What is Magnesium Stearate Used For? A Guide for Supplement Brands

Curious what is magnesium stearate used for? Learn its role in tablets and capsules and when it may not be needed in liquid formulations.

Get a Free Quote Today!

Get a Free Quote Today!So, what is magnesium stearate actually used for in your products?

Think of it as the ultimate production tool. In short, it’s a crucial manufacturing aid that ensures the powdered ingredients in your tablets and capsules are dosed consistently and accurately, every single time. A great way to visualize it is like a light dusting of flour on a baker’s countertop—it prevents sticking and guarantees the entire process runs smoothly and reliably.

Demystifying Magnesium Stearate in Supplement Manufacturing

Magnesium stearate is a simple, inert salt composed of two parts: magnesium (an essential mineral) and stearic acid (a saturated fatty acid found in many common foods). Its role in the supplement world isn't nutritional; it's purely mechanical.

It's what we call an excipient—an ingredient added to a supplement simply to aid the manufacturing process or improve the stability of the final product. Understanding its function is key to making smart decisions for your brand.

The Core Functions

This compound is indispensable for making solid dosage forms like tablets and capsules, and it comes down to a few key reasons. It wears three main hats during production:

- Lubricant: It prevents powdered formulas from sticking to the high-speed machinery used for encapsulation and tablet pressing.

- Flow Agent: It helps powders move smoothly and consistently through the equipment, which is vital for precise, accurate dosing.

- Anti-Adherent: It keeps the individual ingredient particles from clumping together, ensuring a uniform blend in every single capsule or tablet.

Without it, production would slow down, equipment could jam, and the amount of active ingredient in each dose could vary significantly. This makes magnesium stearate a cornerstone of quality assurance for any brand producing solid supplements, directly impacting your speed to market and product reliability.

To make it even clearer, here’s a quick breakdown of its roles from a brand perspective.

Magnesium Stearate Key Functions at a Glance

| Function | What It Does | Why It Matters for Your Brand |

|---|---|---|

| Lubricant | Prevents ingredients from sticking to manufacturing equipment. | Protects expensive machinery, reduces production downtime, and supports rapid, on-time delivery schedules. |

| Flow Agent | Ensures powders flow smoothly and evenly through the machines. | Guarantees consistent fill weights for every tablet and capsule, leading to accurate dosing and a reliable product. |

| Anti-Adherent | Stops powder particles from clumping together. | Ensures a homogenous blend of active ingredients, which is critical for product quality, efficacy, and consumer trust. |

As you can see, each function directly contributes to creating a high-quality, consistent, and marketable final product—the bedrock of a successful brand.

Its Role in the Broader Market

Magnesium stearate's primary use is as a pharmaceutical excipient, serving mainly as a lubricant in tablet and capsule manufacturing. This is a massive part of its market—the pharmaceutical segment was responsible for about 44.18% of the total magnesium stearate market revenue globally in 2024.

This huge demand is driven by its unmatched ability to improve powder flow and prevent materials from sticking to equipment, which ensures both efficiency and consistency.

Getting a handle on these fundamentals is the first step in creating an effective supplement. If you want to take a deeper dive into building a custom product from the ground up, check out our guide on nutraceutical formulation development.

The Three Critical Jobs of Magnesium Stearate

To truly grasp what magnesium stearate is used for, think of it as a specialist on the production line with three non-negotiable jobs. Each one is critical for manufacturing efficiency. We're talking about a smooth, fast, and reliable process—the very pillars that let your brand get to market quickly and build customer trust.

Frankly, trying to create consistent tablets and capsules at scale without this excipient would be nearly impossible. These roles work in tandem to prevent expensive delays and ensure every single unit is uniform, from the first one off the line to the very last.

Let's break down exactly how it pulls this off.

A Master Lubricant for High-Speed Machinery

First and foremost, magnesium stearate is an exceptional lubricant. Picture the complex, high-speed machinery used to press tablets or fill capsules. These machines are a blur of metal surfaces, punches, and dies moving at incredible speeds.

Powdered ingredients, especially botanical extracts, can be surprisingly sticky. Magnesium stearate forms a microscopic barrier between your powder blend and the machine's surfaces. This simple action prevents the formula from caking onto the equipment, which is a lifesaver for preventing jams and keeping the production run humming. For your brand, this means faster turnarounds and dependable, on-time delivery.

The Essential Flow Agent for Dose Accuracy

Next up, it's a superstar flow agent, sometimes called a glidant. Ever tried to pour damp sand through a funnel? It clumps, sticks, and flows unevenly. Powdered supplement ingredients are similar; they’re made of particles of various sizes and textures that don't always move predictably.

Magnesium stearate coats these tiny particles, drastically reducing the friction between them. This allows the entire blend to flow smoothly and consistently through all manufacturing equipment.

This consistent flow is non-negotiable for dose accuracy. It ensures that every single capsule or tablet is filled with the exact same amount of formula, meeting label claims and delivering the precise potency your customers expect with every purchase.

An Anti-Adherent to Maintain Blend Uniformity

Finally, magnesium stearate is a powerful anti-adherent. While lubrication prevents sticking to the machinery, this job prevents the ingredient particles from sticking to each other. Many active ingredients and other excipients have a natural tendency to attract one another and form clumps.

This clumping can ruin the uniformity of a blend, creating "hot spots" where active ingredients are over-concentrated and other areas where they’re barely present. By keeping all particles separate and free-flowing, magnesium stearate guarantees the formula stays perfectly homogenous from start to finish. This role is fundamental to what magnesium stearate is used for in quality-controlled manufacturing and is the bedrock of your final product's consistency.

Its widespread use across dietary supplements and even cosmetics just goes to show how valuable it is for creating stable, high-quality products. You can dive deeper into the global demand for this versatile excipient by reading these insights on the magnesium stearate market.

Why You Won't Find It in Liquid Supplements

Here's a crucial distinction for brands looking to carve out a unique space in the market: while magnesium stearate is a workhorse in solid supplements, it's completely unnecessary in liquids.

Its entire job is to manage the friction and flow of dry powders. That's a challenge that simply disappears when your ingredients are suspended in a liquid base. This fundamental difference creates a huge opportunity for your brand.

Liquid formulations naturally lead to cleaner, simpler ingredient labels. You get to skip the manufacturing aids that are non-negotiable for tablets and capsules. For consumers who are scrutinizing every ingredient, that's a powerful selling point.

The Science of Insolubility

The biggest reason you'll never see magnesium stearate in a liquid supplement comes down to basic chemistry: it is insoluble in water.

Trying to add it to a liquid formula would be like trying to dissolve a spoonful of wax in a glass of water. It would just float around, creating a cloudy, unappealing mess.

This insolubility makes it functionally useless and aesthetically a disaster in a liquid product. Instead of solving a problem, it would create one, undermining the very clarity and purity that make liquid supplements so attractive to begin with.

This distinction is more than just a formulation detail; it's a strategic advantage. By choosing a liquid format, you bypass the need for flow agents and lubricants, positioning your product as a cleaner, more direct delivery system.

Embracing a Cleaner Formulation

For brands focused on the liquid market, the absence of excipients like magnesium stearate isn't a limitation—it's a core benefit. This is where our expertise as a dedicated liquid supplement manufacturer becomes your greatest asset. We specialize in turning this formulation advantage into a competitive edge for your brand.

We focus on what truly matters in liquid products: the purity and potency of the active ingredients. This requires a completely different set of technologies and a partnership mindset dedicated to genuine innovation.

Our forward-thinking process is built around this philosophy:

- Advanced Botanical Extraction: We use proprietary, temperature-controlled methods to gently pull the maximum potency from raw ingredients, all without the use of harsh solvents.

- Cold-Fill Technology: This innovative process preserves the integrity of delicate compounds that heat can destroy, ensuring your final product is as effective as possible.

- Complete Customization: We act as your R&D partner, helping you develop unique, tailored formulas that speak directly to the needs of your target audience.

By leveraging these forward-thinking techniques, we help you create a product that not only works but also aligns perfectly with the clean-label demands of today's wellness shoppers. To see how this applies across different product types, you can find valuable insights by understanding the process of locating a manufacturer for all liquid dietary supplement ingredient types. This is how you position your brand as a leader, not just another follower.

Navigating Safety and Quality Standards

Whenever we discuss an ingredient, the first question on any responsible brand manager's mind is always safety. Let's get right to it: The FDA has given magnesium stearate GRAS (Generally Recognized as Safe) status when used appropriately in manufacturing.

This isn't just a rubber stamp. It means the ingredient has been thoroughly reviewed and is considered safe for its intended purpose. In a typical supplement, magnesium stearate makes up a tiny fraction of the total formula—usually less than 2%. That small, highly effective amount is all that’s needed to keep tablet and capsule production running smoothly and consistently.

This is where your choice of a manufacturing partner becomes absolutely critical. A quality-obsessed partner doesn’t just meet the standards; they build their entire operation around them.

Your Assurance of Quality and Compliance

For brand owners, confidence in your final product starts with your manufacturer's obsession with compliance. As a cGMP and UL-certified, FDA-registered facility, we operate under strict protocols for every single ingredient. This isn't just about following rules; it's about a partnership built on trust.

Our rigorous third-party testing is your guarantee. We verify that every component meets the highest standards for purity and safety, providing you with complete peace of mind and a product you can proudly stand behind.

This level of scrutiny is non-negotiable. The global market for magnesium stearate is huge and growing, valued at nearly USD 478 million back in 2021 with projections climbing much higher. With its widespread use across the pharmaceutical and food sectors—especially in the Asia-Pacific region, which holds over 40% of the revenue share—ensuring a pure and reliable source is paramount. You can dig into more of these market dynamics and projections to see just how significant this ingredient is on a global scale.

Documentation and Sourcing Transparency

A huge part of our partnership mindset is providing the documentation you need, no questions asked. We maintain meticulous records for every ingredient, including Certificates of Analysis (CofA), to ensure full traceability and transparency.

Choosing the right partners and knowing the rules are foundational to your brand's success. To build on this, we strongly recommend reviewing the core dietary supplement manufacturing requirements to ensure you're protected from every angle. We handle the complexities of compliance so you can focus on building your business, confident that your product is safe, effective, and ready for market.

Exploring Clean Label Alternatives in Formulation

For brands laser-focused on creating an ultra-clean label for their solid products, understanding the alternatives to magnesium stearate is key. While it’s the industry standard for a good reason, other ingredients can also serve as effective flow agents, each with its own unique profile.

This is exactly the kind of formulation challenge we thrive on. Think of us as your dedicated R&D partner, here to guide you through these complex decisions. We'll help you weigh the pros and cons to develop a product that perfectly aligns with your brand's unique goals and promise.

Common Alternatives and Their Trade-Offs

When you really dig into what magnesium stearate is used for, you’ll find its efficiency is tough to match. That said, certain alternatives definitely appeal to specific consumer segments who are looking for something different.

A few popular options include:

- Rice Hull Concentrate: A go-to plant-based option, this is a gluten-free fiber that does a solid job of improving powder flow. It's often perceived as a more "natural" ingredient by consumers scanning the label.

- Silica (Silicon Dioxide): This is another common flow agent that works very well at preventing clumping and keeping powders moving. It's effective in tiny amounts, but it can sometimes face scrutiny from hyper-aware consumers.

- Ascorbyl Palmitate: This is a fat-soluble form of Vitamin C. It pulls double duty, functioning as both an antioxidant and a flow agent, which offers a nice dual benefit. The catch? It's often a more costly option.

While these alternatives can be excellent choices, they almost always involve trade-offs. You might be looking at slower manufacturing speeds, higher costs, or slight differences in overall performance compared to the proven efficiency of magnesium stearate.

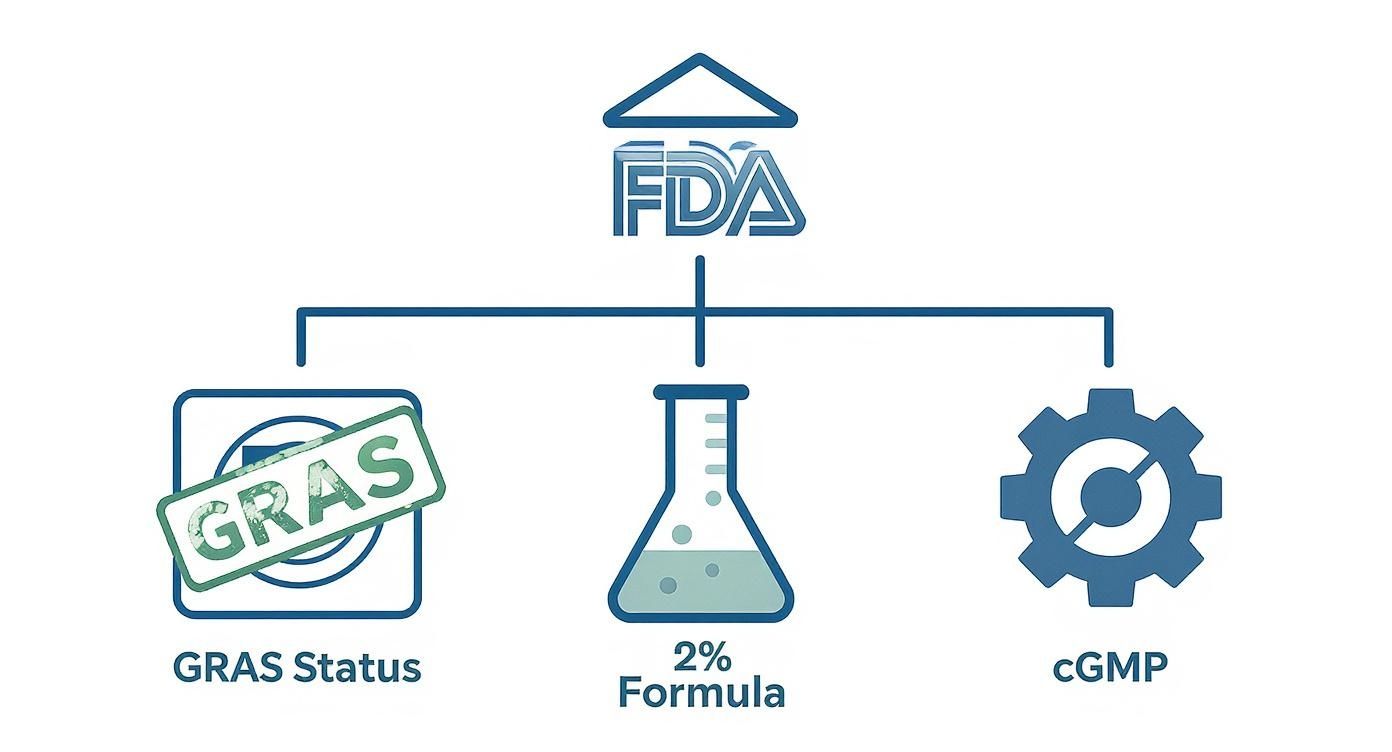

The diagram below helps put things in perspective, illustrating the strict hierarchy of safety and quality standards that govern ingredients like magnesium stearate and reinforcing why compliance is so critical.

This visual shows how top-level FDA oversight flows down to GRAS status, specific formula limits (like the 2% rule), and mandatory cGMP certifications. It's a multi-layered safety net designed to protect consumers.

Choosing an alternative isn't just a matter of swapping ingredients. It’s a strategic decision that impacts your supply chain, production timeline, and final price point. Our role as your partner is to provide the data and expertise needed to make that decision with confidence.

Ultimately, whether you stick with the industry standard or opt for a clean-label alternative, the goal is always the same: creating a safe, effective, and consistent product. We help you navigate these choices to ensure your formulation is not only marketable but also manufacturable at scale, meeting our shared commitment to speed, reliability, and uncompromising quality.

Your Partner for Innovative Liquid Formulations

Diving into the technical role of an ingredient like magnesium stearate reveals the depth of expertise that goes into making great supplements. While it's an absolute must-have for quality tablets and capsules, we believe the future for many of the most exciting brands lies in clean, effective liquids. And that happens to be our specialty.

We pair a relentless commitment to quality and compliance with the customization and flexibility your brand needs to stand out in a crowded market. We've built our entire approach around a simple idea: partnership.

Think of us as your R&D partner from concept through launch. We're here to help you bring a groundbreaking liquid supplement from a rough idea all the way to a successful launch.

From Custom Formulas to Scalable Production

Our entire process is built to wrap around your brand's specific needs. We have the flexibility to manage everything from small pilot runs for market testing to full-scale production, ensuring you can grow without hitting a ceiling. That kind of adaptability is a game-changer for new startups and established brands alike.

We're here to help you navigate all the tricky parts—formulation, sourcing, flavoring—to create a product that is truly one-of-a-kind.

The Competitive Edge of Speed and Reliability

In the fast-paced world of e-commerce, getting to market fast is a massive competitive advantage. We take pride in our rapid turnaround times and transparent project timelines, all backed by an exceptional on-time delivery record you can count on.

Our state-of-the-art, FDA-registered facility is both cGMP and UL certified, which is our guarantee that every single bottle meets the highest possible standards for safety and quality. Let’s talk about how our speed, reliability, and passion for innovation can be the engine for your brand’s growth. We're ready to help you build your next best-seller.

Answering Your Questions About Magnesium Stearate

As a brand owner, you are the ultimate guardian of your product and your customers' trust. Getting clear, authoritative answers is non-negotiable. Here are the most common questions we get from partners about magnesium stearate and how we handle it in formulation.

Does Magnesium Stearate Affect Nutrient Absorption?

This is a persistent myth we’re always happy to clear up. Some older, often misinterpreted studies suggested it might slow down how quickly a tablet dissolves. However, the overwhelming body of modern evidence confirms this isn't a real-world concern.

At the tiny amounts used in supplements—typically just 0.25% to 1.5%—it has no meaningful impact on your body's ability to absorb the active ingredients. Its job is done during manufacturing. After that, it simply passes through your digestive system without interfering.

As a cGMP-certified manufacturer, we live and breathe precision. We meticulously calculate and verify that every excipient is used at a safe, effective level that protects, not hinders, your product’s bioavailability.

Is Magnesium Stearate Vegan?

It certainly can be, and for many brands, this is a make-or-break detail. The "stearate" part comes from stearic acid, which can be sourced from either animal fats or, more commonly today, vegetable oils like palm or coconut. The source is everything.

We are committed to total supply chain transparency. For brands targeting a vegan, non-GMO, or allergen-free promise, we exclusively source plant-based magnesium stearate. This isn't an afterthought; it's a standard part of our customization process to ensure your final product perfectly matches your brand's core values.

Partnering with a manufacturer who documents every single ingredient source isn't just good practice—it's essential for brand integrity. We provide full traceability so your "vegan" claim is backed by verifiable proof, protecting both you and your customers.

Why Is Controlling the Amount So Important?

With magnesium stearate, precision is everything. The amount used is a delicate balancing act that directly impacts both manufacturing efficiency and final product quality.

- Too Little: Powders get sticky. This can cause equipment to jam, leading to inconsistent tablet weights and, most critically, inaccurate dosages.

- Too Much: You can get what's called "over-lubrication." This can make tablets too soft, cause them to take longer to break down, or in some cases, slightly slow the release of the active ingredients.

Our R&D and production teams don't guess. For every unique formula, we run precise calculations and rigorous tests to find the absolute minimum amount needed. This sweet spot ensures a smooth, high-speed production run without ever compromising the quality and performance of your finished product. It's how we deliver on our promise of both speed and compliance.

Ready to create a standout liquid supplement that bypasses these formulation challenges entirely? The team at Triton Nutra Group is your dedicated R&D partner, specializing in clean, potent, and market-ready liquid formulas. Let’s build your next best-seller together.