Choosing The Right Pill Capsule Size: A Guide For Supplement Brands

Unlock your product's potential with the right pill capsule size. Our guide helps brands master dosage, formulation, and consumer appeal. Get a quote today.

Get a Free Quote Today!

Get a Free Quote Today!Picking the right pill capsule size is a foundational decision in supplement development. It's a choice that directly shapes dosage accuracy, your customer’s experience, and manufacturing efficiency. The standard sizing chart runs from the largest, size '000' (triple zero), down to the smallest, size '5'. This system allows us to fit your formula’s active ingredients perfectly into a format that consumers find easy to take.

Navigating The World of Pill Capsule Sizes

Choosing the right capsule size is about more than just measurements; it's a strategic move balancing your formula's physical needs with customer comfort and perception. For a health-and-wellness entrepreneur, this decision impacts everything from the number of capsules in a daily serving to the final bottle size sitting on a retail shelf. Getting it right from the start avoids costly reformulations down the line.

As your R&D partner, we guide you through these crucial early decisions. With deep expertise in formulation and manufacturing—all done in our cGMP, UL-certified, FDA-registered facility—we help you land on a size that is both effective for your product and genuinely appealing to your target market.

Understanding the Standard Sizing System

The capsule sizing system can feel counterintuitive: the smaller the number, the larger the capsule. For instance, a size '0' capsule is significantly larger than a size '3'. This standardized system, however, has been the industry benchmark for over a century, bringing critical consistency to dosing.

Established in 1874, this modern numbering system created a universal language for manufacturing and dosing worldwide. It spans from size 000, which holds about 1.36 mL, down to the tiny size 5, holding just 0.13 mL. This range gives formulators precise control. You can learn more about the history of capsule sizing for a deeper dive.

Your choice of pill capsule size is a crucial intersection of scientific formulation and consumer psychology. It dictates the physical presence of your product and how your customer will interact with it daily.

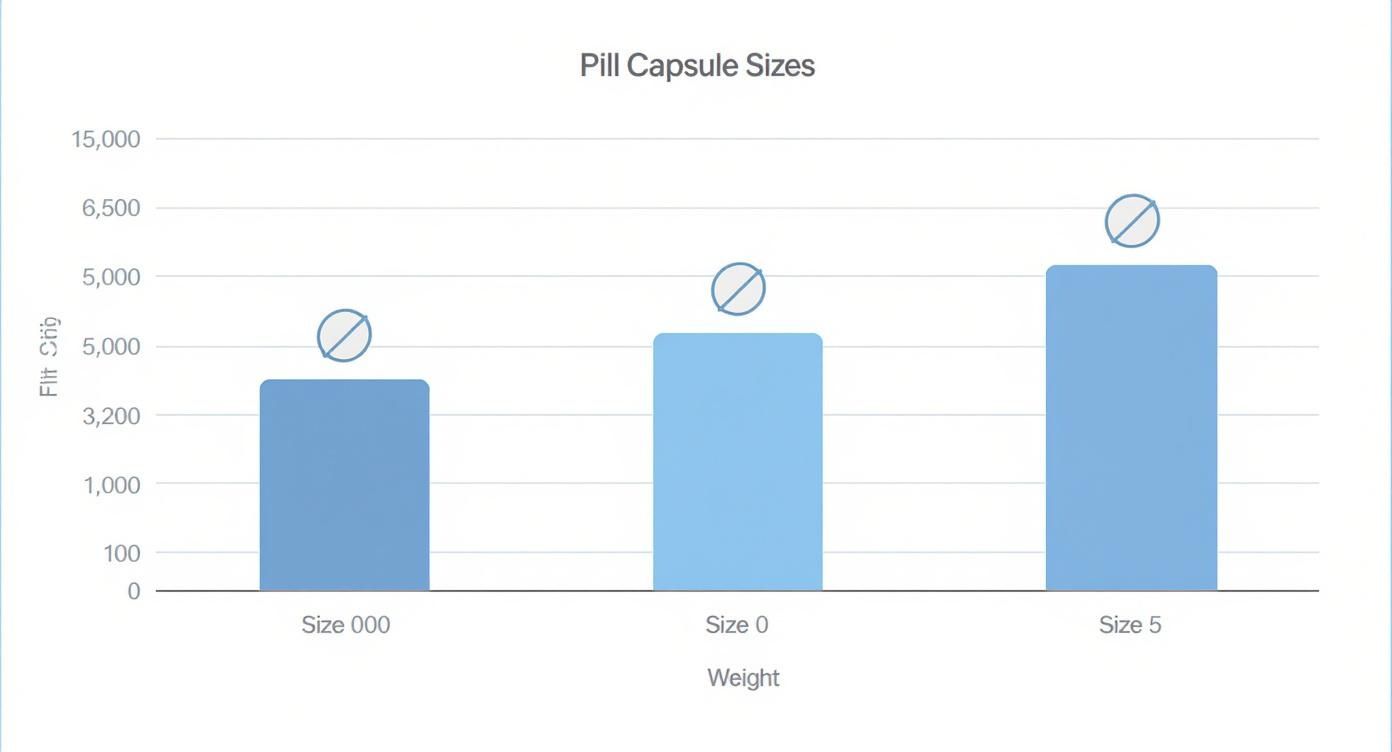

The chart below provides a visual reference for some of the most common capsule sizes and their capacities.

This visual guide highlights the significant difference in capacity between sizes. It clarifies why a high-dose formula might require a '000' capsule, while a highly potent, low-volume ingredient is a better fit for a tiny option like a size '5'. This choice is the first step toward creating a supplement that is compliant, effective, and marketable.

How Capsule Dimensions Impact Your Supplement

When developing a new supplement, it's easy to focus solely on the science of the formula. But the physical size of the capsule is a critical decision that impacts your entire business, from the customer’s first impression to your final profit margin.

Think of it like choosing the right bottle for a fine wine. A size '00' capsule feels substantial, telling the customer they're getting a potent dose. While most adults can handle it, some might find it intimidating to swallow. Conversely, a tiny size '3' capsule is incredibly easy to take. The trade-off? You may need your customer to take two or three to get an effective dose, which can feel like a hassle and drive up costs.

This is where we come in. As your R&D and manufacturing partner, our job is to help you find the perfect balance between a powerful formula and a product that is both commercially smart and a pleasure for your customers to use.

The Consumer Experience: Swallowability and Perception

The most immediate impact of capsule size is swallowability. A capsule that is too large can be a significant hurdle for many people, especially older adults. This isn't a minor issue; it can be the single reason a customer chooses not to repurchase your product.

Perception is just as powerful. In the sports nutrition market, a larger capsule can signal a high-potency formula. For other brands, a smaller, more elegant capsule might communicate precision and purity, appealing to a different consumer base entirely.

Your capsule size is a form of non-verbal communication. It quietly tells customers what your brand values—be it raw power, convenience, or thoughtful accessibility. It’s a crucial part of your product’s story.

It's also worth remembering how popular capsules are. They account for over 18% of all medicines delivered globally. That preference is even stronger in the U.S. supplements market, where 42% of users prefer capsules—a number that skyrockets to 56% among heavy supplement users. This widespread acceptance is a testament to the format's user-friendliness. You can dig into the data on the history and popularity of capsules to see how deep these consumer trends run.

Packaging Logistics and Commercial Impact

The physical dimensions of your capsule create a domino effect through your packaging, logistics, and bottom line.

- Bottle Size: A bigger capsule, like a size '00', requires a bigger bottle for a 30- or 60-day supply, directly increasing your material costs.

- Label Real Estate: The upside of a larger bottle is more surface area. This provides more room for branding, storytelling, supplement facts, and all FDA-required information.

- Shipping & Storage: Larger, heavier bottles cost more to ship and take up more warehouse space. These costs can eat into your profit margins if not planned for properly.

These aren't afterthoughts; they are foundational to a successful product launch. Our expertise in nutraceutical formulation development extends beyond what’s inside the capsule. We help you map out these commercial realities from day one, ensuring the final product isn't just effective, but also profitable and poised for market success.

Calculating Accurate Capsule Fill Weight

A capsule's size indicates its volume, but the real question is how much of your formula can fit inside. It’s like packing a suitcase: you can fill it with fluffy sweaters or heavy books. The volume is the same, but the weights are entirely different.

This is the exact challenge in supplement formulation. A capsule offers a fixed space, but the final weight of its contents depends on the unique density of your powder blend. This is where the science of formulation truly begins.

Why Powder Density Is The Key Metric

Powder density is the single most important variable in determining how much of your formula will fit into a given pill capsule size. Every ingredient is different. Light, airy botanical powders like Ginseng Root take up a lot of room for their weight. Dense minerals like Magnesium Oxide are much heavier for the same volume.

This is why a size '0' capsule might hold 500 mg of one ingredient but over 680 mg of another. Relying on generic online charts sets you up for inaccurate doses and major manufacturing headaches.

As your R&D partner, we don't guess. We perform a tapped density analysis on your exact final formula. This test tells us precisely how much your blend compacts, allowing us to choose the smallest possible capsule that still guarantees an accurate dose every time.

To see this in action, check out how the same size '0' capsule can hold dramatically different amounts of common supplement ingredients.

Fill Weight Conversion Examples for Common Supplements

| Ingredient | Typical Density (g/mL) | Approx. Fill Weight in Size '0' Capsule (mg) |

|---|---|---|

| Creatine Monohydrate | 0.85 | 578 |

| L-Glutamine | 0.70 | 476 |

| Turmeric Root Powder | 0.55 | 374 |

| Spirulina Powder | 0.50 | 340 |

| Magnesium Oxide (Heavy) | 1.20 | 816 |

As you can see, a generic fill weight chart would lead to massive dosing errors. This is why testing your specific formula's density is non-negotiable for creating a compliant and effective product.

The Strategic Role of Excipients

What happens if your target dose of active ingredients doesn't quite fill a standard capsule? This is a common challenge, especially with potent ingredients where only a small amount is needed. You can't leave empty space—that leads to inconsistent weights and rattling capsules that signal low quality to customers.

This is where excipients—sometimes called fillers or flow agents—are essential. These are safe, inert ingredients added to a formula for consistency and manufacturability.

- Bulking Agents: Ingredients like microcrystalline cellulose or rice flour add volume, ensuring the capsule is filled perfectly for a precise, uniform dose.

- Flow Agents: Powders can clump. Ingredients like silicon dioxide act like tiny ball bearings, ensuring the blend flows smoothly through our high-speed encapsulation machines for dead-on fill accuracy.

Excipients are not just "fillers." They are essential formulation tools that enable us to deliver a precise, stable, and high-quality product that meets its label claims—a non-negotiable part of cGMP compliance.

Achieving these precise measurements requires a highly controlled environment. Specialized equipment like pharmaceutical powder fume hoods is critical for handling powders safely and accurately during development and quality control.

Ensuring Potency and Consistency

Ultimately, getting the fill weight right is about delivering on your brand's promise. Your customers trust that every capsule contains the exact dose printed on the label. Our meticulous process, from density testing to careful excipient selection, is designed to protect that trust.

This dedication to accuracy is backed by our in-house quality control and third-party testing protocols. You can dive deeper into our comprehensive approach to supplement ingredient testing to see how we validate the purity and potency of every batch. This diligence ensures your product is not just effective but also fully compliant and ready for success.

Selecting The Right Capsule Material

Beyond size, the material of your capsule makes a powerful statement about your brand. This isn’t just about ticking a dietary preference box; it’s a choice that reflects your values, speaks directly to your target market, and has real consequences for manufacturing, product stability, and overall quality.

As your formulation partner, we help you navigate this critical decision. Our job is to ensure the final product perfectly aligns with your formula’s technical needs and your brand’s promise to the customer. We offer a full spectrum of high-quality, compliant options.

Traditional Gelatin Capsules: The Industry Standard

For decades, gelatin capsules have been the undisputed champion in the supplement and pharmaceutical worlds. Made from bovine or porcine sources, these capsules are workhorses known for their reliability, cost-effectiveness, and flawless performance on high-speed encapsulation equipment.

There’s a good reason they became the standard:

- Proven Performance: Gelatin has a long and safe track record. It’s a trusted, familiar option for mainstream consumers.

- Cost-Effective: Gelatin capsules are typically more economical to produce, which can be a key factor in managing your product's final cost.

- Manufacturing Efficiency: Their physical properties are a perfect match for high-speed, automated filling lines, enabling rapid turnaround times.

For many brands, gelatin remains an outstanding choice, offering a blend of proven performance and economic value that’s tough to beat.

Vegan Capsules: The Rise of Plant-Based Alternatives

Today’s consumers are more informed than ever. The demand for vegan, vegetarian, and clean-label products is a movement, not a trend. As a forward-thinking partner, we provide top-tier vegan options to meet this demand head-on.

The two main players in vegan capsules are HPMC (hydroxypropyl methylcellulose) and Pullulan. Both are excellent plant-based alternatives with distinct strengths.

HPMC, derived from plant cellulose, is the most popular vegan choice. Its secret weapon is its low moisture content (typically 3-7%), making it the superior option for moisture-sensitive (hygroscopic) ingredients like probiotics or delicate botanical extracts. It protects them from degradation and can significantly extend your product's shelf life.

Choosing a vegan capsule isn't just a dietary accommodation; it's a strategic move that can enhance product stability. For moisture-sensitive formulas, an HPMC capsule is the technically superior choice, regardless of your target audience's diet.

Pullulan capsules, made from fermented tapioca, are another fantastic vegan option known for their excellent oxygen barrier properties—a major benefit for ingredients prone to oxidation. Our flexibility with both gelatin and various vegan capsules means we can precisely match the material to your formula’s needs and your brand’s market position, ensuring your product is built on a foundation of quality and strategic foresight.

From Concept to Customer: Manufacturing & Packaging Your Capsules

You've selected your capsule size and material. Now, we build it. This is where theoretical decisions meet production floor realities, and where a true manufacturing partnership shows its value.

The choices made up to this point have a direct ripple effect on manufacturing speed, equipment calibration, and your initial investment, which is tied to Minimum Order Quantities (MOQs). This phase bridges your idea with the physical, compliant, top-shelf supplement that will land in your customer's hands. As your partner, we manage the details so you can focus on building your brand.

How Capsule Size Dictates Production Speed

Your capsule size has a measurable impact on how fast we can produce your product. Think of our high-speed encapsulation machines as precise, automated assembly lines. It's simple physics: smaller capsules, like a size '2' or '3', tend to run faster and more smoothly than a giant size '000'.

Why should you care?

- Go-to-Market Speed: Faster run times mean a quicker turnaround on your order. In a competitive market, launching sooner is a huge advantage.

- Machine Tooling & Calibration: Every capsule size requires its own unique tooling. Our cGMP-compliant facility is built to handle a massive range of sizes, but the setup for each run is a critical piece of the production puzzle.

- Minimum Order Quantities (MOQs): MOQs are often linked to production run efficiency. For a smaller pilot batch, it's often more practical to choose a common capsule size that doesn't require extensive specialized setup.

We provide transparent timelines from the start, factoring in your capsule choice to give you a delivery schedule you can rely on. Our flexibility allows us to manage everything from pilot batches to full-scale production, supporting your brand at every stage of growth.

The Unbreakable Rules of cGMP Quality

Once the machines are running, our focus sharpens to absolute precision. This is a non-negotiable mandate under the FDA’s cGMP (Current Good Manufacturing Practice) regulations. Two of the most critical checks we perform are for fill accuracy and weight variation.

Fill accuracy ensures every capsule contains the precise amount of your formula, down to the milligram. Weight variation testing involves systematically pulling samples throughout the entire run and weighing them to confirm zero deviations. This process guarantees that the first capsule off the line is just as potent and safe as the last one.

In manufacturing, consistency is the bedrock of compliance and consumer trust. Our rigorous, cGMP-mandated testing for weight variation ensures every capsule meets its label claim, protecting your brand's integrity and your customers' well-being.

This commitment to quality is everything. To learn more about what this looks like in a partner, check out our guide on finding a reputable supplement manufacturer.

Packaging: The Final Piece of the Puzzle

The last step is connecting your capsule to its final home: the packaging. The capsule's physical size directly determines the bottle size needed for a 30, 60, or 90-day supply. This, in turn, dictates the "real estate" you have on your label for branding and FDA-required information.

The equation is simple: a larger capsule requires a larger bottle, giving you more space for compelling marketing copy and a clear, easy-to-read Supplement Facts panel.

The principle of sizing for a specific purpose is universal. Microcapsules used in industrial chemistry are measured in microns (1/1000th of a millimeter), a world away from the millimeter scale we use. While the application is different, the core idea is the same: the capsule size is always perfectly tailored to its job, whether it's delivering a chemical agent or a nutritional dose. From the production line to the final sealed bottle, we manage every detail to ensure your product is not only high-quality but also compliant and ready for e-commerce success.

Your Questions About Pill Capsule Sizes Answered

When developing a new supplement, the nitty-gritty details matter. This section tackles the most common, make-or-break questions we hear from brand founders and e-commerce entrepreneurs every day, providing the straight answers you need.

What Is The Most Popular Capsule Size For Supplements?

Hands down, sizes ‘0’ and ‘00’ dominate the market for adult supplements. They hit the sweet spot for many common dosages.

A size ‘0’ capsule is a workhorse, holding about 500 mg of an average density powder, making it perfect for a huge range of vitamin and herbal formulas. The larger ‘00’ size packs in around 735 mg, so it's often reserved for products needing a heavier dose, like amino acids or sports nutrition blends. The final decision often balances the required dose with consumer ease-of-swallowing, where the size '0' is generally seen as the more user-friendly option.

How Do I Determine The Exact Fill Weight For My Custom Formula?

This is where science meets precision. To get an exact fill weight, we must perform a powder density analysis on your specific formula during the R&D stage. Generic online charts are a decent starting point, but they cannot account for the unique properties of your custom ingredient blend.

We take your final powder—actives, excipients, and all—and run a tapped density measurement. This provides a hyper-accurate reading that lets us select the smallest capsule that will consistently hold your target dose. It’s a critical step that ensures accuracy, boosts manufacturing efficiency, and protects your product's integrity.

Can I Put A Liquid Formula Into A Standard Two-Piece Capsule?

In short, no. Standard two-piece capsules are designed exclusively for dry powders. Filling them with a liquid is a recipe for disaster; they will leak, dissolve, or both, resulting in a failed batch and a compromised product.

For oil-based liquids, specialized liquid-fill hard capsules that use a sealing band are an excellent solution we can provide. For anything water-based, however, a softgel is almost always the right delivery system. As your manufacturing partner, we guide you to the technology that guarantees stability and quality for your unique formula.

Are There Regulations Regarding Pill Capsule Size?

While the government does not mandate specific capsule sizes, the FDA’s cGMP regulations (21 CFR Part 111) are incredibly strict regarding dosage accuracy. The rule is simple: your finished product must match the potency and ingredient amounts stated on your label, with no exceptions.

This is why fill accuracy and uncompromising quality control are non-negotiable. Choosing the right capsule size is the first and most important step in building a manufacturing process that guarantees dosage uniformity, protecting both your brand and your customers.

Ready to turn your supplement concept into a market-ready reality? At Triton Nutra Group, we're more than a manufacturer—we're your R&D partner from start to finish. Contact us today for a transparent quote and expert consultation.