Your Partner in Nutraceutical Manufacturing: A Guide for Supplement Brands

Your guide to finding reliable nutraceutical contract manufacturers. Learn to evaluate quality, compliance, and capabilities to scale your supplement brand.

Get a Free Quote Today!

Get a Free Quote Today!Nutraceutical contract manufacturers are your expert production partner, handling the complex science of formulation, sourcing, and manufacturing so you can focus on building your brand. As your R&D partner from concept through launch, we transform your product vision—especially for private-label liquid herbal supplements—into a market-ready reality without the massive overhead of building your own facilities.

Your Partner in Product Growth

Launching a successful supplement brand involves more than a great idea. You have to navigate the complex world of scientific formulation, raw material sourcing, stringent quality control, and ever-changing regulations.

For most entrepreneurs, building that infrastructure from the ground up isn't just wildly expensive—it pulls focus from what you do best: marketing your products and connecting with customers. This is where nutraceutical contract manufacturers become your most valuable players.

Think of us as an extension of your team. We are your R&D department, production floor, and quality assurance experts, all rolled into one. This partnership model lets you tap into our specialized knowledge and state-of-the-art technology from day one. By collaborating, we help you launch with the speed and reliability of an established player.

A true partner offers a suite of services that takes the operational burden off your shoulders. Here's a quick look at what that includes.

Core Services from Your Manufacturing Partner

| Service Area | What It Means For Your Brand |

|---|---|

| Custom Formulation & R&D | Access to food scientists who can refine your concept or develop a new, tailored formula from scratch. |

| Ingredient Sourcing | A vetted network of trusted raw material suppliers, ensuring quality, potency, and supply chain stability. |

| Flexible Manufacturing | State-of-the-art facilities for producing liquids, tinctures, and more, with run sizes from pilot to full scale. |

| Quality & Compliance | Rigorous cGMP, third-party testing in our FDA-registered, UL-certified facility guarantees purity and safety. |

| Packaging & Labeling | Expertise in creating compliant, shelf-stable packaging that meets all retailer requirements. |

| Regulatory Guidance | We help you navigate cGMP, FDA regulations, and other critical compliance hurdles with confidence. |

Ultimately, these services combine to create a seamless, transparent path from your initial idea to a finished product in your customer's hands.

The Power of a Strategic Partnership

The real magic happens in the collaboration. A top-tier manufacturer doesn't just take orders; they act as a strategic advisor. We’ll help you refine your formula for maximum efficacy, suggest innovative flavoring systems to delight your customers, and ensure your packaging meets strict requirements for platforms like Amazon FBA.

This partnership mindset empowers you to:

- Accelerate Speed to Market: Go from concept to launch in a fraction of the time with rapid, transparent timelines.

- Ensure Quality and Compliance: Leverage our deep expertise in cGMP, FDA regulations, and third-party testing to build consumer trust.

- Scale with Confidence: Start with small pilot runs to test the market, then seamlessly ramp up to full production as your brand takes off.

This collaborative approach is fueling the entire industry. The global market for these services was valued at around USD 148.85 billion in 2023 and is projected to more than double by 2030—a clear sign that brands thrive with the right partner.

A partnership with the right manufacturer is about de-risking your investment. You gain immediate access to a compliant, scalable production system, allowing you to pour your resources into building a brand that resonates with your audience.

Choosing the right partner is one of the most critical decisions you'll make. It’s a choice that directly impacts your product quality, brand reputation, and ability to scale. To see what’s possible when you get this right, check out a case study detailing how a supplement brand achieved significant revenue growth.

The Strategic Edge of Outsourcing Production

Deciding to work with a contract manufacturer isn’t just a budget line item—it's one of the smartest strategic moves you can make. You get immediate access to sophisticated technology, like advanced botanical extraction or innovative cold-fill processing, without the multi-million dollar capital investment. That's the real game-changer.

You're not just buying production time; you're tapping into a partner's deep well of regulatory knowledge. We live and breathe the complex worlds of FDA regulations and Current Good Manufacturing Practices (cGMP), making compliance feel effortless on your end. This is about building a solid foundation so you can scale seamlessly.

This partnership frees you up to nail what you do best—marketing, brand building, and connecting with your customers—while we handle the details of making a world-class product with a reliable, on-time delivery record.

Instantly Access Expertise and Technology

Bringing a new liquid herbal supplement to market demands a specific mix of scientific know-how and specialized equipment. Instead of spending years (and a fortune) building that from scratch, you get it from day one by partnering with us.

A great partner comes with a fully-staffed team of food scientists, quality control specialists, and regulatory gurus who have seen it all. We've already made the heavy investments in the machinery needed for precise formulation, production, and packaging. This includes innovations like:

- Advanced Extraction Methods: We utilize cutting-edge, temperature-controlled botanical extraction to preserve the delicate compounds in herbal ingredients, locking in maximum potency.

- Precision Blending and Filling: Our equipment guarantees that every single bottle has a consistent, uniform formula that perfectly matches what's on the label.

- In-House Quality Labs: With on-site testing for microbial contamination, heavy metals, and ingredient identity, we get real-time quality assurance at every stage.

Plugging into this existing infrastructure slashes your startup costs and lets you completely sidestep the painful learning curve of supplement manufacturing.

Achieve Compliance and Reduce Risk

The nutraceutical industry is wrapped in tight regulations for one simple reason: consumer safety. For a new brand, trying to get a handle on all the FDA requirements and maintaining cGMP compliance can feel like a full-time job. A single mistake in labeling or product safety can tank your brand's credibility for good.

Working with an established, UL-certified, and FDA-registered facility is your best insurance policy. These partners build their entire operation around compliance, with documented processes, rigorous testing protocols, and a culture of quality.

We take the weight of these responsibilities off your shoulders, managing the burden of:

- SOPs (Standard Operating Procedures): We maintain hundreds of meticulous, documented procedures covering every aspect of production.

- Third-Party Audits: We regularly undergo tough inspections from outside agencies to prove our systems meet the highest industry standards.

- Documentation and Traceability: We create a detailed paper trail for every raw ingredient, tracking it from the supplier all the way to your finished product.

This partnership turns a huge potential liability into a core strength for your brand. You can confidently tell your customers that your product is made to the absolute highest standards of safety and quality.

Scale Your Brand with Agility and Speed

One of the toughest challenges for a growing brand is matching production to demand. Make too much, and you're stuck with wasted inventory. Make too little, and you face lost sales and unhappy customers. A contract manufacturing partner gives you the flexibility you need to grow smarter.

Our model allows you to start with a small pilot run to test a new formula or enter a new market with minimal financial risk. Then, as your sales take off, you can seamlessly ramp up to full-scale production runs. That kind of agility is a massive competitive advantage.

By outsourcing production, you convert a huge fixed cost—a factory—into a variable cost that scales directly with your revenue. This frees up precious capital, allowing you to invest it back into what drives growth: killer marketing campaigns and customer acquisition. It's a much more efficient way to build a brand that lasts.

Vetting Partners for Quality and Compliance

Choosing the right manufacturing partner is one of the most important decisions you'll make. This isn't just a transaction; it's an act of trust. Your choice directly impacts your product's safety, your brand's reputation, and your ability to grow. Let's look past the sales pitch to find a true long-term partner invested in your success.

When you start talking with potential nutraceutical contract manufacturers, the conversation must begin with certifications. These aren't just logos for a website; they represent a hard-earned, verifiable commitment to quality and safety.

Deconstructing the Alphabet Soup of Certifications

Understanding what these credentials actually mean is the first step. Think of each one as another layer of accountability that protects both your brand and your customers.

-

cGMP (Current Good Manufacturing Practices): This is the FDA's rulebook. A cGMP-certified facility follows strict protocols for everything—from how they handle raw materials to final product testing and documentation. It ensures the identity, strength, quality, and purity of your products.

-

FDA-Registered Facility: This is the bare minimum. It means the manufacturer is on the U.S. Food and Drug Administration's radar and subject to inspections. If a potential partner isn't FDA-registered, walk away.

-

UL Certification: This credential takes things a step further. UL is an independent, third-party organization that conducts its own audits to verify that a manufacturer not only meets but exceeds cGMP standards. It’s a powerful sign of a deep, serious commitment to quality control.

These certifications are the foundation of any trustworthy partnership. If a manufacturer is vague or can't provide clear documentation for these, consider it a major red flag.

Beyond Certifications: The Pillars of a True Partnership

While certifications are non-negotiable, they’re just the start. The best manufacturing partners operate as an extension of your team—part R&D lab, part supply chain expert, and part growth strategist. To find that kind of partner, you have to dig deeper and ask the right questions.

A great manufacturer doesn't just make your product; they help you make it better. Their team of formulators and scientists should feel like your own, offering insights that can improve your product's efficacy, taste, and marketability.

Your partner’s R&D capabilities are crucial. Can they help you create a one-of-a-kind formula? Do they have real-world experience with the latest botanical extraction methods or flavoring technologies that can set your product apart?

And it doesn't stop there. You need to get granular on their testing protocols and supply chain transparency. A manufacturer's promise of quality is only as strong as its weakest link. For a deep dive into what this involves, take a look at these dietary supplement manufacturing requirements.

Your Vetting Checklist: Essential Questions to Ask

Before signing a contract, you need clear, direct answers to some tough questions. A transparent partner will welcome this scrutiny and have detailed responses ready. This table breaks down what you should be asking and why it's so important.

Essential Vetting Questions for Potential Partners

| Category | Essential Question to Ask | Why It Matters |

|---|---|---|

| Quality & Testing | "Can you walk me through your third-party testing process for purity, potency, and contaminants?" | This confirms they use an unbiased, external lab to verify the quality of both raw materials and finished goods. |

| Supply Chain | "How do you vet your raw material suppliers, and can you provide documentation for traceability?" | This shows their commitment to sourcing high-quality, authentic ingredients and proves they maintain a transparent supply chain. |

| Flexibility | "What are your minimum order quantities (MOQs) for pilot runs versus full-scale production?" | A partner with flexible run sizes lets you test the market with less risk and scale up production as your brand grows. |

| Expertise | "What is your experience with our specific product category (e.g., liquid herbals, tinctures)?" | Specialized experience means they understand the unique challenges of your product, from formulation to ensuring stability. |

These questions get right to the heart of a manufacturer's operational integrity. Remember, beyond just making the product, you need a partner who understands the bigger picture. Knowing the importance of retail compliance is key to making sure your product actually makes it to the shelf—and stays there.

By focusing your evaluation on certifications, R&D collaboration, and total operational transparency, you elevate the relationship beyond a simple vendor-client dynamic. You find a true partner who is genuinely invested in your brand's growth and has the tools to help you build a product that customers will love and trust.

The Manufacturing Journey from Concept to Creation

Turning a supplement idea into a physical, market-ready product is a journey with several key milestones. Think of it like building a custom house: you’re the visionary with the blueprint, and your manufacturing partner is the expert builder bringing it to life. Understanding this process gives you clarity and confidence, ensuring a much smoother launch.

This walkthrough pulls back the curtain on how your product goes from a simple concept to a finished good. We'll break down each critical phase, outlining your role and how your manufacturing partner makes the collaboration a success.

Phase 1: Discovery and Formulation

It all starts with a conversation. In our discovery call, you'll share your vision—who the product is for, the benefits you want to deliver, what makes it unique, and ideas for flavor. You bring the passion; we bring the formulation expertise.

Our job is to translate that vision into a formula that’s effective, safe, and manufacturable. We'll discuss active ingredients, dosage forms (like liquid herbals or tinctures), and flavoring systems. In this hands-on R&D process, our food scientists become an extension of your team, working to create something scientifically solid and commercially powerful.

For a closer look at this crucial first step, check out our guide to nutraceutical formulation development.

Your Responsibilities:

- Provide a clear product brief: Define your target customer, key benefits, and brand differentiators.

- Share your vision for flavor and texture: Guide the sensory experience you want to create.

- Give timely feedback: Stay engaged during R&D to help us perfect the formula.

Phase 2: Sourcing and Pilot Testing

With the formula locked in, we source the raw ingredients. A top-tier nutraceutical contract manufacturer does more than just find ingredients; we meticulously vet suppliers to guarantee purity, potency, and consistency. We tap into our established network to source high-quality raw materials, each backed by a Certificate of Analysis (CoA) to verify its identity and safety.

Then, before a full production run, we create a small pilot batch. This is your chance to physically hold, taste, and test the product. The pilot batch lets you confirm that the flavor, color, and texture are exactly what you envisioned. It’s a vital quality check that prevents expensive surprises later and ensures the final product is a perfect match for your brand.

The pilot batch isn't just a sample; it's a tangible prototype of your brand's promise. It’s the final check to ensure the science of the formula translates into the exceptional customer experience you envision.

Phase 3: Full-Scale Production and Quality Control

Once you approve the pilot batch, we begin full-scale production. This is where our cGMP-certified facility, modern equipment, and rigorous protocols take over. Every step is guided by Standard Operating Procedures (SOPs) to ensure every bottle is identical in quality.

Our process includes:

- Material Verification: We re-test all incoming raw materials to double-check their identity and purity.

- Precision Blending: Using advanced machinery, we blend ingredients to your exact formula, ensuring perfect consistency.

- Controlled Filling & Bottling: Our automated lines fill and seal each container in a controlled environment to prevent contamination.

- In-Process Checks: Our quality team is on the floor, conducting checks throughout the run to monitor critical metrics like fill weight and seal integrity.

This obsessive oversight and rapid turnaround guarantee that every unit we produce meets the absolute highest standards for safety and quality.

Phase 4: Packaging and Final Validation

The final stage is getting your product ready for the world. We handle the entire packaging process, from applying your custom labels to printing lot codes on each bottle for complete traceability. We also ensure your packaging is compliant for your chosen sales channels, whether that's Amazon FBA, retail shelves, or your own website.

Before anything ships, there’s one last validation step. We send a sample from the finished batch to an independent, third-party lab for testing. This final analysis verifies the potency and purity of the product in its final form, giving you unbiased proof that what's on the label is exactly what's in the bottle. That certificate is your ultimate quality guarantee and a powerful way to build trust with your customers.

Navigating Market Trends and Global Opportunities

A truly great manufacturing partner does more than just fill bottles; they provide strategic intelligence to help you compete and grow. Understanding where the market is heading is the secret to making smarter decisions about your products and your brand's future. It's about positioning yourself not for where the industry is today, but where it will be tomorrow.

The nutraceutical world is global. North America holds a massive 34.23% revenue share, but the real story for ambitious brands is the explosive growth happening elsewhere. The Asia Pacific region, for example, is set to expand at a compound annual growth rate of nearly 14% through 2030. That’s a huge signal for future expansion. You can dig into more of this data and discover insights about the nutraceutical contract manufacturing market for yourself.

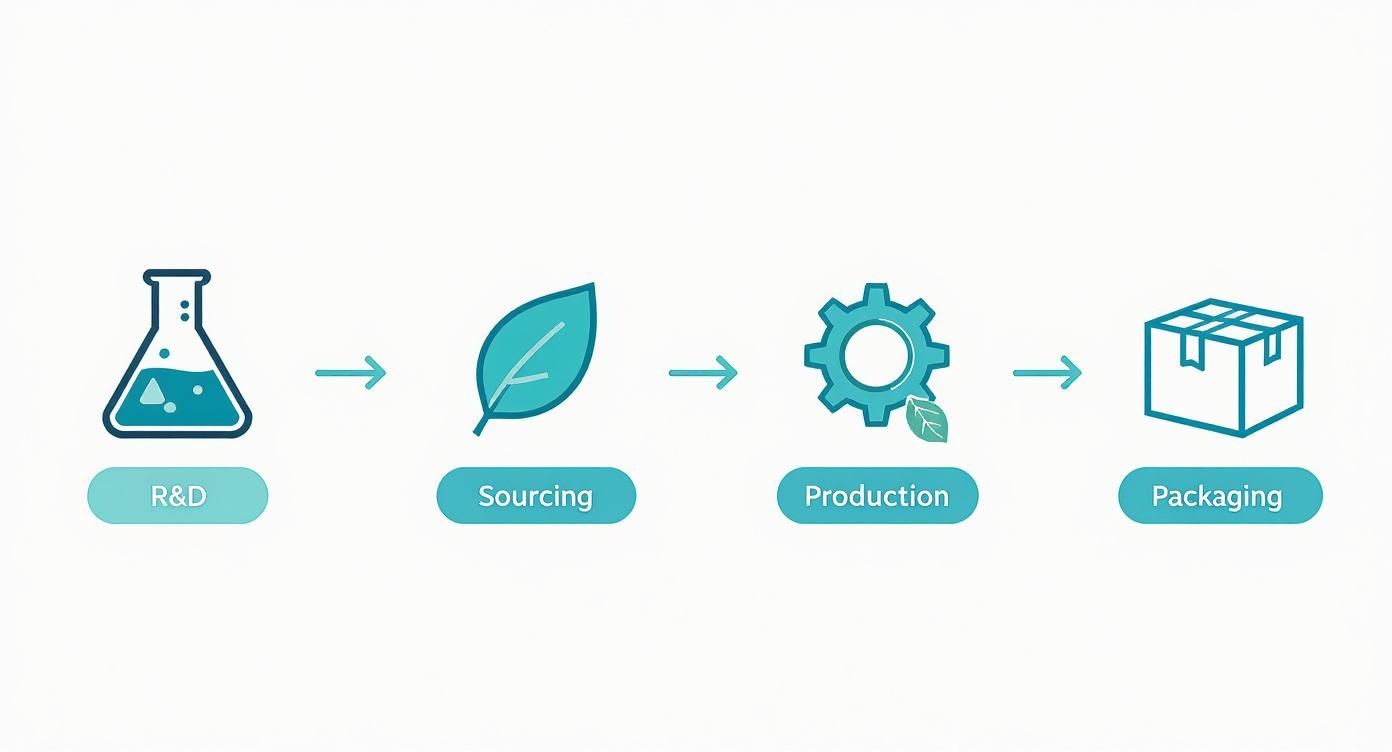

This infographic lays out the typical journey you'd take with a manufacturing partner, from a simple idea to a finished product on the shelf.

This clear process—covering R&D, sourcing, production, and packaging—is what allows sharp, agile brands to launch innovative products without getting bogged down.

Capitalizing on Key Product Trends

Beyond knowing where to sell, you need to know what to sell. Consumer tastes and scientific breakthroughs constantly shift demand. A forward-thinking partner helps you see these changes coming.

A few key trends are driving the industry forward:

- Functional Foods and Beverages: People want products with targeted benefits like better focus, stress relief, or deeper sleep. This is where liquid supplements, herbal tinctures, and functional shots are really shining.

- The Dominance of Tablets: Despite the hype around gummies, tablets remain a market heavyweight. They are inexpensive to produce, accurate for dosing, and shelf-stable, making them a go-to for many foundational supplements.

- Niche Market Customization: There’s a growing appetite for products that fit specific lifestyles, like vegan, keto, or allergen-free formulas. This is a golden opportunity for brands to build a loyal following within dedicated communities.

By steering your product development toward these trends, you create supplements that feel essential, not just optional. It's all about meeting your audience with the exact solutions they’re already looking for.

Your Partner in Strategic Growth

Ultimately, the right nutraceutical contract manufacturer isn't just a supplier; they're your strategic R&D arm. We help you translate raw market data into a real competitive edge. Our job is to deliver the operational muscle and industry know-how to turn your vision into a successful, scalable brand.

Our flexible approach allows you to start small with pilot runs before scaling to full production. This lets you test new ideas that tap into emerging trends without taking on massive risk. It’s this partnership mindset that helps you stay agile and innovative. By working together on everything from ingredient sourcing to final packaging, we help you build a product line that not only meets today’s standards but is ready for tomorrow's opportunities.

Common Questions About Manufacturing Partnerships

Stepping into a partnership with a nutraceutical contract manufacturer is a big move, and it’s natural to have questions. Getting clear, straightforward answers is the only way to build the confidence you need. Below, we’ve tackled some of the most common concerns we hear from entrepreneurs just like you.

This isn’t just about logistics; it’s about building a foundation of trust. The right partner will be transparent and ready to walk you through every question, ensuring you feel secure in your choice.

What Are Typical Minimum Order Quantities (MOQs)?

Minimum order quantities, or MOQs, are top of mind for brands of all sizes, especially those just starting. The specific number can vary depending on formula complexity, ingredient rarity, and product format (a liquid tincture has different requirements than a powder).

For a new custom formula, a smaller pilot run is often the first step. This could be just a few hundred units, designed for you to test the market and give final approval. For a full production run, you’re often looking at a starting point in the 1,500 to 5,000 unit range.

The most important trait in a manufacturing partner is flexibility. You want a team that offers scalable solutions that grow with you. A true partner can take you from a small-batch launch all the way to mass production without ever cutting corners on quality.

Being open about your business goals from the start is crucial. When your manufacturer understands your vision, they can create a production plan that’s a perfect fit for your needs and budget.

How Is My Product Formula and IP Protected?

Your formula is the heart of your brand—it’s your intellectual property (IP), and protecting it is non-negotiable. This is one of the most serious responsibilities a manufacturing partner has, and any reputable company will have ironclad procedures to guard your proprietary information.

The entire partnership should start with a comprehensive Non-Disclosure Agreement (NDA). This legally binding contract ensures your unique formula, ingredient lists, and business strategies remain completely confidential. It’s the legal framework that guarantees your trade secrets stay secret.

Think of your manufacturer as the expert guardian of your formula. Our job is to take your IP, protect it rigorously, and use it only to produce your product to your exact specifications. Before you sign anything, ensure your potential partner can clearly outline their process for IP protection.

What Is the Average Timeline from Idea to Finished Product?

Understanding the timeline from concept to a market-ready product is essential for planning your launch and marketing strategy. The total time can shift depending on project complexity.

- For a straightforward project using existing, readily available ingredients, the process can often be completed in about 8-12 weeks. This covers formulation, sourcing, production, and packaging.

- For a fully custom formulation involving unique raw materials, extensive R&D, and stability testing, a longer timeline is needed. These projects typically land in the 4-6 month range.

The single most critical factor for keeping any project on track is clear, consistent communication. A reliable partner provides a transparent project timeline from the start, complete with key milestones for your approval. This approach eliminates surprises and lets you plan your launch with confidence. Our guide on finding a reputable supplement manufacturer offers more key things to look for.

Can You Help with Label Design and Compliance?

Yes, a full-service partner absolutely should. Your product's label is more than branding; it's a legal document that must meet strict FDA guidelines. Getting it wrong can lead to serious compliance headaches, fines, or even having your product pulled from shelves.

While you are ultimately responsible for your marketing claims, a knowledgeable manufacturing partner provides critical guidance on label compliance. This includes making sure your:

- Supplement Facts panel is formatted correctly.

- Ingredient list is accurate and declared properly.

- Allergen warnings are included where needed.

- Net quantity of contents and other required statements are present and correct.

We act as your compliance checkpoint, reviewing your label designs to help you sidestep common pitfalls. This collaborative approach helps ensure your packaging isn't just beautiful but also fully ready for retail, whether on Amazon FBA, Shopify, or in a brick-and-mortar store.

Ready to turn your vision for a liquid herbal supplement into a reality? The team at Triton Nutra Group is your dedicated partner from concept through launch. With our expertise in custom formulation, cGMP-certified production, and rapid turnaround times, we provide the quality, flexibility, and reliability you need to succeed.

Request a free quote today and let's build your next best-selling product together.