Your Partner for Devils Claw Root Private Label Manufacturing

Partner with a top Devils Claw Root private label contract manufacturer. Get expert formulation, certified quality, and reliable support to launch your brand.

Get a Free Quote Today!

Get a Free Quote Today!Finding the right Devils Claw Root private label contract manufacturer isn't just about sourcing a product—it's about finding an R&D partner to launch your brand. The right partner provides the expertise, compliance, and infrastructure you need to get a high-quality product to market, fast, without the massive expense of building your own facility.

Capitalizing on the Devils Claw Root Wellness Trend

The wellness industry is experiencing a massive shift. Consumers are actively seeking natural, plant-based solutions for common health issues like joint discomfort and inflammation. Devil's Claw Root (Harpagophytum procumbens) is perfectly positioned at the center of this movement, capturing the attention of a growing audience tired of synthetic options.

This isn't just a fleeting trend. The global Devil's Claw Root market was valued at around USD 290 million and is projected to grow at a Compound Annual Growth Rate (CAGR) of about 6.1%.

That growth is expected to push the market’s value to nearly USD 492 million by 2033. This is a clear signal of strong, sustained consumer demand that forward-thinking brands can capitalize on.

The Private Label Advantage

For e-commerce founders and brand managers, this is a golden opportunity. The challenge? The barriers to entry for supplement manufacturing are notoriously high. You face huge capital investments in equipment, a maze of complex FDA regulations, and the difficulty of building a reliable global supply chain.

This is exactly where the private label model is a game-changer. By partnering with a specialized contract manufacturer, you sidestep these roadblocks. You instantly gain access to:

- A cGMP certified, UL certified, and FDA-registered facility without spending a dime on construction.

- Established global sourcing relationships for high-quality, verified raw Devil's Claw Root.

- In-house R&D and quality control teams who ensure your product is both effective and compliant.

- Flexible, scalable production that grows with your brand, from pilot runs to full-scale manufacturing.

Key Takeaway: Private labeling transforms a high-risk, high-cost venture into a streamlined, speed-to-market strategy. It frees you to focus on what you do best—building your brand and connecting with your customers.

Turning a Market Trend into Your Success

Knowing a trend exists isn't enough; you need to act with precision and speed. A top-tier Devils Claw Root private label manufacturer is your launchpad, providing the entire operational backbone for your brand. We're not just a vendor; we are a collaborator in your growth, handling the complex production details so you can capture market share.

This partnership is built on more than just filling bottles. It’s about collaborative formulation, transparent timelines, and an unwavering commitment to quality. To capitalize on market trends and attract potential clients, it's wise to implement targeted SEO strategies for manufacturers. When you choose the right manufacturing partner, you turn a powerful consumer trend into your brand's next successful product line, ready to launch with confidence.

Inside the Formulation and Sourcing Process

The difference between a top-selling supplement and one that fails to gain traction often comes down to what happens long before production begins. It starts with an intelligent formula and ethically sourced, potent raw materials. As your Devils Claw Root private label contract manufacturer, our process is built to turn your vision into a scientifically sound, market-ready product.

This is a collaborative R&D process where we become your formulation partner. We help you navigate the critical decisions that define your product's effectiveness, safety, and appeal to your target customer.

From Raw Root to Potent Extract

The journey begins with the Devil’s Claw Root itself. The quality of the final extract depends entirely on the quality of the raw botanical. This means paying close attention to where and how it's grown, harvested, and processed. A transparent supply chain isn't a luxury; it's a necessity for brand integrity.

Understanding the global supply chain is part of our expertise. The market for this botanical is heavily concentrated in a few key regions. China currently dominates the global export market, accounting for roughly 58% of total export shipments in a recent year, making them the largest global supplier, with France and Spain following.

A true manufacturing partner doesn’t just source ingredients; they verify them. We demand full traceability from our suppliers, complete with Certificates of Analysis for every batch, confirming identity, purity, and the absence of contaminants.

This level of scrutiny is non-negotiable. It's the only way to ensure the Devil's Claw Root in your product is exactly what it claims to be—free from heavy metals, pesticides, and microbial contamination. This is the bedrock of a safe and effective supplement.

Optimizing for Bioavailability and Potency

Once we have verified raw materials, the science of formulation begins with extraction. The goal is to isolate the active compounds in Devil's Claw Root—primarily harpagosides, which are responsible for its anti-inflammatory properties. The extraction method we choose directly impacts the final product's potency and bioavailability (how well your customer's body can absorb and use the active ingredients).

Different methods yield different results, and a true partner guides you through the options. We leverage innovative techniques, including:

- Alcohol-Free Extraction: Using mediums like glycerin or purified water provides a gentler way to protect delicate botanical compounds from harsh solvents.

- Cold-Fill Technology: This advanced process avoids heat degradation, ensuring the final extract retains its full potency from plant to bottle.

- Standardization: This is key. We concentrate the extract to guarantee a specific percentage of active compounds, like harpagosides, in every single batch, ensuring consistency and efficacy.

The right approach depends entirely on your product goals. To better understand these techniques, we recommend reading our guide on herbal extraction methods. This knowledge will empower you during our collaborative formulation process.

Let's consider a real-world example. A brand wants to launch a high-potency liquid tincture for joint support targeting active adults over 40. They need a product that delivers fast, noticeable results.

In this case, a standardized, alcohol-free glycerin extract is the perfect fit. Glycerin is a gentle solvent that preserves the active compounds and provides a slightly sweet, palatable taste without adding sugar. By standardizing the extract to a high level of harpagosides, the brand can confidently make potency claims on its label, knowing every bottle delivers consistent effects. This R&D-driven approach ensures the final product is a targeted solution built for a specific audience.

Key Formulation Considerations for Devil's Claw Root

Having a clear idea of these formulation factors will make our development process smoother. This table breaks down the key decision points and why each one matters for your product's success.

| Formulation Factor | Impact on Product | What to Discuss with Your Manufacturer |

|---|---|---|

| Form Factor | Determines user experience, dosage, and cost. Affects which consumers you appeal to. | Capsules vs. liquid tinctures vs. powders. What form best suits your target audience's lifestyle? |

| Standardization | Guarantees consistent potency and effectiveness in every bottle. Allows for specific label claims. | What percentage of harpagosides should the extract be standardized to? How does this align with clinical studies? |

| Excipients | Affects the product's stability, bioavailability, and manufacturing efficiency. | What binders, fillers, or flow agents are necessary? Are there "clean label" options available? |

| Bioavailability Enhancers | Can significantly improve the absorption of active compounds, making the product more effective. | Should ingredients like black pepper extract (piperine) be included to boost absorption? |

| Synergistic Ingredients | Pairing Devil's Claw Root with other compounds can create a more comprehensive, targeted formula. | Does it make sense to add other joint-support ingredients like turmeric, boswellia, or MSM? |

Each of these factors helps create a final product that stands out in a crowded market. As your manufacturing partner, we guide you through these choices, balancing efficacy, cost, and marketability to bring your vision to life.

Achieving Rock-Solid Quality and Compliance

In the world of supplements, the promises on your label are only as good as the quality control backing them up. For any serious wellness brand, quality and compliance aren't just buzzwords; they are the bedrock of consumer trust and brand longevity.

In the world of supplements, the promises on your label are only as good as the quality control backing them up. For any serious wellness brand, quality and compliance aren't just buzzwords; they are the bedrock of consumer trust and brand longevity.

When vetting a Devils Claw Root private label contract manufacturer, their commitment to these standards must be a top priority. A slick website means nothing if the product inside the bottle doesn't meet the absolute highest safety and purity standards.

The cGMP Gold Standard

You’ll see cGMP often, but what does it really mean for your product? Current Good Manufacturing Practices are the FDA's master rulebook for every step of production.

This isn't just about keeping the facility clean. It governs everything—from how raw materials are received and quarantined to how every piece of equipment is sanitized between runs. It demands meticulous documentation, ensuring every step is recorded for complete traceability. A cGMP-certified manufacturer proves their processes are repeatable and consistently yield a safe, pure product. This is your most critical line of defense.

Why FDA Registration and UL Certification Matter

Beyond cGMP, two other credentials are vital. An FDA-registered facility means the Food and Drug Administration can inspect the manufacturer at any time—the bare minimum for operating legally.

A UL certification takes quality commitment to the next level. UL is a globally recognized third-party safety science company. When a manufacturer voluntarily undergoes and passes UL's rigorous cGMP audits, it shows a proactive investment in best-in-class systems, not just doing enough to get by.

The bottom line is simple: partnering with a manufacturer that isn't cGMP certified, FDA-registered, and UL certified is a massive risk to your brand's reputation and your customers' health. Consider these non-negotiable.

Decoding Third-Party Testing and the CoA

This is where claims are proven. The best manufacturers don't just test their products in-house; they send samples from every single batch to an independent, third-party lab for unbiased verification.

This process confirms two critical things: potency (does the product contain the amount of Devil's Claw Root extract your label claims?) and purity (is it free from contaminants like heavy metals, pesticides, and microbes?).

The results are compiled into a Certificate of Analysis (CoA). This is your official proof that the product is what it says it is. As a brand owner, you must know how to read it. It should clearly show:

- Product and Batch Number: To link the results directly to your specific run.

- Identity Test: To confirm the botanical is, in fact, Devil’s Claw Root.

- Assay for Potency: To measure the concentration of active compounds like harpagosides.

- Microbiological Screening: To check for bacteria, yeast, and mold.

- Heavy Metals Analysis: To test for lead, mercury, arsenic, and other contaminants.

A top-tier manufacturing partner provides this documentation transparently for every batch. It’s the only way to know with confidence that what's on your label is exactly what's in the bottle. To dive deeper into this critical process, learn more in our overview of herbal supplement testing.

Building a True Manufacturing Partnership

Choosing a private label manufacturer for your Devil’s Claw Root supplement isn't just comparing price quotes. You’re not buying a commodity; you’re entrusting a critical part of your brand to another company. Their performance directly impacts your product's quality, your reliability, and your ability to scale.

The wrong choice leads to missed deadlines, compliance headaches, and a product that fails to meet customer expectations.

But the right partner becomes your growth engine. It’s a relationship built on transparency and shared goals, where they function as an extension of your team. You aren’t looking for a supplier—you’re looking for your R&D partner from concept through launch, one as invested in your success as you are.

Moving Beyond the Spec Sheet

Every manufacturer will claim they deliver great quality and service. The real differentiator lies in how they operate, solve problems, and support your growth.

A key indicator of a true partner is their focus on operational excellence. Are they constantly finding ways to improve supply chain efficiency? A manufacturer that refines its own processes can offer you faster lead times, consistent quality, and reliable delivery. It shows they're thinking long-term, not just about your next purchase order.

A partnership mindset means your manufacturer operates as an extension of your team. They anticipate problems, communicate proactively, and offer solutions, not excuses. This shift from a transactional relationship to a collaborative one is the single most important factor for long-term success.

Scalability From Pilot Batch to Full Production

You have big plans for your brand. Today, you might need a small pilot run of 1,500 units. But in six months, a viral launch could mean you suddenly need 50,000 units. Can your manufacturer make that jump seamlessly?

This is a critical conversation. A manufacturer’s flexibility with production volume demonstrates their commitment to helping brands at every stage.

- Pilot Runs: The ability to produce small, affordable batches gives you incredible agility. You can launch new formulas, get customer feedback, and prove your concept without risking massive capital.

- Full-Scale Production: As you grow, you need a partner with the capacity and systems to ramp up production without letting quality or delivery times slip. This requires rock-solid project management and a finely tuned supply chain.

A partner built for growth will have clear processes for both. They'll work with you on inventory planning and demand forecasting, making the leap from a small test run to full-scale production feel smooth and controlled.

A Checklist for Finding Your R&D Partner

When vetting potential manufacturers, push past standard questions. Use this checklist to gauge if they are a genuine partner who can help you innovate and scale.

- Project Management: How do they manage a project? Will you get a dedicated point of contact? Ask them to walk you through their process from purchase order to shipment. Crystal-clear communication and transparency are signs of reliability.

- Problem-Solving Track Record: Ask for a specific example of when a project faced a challenge—a raw material delay or a packaging issue. How did they handle it? What was the outcome for their client? Their answer reveals their accountability.

- Formulation Flexibility: What if you want to add synergistic ingredients like Boswellia or Turmeric to create an enhanced joint blend? A true partner will have a scientific, collaborative discussion with you, not just send a revised quote.

- On-Time Delivery Record: What is their on-time, in-full delivery rate? A manufacturer who tracks performance should be able to provide this metric. On-time delivery is the lifeblood of your business; it prevents stockouts and keeps your customers happy.

Your Product Launch Timeline From Concept to Customer

A mismanaged timeline can lead to disaster: missed marketing opportunities, frustrating stockouts, and unhappy customers. When working with a Devil’s Claw Root private label contract manufacturer, a clear, predictable timeline isn't just helpful—it's the bedrock of a successful launch.

Predictability is everything. A reliable manufacturing partner provides a transparent, step-by-step schedule that removes guesswork, allowing you to plan your launch with confidence.

Let's walk through what that journey looks like.

Phase 1: The Foundation (Weeks 1-4)

The first month is about alignment and preparation. This phase kicks off the moment you approve our quote and send a purchase order. During these crucial weeks, we lock in the final formula, confirm your packaging choices, and immediately begin sourcing every component.

While we secure raw materials and bottles, your team has a key role: finalizing the label design. A common delay we see is brands waiting on their own artwork. Completing this in parallel can shave weeks off the total production time.

Insider Tip: The day you sign the agreement, ask your manufacturer for the label die lines—the exact template for your bottle. Give that to your designer immediately. This ensures your labels are printed and ready the moment production is finished, preventing a costly delay at the finish line.

Phase 2: Production and Quality Assurance (Weeks 5-8)

Once all raw materials and packaging components arrive and pass our stringent quality inspections, we move to the production floor. Here, your product truly comes to life. Our team meticulously compounds the formula, using advanced extraction and our innovative cold-fill technology to protect the potency of the Devil’s Claw Root.

This is not a "set it and forget it" process. Quality assurance is integrated into every step:

- In-Process Checks: We constantly monitor everything from mix consistency to the exact fill weights in every bottle to ensure they meet your specifications.

- Finished Product Testing: After production, we send samples to an independent, third-party lab for final verification of potency and purity.

- Documentation: A complete Certificate of Analysis (CoA) is generated. This document is your proof of quality and compliance.

This is where a manufacturer's dedication to cGMP standards truly shines. That intense focus on detail ensures your final product is not only effective but also safe and consistent from batch to batch.

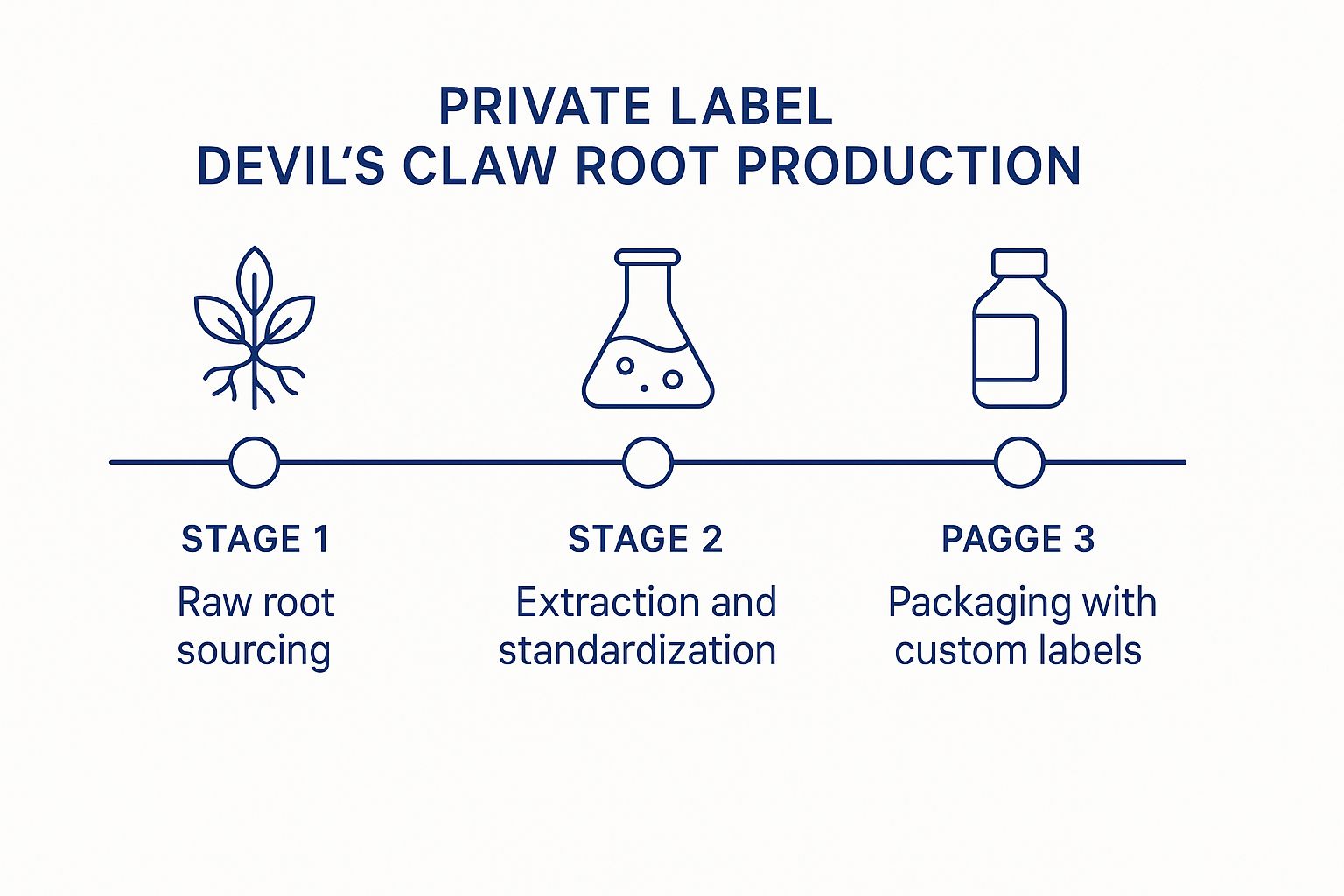

As you can see, each stage—from sourcing the raw herb to extracting active compounds and packaging the finished liquid—builds methodically on the last.

Phase 3: Finalization and Shipment (Weeks 9-10)

With your liquid supplement produced and fully tested, we enter the home stretch. In this final stage, your pre-printed labels are applied, lot numbers and expiration dates are added, and finished units are packed into master cartons for shipping.

This is the moment where planning pays off. Because you had a predictable timeline, your marketing and sales teams are primed. Your e-commerce pages are live, your launch emails are scheduled, and your entire launch strategy is ready to deploy.

We then ship the product directly to your warehouse or fulfillment center. Our structured, 10-week process for a stock formula provides the reliability and speed you need to build and scale a successful brand.

For a deeper look at the concept phase, our guide on starting your own custom liquid supplement brand is a valuable resource. Ultimately, a transparent timeline from your manufacturing partner turns a complex process into a manageable path to market.

Common Questions About Private Label Manufacturing

Stepping into the supplement space brings questions, and that's a good thing. It shows you're committed to getting it right. Here are some straight answers to the most common questions we hear from entrepreneurs like you.

What Are the Minimum Order Quantities (MOQs)?

MOQs directly impact your startup costs and can vary significantly.

For a stock liquid formula that a manufacturer has already developed, you can often start with an MOQ around 1,000 to 1,500 units. This is an excellent way to test the market without a massive initial investment.

For a completely custom formula, the numbers are higher. For a unique blend built from scratch, plan on MOQs in the range of 3,000 to 5,000 units. This covers the dedicated R&D, specialized ingredient sourcing, and testing required for a product that is 100% yours.

A true partner understands the need to scale. Ask them: "Can you support my growth from a 1,500-unit pilot run to a 50,000-unit order without sacrificing quality or speed?" Their answer will tell you everything.

How Long Does the Private Label Process Take?

Your timeline dictates your launch strategy and sales goals.

For a standard private label product using an existing stock formula, a reliable timeframe is 6 to 10 weeks. This covers everything from label approval and component sourcing to the production run and final quality checks.

For a fully custom formula, budget for 12 to 20 weeks from concept to completion. The R&D phase alone—formulating, flavor profiling, and stability testing—can take 6-8 weeks before your product even enters the production queue. Being responsive with approvals is the best way to keep this process moving efficiently.

What Quality and Safety Certifications Should I Look For?

Certifications are non-negotiable proof of a manufacturer's commitment to quality.

At a minimum, your partner must be cGMP (Current Good Manufacturing Practices) certified and operate in an FDA-registered facility. This is the legal baseline for manufacturing supplements in the US.

To distinguish the best from the rest, look for additional third-party certifications like UL or NSF. These organizations conduct rigorous, independent audits that go beyond the basics. You should also demand third-party testing from ISO-accredited labs to verify the identity, purity, and potency of every batch, backed by a detailed Certificate of Analysis (CoA).

Can I Provide My Own Packaging and Labels?

Yes, this is a common request. Most experienced contract manufacturers are flexible and can work with client-supplied components like bottles, caps, and labels. This gives you total control over your brand’s aesthetic.

The key is to communicate this early. Your manufacturing partner needs to confirm that your components are compatible with their bottling lines to avoid production issues. They will provide a "die line"—a precise blueprint for your label designer—to ensure your final label fits perfectly and includes all FDA-required information.

Ready to turn your vision for a Devil’s Claw Root supplement into a top-selling product? We are more than just a manufacturer—we are your R&D partner from concept through launch. Let’s build your next success story together. Request a Free Quote and Consultation Today.