Packaging of Liquids: A Guide for Private Label Herbal Supplements

Learn essential tips on packaging of liquids for supplements to ensure quality, compliance, and impactful branding. Click to optimize your packaging!

Get a Free Quote Today!

Get a Free Quote Today!For visionary brand managers, e-commerce founders, and health-and-wellness entrepreneurs, the packaging of liquids is more than just a container. It's a strategic decision that protects your product's integrity, ensures customer safety, and defines your brand's reputation. When you're launching a private-label liquid herbal supplement, getting this right is non-negotiable.

Why Your Liquid Supplement Packaging Matters

When you're launching a private-label liquid herbal supplement, that bottle is your first handshake with a potential customer. It needs to communicate quality, trust, and efficacy before they ever taste the product inside. But beyond the label, your packaging is the primary line of defense for the complex, often delicate formula you’ve invested so much in.

This goes far beyond simply preventing leaks. A smart packaging strategy tackles the unique challenges of liquid supplements head-on.

- Preserving Potency: Many botanical ingredients are incredibly sensitive to light, oxygen, and temperature. The wrong material can degrade your high-quality formula, making it less effective over time. We use advanced techniques like our innovative cold-fill technology to protect these delicate compounds.

- Ensuring Dosage Accuracy: The delivery mechanism—be it a dropper, pump, or measuring cap—must be precise. An inconsistent dose leads to a poor customer experience and erodes trust in your product's reliability.

- Meeting Strict Compliance: The supplement industry operates under tight regulations. As your partner, we ensure your packaging meets cGMP (Current Good Manufacturing Practices) and is produced in our UL certified, FDA-registered facility, guaranteeing it's safe and non-reactive with your formula.

The Strategic Value of Smart Packaging Decisions

Choosing your packaging isn't a final detail; it's a core component of your product development strategy. The global liquid packaging market is booming, driven by demand for safe, effective, and appealing solutions. If you want to dive deeper into the market dynamics, you can explore the latest research on the global liquid packaging market. This growth underscores how vital the right container is for commercial success.

As your manufacturing partner, we see packaging as the bridge between your brilliant formula and your customer. It’s where our commitment to quality becomes tangible, protecting your investment and ensuring the end-user receives the exact product you envisioned.

We don't just fill bottles. We act as your R&D partner from concept through launch. By guiding you through material science, preservation technology, and regulatory hurdles, we empower you to make informed choices that build a successful, resilient brand. Our flexibility, from small pilot runs to full-scale production, ensures your packaging isn't just a container—it's a competitive advantage built on speed and reliability.

Critical Decision Factors for Liquid Supplement Packaging

When you're deep in product development, it's easy to get overwhelmed. This table breaks down the most critical factors to weigh when selecting your packaging. Nail these, and you're on your way to creating a product that stands out for all the right reasons.

| Key Factor | Why It's Crucial for Your Brand | Common Solutions |

|---|---|---|

| Material Compatibility | The wrong material can react with your formula, leaching chemicals or degrading active ingredients. This compromises safety and efficacy. | Glass (especially amber or cobalt blue for UV protection), HDPE and PET plastics (food-grade and non-reactive). |

| Product Preservation | Exposure to light, oxygen, and heat can destroy the potency of sensitive botanicals and vitamins, shortening shelf life. | UV-resistant materials (colored glass/plastic), airtight seals (induction liners, tamper-evident caps), and innovative filling tech like cold-fill processing. |

| Dosage Accuracy & Dispensing | Inconsistent dosing frustrates customers and can lead to poor results, damaging your brand's credibility. | Calibrated glass droppers, metered pumps, or orifice reducers for controlled drops. |

| Regulatory Compliance | Failure to meet FDA and cGMP standards can result in recalls, fines, and a total loss of consumer trust. | Using materials with a history of safety, sourcing from reputable suppliers, and manufacturing in a UL certified, cGMP-compliant facility. |

| Brand Perception & Shelf Appeal | Your packaging is your #1 marketing tool on the shelf. It must communicate quality and align with your brand's story. | High-quality label printing, unique bottle shapes, premium finishes (matte, soft-touch), and functional yet elegant closures. |

Ultimately, each of these factors is interlinked. A beautiful bottle is useless if it doesn't protect the formula, and a compliant package that's hard to use will never win repeat customers. The goal is to strike the perfect balance between product integrity, regulatory adherence, and an exceptional customer experience.

Choosing the Right Materials and Containers

The foundation of an excellent liquid supplement is the package it comes in. Choosing the right material for your specific formula isn't just about aesthetics; it's a critical decision that directly impacts potency, safety, and shelf life.

Think of your container as a specialized vault designed to protect the valuable ingredients inside. As your R&D partner, we guide you through this process, ensuring the material you choose is a perfect match for your product. For liquid herbal supplements, the main contenders are almost always glass and specific high-performance plastics. Each has pros and cons you'll need to weigh.

The Gold Standard: Glass

For high-potency herbal extracts, glass is often the undisputed champion. Its biggest advantage? It’s chemically inert. That's an industry term meaning it won't react with your formula or leach unwanted substances into the product, which is vital for maintaining purity.

Beyond that, colored glass offers a crucial line of defense against degradation.

- Amber & Cobalt Blue Glass: These aren't just for a premium, apothecary look. They serve a real purpose: blocking harmful UV light that can break down sensitive vitamins and botanical compounds. This actively preserves your formula’s potency.

- Clarity & Perception: For products that aren’t light-sensitive, clear flint glass is a great option. It offers a crystal-clear view of the liquid, which can go a long way in building consumer trust.

Of course, glass isn't perfect. It's heavier and more fragile than plastic, which can increase shipping costs and risk of breakage. This is the classic trade-off between maximum protection and logistical realities.

High-Performance Plastics

Modern plastics offer a lightweight, durable, and often more cost-effective alternative to glass. But it's critical to choose the right kind of plastic. As a cGMP and UL certified manufacturer, we only use high-quality, food-grade plastics that have been rigorously tested for compatibility with supplement formulas.

The most common options you'll see are:

- PET (Polyethylene Terephthalate): You know this one. It’s prized for its clarity, strength, and great barrier properties against oxygen and moisture. It’s an excellent, highly recyclable choice for many supplements.

- HDPE (High-Density Polyethylene): This is the opaque, more rigid plastic. HDPE is a true workhorse—extremely tough with fantastic chemical resistance, making it perfect for products where transparency isn't a priority.

While plastics are more resilient and lighter to ship, they don't offer the same inherent UV protection as dark glass unless they are treated with special additives.

Key Insight: The decision between glass and plastic is never just about cost. It’s a strategic choice about preserving your product's integrity. We often recommend amber glass for complex, light-sensitive herbal formulas and high-quality PET for sturdier products like liquid vitamins.

Comparing Materials for Liquid Supplement Bottles

To make this clearer, let's break down the key differences in a table. This is a direct comparison of the most common materials, highlighting properties that matter most for your product and brand.

| Material | Primary Benefits | Key Considerations | Ideal For |

|---|---|---|---|

| Amber Glass | Excellent UV protection; chemically inert (no leaching); premium feel. | Heavier; more fragile (higher shipping/breakage risk); higher cost. | Light-sensitive herbal tinctures, high-potency extracts, essential oils. |

| Clear Glass | Chemically inert; shows off product clarity and color; recyclable. | No UV protection; heavier and more fragile than plastic. | Products not sensitive to light; building trust through transparency. |

| PET Plastic | Lightweight; shatter-resistant; good moisture and oxygen barrier; clear. | Can be permeable to some compounds; requires UV inhibitors for light protection. | Liquid vitamins, syrups, and general supplements where durability is key. |

| HDPE Plastic | Very durable and rigid; excellent chemical resistance; opaque. | Not transparent; can have a less premium feel than glass or PET. | Bulk-size products, supplements that need robust chemical resistance. |

Ultimately, the "best" material depends entirely on what's inside the bottle. A delicate botanical extract has very different needs than a simple vitamin C syrup, and your packaging choice needs to reflect that.

Matching Containers to Your Product

Once you’ve settled on a material, the next step is picking the right container format. This decision impacts everything from accurate dosing to the overall user experience.

- Boston Round Bottles: These are the industry standard for a reason. Available in both glass and plastic, they are perfect for tinctures and serums where you need precise, small doses administered by a dropper.

- Vials: Smaller than bottles, vials are great for single-use "shots," product samples, or highly concentrated formulas where a little goes a long way.

- Jugs and Larger Bottles: For bulk products or multi-serving formulas like liquid vitamin C or elderberry syrup, larger containers with simple screw caps or pumps offer convenience for the whole family.

The viscosity of your liquid—how thick or thin it is—also plays a huge role. Trying to get a thick, syrupy formula out of a narrow dropper would frustrate your customer. A bottle with a wider mouth and a measuring cap is a much more practical solution. Making the right call here is a key part of our collaborative process, showcasing our partnership mindset.

Don't forget sustainability. For many modern brands, this is non-negotiable. Beyond the primary container, think about the labels and branding. Exploring sustainable printing practices is another crucial piece of the puzzle for reducing your product's environmental footprint.

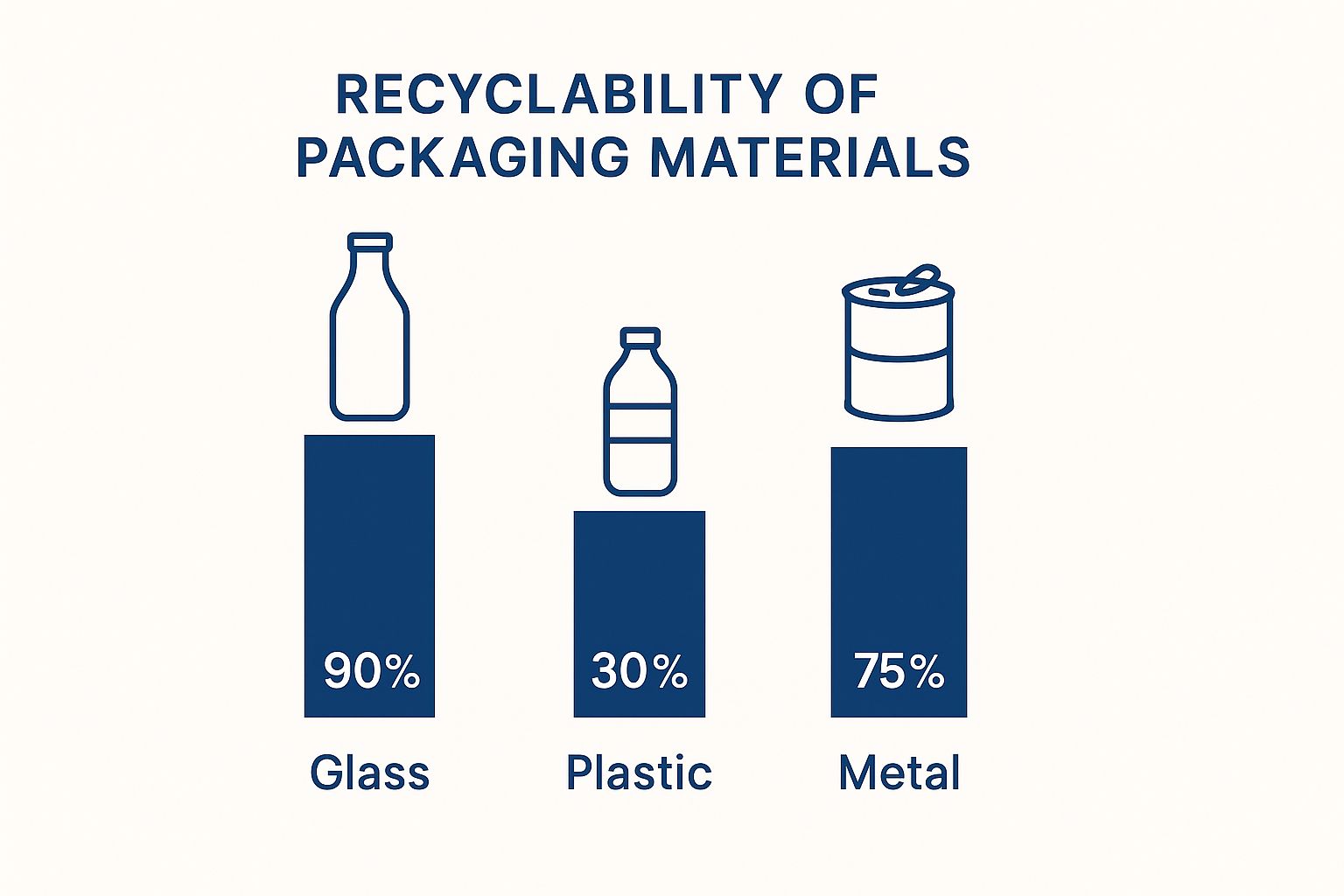

This infographic paints a pretty clear picture of how different packaging materials stack up when it comes to recycling.

The data shows that while materials like glass and metal have impressive recyclability rates, plastic still has a lot of catching up to do. This really underscores the need for brands to choose highly recyclable plastics like PET and to actively encourage their customers to recycle.

Sealing and Preservation to Ensure Product Integrity

Once you’ve selected the perfect bottle, the next mission is ensuring what’s inside stays pure, potent, and safe. This is where the science of preservation kicks in. The right seal is more than a lid; it’s an active defense system that guards your formula, extends shelf life, and builds unshakable trust with your customers.

A leaky bottle or a broken seal isn't just a messy inconvenience—it's a direct blow to your brand's reputation. As your manufacturing partner, we engineer a complete sealing solution that protects your product from every angle. It all starts with the cap.

Caps and Closures That Build Trust

The cap on your bottle performs a dual role. It must prevent leaks, of course, but it also needs to provide clear proof of the product's safety and integrity. A simple screw-top might seem adequate, but for supplements, the standard is much higher.

Here’s what you need to consider:

- Tamper-Evident Closures: These are non-negotiable. A tamper-evident seal, like a plastic shrink band or a ring that breaks away when opened, gives customers instant visual proof that the product is untouched. It's a silent, powerful signal of quality control.

- Child-Resistant Caps (CRCs): If your formula contains any ingredients that could be harmful to children, CRCs are a legal and ethical requirement. These "push-and-turn" caps are mandated by the Poison Prevention Packaging Act. A mistake here can lead to recalls and serious brand damage.

Getting the closure right isn’t just about compliance. It’s about showing your customers you prioritize their safety from the moment they hold your product.

The Airtight Barrier: Liners and Seals

Underneath the cap, you'll find another vital component: the liner. This is the seal that presses against the bottle's rim, creating an airtight barrier that stops leaks, blocks oxygen, and keeps contaminants out.

Your product's seal is its first promise of purity to the customer. A strong, intact seal means the potent, precisely crafted formula you paid for is exactly what’s inside, completely untouched since it left our cGMP facility.

We use two main types of liners to create this hermetic seal:

- Induction Seals: You've seen these a million times—they're the foil liners on top of supplement bottles. An induction machine uses an electromagnetic field to heat the foil, bonding it to the bottle's rim. The result is an incredibly strong, airtight, and tamper-proof seal.

- Pressure-Sensitive Liners: These liners have an adhesive that sticks to the bottle's rim when the cap is tightened. They are simpler to apply but generally provide a less robust seal than induction liners, making them better suited for products less sensitive to oxygen.

For a high-potency herbal formula, an induction seal is almost always the right choice. It offers the ultimate protection against the oxidative damage that can quickly degrade your active ingredients.

Advanced Preservation for Modern Formulas

Protecting a modern supplement goes beyond a physical seal. How we handle the product during filling is just as critical, especially for brands committed to clean, preservative-free formulas. This is where our forward-thinking approach sets you apart.

The entire liquid packaging market is growing, pushed by consumer demand for smarter solutions. You can find more analysis on liquid packaging market trends to see how innovation is shaping the industry.

As your partner, we use advanced technologies to maintain your formula's purity without relying on harsh preservatives, demonstrating a deep understanding of what today's health-conscious consumer wants.

Two key innovations we use are:

- Cold-Fill Processing: Traditional hot-fill methods can be brutal on the delicate phytochemicals in botanical extracts. We use advanced cold-fill technology, bottling in a temperature-controlled environment to preserve the full potency and natural profile of your ingredients.

- Aseptic Packaging: In this highly advanced process, we sterilize the liquid formula and packaging materials separately in a sterile environment before filling. This eliminates contaminants from the start, allowing for a shelf-stable product with minimal or no preservatives—perfect for clean-label supplements.

By pairing the right physical seals with sophisticated processing techniques, we deliver a final product that is safe, stable, and as potent as the day it was formulated.

Navigating Regulatory and Compliance Demands

For any serious supplement brand, compliance isn't just a box to check—it's the bedrock of your business. Getting the packaging of liquids right means navigating a strict set of rules designed to keep consumers safe. As your manufacturing partner, we don’t just follow these rules; we integrate them into our process, turning complex regulations into your competitive advantage.

It can feel intimidating, but it boils down to one thing: proving your product is safe, consistent, and exactly what you claim it is. This is where partnering with an expert facility becomes non-negotiable.

Understanding cGMP and FDA Oversight

The two most important acronyms you need to know are cGMP and FDA.

- cGMP (Current Good Manufacturing Practices): This is the FDA's baseline for quality control, covering everything from raw materials to the final sealed bottle. For packaging, cGMP demands that every material is appropriate and won't leach anything harmful into your formula.

- FDA Registration: A facility that is FDA-registered is on the agency's radar, showing a commitment to transparency and accountability. Working with an FDA-registered and UL certified partner like us means your product is made in a facility designed to meet—and exceed—these critical standards.

This commitment is our promise that every bottle leaving our facility is traceable, safe, and consistently high-quality.

Partnership Insight: We see compliance as a team sport. We are your dedicated quality control partner, ensuring your packaging choices align with cGMP and FDA requirements from the start. This rigorous approach is a pillar of our speed and reliability.

The Critical Role of Third-Party Testing

How do you really know your packaging is safe and your formula is potent? The answer is third-party testing. This is where you send samples of your product and packaging to an independent, accredited lab for unbiased analysis.

This step is essential for two reasons:

- Verifying Formula Potency: The lab confirms that the active ingredients are present at the exact levels stated on your label.

- Ensuring Packaging Safety: The lab runs tests to spot any potential leaching—the transfer of unwanted chemicals from the container into your liquid. This confirms your chosen bottle, cap, and liner are completely non-reactive with your formula.

This is your ultimate proof of quality. It provides the hard data needed to stand behind your product with 100% confidence, assuring you and your customers that your brand is built on integrity. For a deeper dive into these standards, our guide on dietary supplement manufacturing requirements provides essential context.

A cornerstone of successful liquid supplement packaging is mastering regulatory compliance in labelling. The information on the outside of the bottle is just as regulated as the product inside. Getting this right protects your business and your customers.

Designing Packaging That Builds Your Brand

While materials and seals protect your product, the design is what sells it. Great packaging moves beyond function to become your brand’s most powerful storyteller. It's the visual handshake that grabs a customer’s attention and instantly communicates your values.

As your R&D partner, we help you turn a simple bottle into a compelling brand asset. It’s a delicate balance between mandatory compliance and creative expression, and our job is to ensure your packaging is both compliant and remarkable.

Balancing Compliance With Branding On Your Label

Every liquid supplement label is a blend of science and art. On one hand, you have non-negotiable elements required by regulators. On the other, you have a canvas for building an identity that connects with your audience.

Mandatory Elements:

- Supplement Facts Panel: The FDA-required breakdown of nutritional and ingredient information. It must be clear, accurate, and correctly formatted.

- Net Quantity of Contents: The amount of liquid in the bottle (e.g., 2 fl oz / 60 mL).

- Ingredient List: A complete list of all ingredients, listed in descending order by weight.

- Manufacturer Information: The name and address of your company or distributor.

Branding Elements:

- Logo & Brand Name: The face of your brand; it should be instantly recognizable.

- Color Palette: Colors create emotion and can make your product stand out.

- Typography: Fonts set a specific tone, whether it's clinical and modern or natural and earthy.

- Brand Messaging: Your chance to use a tagline or short description to tell customers what makes you different.

A well-designed label makes compliance information feel like a natural part of the design, not a tacked-on legal chore. This harmony builds trust and makes your product look professional.

The most successful brands don't just put a logo on a bottle. They create an experience. Your packaging design is the first chapter of your brand’s story, setting expectations for the quality and care found inside.

Standing Out With Premium Finishes and Materials

In a sea of competitors, small details make a huge difference. The physical feel and appearance of your label can elevate your product from just another supplement to a premium wellness solution. We offer a full suite of customization options to achieve that perfect feel.

Consider the tactile experience:

- Matte vs. Gloss: A gloss finish creates a vibrant, eye-catching look. A matte finish, conversely, provides a more subtle, sophisticated, and luxurious feel.

- Metallic Foils & Embossing: A flash of gold, silver, or copper foil can signal a high-end product. Embossing—a raised design—adds a physical texture that invites touch and conveys craftsmanship.

When designing packaging that builds your brand, it can be helpful to look at how other industries use branding. Exploring the appeal of branded water bottles in the promotional world, for instance, offers great insight into creating a desirable, reusable item. These same principles apply to making your supplement packaging feel like a keeper.

Enhancing the Unboxing Experience with Secondary Packaging

Your customer's interaction with your brand doesn't stop with the bottle. The "unboxing experience" has become a massive part of e-commerce, giving you another powerful opportunity to impress your customers and reinforce your brand’s quality.

This is where secondary packaging—the box your bottle arrives in—shines. A custom-printed box does more than just protect the bottle; it turns a simple delivery into an event.

- Reinforces Brand Identity: A box gives you more real estate for your branding, story, and product benefits.

- Creates a Premium Feel: A well-designed box makes the product feel more substantial and gift-like, instantly increasing its perceived value.

- Offers Practical Protection: It adds a critical layer of defense against transit damage, reducing returns and keeping customers happy.

From the label finish to the box design, every choice is a chance to build a stronger connection with your customer. We collaborate with you to ensure every element is perfectly aligned, creating a cohesive and memorable brand experience.

Your Partnership for Success, From Concept to Launch

Bringing a new liquid supplement to market involves a thousand critical decisions. You're juggling bottle selection, regulatory mazes, and brand creation. It's a lot.

But you don't have to do it alone. The right manufacturing partner is an extension of your team. We see our role as transforming this complex process into a clear, manageable path to launch.

Think of us as your dedicated R&D department, your collaborator from initial concept to final shipment. We combine deep industry expertise in the packaging of liquids with a flexible, partnership-first mindset. This approach is built to give your brand the exact support it needs, when it's needed most.

Flexibility and Speed for Modern Brands

We understand that every brand is on a unique journey. You might be a startup testing the waters with a small pilot batch or an established company scaling up production. Our facility is designed for this flexibility.

Our ability to handle run sizes from pilot to full scale means you can stay agile and respond to market demands. This adaptability is paired with a serious commitment to speed and reliability. We provide transparent timelines and have a proven on-time delivery record, so you can plan your launch with confidence.

Your vision deserves a partner as committed to its success as you are. We build that partnership on a foundation of quality, customization, and a shared goal of creating a best-in-class product that customers will love.

Your Guide Through the Private Label Process

Our goal is to do more than just manufacture your product. We empower you with the knowledge to make smart, strategic decisions for your brand's future.

We will guide you through every stage, ensuring your formula, packaging, and branding work in perfect harmony. Our expertise covers everything from advanced botanical extraction and flavor customization to meticulous third-party testing, ensuring your supplement is built on a solid foundation of quality and compliance.

This collaborative framework is central to how we help brands thrive. For a complete overview of the process, we've put together a detailed guide on the world of private label liquid supplements.

Ready to see how our hands-on expertise can bring your vision to life? Let’s start the conversation. We’re here to discuss your project, answer your questions, and show you how a true partnership can set you up for lasting success.

Got Questions? We've Got Answers

Stepping into the world of liquid supplement packaging can feel complex. As your R&D partner, we believe the best decisions come from clear, straightforward answers. Here are a few common questions we get from brand owners like you.

What Is the Most Important Factor in Liquid Supplement Packaging?

Hands down, the single most critical factor is material compatibility. Your packaging is your formula's home until it reaches the customer. It absolutely must be non-reactive with your ingredients to prevent any chemical leaching.

This is non-negotiable for preserving your product's purity, potency, and shelf life. For delicate botanical extracts, UV-protective materials like amber glass are the gold standard. They act like sunglasses for your supplement, preventing light from degrading the formula.

How Do I Make My Supplement Packaging Tamper-Evident?

The two most trusted industry methods are induction seals and shrink bands.

- An induction seal is the foil liner heat-sealed onto the bottle's rim.

- A shrink band is the plastic sleeve that tightly hugs the cap and neck.

Both give your customer an immediate, clear sign if the product has been opened. These features are often paired with child-resistant caps for both safety and regulatory peace of mind.

What Is a Typical Lead Time for Custom Liquid Packaging?

The honest answer is: it depends. Lead times can vary based on project complexity and component availability.

However, a great manufacturing partner with strong supplier relationships and flexible production lines can deliver with impressive speed. We prioritize transparent timelines and rapid turnaround, working to get you from design approval to finished product in just a few weeks. We give the same focus and urgency to small pilot runs and full-scale production orders.

Ready to create a high-quality liquid supplement with packaging that truly stands out? The team at Triton Nutra Group is here to guide you every step of the way, from concept to launch. Request your free consultation and quote today!