Your Guide to Partnering with a White Willow Bark Private Label Contract Manufacturer

Learn how to select a reliable White Willow Bark private label contract manufacturer for quality, custom formulas, and scalable supplement launches.

Get a Free Quote Today!

Get a Free Quote Today!A White Willow Bark private label contract manufacturer is a specialized partner that produces and packages liquid supplements or capsules on your behalf, allowing you to sell them under your own brand. This partnership model is your fastest path to market, letting you bypass the immense overhead of building your own manufacturing facility. You gain immediate access to deep expertise in formulation, botanical sourcing, and regulatory compliance to launch a top-tier product your customers will trust.

Finding the Right Manufacturing Partner for Your Brand

Let's be direct. Turning a great idea—like a White Willow Bark supplement—into a product that sells is a major undertaking. The wellness market is booming, and your brand's success hinges on one critical decision: choosing your manufacturing partner.

This isn't just about finding a supplier. It's about finding a partner who understands the nuances of botanical quality, who lives and breathes regulatory compliance, and who can act as an extension of your team.

This is a collaboration, not a transaction. A top-notch manufacturer becomes your R&D partner, guiding you from sourcing high-quality raw ingredients all the way to final bottling. Their job is to help you navigate the complexities of creating a supplement that is effective, safe, and stands out on a crowded shelf.

From Concept to Customer: A Partnership Mindset

The best partners don’t just take an order and send an invoice. They actively contribute to your vision. Think of them as your outsourced R&D department, helping you perfect your formula, choose the right delivery method (liquid or capsules?), and ensure your label claims are both powerful and compliant. It’s this collaborative energy that separates a basic supplier from a true launch partner.

The most successful private label launches happen when the brand and manufacturer are in complete sync. Your partner's dedication to quality, transparency, and innovation directly reflects on your brand's reputation and potential for long-term success.

This partnership mindset is crucial in a rapidly growing market. Consumer demand for White Willow Bark Extract is soaring, driven by a desire for its bioactive compounds like polyphenols and flavonoids. The global herbal supplement market, valued at around USD 46.12 billion, is projected to hit nearly USD 68.27 billion. That’s serious growth you can capitalize on with the right partner.

Vetting Your Potential Partner

So, how do you choose the right one? It takes serious vetting. While you can explore the benefits of white label services for a general overview, supplement manufacturing has its own high-stakes rules. You need to look past slick marketing and dig into their actual processes, certifications, and track record.

For a deeper dive, our guide on finding a reputable supplement manufacturer is an excellent resource.

To focus your search, here's a quick table outlining the non-negotiables you should look for in a manufacturing partner.

Key Partner Attributes for Your White Willow Bark Launch

| Attribute | Why It Matters for Your Brand |

|---|---|

| Quality & Compliance | Look for cGMP & UL certification, FDA registration, and mandatory third-party testing. This is your brand's proof of safety and quality. |

| Customization & Flexibility | Your R&D partner must be able to create custom formulas and handle run sizes from pilot to full-scale production. |

| Speed & Reliability | The partner should offer rapid turnarounds, transparent timelines, and an impeccable on-time delivery record to protect your launch. |

| Botanical Expertise | For White Willow Bark, you need a partner who understands sourcing, advanced botanical extraction, and standardization of active compounds. |

Finding a partner with these qualities is the goal. This guide will break down what each of these means in the real world, so you can confidently select a manufacturer that will champion your product from concept to successful launch.

Navigating Quality and Compliance Standards

In the supplement world, quality isn't just a selling point—it’s the absolute foundation of your brand. It builds customer trust and drives repeat business. For any e-commerce founder or brand manager, mastering the layers of quality control is non-negotiable. This goes beyond a list of certifications; it's about understanding what they really mean for your White Willow Bark supplement.

When you start talking to a potential White Willow Bark private label contract manufacturer, you'll hear plenty of acronyms. The bare minimum is cGMP (Current Good Manufacturing Practices), the FDA-enforced standard covering everything from facility cleanliness to record-keeping.

But a cGMP certification is just the price of admission. The best partners go further, pursuing additional certifications like UL certified or NSF. This demonstrates a proactive, deep-seated commitment to quality. They aren't just meeting the minimum; they're investing in systems designed to protect your brand.

Beyond the Basics: Proving Purity and Potency

For a botanical product like White Willow Bark, the true test of a manufacturer is their ability to prove the raw material is what they claim. This is a huge pitfall. A major industry challenge is suppliers who dilute products, passing off simple powdered bark as a high-potency "extract." This shortcut guts the product's effectiveness and compromises dosage accuracy.

A top-tier partner uses science to combat this. They don't just trust a supplier's word; they verify it. This is where specific testing methods become your brand’s best defense.

Key Botanical Identification & Potency Tests

- HPTLC (High-Performance Thin-Layer Chromatography): This acts as a chemical fingerprint for plants. It’s a visual test that confirms your material is truly Salix alba (White Willow) and not a cheaper, look-alike plant.

- HPLC (High-Performance Liquid Chromatography): Once HPTLC confirms the species, HPLC quantifies how much of the active compound is present. It precisely measures the concentration of salicin, guaranteeing your product delivers on its label promise.

- DNA Barcoding: This is a cutting-edge technique that analyzes the plant's genetic material. It offers definitive, undeniable proof of the species, making it an incredibly powerful tool against adulteration.

When a manufacturer uses these tests, they are building a wall of scientific proof around your product, ensuring what's in the bottle is exactly what you promise your customers.

Decoding the Certificate of Analysis (CoA)

Every legitimate batch of your supplement must come with a Certificate of Analysis (CoA). This document is your quality report card, but it's only useful if you know how to read it. It might look intimidating, but focusing on a few key sections reveals the full story.

First, insist on a CoA from an independent, third-party lab for the final product. This is non-negotiable, as it provides an unbiased report on safety and potency.

Expert Tip: Never accept an in-house CoA as the final proof of potency. While in-house testing signals a strong internal quality process, the final word must always come from a verified, independent third-party laboratory. This removes any potential conflict of interest and provides the ultimate assurance for you and your customers.

Once you have that third-party CoA, dig in. Does the salicin content match your target percentage? Are heavy metal levels (lead, arsenic, mercury) well below acceptable safety limits? Does it show the product is free from microbial contaminants like E. coli and salmonella?

Answering these questions gives you concrete confidence in your product. This deep dive into quality is a crucial part of the process, something we explore even further in our comprehensive guide to launching private label liquid supplements. A great manufacturing partner won't just hand you these documents; they'll walk you through them, ensuring you understand every detail.

Crafting Your Signature White Willow Bark Formula

This is where your brand's unique vision becomes a physical product. Moving from a general idea to a standout, market-ready supplement is a deeply creative and strategic process. A top-tier White Willow Bark private label contract manufacturer acts as your R&D partner, helping you navigate the nuances of custom formulation to create something that truly connects with your audience.

It all starts with your vision. Who are you trying to help? What specific problem are you solving? Nailing down these answers is the bedrock of building a formula people will want to buy.

Building a Synergistic Blend

White Willow Bark is a powerhouse on its own, but its effects can be beautifully amplified when combined with other complementary ingredients. This is your first real chance to differentiate your brand. Instead of just another single-ingredient product, you can create a smarter, synergistic blend that targets a specific consumer need.

Consider the possibilities for your product line:

- For enhanced joint support: Combine White Willow Bark with turmeric and boswellia. This classic trio addresses discomfort from multiple angles, making it a perfect fit for customers with active lifestyles.

- For fast-acting muscle relief: Pair it with magnesium and arnica. This formula would be a game-changer for athletes or anyone needing quick relief from soreness, offering a blend that supports both relaxation and recovery.

- For daily wellness and calm: A thoughtful combination with L-theanine and passionflower could create a product aimed at dialing down daily stress and its physical side effects, tapping into the massive mental wellness market.

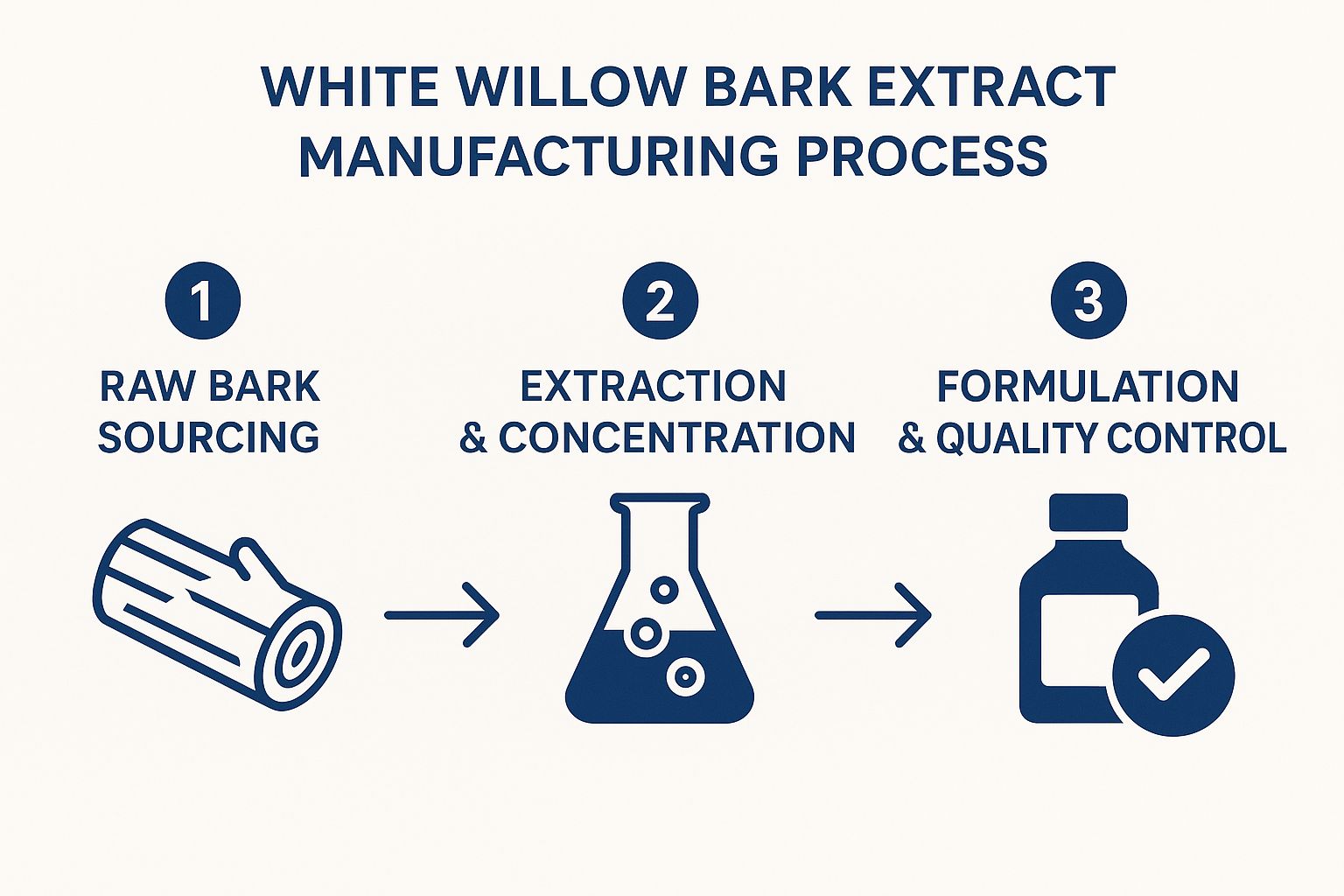

This graphic breaks down the manufacturing journey, from the moment raw materials arrive to the final formula you create.

As you can see, formulation is that final, crucial step where top-notch ingredient quality and scientific precision come together to produce your unique product.

Choosing the Right Delivery Format

How your customer takes your supplement is just as critical as what's in it. The delivery format impacts their experience, perceived effectiveness, and ultimately, your target audience. Your manufacturing partner should have the technology and flexibility to offer several options.

For instance, a fast-acting liquid tincture is often the go-to for athletes or anyone seeking immediate relief. Liquids generally have higher bioavailability, meaning the body can absorb active compounds faster. This format is ideal for a brand focused on performance and rapid results.

On the other hand, convenient daily capsules are perfect for customers focused on long-term, consistent wellness. They’re simple to dose, easy to transport, and fit seamlessly into a daily supplement routine. This approach works well for general wellness or foundational health brands. For a complete rundown of the steps involved, you can learn more about how to create a supplement formula in our detailed guide.

Partnership Insight: A truly forward-thinking manufacturer will offer innovative tech like a cold-fill process for liquid supplements. This method is crucial because it protects delicate botanical compounds like salicin from being destroyed by heat, ensuring the product your customer receives is just as potent as the one you designed in the lab.

Meeting Modern Consumer Demands

Let's be honest: today’s wellness consumers are incredibly sharp. They read labels, research ingredients, and demand transparency. To succeed, your formula must meet these expectations. This is where leaning on an experienced partner for clean-label flavoring and sourcing becomes non-negotiable.

Your goal should be a product free from artificial additives. That means:

- Sourcing solvent-free extracts to guarantee purity.

- Using natural sweeteners like stevia or monk fruit.

- Opting for natural flavorings from real fruits and botanicals.

By sweating these details, you’re not just creating a better product—you’re building a brand story rooted in quality and trust. This commitment to clean formulation will set you apart and turn first-time buyers into loyal fans.

Inside the Manufacturing and Sourcing Process

Ever wondered what really happens to raw White Willow Bark from the moment it hits the facility to when it becomes a finished, bottled supplement? This journey reveals a manufacturer's true commitment to quality. It's a precise, multi-stage process that directly dictates your product's final potency, purity, and safety—and as a brand owner, you need to understand it.

The process is far more than just mixing and bottling. It’s a sophisticated science, from selecting the right extraction method to using advanced tech that protects the very compounds you're selling. For e-commerce founders and brand managers, a clear picture of these steps empowers you to ask smarter questions and find a partner genuinely obsessed with quality.

As a White Willow Bark private label contract manufacturer, we believe in pulling back the curtain. Let's walk through how a premium liquid supplement gets made, starting with the most fundamental choice: how to pull the active ingredients from the raw bark.

Extraction: The Heart of Botanical Potency

The method used to extract salicin and other beneficial compounds is one of the most important decisions in the entire process. It’s not a one-size-fits-all scenario. The choice of solvent dramatically changes the final extract's profile and effectiveness.

- Hydroalcoholic Extraction: This is the gold standard for many applications. Using a mix of alcohol and water, this method is fantastic at drawing out a broad spectrum of compounds—both water-soluble and oil-soluble. The result is a more robust, full-spectrum extract that captures the plant's natural synergy.

- Aqueous Extraction: This method uses only water. While great for pulling out water-soluble compounds, it can leave other valuable components behind. It is, however, the perfect choice for brands focused on creating a completely alcohol-free product.

A flexible manufacturing partner will work with you to determine the best approach based on your formula goals and target audience. For example, a high-potency formula for acute relief might benefit most from hydroalcoholic extraction, whereas a daily wellness tincture could be better served with a gentle aqueous base.

Why Transparent Sourcing is Non-Negotiable

Where your White Willow Bark comes from matters. A lot. The quality of your raw material sets the absolute ceiling for your finished product's quality. You simply can't make a premium supplement from a subpar ingredient. This is where your manufacturer's sourcing diligence becomes your brand's greatest asset.

The hard truth is that heavy metal contamination is a serious risk with botanical ingredients. The manufacturing process for White Willow Bark often starts with powdered or comminuted bark. If that material is sourced from polluted agricultural areas, it can contain dangerous levels of contaminants. Since supplement doses can sometimes be higher than those in medical products, this risk gets amplified.

This is exactly why a manufacturer's cGMP protocols must include obsessive contaminant testing and total sourcing transparency. To dig deeper into these safety concerns, you can review the research on supplement manufacturing protocols.

A premier manufacturer doesn't just glance at a supplier's Certificate of Analysis (CoA). They quarantine every single incoming raw material and run their own battery of tests for identity, potency, and contaminants before it ever gets near the production line. This two-gate verification is a non-negotiable part of our process.

Using Innovative Technology for a Superior Product

Once the raw material is verified and extracted, the focus shifts to preserving the integrity of those delicate botanical compounds. Standard production methods often use high heat, which can degrade active ingredients like salicin, essentially "cooking out" the benefits you're promising your customers.

This is where forward-thinking technology makes a world of difference.

We use a proprietary cold-fill process for our liquid supplements. By maintaining a strictly temperature-controlled environment from start to finish, we shield fragile phytochemicals from thermal damage. This ensures the supplement that hits the shelf is every bit as potent and effective as the one we designed in our lab.

This commitment to advanced manufacturing allows your brand to deliver a product that genuinely works, building the kind of customer loyalty and repeat business that lasts. This level of detail separates a mere supplier from a true R&D and production partner.

Ensuring a Fast and Scalable Supply Chain

In e-commerce, two things can kill a brand: running out of stock and moving too slowly. A killer White Willow Bark formula is only half the battle. If you can't get it produced reliably and scale up when a product takes off, you're not just leaving money on the table—you're opening the door for a competitor to walk right in.

This is where your manufacturing partner’s supply chain expertise becomes as crucial as their formulation skills. The right White Willow Bark private label contract manufacturer doesn't just make your product; they help you build a supply chain engineered for speed and built to grow. This partnership allows you to focus on what you do best: marketing and building your brand.

For online brands, being out-of-stock isn't a small hiccup. It's a sales and credibility disaster. A reliable supply chain is your best insurance policy against that nightmare.

Evaluating Production Capacity and Flexibility

Your needs today won't be your needs a year from now. A critical quality in a partner is the ability to handle both small pilot runs and large-scale production. A manufacturer who only does huge runs forces a risky, expensive upfront commitment. Conversely, one who can't scale becomes a roadblock to your growth.

Look for a partner who offers genuine flexibility:

- Pilot Runs: Can they produce a small batch of 1,500-2,500 units? This is the sweet spot for testing a new formula or launching to a select audience without sinking massive capital.

- Scalable Growth: Do they have the machinery and expertise to smoothly scale to 10,000, 50,000, or even 100,000 units per run as your sales accelerate?

This flexibility demonstrates they understand the e-commerce journey and are structured to grow with you, not hold you back.

The True Cost of a Delayed Launch

Speed to market is a massive competitive advantage. Every week your launch is delayed is a week of lost revenue and a week your competitors are capturing market share. A transparent, reliable manufacturer should provide a clear timeline and stick to it.

A partner with an impeccable on-time delivery record isn’t a luxury; it’s a necessity. Production delays create a domino effect, throwing your marketing campaigns into chaos, frustrating early customers, and tarnishing your brand’s reputation before you even get started.

Don't be shy—ask for their on-time delivery stats. A top-tier manufacturer will track this metric and be proud to share it. Honest timelines and proactive communication are clear signs of a partner you can trust to hit your launch date.

Seamless Integration from Sourcing to Fulfillment

The best manufacturing partners offer more than just production. They provide a truly integrated, turnkey solution that simplifies your entire operation. This means they handle the critical, time-consuming details that can easily bog you down.

Integrated Services Checklist:

- Bottle Sourcing: They should have strong relationships with multiple suppliers, offering choices for glass, PET, or other materials without you managing another vendor.

- Labeling: Their team should be experts at applying your labels perfectly, ensuring they meet all die-line specs for a clean, professional finish.

- Final Packing & Kitting: Need individual cartons, multi-pack bundles, or promotional inserts? They should handle all final assembly.

This end-to-end service creates a smooth experience, transforming a complex, multi-vendor headache into a single, streamlined operation. For brands in this space, understanding third-party logistics (3PL) is a huge piece of the puzzle, and a well-connected manufacturer can often help bridge that gap. By managing the entire supply chain, they give you back your most valuable asset: the time and energy to grow your business.

Common Questions About White Willow Bark Manufacturing

When you're vetting a potential manufacturing partner, the details matter. Getting straight, clear answers to your toughest questions is the fastest way to distinguish a true collaborator from a simple order-taker. As an experienced White Willow Bark private label contract manufacturer, we believe in total transparency from day one.

Here are the real-world answers to the questions we hear most often from ambitious brand owners like you.

What Is a Realistic Minimum Order Quantity?

This is almost always the first question a founder asks, and for good reason—it directly impacts your startup costs. The honest answer is that it depends on your formula's complexity and packaging uniqueness. A good partner, one invested in your growth, will offer flexibility.

We believe in letting you test the market first.

- For Market Testing & Pilot Launches: A reasonable starting point is 1,500 to 2,500 units. This provides enough product to launch, gather customer feedback, and prove your concept without tying up all your capital in inventory.

- For Fully Custom Formulas: If you’re developing a unique blend with specialized components, expect MOQs to start in the 5,000 to 10,000 unit range. This volume is often necessary to make the sourcing of custom components and production runs cost-effective.

The goal is to find a manufacturer who can support your initial launch and scale alongside you. We are structured to help you grow from a startup to a category leader.

How Long Does the Entire Process Take?

Be wary of any manufacturer promising an unbelievably fast turnaround. A lightning-fast timeline is a major red flag that critical quality control steps are being skipped. A responsible, quality-focused process takes time.

From quote request to holding your retail-ready product, a trustworthy timeline is typically 12 to 20 weeks.

Here’s a realistic look at that timeline:

- Formulation & Quoting (2-4 Weeks): We work together to finalize your formula, select ingredients, and define the project scope and pricing.

- Raw Material Sourcing & Testing (4-6 Weeks): We source all components and—this is critical—quarantine and test every raw ingredient for identity, purity, and potency.

- Production (2-4 Weeks): Your product is batched, mixed, filled, and bottled according to strict cGMP protocols.

- Third-Party Validation (2-4 Weeks): We send a sample from your finished production run to an independent lab for final verification, confirming what's on the label is in the bottle.

A partner who is upfront about this timeline isn't slow; they are thorough. They are protecting your brand by ensuring every step, from sourcing to final lab validation, is done right.

How Can I Guarantee the Salicin Content Is Accurate?

For a product like White Willow Bark, this is the million-dollar question. Your brand's reputation and your product's efficacy hinge entirely on delivering a precise dose of the active compound, salicin.

Any top-tier contract manufacturer uses a multi-layered verification system that leaves zero room for error.

It begins by sourcing a standardized White Willow Bark extract from a vetted supplier. When that raw material arrives, it’s immediately quarantined and tested in-house (using HPLC) to confirm its potency before production.

Then, after your supplement is bottled, a sample from that finished lot is sent to an independent, third-party laboratory.

You will receive a Certificate of Analysis (CoA) for every batch, which clearly confirms the salicin content meets your label claim. This isn't a nice-to-have; it's non-negotiable proof of quality and transparency.

Will You Help with FDA Compliance for My Label?

While a manufacturer isn't your marketing agency, a true partner provides essential regulatory guidance to keep your brand out of trouble. We see it as our duty to protect our clients from making costly mistakes.

We provide a precise label die-line for your designer to use as a template. More importantly, our in-house compliance team will review your final label design to ensure:

- The Supplement Facts panel is formatted correctly.

- All required information (like net contents and manufacturer's address) is present and accurate.

- Your structure/function claims are worded in a compliant manner.

This collaborative review saves you the headache of reprinting thousands of labels or dealing with regulatory action. It's one more way we act as a true extension of your team, dedicated to your long-term success.

Ready to turn your vision for a premium White Willow Bark supplement into a market-ready reality? The team at Triton Nutra Group is here to be your partner every step of the way, from concept to launch.