Partnering with an Expert Arjuna Terminalia Bark Private Label Contract Manufacturer

Discover how our ArjunaTerminalia Bark private label contract manufacturer can help you develop, source, and launch your herbal product successfully.

Get a Free Quote Today!

Get a Free Quote Today!Choosing the right private label contract manufacturer for your Arjuna Terminalia Bark supplement is the single most important decision for your brand's launch. This isn't just about finding a supplier; it's about securing a strategic partner who is an expert in botanical extraction, cGMP compliance, and market trends. A great partner acts as an extension of your team, guiding you from concept to a polished, shelf-ready product.

Finding Your Strategic Supplement Manufacturing Partner

For brand managers and e-commerce founders, transforming a powerful idea for an Arjuna Terminalia Bark liquid supplement into a successful brand can feel daunting. The journey is filled with critical decisions, but none is more impactful than your choice of a private label contract manufacturer. This partnership goes far beyond putting a label on a stock product. It's about building a collaborative relationship that ensures quality, reliability, and innovation in every bottle.

Think of your manufacturer as your dedicated R&D partner and production facility, all in one. They should be industry insiders who live and breathe botanical supplements—from sourcing high-purity raw materials to mastering the nuances of advanced, temperature-controlled extraction.

The Core Pillars of a Strong Partnership

A successful launch hinges on your partner's capabilities in a few key areas. You need a manufacturer who excels in:

- Quality & Compliance: This is the bedrock of your brand. Your partner must operate from a cGMP-compliant, UL-certified, and FDA-registered facility. This isn't just about ticking boxes; it’s about protecting your product, your brand, and most importantly, your customers.

- Customization & Flexibility: A one-size-fits-all approach is a non-starter. The best partners are your R&D collaborators, helping you craft a unique formula, perfect the flavor profile, and select the ideal packaging. They must also be flexible with production volumes, accommodating everything from small pilot runs to full-scale production.

- Speed & Reliability: Look for a manufacturer with a proven record of rapid turnarounds and on-time delivery. Transparent timelines and dependable execution allow you to plan marketing and launch campaigns with confidence.

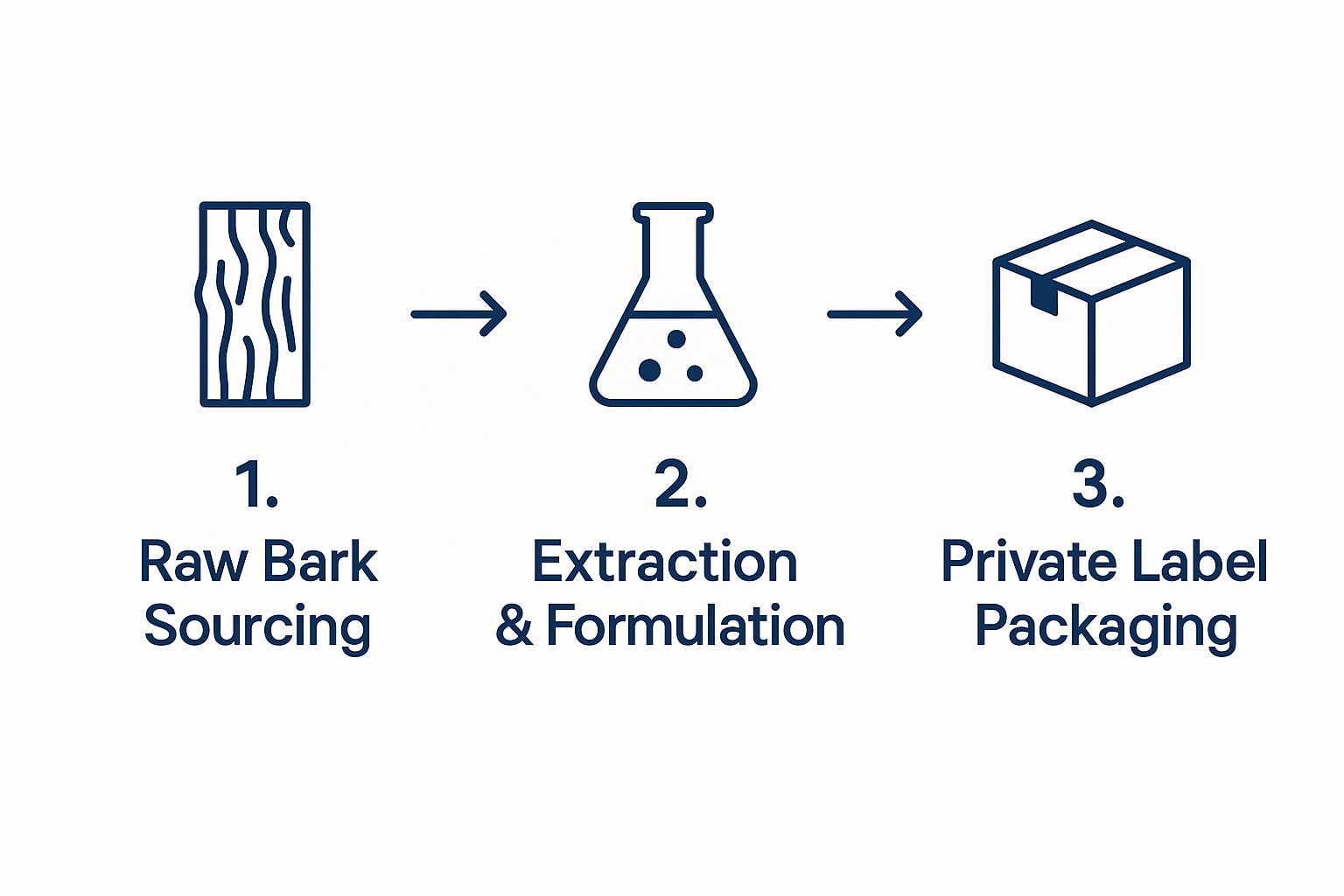

The journey from raw botanical to final consumer product is a sophisticated process. This graphic provides a high-level overview of that transformation.

Each stage—sourcing, extraction, and packaging—demands specialized expertise and rigorous quality control to ensure the final product is both safe and effective.

Navigating the Market with an Expert Guide

The demand for natural health solutions is undeniable. The global Terminalia extract market, which includes Arjuna bark, has seen steady growth, with a compound annual growth rate (CAGR) of around 4.4% in recent years. Projections show this trend is set to continue.

This growth creates a significant opportunity, but it also brings increased competition. An expert manufacturing partner helps you stand out by ensuring your product meets the highest standards for potency and purity. They manage the complex operational details, freeing you to focus on your core strength: building your brand and connecting with your audience. For a deeper dive into this business model, check out our comprehensive guide for starting your own brand of private label liquid supplements.

To help you visualize the collaboration, the table below outlines the key milestones in bringing your Arjuna supplement to market with a manufacturing partner.

Key Partnership Milestones for Your Arjuna Supplement Launch

| Milestone | What It Involves | Your Role | Manufacturer's Role |

|---|---|---|---|

| Initial Consultation & Quoting | Discussing your product concept, target market, and formula ideas. | Bring your vision, research, and goals. Be clear about your brand's unique value proposition. | Act as your consultant, offering expert feedback, formula suggestions, and a detailed preliminary quote. |

| Formula Development & Sampling | Crafting and refining the precise formula, including active ingredients and flavor profiles. | Provide clear, decisive feedback on lab samples. Give final approval on the formulation. | Leverage formulation expertise to develop samples. Revise the formula until it perfectly matches your vision. |

| Branding & Packaging | Designing your label and selecting the bottle, cap, and seal to match your brand. | Finalize your brand design and supply all necessary artwork files. | Source compliant packaging components and verify that label artwork meets all FDA requirements. |

| Production & Quality Control | Manufacturing your first production run under strict cGMP protocols. | Approve the final production proof and submit the purchase order. | Procure and verify raw materials, manage the production line, and conduct in-process and final QC testing. |

| Final Delivery & Launch Support | Packaging the finished goods and preparing them for shipment. | Coordinate logistics for receiving inventory and execute your launch marketing plan. | Provide a Certificate of Analysis (CoA) for the batch and ensure on-time delivery. |

Working through these milestones with a capable partner transforms a complex process into a manageable, step-by-step journey toward launching a successful product.

Key Takeaway: The right manufacturing partner doesn't just make your product; they are your R&D partner from concept through launch. They provide the quality assurance, scalability, and logistical backbone needed to turn a great idea into a market-leading brand.

From Concept to Custom Formula: Your R&D Partner

This is where your vision becomes a reality. Taking your Arjuna Terminalia Bark supplement from a brilliant idea to a finished product is a creative, collaborative process. A top-tier private label manufacturer isn't just an order-taker; they become your de facto R&D team. They are the formulation experts who help you translate your brand’s unique story into a product that is scientifically sound and commercially viable.

The first step is defining your product's core identity. Are you envisioning a powerful, single-ingredient Arjuna extract focused on its renowned cardiovascular benefits? Or are you aiming for a more complex, synergistic blend that addresses multiple wellness needs? The possibilities are truly exciting.

Standalone Powerhouse vs. Synergistic Blend

Opting for a standalone Arjuna extract provides clarity and potency. It's a clean, direct approach that appeals to the informed consumer actively seeking this powerful botanical. With this strategy, the entire focus is on achieving maximum purity and a standardized potency that establishes your product as a hero-ingredient solution.

On the other hand, creating a synergistic blend can significantly broaden your product's appeal and help you capture a unique market niche. Consider pairing Arjuna bark with other botanicals known for their complementary actions.

- For Enhanced Cardiovascular Support: You might blend Arjuna with Gokshura (Tribulus terrestris). In traditional wellness systems, this is a classic combination recognized for supporting heart health and healthy circulation.

- For Stress and Adrenal Support: Combining Arjuna with Ashwagandha (Withania somnifera) is another strategic choice. This creates a compelling formula that addresses both cardiovascular wellness and the body's stress response—a key concern for modern consumers.

- For Metabolic Health: A formulation that includes Cinnamon or Berberine alongside Arjuna could be a major draw for consumers focused on maintaining healthy blood sugar and cholesterol levels.

This isn't just about mixing herbs. Crafting a sophisticated blend requires deep formulation expertise to ensure correct dosages, ingredient compatibility, and product stability. A skilled manufacturing partner is essential to navigate these complexities, ensuring the final product is both safe and exceptionally effective.

Sourcing and Verifying Your Raw Materials

Let’s be clear: the quality of your finished supplement is 100% dependent on the quality of your raw materials. This is an area where there can be no compromise.

A premier Arjuna Terminalia Bark private label contract manufacturer will have an ironclad sourcing process built on transparency and rigorous verification. They won't buy from anonymous brokers; they will have established, long-standing relationships with trusted growers, ensuring a consistent and high-purity supply chain.

Insider Tip: When vetting a potential manufacturer, ask them to detail their vendor qualification program. They should be able to explain precisely how they vet suppliers, what documentation they require, and the steps they take to maintain supply chain integrity from farm to facility.

Before any production begins, that raw Arjuna bark must undergo rigorous testing. This is where the Certificate of Analysis (CoA) becomes your most critical document. It is the formal report that confirms the material's identity, purity, and potency.

A proper CoA for Arjuna bark must include:

- Botanical Identity: Verification that you are getting genuine Terminalia arjuna.

- Potency Assay: Measurement of the key active compounds to ensure efficacy.

- Heavy Metal Analysis: Screening for contaminants like lead, arsenic, mercury, and cadmium.

- Microbiological Screening: Testing for harmful yeast, mold, E. coli, and Salmonella.

This level of scrutiny is what separates premium, trustworthy brands from the rest. It is the guarantee that what's on your label is exactly what's in the bottle. The right partner manages this entire verification process for you, giving you the confidence to build your brand on an unshakable foundation of quality.

Inside a cGMP-Certified Manufacturing Process

Once your custom formula is approved, the project moves from the R&D lab to the production floor. This is where a partner's promises are put to the test. A top-tier Arjuna Terminalia Bark private label contract manufacturer doesn’t just follow a recipe; they execute a finely tuned, multi-stage process designed to protect your brand and deliver a perfect product, every single time.

This entire operation is built on a foundation of non-negotiable credentials. These aren't just acronyms for a website—they represent a verifiable commitment to quality, safety, and consistency.

- FDA-Registered Facility: This is the baseline requirement. It confirms the manufacturer operates under the jurisdiction and inspection of the FDA.

- cGMP Certified: Current Good Manufacturing Practices are the official rules for supplement manufacturing, governing everything from raw material handling and equipment calibration to final product testing.

- UL Certified: This third-party certification provides an extra layer of assurance. UL performs independent audits to confirm a manufacturer is actively and consistently adhering to cGMP standards.

These certifications are your guarantee that your partner has a process you can trust. If you're new to these terms, it’s worth taking a moment to explore what a GMP certificate truly represents in our detailed guide.

The Journey from Raw Material to Finished Bottle

The production of your Arjuna liquid extract is a meticulously controlled process. It begins with verified raw materials and moves through several key stages, each with its own quality control checkpoints.

First is extraction. This is a critical, make-or-break step. The method used directly impacts the potency and stability of the bioactive compounds in the Arjuna bark. While traditional methods exist, forward-thinking manufacturers utilize advanced techniques to better preserve the delicate phytonutrients.

Expert Insight: We utilize innovative cold-fill technology and a proprietary temperature-controlled extraction process. By avoiding high heat—which can degrade sensitive compounds—we capture a more complete and potent profile of the Arjuna bark. This means the final product is closer to nature's design.

From there, we move to formulation and blending. Here, the Arjuna extract is precisely combined with other approved ingredients in calibrated, stainless-steel tanks to prevent any risk of contamination. During this stage, our quality teams pull samples to test for homogeneity, ensuring every drop in the batch is perfectly consistent.

The Critical Role of Third-Party Testing

Even with the most rigorous internal controls, the gold standard for verifying product safety and potency is independent, third-party lab testing. A trustworthy partner will never skip this step—in fact, they’ll insist on it.

After your product is bottled, a sample from the finished batch is sent to an accredited lab. This lab provides a completely unbiased analysis of your final product.

What exactly are they testing for?

- Potency Verification: Does the amount of active Arjuna extract in the bottle match the label claim? This confirms your customers get the dosage they paid for.

- Purity and Safety: The lab runs another full panel for contaminants, including heavy metals, microbes, and pathogens. This is the final safety check before release.

- Ingredient Identity: This step re-confirms that the botanical in the bottle is definitively Terminalia arjuna.

This final, independent validation provides you—and your customers—with total confidence in the product.

This meticulous approach is vital because the raw material itself can be highly variable. Analytical studies of market samples of Terminalia arjuna bark show wide-ranging physicochemical properties, with ash values sometimes reaching 27.77%. This natural variance makes expert manufacturing controls essential for ensuring batch-to-batch consistency. You can dive deeper into how chemical fingerprinting ensures product efficacy in this detailed analysis of Arjuna market samples.

Ultimately, this quality-first process is designed for growth. Whether you're launching a small pilot batch or scaling to tens of thousands of units, the same cGMP-certified processes are always in place. This is how we ensure your brand can grow without ever sacrificing the quality that built your customers' trust.

Perfecting Your Packaging and Launch Logistics

You have invested your expertise into developing a superior Arjuna Terminalia Bark liquid formula. Now, it's time to give it the perfect packaging. Packaging is more than a container; it's the first physical interaction a customer has with your brand. It must protect the product's integrity, communicate its value, and ensure a seamless user experience.

Even a phenomenal product can fail with poor packaging. For a potent botanical extract like Arjuna, this choice is critical. A skilled Arjuna Terminalia Bark private label contract manufacturer will guide you through the options, helping you balance aesthetics, function, and preservation.

Choosing Your Primary Packaging

For liquid supplements, the bottle and dispenser are your primary defense against degradation. The main goal is to shield the formula from UV light and oxygen, which can break down active compounds.

Your most effective choices include:

- Amber or Cobalt Blue Glass Bottles: This is the gold standard. The colored glass provides excellent UV protection, which is critical for safeguarding the delicate phytochemicals in your Arjuna extract. Glass also has an inert, premium feel that resonates with health-conscious consumers.

- High-Quality PET Plastic: Modern, BPA-free PET (polyethylene terephthalate) bottles are a great lightweight and shatter-resistant alternative. If you choose this route, ensure you are using options with UV-blocking additives.

- Dispensing Mechanisms: The right cap is crucial for accurate dosing. Graduated droppers are perfect for concentrated tinctures, while pumps can be more convenient for larger-dose formulas.

Insider Tip: Always request samples of the bottle and dropper combinations you are considering. Test them yourself. Is the dropper's suction effective? Is the cap secure? These small details in the user experience significantly impact customer satisfaction and repeat purchases.

Nailing Your Label and FDA Compliance

Your label is your product's primary salesperson, but it must also be a fortress of compliance. The FDA has strict rules for dietary supplement labeling, and a knowledgeable manufacturing partner will ensure every detail is correct before printing. Errors can lead to expensive recalls or legal issues.

Key elements your label must include:

- Statement of Identity: Clearly states what the product is (e.g., "Arjuna Bark Herbal Supplement").

- Net Quantity of Contents: The amount of liquid in the bottle (e.g., 2 fl oz / 60 mL).

- Supplement Facts Panel: The structured panel listing serving size, servings per container, and all dietary ingredients with their amounts.

- Ingredient List: All ingredients listed in descending order by predominance.

- Name and Place of Business: Your brand's name and address.

Beyond these basics, you must also manage allergen statements and the mandatory FDA disclaimer. A true partner manufacturer will provide a die-line template for your designer and review the final artwork to confirm it meets all regulatory requirements.

Understanding Production Timelines and MOQs

With packaging and labels finalized, the conversation shifts to logistics: Minimum Order Quantity (MOQ) and production turnaround time. A flexible partner understands that new brands often need to start small.

Look for a manufacturer offering reasonable MOQs—around 1,500 to 2,500 units for a pilot run is a positive sign. This allows you to test the market without a massive upfront capital investment. As your brand grows, they should be able to scale with you to runs of 10,000 units or more.

A transparent manufacturer will also provide a clear, realistic production timeline. Typically, from the moment you approve your final proof and issue a purchase order, you can expect a 4 to 6-week turnaround for production, bottling, and final quality assurance. This reliable schedule allows you to confidently plan your marketing campaigns, arrange for fulfillment, and set a firm launch date.

Building a Resilient Supply Chain Partnership

Successfully launching your first production run is a major milestone, but it’s just the beginning. A true competitive advantage comes from forging a genuine partnership with your contract manufacturer, moving beyond a simple transactional relationship.

Your goal is to find a team that feels like an extension of your own—one that is as invested in your long-term success as you are. This means finding a partner who is proactive, not just reactive. They should bring you market insights, suggest future product innovations, and help you anticipate challenges before they become problems. This is what separates a supplier from a growth partner.

Navigating the Arjuna Terminalia Supply Chain

A significant part of this partnership is managing the complex global supply chain for botanicals. Arjuna Terminalia bark is not a simple commodity. Quality can vary dramatically based on origin, harvesting methods, and storage. A top-tier Arjuna Terminalia Bark private label contract manufacturer has invested years in mastering this landscape.

The global network for Terminalia Arjuna involves roughly 93 manufacturers and exporters and about 161 importers worldwide. An experienced partner knows how to navigate this network to secure high-quality raw material consistently, run after run. This expertise becomes your brand's safety net, shielding you from supply shocks that can derail a growing business.

Proactive Inventory and Risk Management

What is your plan if a weather event disrupts a harvest? What happens when a sudden media trend for Arjuna tightens global supply? A manufacturer without a plan will leave you with stockouts and lost sales.

A true strategic partner, however, is already prepared. They practice proactive risk management, which includes:

- Strategic Raw Material Stockpiling: They maintain a strategic inventory of pre-qualified Arjuna bark to buffer against supply chain interruptions.

- Supplier Diversification: A resilient manufacturer has relationships with multiple vetted suppliers in different regions to ensure a reliable backup plan.

- Transparent Communication: If they see a potential disruption, they give you a heads-up. This transparency allows you to adjust marketing and inventory planning before a crisis hits.

Partnership in Action: Imagine your Arjuna supplement is featured on a popular podcast and sales suddenly double. A reactive supplier might quote a 12-week lead time for new materials. A proactive partner, having anticipated your growth potential, already has vetted Arjuna bark in their warehouse. They can schedule your next production run immediately, allowing you to capitalize on the momentum.

Building an adaptable supply chain is fundamental to long-term success. To get a better handle on this, check out these proven strategies for efficient supply chain management.

A Partnership Built for Innovation and Growth

As your brand matures, you will want to innovate and expand. This is where a true partnership pays dividends. A forward-thinking manufacturer becomes your R&D collaborator, actively helping you plan what’s next.

This collaboration could look like:

- Developing a new synergistic formula with another trending botanical.

- Creating a higher-potency "extra strength" version of your flagship product.

- Exploring different delivery formats, like convenient single-serving liquid shots.

This collaborative spirit ensures your brand stays fresh, relevant, and aligned with your customers' needs. Ultimately, this relationship should be about fostering mutual growth, not just fulfilling orders.

Common Questions About Arjuna Supplement Manufacturing

As you prepare to launch your Arjuna Terminalia Bark supplement, practical questions will arise. Partnering with a private label contract manufacturer is a significant step, and you need clear, straightforward answers.

Here are the most common questions we hear from health and wellness entrepreneurs, along with the answers you need to plan your launch effectively.

What Is a Typical Minimum Order Quantity (MOQ)?

This is often the first question founders ask. MOQs can vary significantly. A flexible, growth-minded partner understands that new brands need a realistic starting point.

For a custom liquid Arjuna supplement, a sensible pilot batch is around 1,500 to 2,500 units. This quantity is strategic:

- Market Testing: It’s enough to launch and gather crucial customer feedback without tying up your entire budget.

- Preserving Capital: A smaller initial run keeps cash free for marketing.

- Validating Your Concept: It’s the perfect way to prove your product's potential before scaling up.

Your goal is to find a partner who can scale with you, seamlessly moving from pilot batches to full production without any drop in quality.

How Long Does the Private Label Process Take?

From concept approval to market-ready product, a realistic timeline is typically 12 to 16 weeks. An experienced Arjuna Terminalia Bark private label contract manufacturer with efficient processes can sometimes shorten this, but it’s wise to plan for this window.

Here’s a rough breakdown of that timeline:

- R&D and Formulation (4-6 weeks): The creative phase of developing your unique formula, perfecting flavor, and approving samples.

- Raw Material Sourcing (2-4 weeks): Your partner procures the Arjuna Terminalia Bark and other ingredients and conducts rigorous identity and purity testing.

- Production and QA (4-6 weeks): The final stage, including manufacturing, bottling, labeling, and final third-party quality assurance testing.

Key Takeaway: A manufacturer with solid supplier relationships can often tighten these lead times. Always request a detailed project timeline upfront to align your marketing and launch plans.

What Are the Most Important Certifications?

In an industry built on trust, certifications are non-negotiable proof of quality. They are verifiable promises that you are adhering to the highest standards.

When vetting a potential partner, these are the absolute must-haves:

- cGMP (Current Good Manufacturing Practices) Certified: This is the foundational standard set by the FDA, governing every aspect of production.

- FDA-Registered Facility: This confirms the manufacturer operates under the oversight of the U.S. Food and Drug Administration.

- Third-Party Audits (UL or NSF): These credentials prove that an independent organization has audited the facility and confirmed it meets cGMP standards, adding a powerful layer of credibility.

If you are launching an organic product, USDA Organic certification from your manufacturer is also essential. These credentials protect your brand and give customers confidence in your product's integrity.

Can I Supply My Own Arjuna Bark Material?

This is a logical question, but any reputable, cGMP-certified manufacturer will almost certainly say no.

A trustworthy partner operates a closed-loop quality system built on a meticulous vendor qualification program. They use pre-vetted suppliers whose Arjuna Terminalia Bark has already passed stringent tests for identity, purity, and potency. Introducing an outside raw material would require a lengthy and expensive qualification process to meet their established standards. To protect supply chain integrity and product safety, manufacturers will insist on using materials from their own qualified network.

Ready to turn your vision for a premium Arjuna Terminalia Bark supplement into a market-ready success? The experts at Triton Nutra Group are here to be your dedicated R&D and manufacturing partner, guiding you from concept to launch with transparency and unmatched quality.