Your Partner for Passion Flower Private Label Contract Manufacturing

Discover top Passion Flower private label contract manufacturers for your brand. Learn about formulation, quality control, and scaling your supplement line today!

Get a Free Quote Today!

Get a Free Quote Today!Ready to launch a passion flower supplement into a booming market, but don't have a manufacturing facility in your back pocket? You're on the right track. The smartest path for today's health and wellness brands isn't building from the ground up—it's partnering with an expert Passion Flower private label contract manufacturer.

This strategic move lets you lean on our expertise, guarantee cGMP quality, and slash your time to market. We're not just a supplier; we're your R&D partner from concept through launch.

Launching Your Passion Flower Brand The Smart Way

Your timing is perfect. The global market for passion flower extract is on a powerful upward trend, projected to hit a staggering USD 8.06 billion by 2030. This growth is fueled by a massive consumer shift toward natural solutions for anxiety, sleep, and digestive health.

Partnering with a private label contract manufacturer is more than outsourcing production. It's a strategic alliance. You immediately gain access to our established systems for quality control, regulatory know-how, and production efficiency, all without the massive capital investment of building it yourself.

Choosing Your Manufacturing Path

The manufacturing model you choose defines everything—your level of control, initial investment, and your brand's exclusivity. For entrepreneurs and product managers, this is a critical fork in the road that shapes profit margins and your ability to pivot quickly.

A top-tier contract manufacturer acts as an extension of your team. We aren't just a supplier; we are your R&D partner, your compliance guide, and your operational backbone from the initial concept all the way through a successful launch.

This partnership frees you to focus on what you do best—building your brand and connecting with customers—while we handle the complex logistics of getting your product made right. As you map out your strategy, remember production is one piece of the puzzle. Understanding major sales channels is just as vital. For instance, successfully launching a product on Amazon can give your brand the momentum it needs to thrive.

Comparing Your Options

To make an informed decision, it helps to see the different manufacturing paths laid out side-by-side. Each has distinct advantages depending on your business goals, whether you're aiming for full customization or need to get to market fast. For a deeper dive, our guide on https://tritonnutragroup.com/private-label-liquid-supplements-a-comprehensive-guide-for-starting-your-own-brand is an excellent resource.

Here's a quick overview of how the main options stack up.

Your Manufacturing Options At A Glance

Understanding the key differences between the three primary manufacturing models is the first step in aligning your production with your brand's vision and budget. This table breaks down what you get with each approach.

| Attribute | Private Label Manufacturing | In-House Manufacturing | White Label |

|---|---|---|---|

| Customization | High (custom formulas, flavors, packaging) | Total (complete control over every aspect) | Low (pre-made formula, only label is changed) |

| Upfront Cost | Moderate (no facility or equipment costs) | Very High (facility, equipment, staff, R&D) | Low (minimal setup costs) |

| Speed to Market | Fast (leverages existing infrastructure) | Slow (requires building from scratch) | Very Fast (product is ready to be labeled) |

| Brand Exclusivity | High (your unique formula is protected) | Absolute (proprietary formula and process) | None (same product sold by other brands) |

| Best For | Brands wanting a unique, scalable product | Large, established enterprises with capital | Startups needing to test the market quickly |

Ultimately, the right path depends on your resources, timeline, and long-term vision. For brands that value both speed and uniqueness, private label manufacturing hits the sweet spot, offering customization and brand protection without the prohibitive costs and delays of going it alone.

How to Vet Your Manufacturing Partner

Choosing your manufacturing partner is the single most important decision you'll make for your passion flower supplement brand. A slick website is one thing, but the real test is their commitment to quality, compliance, and genuine partnership. Your brand’s reputation is built on the foundation they provide, so digging deep isn’t just an option—it’s a necessity.

This isn’t about skimming a services list. It's about asking the tough, specific questions that reveal a manufacturer's true capabilities. You need to get past the surface-level claims and understand their real-world processes, from how they source raw ingredients to how they handle inevitable production hiccups.

The Non-Negotiables of Quality and Compliance

Before discussing formulas, the first conversation must be about credentials. These aren't just acronyms to check off a list; they are concrete proof of a commitment to making safe, consistent, and legally sound products.

Any Passion Flower private label contract manufacturer worth partnering with must provide clear, current documentation for these three pillars:

- cGMP Certification: Current Good Manufacturing Practices are the FDA's gold standard. This is non-negotiable—the absolute minimum for any serious supplement manufacturer.

- FDA Registered Facility: This confirms they’re on the FDA’s radar and subject to inspection, adding a critical layer of accountability.

- UL Certification: As a third-party certifier, UL Solutions provides an independent stamp of approval on a facility's cGMP standards. It’s the extra peace of mind that separates the good from the great.

These certifications demonstrate a manufacturer has invested heavily in robust systems for quality control. This is crucial in a market that's only getting bigger. The global passion flower extract market was valued at USD 2.56 billion in 2024, and contract manufacturing is what makes scalable, compliant production possible. You can read the full research on the passion flower extract market to get a better feel for these market dynamics.

Probing Questions for Your Initial Calls

Once you’ve confirmed the foundational certifications, it's time to see how they operate day-to-day. The answers to these questions will tell you everything you need to know about their processes and problem-solving abilities.

Scenario Check: A top-tier manufacturer won't just say, "We have quality control." They'll walk you through their exact SOP for handling an out-of-spec batch. They should be able to explain their quarantine, investigation, and documentation process without hesitation.

Use your first few conversations to gauge their expertise and transparency. Here are some pointed questions to get you started:

- Raw Material Sourcing: "Describe your process for qualifying a new raw material supplier for passion flower. What documentation, like a Certificate of Analysis (CofA), do you require?"

- Testing Protocols: "What specific third-party testing do you perform on finished products? Do you test for identity, purity, heavy metals, and microbial contaminants as standard?"

- Traceability: "If a customer reported an issue, how quickly could you trace the passion flower extract in their specific bottle back to the raw material batch it came from?"

- Handling Deviations: "Walk me through what happens if a batch of our passion flower tincture fails its final potency test. What are your immediate steps?"

Their answers should be confident, detailed, and rooted in clear processes. Vague responses are a major red flag.

Assessing Their Partnership Mindset

Finally, look beyond the technical specs and get a feel for their approach to collaboration. A true partner acts like an extension of your own team. They should offer guidance from the moment you have an idea until you're ready to launch.

Do they proactively offer formulation suggestions? Are they transparent about timelines and run sizes, from pilot to full scale? Do they seem genuinely invested in your success? A great partner might offer flexibility with minimum order quantities, connect you with their regulatory team to review your label, and demonstrate a clear record of on-time delivery. These are the tell-tale signs of a manufacturer that's ready to grow with you.

Remember, vetting isn't just about finding a supplier—it's about finding the right one. For more tips on what to look for, check out our in-depth article on key considerations for finding a reputable supplement manufacturer. Taking the time to do your homework now will save you from major headaches and protect your brand's integrity.

Crafting Your Custom Passion Flower Formula

Finding the right Passion Flower private label contract manufacturer means finding a partner, not just a supplier. They shouldn't be a simple order-taker. The best act as your outsourced R&D team, collaborating with you to turn a concept into a tangible, market-ready supplement. This is where you create your brand's unique value.

This hands-on, collaborative process separates a generic product from one that resonates with your customers. It’s about making deliberate choices that shape your product's effectiveness, customer experience, and market perception. A great manufacturing partner guides you through this, transforming your vision into a formula that’s both scientifically sound and commercially successful.

Foundational Formulation Decisions

Before diving into flavors and packaging, you have to nail down your product's core. The two most critical decisions are the delivery format and the extraction method. These choices dictate bioavailability, dosage, shelf life, and consumer appeal.

A flexible, experienced manufacturer will lay out several options, explaining the pros and cons of each in clear, concise language. Their job is to help you match the physical product to your brand's promise.

Your main choices will likely boil down to these:

- Liquid Tinctures: A classic for a reason, known for fast absorption and precise dosing. The best manufacturers utilize advanced, temperature-controlled botanical extraction methods like cold-fill technology to protect passion flower's delicate flavonoids and alkaloids, moving beyond harsh traditional processes.

- Capsules: The ultimate in convenience. For customers who want zero taste and an easy-to-swallow format, capsules are the ideal choice. The key differentiator is the quality of the powdered extract inside. Your partner must offer options with standardized potency to ensure every dose is consistent.

- Powders: Incredibly versatile and perfect for the booming functional beverage market. You can create a standalone passion flower powder or a complex, synergistic blend that customers can mix into smoothies, teas, or yogurt.

Think of your product's format as its first handshake with the customer. A liquid tincture says "traditional and potent," while a dissolvable powder screams "modern and on-the-go." Your manufacturer should help you pick the format that tells your brand's story best.

This first decision sets the stage for everything else. For example, opting for a liquid tincture opens up a world of flavoring possibilities that aren’t relevant for a capsule.

The Art of Synergistic Blends

Passion flower is a powerhouse on its own, but its true magic is often unlocked when combined with other botanicals and nutrients. This is where a manufacturer's deep formulation experience becomes critical. They can help you think beyond a single-ingredient product and create a proprietary blend that solves a specific customer problem.

A sharp R&D team can help you explore combinations that create a powerful synergistic effect, making your product not just different, but more effective than the competition.

Consider these real-world possibilities:

- For a Calming Sleep Aid: Pair passion flower with other well-studied botanicals like chamomile and valerian root. This creates a formula that promotes relaxation and sleep through multiple biological pathways.

- For Digestive Wellness: Combine passion flower's calming effects with the soothing properties of ginger and peppermint. The result is a formula that addresses stress in both the mind and the gut—a huge need for today's consumers.

- For Stress and Focus: Blend passion flower with an adaptogen like ashwagandha or a nootropic like L-theanine. You'd have a product that helps people manage stress while staying sharp and focused, perfect for busy professionals.

A top-tier partner won't just suggest these ingredients; they'll have the sourcing network and quality control systems to procure pure, potent versions of each one.

Perfecting the Flavor Profile

For any liquid or powder supplement, flavor is a core part of the user experience. An effective formula that tastes awful won't earn repeat customers. The best manufacturers employ flavor specialists who craft custom profiles that match your brand and delight your customers.

This is a true collaboration:

- Defining the Target Profile: First, you'll discuss the goal. Are you going for light and fruity, or more earthy and herbal?

- Developing Samples: Their lab will then create several variations for you to taste.

- Refining Based on Feedback: You provide notes—"a little more berry," "less sweetness"—and they tweak the formula until it's perfect.

Whether you want a simple "Mixed Berry" or a sophisticated "Lavender Honey," your manufacturer must be able to mask bitter herbal notes without relying on artificial sweeteners. Finding that perfect balance is an art that separates premium brands from the rest.

Before committing to a full-scale run, always insist on a pilot run. This smaller batch, typically 500-1,000 units, lets you test everything about your new formula—from taste and effectiveness to stability. It's your final check to ensure the product you launch is exactly the one you envisioned.

Getting a Grip on Production Timelines and Supply Chains

You’ve locked in your custom passion flower formula. Excellent. The next question is, "How long until I can sell this?" Understanding the production process is vital for setting expectations, planning your launch, and ensuring reliability.

A good Passion Flower private label contract manufacturer provides a clear, dependable roadmap. This isn't just about filling bottles; it's a complex process of sourcing, testing, producing, and ensuring quality at every step. Transparency here is key to building a reliable partnership.

Knowing what happens behind the scenes helps you understand why quality takes time and why a partner with a rock-solid supply chain is invaluable.

Breaking Down the Production Schedule

The journey from an approved formula to a pallet of ready-to-ship products has several distinct stages. While your project will be unique, most production runs follow a similar flow. The timeline can shift depending on formula complexity or custom packaging sourcing.

Here’s a realistic look at the four main phases:

- Raw Material Sourcing and Verification (2-4 weeks): This is where it all starts. Your manufacturer taps into their network of vetted suppliers to source every ingredient. Nothing is used until it arrives with a Certificate of Analysis (CofA) and passes stringent in-house tests for identity and purity. This step is non-negotiable.

- Pilot Batch and Stability Testing (4-6 weeks): Before a full run, a small pilot batch is created. This crucial step ensures the formula works at scale and allows for final sensory checks. This batch also kicks off stability testing to confirm your product remains potent and safe throughout its shelf life.

- Full-Scale Production and Quality Control (2-4 weeks): Once the pilot is approved, full production begins. This involves precision batching, mixing, and filling, often using advanced technologies like cold-fill processing to protect active ingredients. Our quality control teams monitor the entire process to ensure every bottle matches your approved formula.

- Finishing, Labeling, and Final Testing (1-2 weeks): In the home stretch, bottles are labeled, tamper-evident seals are applied, and everything is prepped for shipping. A sample from this final batch is sent to an independent third-party lab for final verification of potency and purity—your unbiased seal of approval.

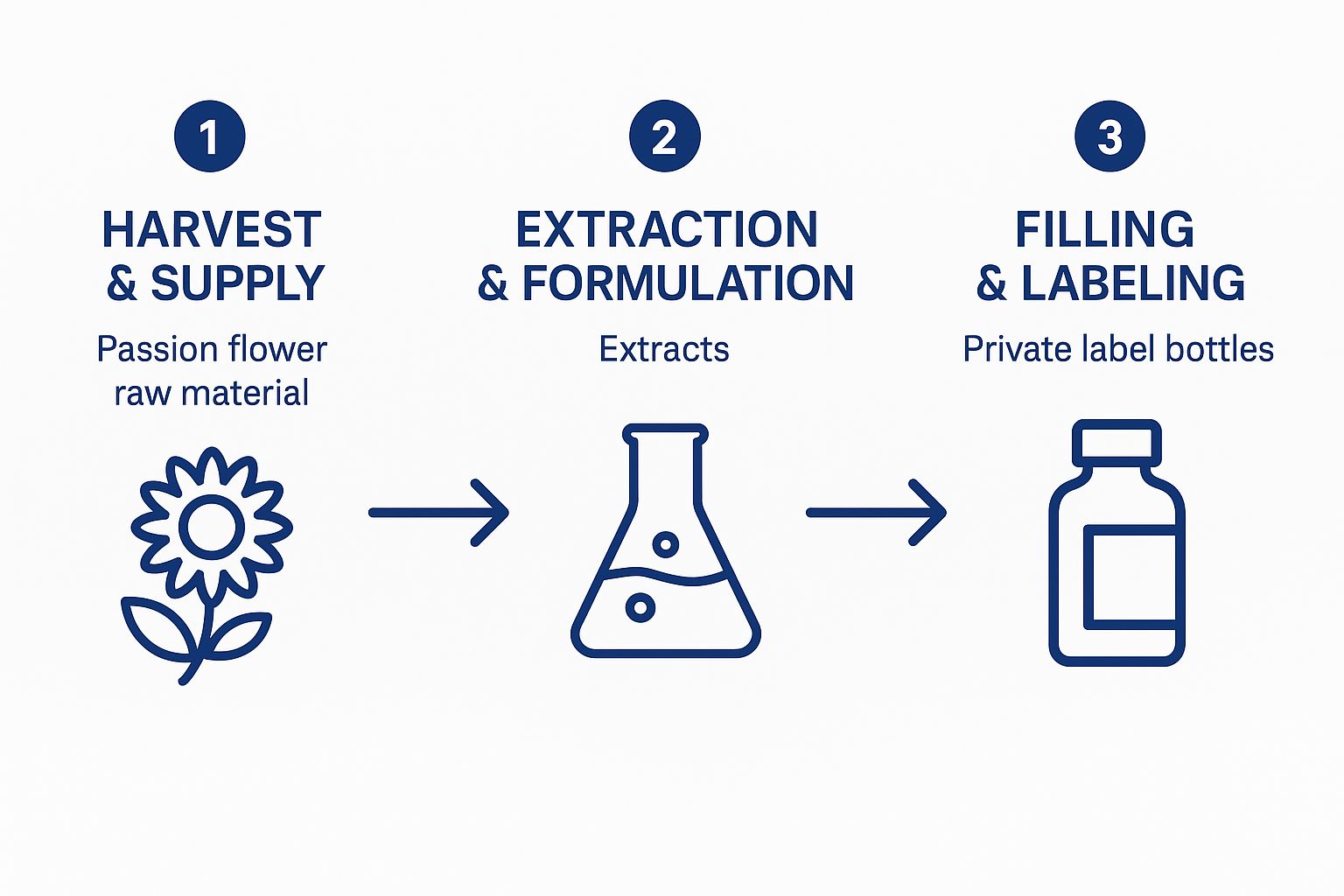

This flow chart gives you a bird's-eye view of how raw materials become a finished private label product ready for your customers.

As you can see, each stage logically follows the next. It’s a methodical process designed to guarantee quality and deliver on time.

Navigating MOQs and Supply Chain Resilience

Two terms you’ll hear often are Minimum Order Quantities (MOQs) and lead times. MOQs are the smallest batch size a manufacturer can run efficiently. For a new launch, you want a partner with flexible MOQs, perhaps starting with a pilot run of 1,000-2,500 units. This lets you test the market without sinking significant capital into inventory.

A manufacturer’s supply chain is the invisible engine of your brand's reliability. Our strong network means consistent access to high-quality passion flower extract, protecting you from stockouts and delays that can damage customer trust.

A resilient supply chain is your best insurance against the unexpected. Ask potential partners how they handle risk. Do they have backup suppliers for critical ingredients? How do they manage lead times for custom packaging?

Their answers reveal their experience and operational strength. As a brand owner, understanding these details is crucial. For a deeper dive, check out our guide on the world of private label liquid supplements. Ultimately, a strong manufacturing partnership ensures that when you promise a product to your customers, you have the supply chain to back it up.

Designing Packaging That Sells Your Product

Your product’s packaging is its first handshake with a customer. In a crowded market, it's often the deciding factor that gets your product noticed. It’s more than a container—it’s a silent salesperson, a key part of your brand story, and your first line of defense against regulatory issues.

A versatile Passion Flower private label contract manufacturer doesn't just fill bottles. We act as a partner, helping you translate your brand vision into a physical form that connects with people. We guide you through the maze of material choices, design specs, and complex labeling rules to create something beautiful, functional, and 100% compliant.

Selecting the Right Vessel for Your Formula

The container you choose directly impacts user experience, shelf life, and perceived value. A seasoned manufacturer presents a curated range of options, explaining the advantages of each for your specific formula. We consider everything from protecting delicate botanical compounds to matching your target customer's aesthetic.

Here are a few common options you'll likely discuss:

- Classic Amber Glass Bottles: The gold standard for liquid tinctures. The amber color provides essential UV protection, preserving the potency of your passion flower extract. Glass also conveys a premium, clean feel that resonates with health-conscious consumers.

- Modern PET Plastic Bottles: A lightweight and shatter-resistant alternative. High-quality, BPA-free PET (polyethylene terephthalate) is a smart, cost-effective choice, especially for larger volumes or direct-to-consumer shipping.

- Eco-Friendly Pouches: A fantastic option for powders. Flexible pouches minimize shipping space and often have a lower carbon footprint, a huge selling point for environmentally aware customers. They can also be designed with convenient resealable zippers.

A good partner gets into the details. We’ll discuss which dropper cap provides the most accurate dosage or what liner material prevents leaks. This level of detail ensures your product isn't just attractive but also safe and easy for your customers to use.

Mastering FDA Labeling Compliance

This is where a true manufacturing partnership pays for itself. While your brand is ultimately responsible for your label, a top-tier manufacturer acts as your expert compliance guide. A simple labeling mistake can trigger costly recalls, legal trouble, and a complete loss of consumer trust.

Your label is a legal document. Every claim, every ingredient, and every font size is under scrutiny. A cGMP-certified partner with an in-house regulatory team is your best defense against compliance pitfalls.

Our team will meticulously review your artwork to ensure it meets all FDA requirements for dietary supplements. This isn't a quick glance; it's a deep dive into:

- Supplement Facts Panel: Correctly formatting the serving size, ingredients, and amounts per serving.

- Health Claims: Ensuring any structure/function claims are permissible and paired with the required FDA disclaimer.

- Allergen Warnings: Clearly identifying any of the top nine major food allergens.

- Net Quantity of Contents: Accurately stating the amount of product in the container.

A Collaborative Design and Review Process

Creating compliant, sales-driving packaging is a team effort. A good manufacturer works seamlessly with your graphic designer, providing precise die lines and templates. We also offer practical feedback on material compatibility to prevent issues like ink smudging or peeling labels.

This collaborative loop protects your brand and smooths your path to market. It's a key reason why private label contract manufacturing for passion flower extracts is a booming sector. Market forecasts for 2025 to 2035 predict steady growth of around a 3.6% CAGR for the passion flower extract market, with private labels being a major driver of this expansion.

You can explore more data on the passion flower market to see these trends for yourself. By working with an expert partner, you ensure your product not only rides this wave of growth but stands out with packaging that is compelling, compliant, and perfectly aligned with your brand.

Got Questions About Passion Flower Manufacturing? We’ve Got Answers.

Even with a solid plan, specific questions will come up. That’s normal. This is where we tackle the most common inquiries from brand founders looking for a Passion Flower private label contract manufacturer.

What’s a Typical Minimum Order Quantity (MOQ)?

There's no single number for Minimum Order Quantities (MOQs). It shifts based on formula complexity and packaging choices.

For a straightforward liquid formula, a partner might offer a pilot run as low as 500–1,000 units, which is great for market testing. For a fully custom formula with unique ingredients and bespoke packaging, you're likely looking at a starting point around 2,500–5,000 units.

The key is finding a partner who can grow with you.

Don't just focus on the first MOQ. The real question is about scalability. You need to ask them directly: "Can you take us from a 1,000-unit test run to 100,000 units and beyond?"

How Long Does It Realistically Take from Idea to Finished Product?

Setting a realistic timeline is crucial for a stress-free launch. From signing off on your final formula to holding the finished product, you should budget for about 12 to 20 weeks.

This timeline typically breaks down into these key phases:

- Formulation & R&D: 4–6 weeks

- Sourcing & Testing Ingredients: 2–4 weeks

- Pilot Batch & Stability Testing: 4–6 weeks

- Full-Scale Production & Packaging: 2–4 weeks

This can flex. Using a stock formula might shorten the timeline. Conversely, sourcing rare botanicals or engineering custom packaging will add time. A transparent manufacturing partner will provide a detailed project timeline upfront.

Who’s on the Hook for FDA Labeling Compliance?

Let's be crystal clear: your brand is 100% legally responsible for every word and claim on your product label. Period.

That said, a top-tier contract manufacturer is your compliance co-pilot. Their in-house regulatory team should review your label artwork, ensuring every detail meets FDA guidelines for dietary supplements (21 CFR Part 111). This includes everything from the Supplement Facts panel to the precise wording of your claims.

Avoid any manufacturer who is vague on FDA regulations. A simple labeling mistake can trigger recalls and land your brand in legal hot water. It's not worth the risk.

Can I Bring My Own Passion Flower Extract to the Party?

This is a common question, and the answer is usually "probably not." Most cGMP-certified facilities insist on using their own network of vetted raw material suppliers. This isn't to be difficult—it’s the only way they can guarantee the purity, potency, and traceability of every ingredient from farm to bottle.

Allowing an outside ingredient into a controlled environment introduces a significant quality and liability risk. If you have a truly unique, proprietary extract, prepare for an extensive validation process. Your manufacturer will require a Certificate of Analysis (CofA) from a trusted third-party lab and will conduct their own independent tests before it enters their production line. This will add significant time and cost to your project.

Ready to turn your vision for a passion flower supplement into a market-ready success? At Triton Nutra Group, we act as your dedicated R&D and manufacturing partner, guiding you from concept to launch with transparency, speed, and expertise. Request your free consultation and quote today!