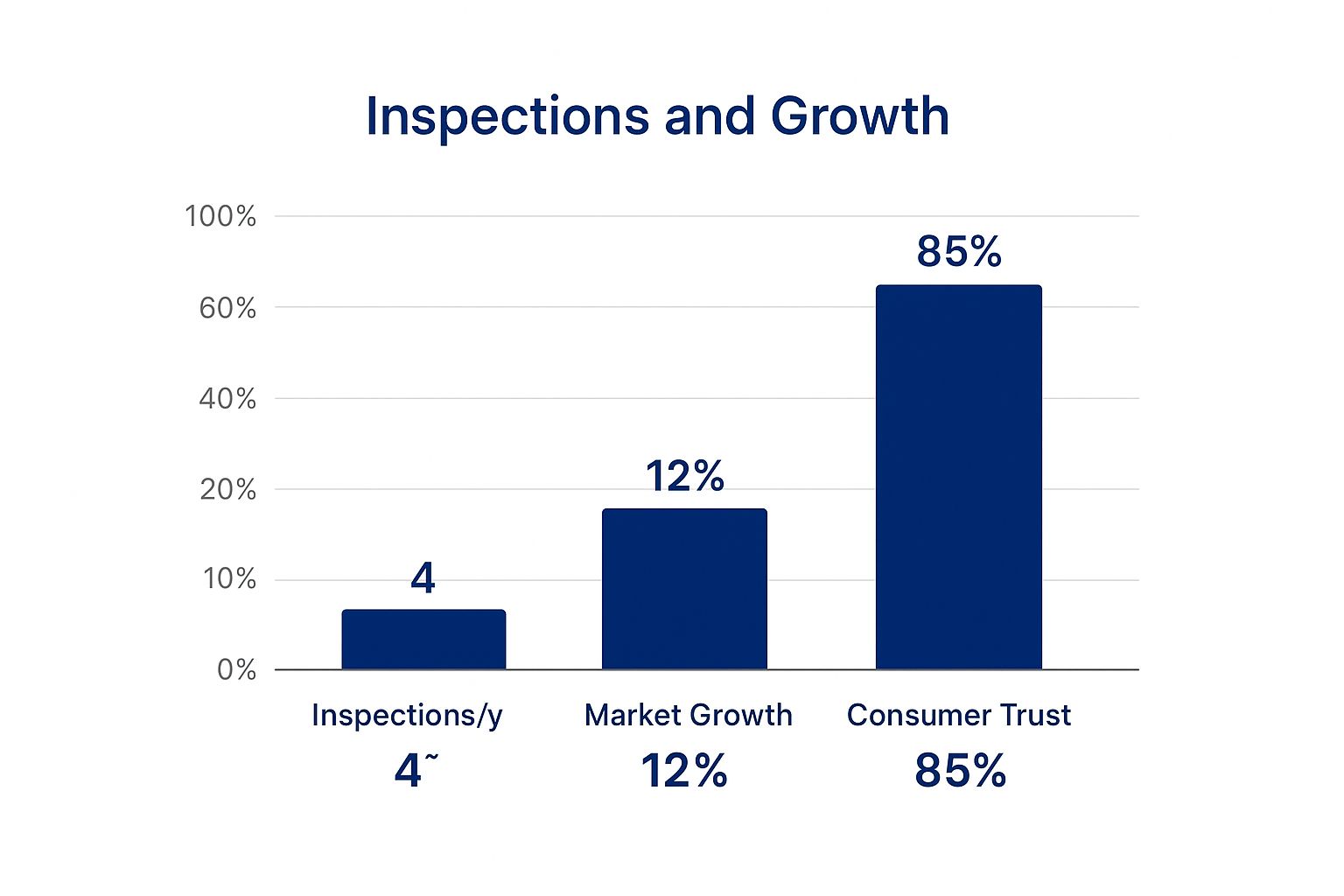

The supplement industry is booming, which means more opportunity but also more scrutiny. This chart gives you a bird's-eye view of the industry, highlighting just how important it is to choose a manufacturing partner you can trust.

The data makes it clear: this is a massive, growing market where consumer trust is everything, and regulations are always a factor. Partnering with a compliant, high-quality manufacturer is your best strategy for succeeding in this environment.

To put some numbers on it, the global dietary supplement industry is on track to hit nearly $60 billion in the U.S. and almost $200 billion worldwide by 2025. In a market this huge, public health is a major focus, and organizations like the American Medical Association are pushing for stronger regulations. This industry-wide push for higher standards makes your choice of a compliant FDA-registered supplement manufacturer more critical than ever before.

For a deeper dive into what to look for, our guide on key considerations for finding a reputable supplement manufacturer is a great next step. It's packed with more questions to ask as you build your shortlist.

To make things even easier, here's a quick-reference table you can use to compare the essential qualifications of any potential manufacturing partners you're considering.

Manufacturer Vetting Checklist

| Qualification | What to Look For | Why It Matters |

|---|---|---|

| FDA Registration | A current and valid FDA registration number. Don't be afraid to verify it. | This is the baseline for legal operation in the U.S. and shows they are on the FDA's radar. |

| cGMP Compliance | Third-party certification from bodies like NSF or UL, not just self-proclaimed compliance. | Independent audits prove their processes, facility, and documentation meet high industry standards. |

| Raw Material Testing | Proof of identity, purity, and potency testing for all incoming ingredients. | Guarantees your product starts with clean, effective ingredients, free from contaminants. |

| Finished Product Testing | Reports from a third-party lab confirming the final product meets label claims. | Ensures the product your customers receive is safe, effective, and exactly what you promised. |

| Transparency | Willingness to share documentation, answer detailed questions, and allow facility tours. | A transparent partner has nothing to hide and is confident in their quality systems. |

| Production Capacity | Can they handle your current order volume and scale up with you as your brand grows? | Avoids production bottlenecks and ensures you can meet customer demand without switching partners. |

This checklist isn't exhaustive, but it covers the core, non-negotiable elements. A partner who can confidently check every one of these boxes is one worth having a serious conversation with.

Matching Production Capabilities to Your Vision

You’ve confirmed a manufacturer meets all non-negotiable quality standards. That's a huge step. But now comes the part where you see if their technical capabilities align with what you want to create.

An FDA-registered supplement manufacturer might have a wall full of certifications, but if their expertise is in simple powder blends and you’re developing a complex liquid herbal tincture, they aren't the right partner. It's that simple. Your unique formula deserves a team that understands the science behind it.

This is where you shift from checking boxes on a compliance sheet to truly evaluating their capabilities. You're not looking for someone who just follows a recipe; you need a partner who can contribute to making your product even better. That process starts by digging into their experience with ingredients similar to yours, especially tricky botanicals that require specialized handling.

Probing Their Technical and R&D Expertise

A true manufacturing partner is an extension of your R&D team. They should be able to talk shop with you, discussing ingredient synergy, bioavailability, and stability with confidence.

When you get them on the phone, get technical.

Here are a few questions to see how deep their knowledge really goes:

- Ingredient Experience: "Tell me about your experience with [mention a key ingredient, e.g., ashwagandha extract]. What sourcing or formulation challenges have you solved?"

- Customization Flexibility: "We're aiming for a specific flavor profile. How does your team handle flavor masking for bitter herbs? Walk me through your process for developing a custom flavor from scratch."

- Technological Edge: "What methods, like cold-fill technology, do you use to protect the integrity of heat-sensitive botanicals during production?"

Pay close attention to their answers. You’ll quickly learn whether they're just order-takers or genuine formulation experts who can help you refine and perfect your vision.

A great manufacturer won't just ask for your formula; they'll ask about it. They’ll want to understand your goals, your target audience, and the 'why' behind your ingredient choices to help you create the best possible product.

From Small-Scale Pilots to Full Production Runs

As your brand grows, your needs will change. Your manufacturing partner must be able to scale right along with you. A key sign of their flexibility is how they handle production volumes. Will they support a small pilot run so you can test the market without sinking your capital into massive inventory?

This is a make-or-break issue for new brands. Committing to a 5,000-unit order before you know if customers want the product is a huge gamble. A partner offering smaller, more manageable minimum order quantities (MOQs) shows they're invested in helping you grow the right way.

But they also need the horsepower for full-scale production down the line. Ask them directly about their scalability:

- What are your typical turnaround times for a pilot run versus a full production run?

- At what volume do you offer price breaks?

- How do you maintain consistent quality when scaling from 500 units to 50,000 units?

The sweet spot is finding a partner who is nimble enough for small pilot batches but powerful enough for high-volume manufacturing. That adaptability gives you the support you need at every stage of your brand’s journey.

Finding a Partner, Not Just a Supplier

Technical skills and certifications are the price of admission in this industry. But what truly separates a decent supplier from a game-changing partner? It's their collaborative spirit and unwavering reliability.

You're not just buying a product off a shelf; you're entrusting a critical piece of your business—your reputation and your customers' trust—to another company.

This is where you look beyond the lab coats and machinery to gauge their commitment to your brand's success. The best FDA-registered supplement manufacturer operates as a true extension of your team. They bring strategic insights to the table because they get it: their success is directly tied to yours.

You’ll see this partnership mindset shine brightest when things don't go according to plan. Supply chain disruptions happen. Unexpected formulation challenges pop up. The real test is how your manufacturer communicates and collaborates to solve these problems.

Gauging Reliability and Communication

A transactional supplier goes silent when there's an issue, leaving you in the dark. A true partner picks up the phone immediately, explains the situation with total transparency, and comes to you with solutions, not just problems. That proactive communication is the bedrock of a strong, long-term relationship.

Before signing a contract, get a sense of their operational reliability. Ask pointed questions that reveal their real processes:

- Lead Times and Delays: "What are your current average turnaround times? Can you share your on-time delivery rate for the last six months?"

- Problem-Solving Protocol: "Walk me through your process when a raw material shipment is delayed. How and when is my team notified, and what are your contingency plans?"

- Accessibility: "Who will be our dedicated point of contact? What is your standard response time for client inquiries during an active production run?"

Their answers will tell you everything. Vague responses are a red flag. Detailed, confident answers suggest they have robust, battle-tested processes in place.

A partner sees your launch timeline as their own. They understand that a two-week delay on their end can derail your marketing calendar and kill your brand's momentum. Their commitment to hitting deadlines is a direct reflection of their respect for your business.

Ultimately, you’re looking for a collaborator invested in your journey from concept to launch and beyond. This is the manufacturer who helps you navigate regulatory hurdles, offers suggestions to improve your formula's stability, and actively works with you to scale production as your brand explodes.

Choosing this kind of partner isn't just a logistical decision; it's a strategic one that will pay dividends long after your first production run, protecting your brand and setting you up for sustainable growth.

Navigating a Complex Global Supply Chain

Your product's quality story doesn't start on the production line. It begins thousands of miles away, where your raw materials are harvested and processed. In today’s market, ingredients travel across continents, creating a global supply chain that’s both a huge opportunity and a massive risk.

Sourcing a potent botanical from its native region can give your product an incredible edge. But that global reach introduces variables—from different agricultural standards and transportation issues to the risk of ingredient adulteration.

This is why your manufacturer’s grip on their supply chain isn't just a logistical footnote. It’s a core pillar of their commitment to quality.

From Global Sourcing to Local Accountability

A top-tier FDA-registered supplement manufacturer doesn't just hope for the best. They build a resilient, transparent supply chain by putting every single supplier under the microscope. This goes beyond glancing at a Certificate of Analysis. It's about building relationships and, most importantly, running their own verification tests.

When a shipment of ingredients arrives at a cGMP-compliant facility, it's immediately quarantined. It doesn't move an inch closer to production until its identity, purity, and potency have been independently confirmed.

This is your brand’s most critical line of defense. It protects you from:

- Adulterated Ingredients: Ensures you aren't using raw materials cut with cheap fillers.

- Contaminants: Screens for heavy metals, pesticides, or microbial growth.

- Potency Issues: Confirms the active compounds are present at the levels needed to be effective.

Your manufacturer is the final gatekeeper of quality. Their ability to manage and validate a global supply chain transforms international ingredients into a safe, consistent product that builds consumer trust.

The American supplement market is a $50 billion industry scrutinized by consumers who demand transparency. While there are thousands of manufacturers globally—over 4,000 in India alone—very few can meet the strict standards required to enter the U.S. market.

Partnering with a manufacturer who has mastered supply chain compliance is non-negotiable for any brand that wants to succeed here. You can get a deeper look into these challenges from the NSF's analysis of U.S. market entry.

This meticulous process isn’t just about ticking FDA boxes. It’s about protecting your brand’s reputation. One supply chain failure can trigger a product recall, destroy customer loyalty, and create legal headaches that could sink a growing business. When you choose a partner with a rock-solid global sourcing and verification program, you’re securing a powerful competitive advantage.

Staying Ahead of FDA Scrutiny and Regulations

Choosing an FDA-registered supplement manufacturer isn't just about today; it’s about strategically planning for tomorrow. The regulatory environment for dietary supplements is only getting tighter. Partnering with a forward-thinking, compliance-obsessed manufacturer is one of the smartest moves you can make for your brand's longevity.

The FDA's enforcement activities are ramping up. A proactive manufacturing partner keeps their finger on the pulse of these trends. This vigilance shields your business from warning letters, costly recalls, and the legal headaches that can derail a growing brand. Your manufacturer’s commitment to compliance is a direct reflection of your own ability to scale and succeed.

Why Proactive Compliance Is a Competitive Advantage

A manufacturer that just reacts to new regulations is always playing catch-up. A true partner anticipates them. They invest in their quality systems not just because they have to, but because they know it’s the bedrock of a sustainable business—for them and for you.

This proactive approach is essential as regulatory bodies sharpen their focus. For instance, the FDA is signaling much stronger enforcement across the board. Between 2020 and 2024, the agency published over 200 complete response letters for new product applications and has pushed for greater collaboration on product recalls to better protect consumers. You can see how these FDA actions are shaping the industry and what it means for brands like yours.

This trend underscores why a partner who meticulously documents every step and stays ahead of labeling updates is such a powerful asset. It's about more than just dodging trouble; it’s about building a brand that customers trust without a second thought.

Choosing a manufacturer is a long-term strategic decision. A partner who obsesses over regulatory details and invests in staying ahead of the curve is actively protecting your brand’s future value and market position.

This level of diligence is what it takes to navigate the complexities of the supplement world. For a deeper dive into the specific rules governing this space, you can explore our detailed guide on the core FDA regulations for dietary supplements. In the end, your choice of manufacturer will determine whether you’ll be reacting to industry shifts or leading the charge with a brand built on an unshakable foundation of quality and compliance.

Your vision for a standout liquid supplement deserves a manufacturing partner who matches your commitment to quality and innovation. At Triton Nutra Group, we act as an extension of your team, providing the expertise, flexibility, and rapid turnaround times to bring your product to life with confidence.

Ready to create a product that stands out? Request a free quote today and let’s build something exceptional together.