Your Partner From Concept to Launch: The Ultimate Guide to Angelica Root Private Label Contract Manufacturing

Discover reliable Angelica Root private label contract manufacturer services. Customize your products and grow your brand today!

Get a Free Quote Today!

Get a Free Quote Today!The demand for potent botanicals like Angelica Root is surging. For ambitious health and wellness brands, this is a can't-miss opportunity. The fastest, most strategic path to market is partnering with a specialized Angelica Root private label contract manufacturer. This approach lets you bypass the immense investment in facilities, R&D, and regulatory compliance, transforming your product concept into a market-ready reality with speed and precision.

Why Partner with an Angelica Root Private Label Expert?

Launching a new herbal supplement can be daunting. You're juggling formulation science, complex FDA regulations, and the logistics of production. As a brand manager or e-commerce founder, your goal is clear: launch a superior product quickly without compromising on quality. This is where the right manufacturing partner becomes your most valuable asset.

Choosing an expert private label partner isn't just outsourcing production. It's about gaining an instant R&D team, a dedicated compliance department, and a scalable operations partner. You get immediate access to innovative botanical extraction processes and our advanced cold-fill technology, all without the multi-million-dollar upfront cost.

The Strategic Advantage of Private Labeling

Think of private labeling as your ultimate strategic shortcut. Instead of spending years and a fortune building a cGMP-certified facility, you leverage an existing, proven infrastructure. This frees up your capital and energy to focus on what you do best: building your brand, engaging customers, and driving sales. A true partner collaborates with you from the initial concept all the way through a successful launch and is ready to scale production as you grow.

The market is not just growing; it's accelerating. Valued at USD 463.2 million in 2023, the global market for Angelica Root Extract is projected to reach USD 790.8 million by 2032. That represents a compound annual growth rate (CAGR) of 6.1%, fueled by consumers actively seeking natural, effective wellness solutions. You can explore the global Angelica Root market trends to see the opportunity for yourself.

Your R&D partner from concept through launch. This partnership mindset is what separates a mere supplier from a strategic ally. We combine your brand vision with our manufacturing and formulation expertise to create a product that commands attention on the shelf.

This guide is your roadmap. We’ll walk you through the entire private label process, from vetting a manufacturer for quality and compliance to crafting a unique formula your customers will love.

Private Label vs. In-House Manufacturing at a Glance

Choosing your production path is a critical business decision. Here’s a clear breakdown of partnering with a private label manufacturer versus building it all yourself.

| Factor | Private Label Partner | In-House Manufacturing |

|---|---|---|

| Initial Investment | Low to moderate (formulation, inventory) | Extremely high (facility, equipment, staff) |

| Time to Market | Fast (weeks to months) | Slow (years) |

| Expertise Required | Minimal; partner provides R&D and compliance | Extensive knowledge of formulation, regulations, and production required |

| Operational Focus | Branding, marketing, and sales | Managing production, supply chain, and compliance |

| Scalability | Easy; partner handles increased production | Complex and capital-intensive |

| Risk | Lower financial and operational risk | High financial and operational risk |

Ultimately, a private label partnership empowers you to enter the market with speed and agility, backed by established expertise—a decisive advantage in a competitive landscape.

Navigating Quality and Compliance Standards

When you launch an Angelica Root supplement, your brand’s reputation is on the line with every bottle. For any herbal product, a foundation of quality is non-negotiable. Vetting a potential Angelica Root private label contract manufacturer must begin with their quality systems and compliance credentials.

These standards aren't just red tape; they are the framework ensuring your product is safe, consistent, and effective. A top-tier partner doesn’t just meet these standards—they embody them as a core business principle.

The Non-Negotiable Credentials

Before discussing formulas or pricing, verify these baseline certifications. They separate legitimate, professional operators from risky propositions and are your first line of defense.

-

cGMP Certified: This is paramount. Current Good Manufacturing Practices (cGMP) are the FDA's rules for manufacturing. A cGMP-certified facility demonstrates robust systems controlling every aspect of production, from raw material intake to finished product shipment.

-

FDA-Registered Facility: While the FDA doesn't "approve" dietary supplements, every manufacturer must register their facility with the agency. This is mandatory. If a potential partner isn’t registered, it's a deal-breaker.

-

UL Certified: A UL certification adds another powerful layer of trust. It signifies that an independent third-party organization has audited the facility's processes and confirmed they meet exceptionally high quality and safety protocols. It’s an extra stamp of assurance that they are serious about compliance.

Key Takeaway: Don't just take a manufacturer's word for it. Request copies of their current certifications. A transparent, confident partner will provide this documentation without hesitation.

Many established manufacturers offer a full suite of services—formulation, extraction, blending, bottling, and packaging—for brands launching tinctures, topicals, and supplements. These partners operate under strict regulatory frameworks, including the FDA's GMP standards (21 CFR Part 111), and may also hold USDA Organic certification.

Decoding Raw Material Quality and Testing

A brilliant formula is worthless if the ingredients are substandard. This is where traceability and rigorous testing are critical. You must know exactly what's in your product and where it came from.

Any top-tier manufacturer will provide a Certificate of Analysis (COA) for every raw ingredient. This lab report verifies the botanical's identity, potency, and purity, confirming it is free from contaminants like heavy metals, pesticides, and microbes.

The best partners go further. They conduct their own in-house verification testing on all incoming materials and send the final, bottled product out for third-party lab testing. This double-check system is your ultimate guarantee that what's on the label is precisely what's in the bottle.

When interviewing a potential manufacturer, ask direct questions about their testing protocol:

- Raw Material Testing: Do you test every batch of incoming Angelica Root for identity, purity, and potency?

- In-Process Checks: What quality control steps do you take during production to ensure batch-to-batch consistency?

- Finished Product Testing: Do you send every final lot to an independent lab for verification? Can I review those reports?

This level of scrutiny builds brand trust and protects you from potential disaster. A rock-solid quality control system is a clear sign of a reliable Angelica Root private label contract manufacturer. For more on this topic, our broader guide on nutraceutical contract manufacturing is a useful resource.

Crafting Your Unique Angelica Root Formula

In a crowded market, a generic, off-the-shelf supplement won't cut it. To build a loyal customer base, your product needs a unique identity that solves a specific problem for your target audience.

This is where you move beyond simple white-labeling. A true Angelica Root private label contract manufacturer acts as your R&D partner, helping you build a custom product from the ground up. We merge your brand vision with our deep formulation expertise to create a supplement that is uniquely yours.

Beyond the Basics: Customization Options

Effective product development starts with your "why." Are you creating a digestive aid? A calming tincture for stress? A supportive blend for women's wellness? Your answer guides every formulation decision.

Our skilled R&D team can open up a spectrum of possibilities. This isn't just about tweaking an ingredient; it’s a holistic approach to crafting a standout product.

- Synergistic Herbal Blends: Angelica Root is a powerhouse, but its effects can be beautifully amplified by complementary botanicals. For a digestive formula, we might suggest adding ginger and peppermint. For a stress blend, we could explore combining it with ashwagandha or lemon balm for a more comprehensive effect.

- Targeted Carrier Liquids: The base liquid is more than a delivery system; it's part of the customer experience. We can work with anything from organic vegetable glycerin for natural sweetness to purified water for a clean, neutral profile.

- Advanced Extraction Methods: How you extract active compounds from the plant matters immensely. We use innovative temperature-controlled cold-fill technology and proprietary, alcohol-free extraction methods to protect the delicate phytochemicals in Angelica Root, ensuring maximum potency.

Real-World Formulation Scenarios

Let's make this tangible. Imagine you're an e-commerce founder focused on natural solutions for stress and sleep. You want to launch an Angelica Root product that hits that specific target.

Instead of a simple tincture, we'd collaborate with you to design a "Tranquility Blend." We would start with a potent Angelica Root extract. From there, we might suggest adding Valerian Root for its sedative properties and Chamomile for its calming effects. To create a pleasant pre-bedtime ritual, we could develop a subtle, natural honey-lemon flavor.

The result is a highly targeted, marketable product that solves a clear customer need.

Partnership in Action: A great manufacturer doesn't just take orders. They bring ideas to the table, challenge assumptions, and apply their deep industry knowledge to make your final product even better than your initial concept.

This detailed formulation work transforms a simple supplement into a hero product for your brand. To dive deeper into this process, our guide to private label liquid supplements offers a complete look at starting your brand. This collaborative spirit is essential for long-term success.

From Production Runs to Scaling Your Brand

You’ve perfected your custom Angelica Root formula. Now it’s time to transform that idea into a physical product. This is where your partnership with a Angelica Root private label contract manufacturer comes to life, moving your vision from a lab sample to a brand poised for growth. This is a carefully managed process built for efficiency, reliability, and scale.

The journey begins with your first production run. A flexible partner won't force you into a massive order. They'll offer flexible run sizes, allowing you to start with a smaller pilot batch or a more substantial initial order. This flexibility is crucial for managing cash flow and avoiding the risk of excess inventory.

Navigating MOQs and Lead Times

Two key terms in production planning are Minimum Order Quantities (MOQs) and lead times.

MOQs are the smallest number of units a manufacturer will produce in a single run. For a new brand, finding a partner with low MOQs—such as 500 or 1,000 units—is a game-changer. It dramatically lowers your upfront investment and risk.

Lead time is the period from placing your order to receiving the finished products. A reliable timeline dictates your launch date, marketing campaigns, and inventory management. A proficient contract manufacturer can often deliver an order in 4 to 6 weeks, enabling agile launches and rapid restocking. With a clear lead time, you can plan with confidence and prevent costly stockouts.

The Critical Role of Packaging and Labeling

Your packaging is your product's first impression. It must protect your formula and communicate your brand's quality instantly. A great contract manufacturer will guide you through the maze of options.

- Bottles and Droppers: Dark-colored glass, like amber, is the industry standard for protecting light-sensitive extracts like Angelica Root from potency degradation. You can also choose between standard or metered droppers for precise dosing.

- Labels and Compliance: Your label must be both beautiful and compliant. It needs to be on-brand while strictly adhering to all FDA labeling requirements, including the supplement facts panel, net quantity, and ingredient list.

- Secondary Packaging: A custom box adds a premium feel and provides more space for your brand story. Your manufacturing partner should be able to source and assemble all components seamlessly.

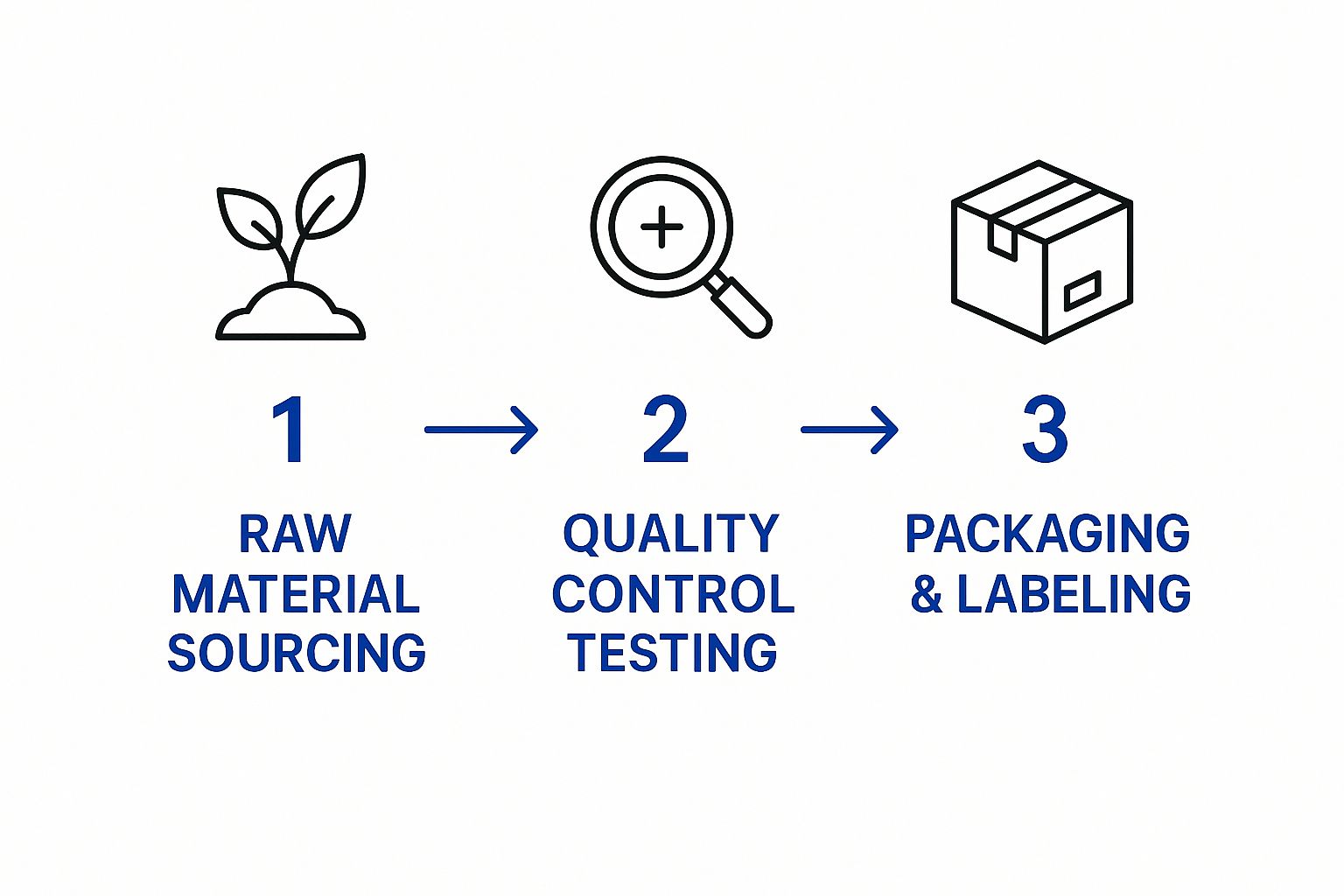

This graphic illustrates the flow from sourcing high-quality raw materials to the final, shelf-ready product.

As you can see, quality isn't a final check; it's embedded in every step to ensure your product is both safe and effective.

Planning for Growth and Scalability

Choose a partner who is ready to grow with you. They need the capability to handle your initial small runs and seamlessly scale to full production as your brand takes off. Switching manufacturers mid-growth is a massive disruption you want to avoid.

A partner's true value is revealed when you need to scale. A manufacturer who can ramp up from 1,000 to 10,000 units without sacrificing quality or extending lead times is an invaluable asset for long-term growth.

Scalability should also include services that support your expansion, such as in-house fulfillment, direct shipping to Amazon FBA, or R&D for new products. When you align with a partner invested in your journey, remarkable things happen—just look at how a supplement brand increased its revenue by 25x. Stories like this demonstrate the power of a strong manufacturing partnership.

Choosing a Partner for Long-Term Success

Selecting a contract manufacturer is not a one-time transaction; it’s the beginning of one of your brand's most critical relationships. The right partnership will fuel your growth long after the first invoice is paid. Your goal is to find an Angelica Root private label contract manufacturer who functions as an extension of your team.

A great partner moves beyond order-taking. They bring proactive problem-solving, transparent communication, and relentless reliability. They are your strategic asset, alerting you to market trends, new botanical discoveries, and production innovations that provide a competitive edge.

The Pillars of a Strong Manufacturing Relationship

While pricing and turnaround times are important, a lasting partnership is built on three core pillars. Don't settle for a manufacturer who doesn't excel in all three.

-

Unwavering Quality and Compliance: This is the absolute starting point. Your partner must live and breathe cGMP standards, hold key certifications (FDA-registered, UL-certified), and be fully transparent about their sourcing and third-party testing protocols.

-

Deep Customization and Flexibility: Your brand is unique, and your products should be too. A great partner has the R&D expertise to help you build a custom formula from scratch. They should offer flexibility in ingredients, flavors, packaging, and run sizes—from pilot to full scale.

-

Proven Speed and Reliability: In the fast-paced world of e-commerce, you need a partner you can count on. This means clear communication, trustworthy timelines, and a proven record of on-time delivery. When your manufacturer is reliable, you can focus on marketing and sales, confident that your inventory is secure.

A great partner is a collaborator, not just a supplier. They are your R&D team, your compliance experts, and your scaling solution, all rolled into one. This partnership mindset is what separates good manufacturers from great ones.

Moving From Learning to Action

With this framework, you are ready to move from research to outreach. The goal is to find a manufacturing partner who not only understands your vision but is excited to help you realize it. This isn't just a search for a vendor; it's about finding a team invested in your success.

The right partner will guide you through the entire journey, from idea to a thriving brand. This relationship is one of the most critical decisions you'll make. For a closer look at the initial steps, our guide on how to start a supplement brand can provide more context. Your mission now is to find a partner whose values align with yours and who has the expertise to ensure your success.

When diving into private label manufacturing, especially with a unique botanical like Angelica Root, questions are inevitable. It’s a complex process, and you want to get it right.

As an experienced Angelica Root private label contract manufacturer, we’ve guided countless brands through this exact journey. Here are some of the most common questions we get from entrepreneurs and brand managers just like you.

Getting Started With Formulations

The formula is often the first hurdle. Many clients have a brilliant idea but need help translating that vision into a real, compliant, and shelf-stable product. This is where a true partnership begins.

A common question is, "Do I need my exact formula ready before I call you?" Absolutely not. In fact, most clients don't. Knowing your target customer and desired benefit—like digestive support or stress relief—is a great start. Our R&D team is here to build with you. We can develop a custom formula from scratch, suggest synergistic herbs to complement Angelica Root, and perfect the flavor profile.

Another concern is Minimum Order Quantities (MOQs). "What's a typical starting order size?" We understand that cash flow is critical. That’s why we offer flexible MOQs starting as low as 500 or 1,000 units. This allows you to launch your product and test the market without tying up capital in excess inventory.

Finally, we always get questions about sourcing. "Can I provide my own Angelica Root?" While we appreciate the desire for control, we insist on using our vetted raw material suppliers to ensure cGMP compliance and traceability. We have long-term relationships with our growers and run every batch through rigorous in-house and third-party testing to guarantee purity and potency. This is how we ensure your final product is safe, effective, and has a clear history from farm to bottle.

Understanding Quality and Compliance

The regulatory landscape can seem intimidating, but a good manufacturing partner makes it straightforward. Savvy brand owners know that certifications and testing are where reputations are made.

"What do cGMP, FDA-registered, and UL-certified really mean for my product?"

- cGMP (Current Good Manufacturing Practices): This is the FDA's rulebook for quality control. Our cGMP certification means we have proven systems for everything—from receiving raw materials to shipping the final product—to ensure your supplement is safe, pure, and potent.

- FDA-Registered: This is mandatory. Any facility making dietary supplements in the US must be registered with the FDA. It’s the baseline for legal operation.

- UL Certified: This is a voluntary, third-party certification that goes beyond cGMP. It demonstrates an extra commitment to quality, involving regular, stringent audits of our processes by an independent body.

We always provide clients with copies of our current certifications. Transparency is the bedrock of a strong partnership. Hesitation to share this information is a major red flag.

Another key concern is testing. "How do I know what's on the label is actually in the bottle?" This is one of the best questions to ask. Our multi-stage quality control process includes testing all incoming raw materials against a Certificate of Analysis (COA), performing in-process checks, and, most importantly, sending every finished batch to an independent, third-party lab for final testing. You receive that final COA, giving you and your customers total confidence.

The Production and Packaging Process

Once the formula is locked in, the conversation shifts to logistics—the exciting part where your vision becomes a physical product.

"How long will it take to get my first order?" While it can vary, a typical turnaround for a new liquid supplement is 4 to 6 weeks. This timeline begins after you approve the final formula and label artwork and covers sourcing, production, quality control, and third-party testing. We provide a clear timeline so you can plan your launch with certainty.

Packaging is always a hot topic. "What are my options for bottles and labels?" The industry standard for Angelica Root tinctures is amber or cobalt blue glass to protect the formula from UV light. We can help source bottles, droppers (standard or metered), and tamper-evident seals. For the label, you can provide your own FDA-compliant artwork, or we can connect you with design partners specializing in supplement branding.

We also get asked about our process. "What is cold-fill technology and why does it matter?" Many botanical compounds, including those in Angelica Root, are damaged by heat. Our proprietary temperature-controlled cold-fill process and alcohol-free extraction methods are designed to protect these delicate phytochemicals. This ensures your final product delivers maximum potency, setting it apart from supplements made with harsher, heat-based methods. It’s a key reason top brands choose us as their Angelica Root private label contract manufacturer.

To help summarize, here is a quick-reference table of common questions.

Common Questions About Private Labeling

Here are the most frequently asked questions about the private label process for Angelica Root supplements.

| Question | Answer |

|---|---|

| Do I need a finished formula to start? | No. We partner with you to develop a custom formula from scratch based on your brand’s goals and target audience. |

| What are your Minimum Order Quantities (MOQs)? | Our MOQs start as low as 500-1,000 units, offering a low-risk path to launch your new supplement. |

| How long does the first production run take? | Typically, you can expect your first order in 4 to 6 weeks after the formula and label artwork are finalized. |

| Do you use heat in your manufacturing? | No. We use a proprietary temperature-controlled cold-fill process to protect delicate botanical compounds and ensure maximum potency. |

| How do you ensure product quality? | We are cGMP and UL certified, FDA-registered, and conduct rigorous in-house and independent third-party lab testing on every batch. |

The right partner will make this process feel less like a series of hurdles and more like a collaborative journey to success.

Ready to turn your vision for an Angelica Root supplement into a market-ready success? Triton Nutra Group is your dedicated partner from concept to launch. Request a free quote today and let’s build your brand together.