A Founder's Guide to the Manufacturing of Protein Powder

Discover the complete manufacturing of protein powder, from raw material sourcing to final packaging. An expert guide for founders on quality and success.

Get a Free Quote Today!

Get a Free Quote Today!Turning raw materials like milk, peas, or soybeans into a fine, shelf-stable supplement is a complex journey. It’s a process involving careful extraction, filtration, drying, and blending, all performed under strict quality controls to create a product that is safe, effective, and meets precise nutritional targets.

For any brand founder or e-commerce entrepreneur, understanding this process is the first step toward building a product that stands out in a competitive market.

The Blueprint for Manufacturing Protein Powder

Welcome to the definitive guide for brand builders. This is where your vision for a market-leading protein powder takes shape. We’re here to demystify the manufacturing journey, breaking down complex production steps into a clear, actionable roadmap from concept to launch.

Think of us as your R&D partner. We'll guide you from selecting your raw ingredients all the way to a finished, shelf-ready product that customers will love. We'll explore the critical choices that define your brand, from the pros and cons of whey versus plant-based proteins to ensuring the cGMP compliance that builds rock-solid consumer trust.

Why Manufacturing Is Your Strategic Advantage

Let's be clear: the global demand for high-quality protein supplements is exploding. The high protein powders market is projected to swell from USD 27.0 billion in 2025 to USD 49.6 billion by 2035, growing at a compound annual growth rate (CAGR) of 6.3%. You can explore more data on the high protein powders market to see this trajectory for yourself.

This boom presents a massive opportunity, but it also means the market is more crowded than ever. Success is no longer just about marketing; it's about the quality of the product itself. Your manufacturing process is where you build your competitive edge.

A superior manufacturing process isn't just a back-end operation; it's a core component of your brand's promise. It directly impacts taste, mixability, purity, and ultimately, customer loyalty.

By focusing on production from day one, you can create a product that stands out for its quality and consistency. This guide frames manufacturing not as a hurdle, but as your single greatest strategic advantage.

Key Stages in Protein Powder Manufacturing

To give you a bird's-eye view, the manufacturing journey can be broken down into several distinct stages. Each step presents its own set of challenges and opportunities for a brand to dial in quality and create a unique product.

| Stage | Core Activity | Key Consideration for Brands |

|---|---|---|

| 1. Raw Material Sourcing | Selecting and procuring the base protein source (e.g., whey, casein, soy, pea). | Purity, protein content, allergen profile, and supplier reliability are critical. |

| 2. Formulation & Blending | Combining the base protein with other ingredients like flavors, sweeteners, and functional additives. | Achieving the desired taste, texture, nutritional profile, and mixability. |

| 3. Production & Processing | Applying specific manufacturing techniques (e.g., spray drying, agglomeration) to create the powder. | The chosen method directly impacts solubility, density, and overall user experience. |

| 4. Quality Control & Testing | Conducting rigorous tests for purity, potency, contaminants, and label accuracy. | Essential for cGMP compliance, consumer safety, and building brand trust. |

| 5. Packaging & Labeling | Filling, sealing, and labeling the final product in consumer-ready packaging. | Must comply with FDA regulations and protect the product from moisture and degradation. |

This table provides a high-level roadmap. Now, let's get into the specifics of what you'll learn.

What You Will Learn

Our goal is to give you the knowledge you need to choose the right manufacturing partner and launch a successful, high-quality supplement. Throughout this guide, we'll cover the essential stages of production in detail.

- Ingredient Selection: The science and strategy behind choosing whey, casein, or plant-based proteins.

- Production Methods: A look inside the factory at core techniques like dry blending and spray drying.

- Quality & Compliance: Making sense of cGMP, third-party testing, and FDA requirements.

- Packaging & Stability: How to properly protect your product and ensure its shelf-life.

- Choosing a Partner: The critical questions to ask any potential contract manufacturer.

This introduction sets the stage for a deep dive into each of these areas, providing you with a complete blueprint for success.

Selecting Your Core Ingredients and Formulation

The heart of any protein powder isn't the packaging—it's the raw materials. This first choice is the foundation for everything that follows, setting the stage for your target audience, price point, and brand identity.

Think of your core protein source as the chassis of a high-performance car. Everything else, from flavors to functional ingredients, is built on top of it. This decision will define the entire customer experience, influencing digestibility, mouthfeel, allergen profile, and nutritional impact.

Navigating Animal-Based Proteins

For decades, whey protein has been the industry standard, and for good reason. It’s a complete protein derived from milk during cheesemaking, celebrated for its rapid absorption. But not all whey is the same, and knowing the difference is critical.

The real distinction comes down to processing and purity:

- Whey Protein Concentrate (WPC): The most common form, WPC goes through basic filtration, leaving it with a protein content of 70-80%. It retains more natural fats and lactose, giving it a creamier taste but making it less suitable for those with lactose sensitivity.

- Whey Protein Isolate (WPI): The refined, purer version. It undergoes extra processing, like cross-flow microfiltration, to remove most of the fat and lactose. The result is a powder that's typically 90% or more protein—a premium choice for low-carb or "clean" formulas.

- Whey Protein Hydrolysate (WPH): Think of this as pre-digested protein. The long protein chains are broken down into smaller pieces (peptides) through enzymatic hydrolysis, making it the fastest-absorbing whey available. It's often reserved for medical nutrition or elite athletic recovery products.

Your choice here directly impacts cost, flavor profile, and your target customer. A WPC-based blend is great for the general wellness crowd, while a WPI or WPH formula speaks directly to serious athletes willing to pay more for purity and performance.

Tapping into the Plant-Based Boom

The plant-based protein market isn't a niche; it’s a movement. In 2024, the global market is pegged at an estimated $16.05 billion, and it's projected to climb to $20.43 billion by 2029. This growth is fueled by consumers demanding vegan, sustainable, and allergen-friendly options.

Leading sources include pea, soy, and brown rice. Pea protein has exploded in popularity due to its high digestibility and neutral taste. Soy remains a powerhouse as one of the few complete plant proteins, and brown rice is a fantastic hypoallergenic choice.

The biggest challenge with plant-based powders is achieving a smooth texture and a complete amino acid profile. This is often solved by blending multiple sources—like pea and rice—to ensure the final product delivers comprehensive nutrition.

The art of a great plant-based protein isn't just in the source, but in the formulation. Success hinges on masking earthy notes, eliminating grittiness, and ensuring the final product delivers a complete and bioavailable amino acid profile comparable to its dairy-based counterparts.

Beyond Protein: The Art of Formulation

A great product is more than its main protein source. The magic happens during formulation—the strategic process of building a blend that nails taste, function, and mixability. This is where partnering with an experienced manufacturer really pays off.

This stage involves several critical components:

- Flavoring and Sweetening: Masking the natural, sometimes "off" notes of protein sources is an art form. Will you go with natural sweeteners like stevia and monk fruit, or artificial options like sucralose? Your answer will define your "clean label" appeal.

- Solubility and Mouthfeel: No one wants a clumpy, gritty shake. Additives like lecithin (from soy or sunflower) act as emulsifiers, helping the powder dissolve smoothly into liquid. The goal is a silky texture every time.

- Functional Ingredients: This is where you can truly differentiate. Adding creatine helps target strength athletes. Probiotics appeal to customers focused on gut health. Digestive enzymes can improve absorption and comfort.

Crafting a formula that balances all these elements is a complex puzzle. Our ability to tailor formulas, flavors, and packaging from pilot to full-scale runs gives you the flexibility to perfect your product without a massive upfront commitment.

Inside the Factory: How Your Protein Powder Is Made

We've nailed down the "what"—the ingredients in your formula. Now it's time to pull back the curtain on the "how." Let's step onto the factory floor where your raw materials are transformed into a finished, scoopable powder.

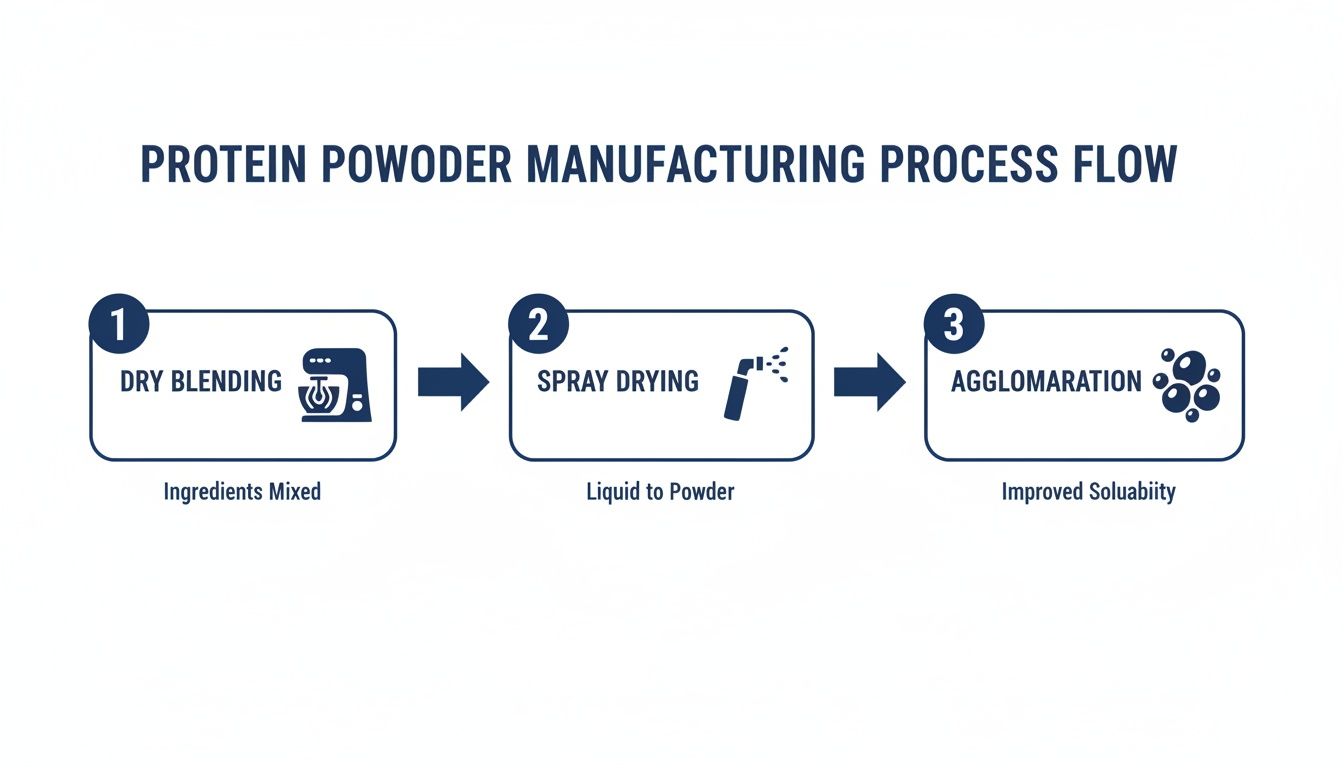

Understanding core production methods is essential for any brand founder. Each technique directly impacts your powder's final personality—its texture, how smoothly it mixes, and its final cost. Think of them as specialized tools, each chosen for a specific job.

Dry Blending: The Art of the Perfect Mix

The most common method is Dry Blending. Imagine a massive, precise kitchen mixer. All your powdered ingredients—the protein base, flavors, sweeteners, and functional additives—are loaded into a huge industrial blender, typically a ribbon or V-blender.

These machines are engineered for one thing: perfect homogeneity. The goal is to ensure that every single scoop a customer takes has the exact same composition. No clumps of sweetener or pockets of unflavored protein—just a perfectly uniform mixture from top to bottom.

Dry blending is the go-to for simpler formulas where all components are already powdered. It's reliable and cost-effective, but the final product is only as good as the raw ingredients you put in.

Spray Drying: From Liquid to Powder in a Flash

What if your protein source starts as a liquid, like the whey left over from cheesemaking? That's where Spray Drying comes in. Think of it like a giant, super-hot perfume atomizer.

The liquid protein concentrate is blasted as a fine mist into a chamber of hot air. The intense heat evaporates the water almost instantly, leaving behind delicate, dry protein particles that fall for collection.

This rapid drying is brilliant because it minimizes heat exposure, preserving the protein's nutritional integrity. The delicate protein structures aren't damaged, ensuring the final powder is high-quality.

Advanced Techniques That Create a Premium Experience

While dry blending and spray drying are fundamental, advanced techniques separate a good product from a great one. This is where a top-tier manufacturing partner earns their keep, solving consumer complaints like clumping and grittiness.

Two of the most important advanced processes are:

- Agglomeration: Ever dealt with a powder that leaves stubborn clumps in your shaker? Agglomeration is the solution. This process lightly moistens the fine powder, causing particles to stick together into larger, more porous granules. These bigger granules dissolve into liquid with ease, creating that smooth, clump-free shake everyone wants.

- Micronization: This technique is all about mouthfeel. Micronization is a milling process that grinds powder particles down to a much smaller, finer size. The result is a powder with a silky, less gritty texture—a game-changer for plant-based proteins, which can often feel chalky.

Choosing the right combination of these manufacturing methods isn't just a technical decision; it's a strategic one. You're constantly balancing the desire for a premium consumer experience—great taste, smooth texture, effortless mixing—with the need to manage production costs and hit your target price point.

Comparing Protein Powder Manufacturing Methods

To make things clearer, let's break down how these methods stack up. The right choice depends on your raw materials, budget, and the experience you want to give your customers.

| Method | Best For | Impact on Solubility | Relative Cost |

|---|---|---|---|

| Dry Blending | Simple formulas using pre-powdered ingredients. | Depends on raw ingredient quality. | $ |

| Spray Drying | Converting liquid protein sources (like whey) into powder. | Creates fine powders, good starting point. | $$ |

| Agglomeration | Improving mixability and preventing clumps. | Excellent; creates "instantized" powder. | $$$ |

| Micronization | Creating an ultra-smooth, non-gritty texture. | Good; smaller particles dissolve well. | $$$ |

As you can see, investing in advanced processes like agglomeration directly translates to a better, more "instantized" product, but it comes at a higher cost. This is a critical trade-off every brand has to navigate.

The global protein powder market, valued at USD 24.24 billion, is on track to hit USD 39.23 billion by 2032. A huge driver of this growth is the use of advanced technologies like ultrafiltration in North American facilities, which create whey isolates that are over 90% pure protein. This is a perfect example of how process innovation leads directly to premium, high-value products. For a deeper dive into these numbers, check out the full protein powder market research.

Understanding how your product is made gives you the knowledge to have meaningful conversations with your manufacturing partner. It empowers you to make smarter choices that will define your product's quality and give you an edge in a crowded market.

Upholding Excellence in Quality and Compliance

In the supplement world, a product is only as good as the trust people have in it. After you’ve selected your ingredients and production method, the real work begins: ensuring every single batch is safe, pure, and consistent.

This isn’t just about ticking boxes; it’s about protecting your brand’s reputation and your customers’ health. The manufacturing of protein powder is guided by a strict set of standards to prevent contamination, guarantee what's on the label is in the tub, and maintain integrity from start to finish. For a brand founder, these are non-negotiables.

The infographic below highlights the core production methods where these quality control checkpoints are absolutely essential.

As you can see, whether you're doing a simple dry blend or something more involved, quality oversight has to be woven into every single step.

The Gold Standard: cGMP and FDA Registration

When a manufacturer is cGMP certified, it means they live by the FDA’s Current Good Manufacturing Practices. This is more than a certificate on a wall; it's an operational philosophy that governs everything they do.

Think of cGMP as the master rulebook for the facility. It dictates every detail, including:

- Personnel Training: Ensuring every team member knows sanitation protocols and their role in preventing mistakes.

- Facility Cleanliness: Enforcing strict, documented cleaning schedules for all equipment to stop cross-contamination.

- Material Handling: Using rigid procedures for receiving, testing, and storing raw ingredients to keep them pure.

- Record Keeping: Demanding meticulous documentation for every step of every batch, creating a traceable history from raw material to finished product.

Operating in an FDA-registered and UL-certified facility adds another layer of assurance. It's a clear signal that a manufacturer is transparent, accountable, and committed to upholding the highest industry standards. This is our baseline for quality and compliance.

The Power of Third-Party Testing

While in-house testing is a cGMP requirement, independent third-party testing is what builds unshakable trust. This is where you send samples from each production run to an unaffiliated, accredited laboratory for an unbiased analysis.

These labs act as an impartial referee, confirming two critical things:

- Potency and Purity: They verify that the protein content you claim on your label is actually in the product. If your label promises 25 grams of protein per scoop, the lab confirms it.

- Contaminant Screening: They run tests for contaminants like heavy metals (lead, arsenic), microbes (E. coli, salmonella), and other impurities.

Third-party validation is your ultimate insurance policy. It gives you objective proof that your product is not only effective but, more importantly, safe. This protects you from liability and cements your customers' confidence in your brand.

Allergen Control: A Non-Negotiable Priority

In the world of protein powders, common allergens like milk, soy, and nuts are everywhere. Any top-tier manufacturing partner must have an ironclad allergen control program to prevent cross-contamination.

This means dedicated production lines, validated cleaning procedures between runs, and smart scheduling to keep allergenic ingredients separate. A key part of this is implementing systems like HACCP certification, which proactively identifies and controls potential safety hazards before they become a problem.

A manufacturer's dedication to quality is a direct reflection of their commitment to you and your customers. To learn more, check out our guide on comprehensive supplement ingredient testing and see the lengths we go to ensure product integrity.

Packaging: Your Product's First and Last Line of Defense

You've spent months perfecting your protein blend. But all that hard work can be undone if the packaging fails. This isn't just about a pretty container; it's about protecting your investment and making a great first impression.

Think of your packaging as the final guardian of your formula. It stands between your pristine powder and its three enemies: moisture, oxygen, and light. Let any of those sneak in, and you’re looking at clumping, nutrient degradation, and off-flavors—a recipe for a bad review.

Choosing the Right Container

The right package does more than just hold your product; it communicates your brand's value and fits your customer's lifestyle. There are a few tried-and-true options on the market.

- Rigid Tubs (HDPE/PET): This is the classic for a reason. Tubs feel substantial and premium, stack well on retail shelves, and offer a large canvas for branding. They’re the go-to for larger, bulk sizes.

- Flexible Gusseted Bags: For a more cost-effective and eco-conscious option, bags are a fantastic choice. They're lighter, which means lower shipping costs, and modern multi-layer films offer incredible barrier protection.

- Single-Serving Stick Packs: Convenience is king. Stick packs are perfect for customers on the go, for trial sizes, or for subscription boxes. You get perfect portion control and guaranteed freshness with every use.

The Science of Keeping It Fresh

Shelf-life isn't an accident; it's science. We obsess over the details of materials and sealing technology to give your product a robust defense.

The best packaging uses high-barrier materials, like foil-lined films or specialized polymers that are practically Fort Knox against oxygen and moisture. The seal is just as critical. We use heat induction seals under the cap, which create an airtight barrier that not only keeps the powder fresh but also provides clear tamper evidence—a small detail that builds huge trust.

Packaging is the final guardian of your investment. It ensures the quality meticulously crafted during formulation and production is the same quality your customer experiences. A secure seal and the right material are non-negotiable for brand trust.

The scale of your operation can also steer your packaging decisions. Industry giants like Omega Protein focus on massive, industrial-scale processing. Your job, as a consumer brand, is to take that amazing 80-90% protein content and protect it all the way to the customer's kitchen. You can discover more insights about protein market leaders to see how the big players operate. We handle that final, vital step, ensuring your product is safe, stable, and looks incredible, no matter your run size.

Choosing the Right Manufacturing Partner for Your Brand

Picking a contract manufacturer is the most important decision you'll make for your supplement brand. You're not just buying a service; you're building a partnership that will define your product's quality, shape your brand's reputation, and determine your ability to grow.

The right partner becomes an extension of your team—as invested in your success as you are. They bring the machinery, regulatory knowledge, and production know-how that frees you up to build your brand. The wrong partner is a fast track to production delays, quality nightmares, and a damaged reputation.

Moving Beyond Price: The Core Pillars of a Great Partner

It’s easy to fixate on the cost per unit. But a rock-bottom price can hide downstream costs like poor quality or unreliable service. For new founders navigating this complex world, understanding effective startup outsourcing strategies is a great way to frame these decisions around long-term value, not just short-term cost.

Instead of leading with "How much?", shift your focus to these three foundational pillars:

- Quality and Compliance: Are they cGMP certified, FDA-registered, and UL-certified? These are the absolute baseline for trust and safety in protein powder manufacturing.

- Flexibility and Customization: Can they grow with you? You need a partner who can handle small pilot batches for market testing as easily as they can scale up to full production runs.

- Speed and Reliability: Do they deliver on time? Ask for their average turnaround times and their communication process. Our rapid turnarounds, transparent timelines, and on-time delivery record are key parts of our partnership promise.

Think of your manufacturing partner as your R&D collaborator, compliance expert, and production engine all rolled into one. The relationship you build with them is the bedrock of your brand's future, so choose a partner who is genuinely committed to quality and transparency.

The Essential Vetting Checklist

To help you find a partner who aligns with your vision, use this checklist during your initial calls. The goal is to dig deeper than the sales pitch and uncover what they're really capable of.

Ask these critical questions:

- Certifications: "Can you send over the documentation for your cGMP, FDA, and UL certifications?" A confident, legitimate partner will have this ready.

- Run Sizes: "What are your minimum order quantities (MOQs) for a custom formula? And how do you help brands scale up to larger volumes?"

- Timelines: "What’s your standard lead time from formula approval to finished product delivery? How do you communicate potential delays?"

- In-House Support: "Do you offer in-house formulation and R&D support? Can your team help us develop a unique flavor or incorporate specific functional ingredients?"

- Testing Protocols: "Can you walk me through your third-party testing process? Specifically, how do you verify protein content and screen for contaminants?"

- Transparency: "What kind of visibility will I have into the production process? How are project updates handled?"

Finding the right team is a make-or-break step for your launch. By asking these targeted questions, you elevate the conversation from a simple transaction to a strategic discussion. This is how you find a real partner who is not only equipped but genuinely excited to help you succeed.

Answering Your Protein Powder Manufacturing Questions

Diving into creating a new protein supplement brings up a lot of questions. Getting straight answers is the first step toward making smart decisions for your brand. Let's tackle some of the most common questions we hear from brand owners.

Think of this as your cheat sheet for understanding the essentials of quality, flexibility, and what a true manufacturing partnership looks like.

What Is a Typical Minimum Order Quantity for Custom Protein?

Minimum Order Quantities (MOQs) vary widely based on formula complexity and packaging. A good manufacturing partner won't box you into one massive number. We offer the flexibility you need, from smaller pilot runs to test the market all the way up to full-scale production.

The real key is finding a partner who can grow with you. Ask about production capacity and tiered pricing for bigger orders. This way, you're not just planning for your launch—you're setting yourself up for future success.

How Long Does the Full Manufacturing Process Take?

From final formula approval to the day your product arrives, you can generally expect a timeline of 8 to 12 weeks. This window covers sourcing and testing raw materials, production line scheduling, and all necessary quality control checks.

A reliable partner will be transparent about this, giving you a detailed timeline from the start. Our commitment to speed and reliability lets you confidently plan your marketing, line up retail partners, and schedule your launch, knowing your inventory will be there when you need it.

Partnership Takeaway: A transparent timeline is about more than just dates—it's about trust. Your manufacturer should walk you through each stage and keep you updated, turning the production process into a predictable, manageable part of your business strategy.

Can I Supply My Own Proprietary Ingredients?

This is a common question, and the answer is usually a qualified "yes." While some manufacturers accept client-supplied ingredients, it always comes with a strict vetting process to remain compliant. Your ingredient supplier must provide a Certificate of Analysis (CoA) and any other documentation needed to meet our quality standards.

This isn't us being difficult; it's a non-negotiable part of upholding cGMP (Current Good Manufacturing Practices). It’s a critical step to guarantee the safety, purity, and integrity of your final product, protecting both your customers and your brand.

What Is the Real Difference Between Protein Concentrate and Isolate?

The main difference is protein purity, which comes from how it's processed. We use active voice to make this clear:

- Protein Concentrate: We use basic filtration to produce a powder that is typically 70-80% protein, leaving some of the natural fats and carbs (like lactose) present.

- Protein Isolate: We use advanced filtration, like cross-flow microfiltration, to strip out most of the fats and carbs. This creates a much purer product that is 90%+ protein.

So, which should you choose? Isolates are perfect for premium, low-carb formulas or for targeting customers who are sensitive to lactose.

Ready to turn your idea into a protein supplement that stands out? The team at Triton Nutra Group is here to be your dedicated partner, from the first concept to the final launch. We bring deep expertise in formulation, cGMP-certified manufacturing, and regulatory compliance to the table. Request a free quote today and let's start building your brand together.