Your Guide to Liquid Supplement Contract Manufacturing

Discover how liquid supplement contract manufacturing turns your vision into a reality. Learn the process, costs, and how to choose a quality cGMP partner.

Get a Free Quote Today!

Get a Free Quote Today!Liquid supplement contract manufacturing is your strategic path to launching a world-class product without the overwhelming cost and complexity of building your own production facility. Think of it as a partnership built for growth: you bring the brand vision, and we, as your expert manufacturing partner, handle every technical detail—from sourcing premium raw ingredients and perfecting your formula to bottling and final compliance checks.

This model frees you to focus on what you do best—building your brand and connecting with your audience—while we manage the heavy lifting of production with speed and precision.

Your Partner in Liquid Supplement Manufacturing

Bringing a liquid supplement from concept to market is a massive undertaking. It requires significant investment in specialized equipment, a deep understanding of complex regulatory compliance, and a dedicated team of experts in formulation, quality control, and scalable production. For most e-commerce founders and even established brands, these barriers can be deal-breakers.

This is precisely where a liquid supplement contract manufacturing partner becomes your most valuable asset. Don't think of us as just another supplier. We are an extension of your team—your R&D partner from concept through launch. We provide the cGMP-certified infrastructure, advanced technology, and years of expertise needed to launch your product successfully.

Our partnership allows you to sidestep the immense capital costs and operational headaches of in-house production. It’s a collaborative model engineered for speed, flexibility, and reliability, designed to get your innovative product on the shelf faster and more efficiently than you could on your own.

The Strategic Advantage of Partnership

Why build from scratch when you can gain an instant competitive edge? Partnering with an experienced manufacturer gives you immediate access to a state-of-the-art, UL-certified, FDA-registered facility without laying a single brick.

This partnership model unlocks key advantages for your brand:

- Cost Efficiency: Avoid the multi-million dollar expense of building, equipping, and staffing a manufacturing plant. You also benefit from our economies of scale on raw materials and packaging, driving down your per-unit cost.

- Immediate Expertise: Instantly leverage our team's deep experience in complex liquid formulation, advanced botanical extraction, and ingredient stability. We've already solved the toughest production challenges, so you don't have to.

- Flexibility & Scalability: Start with a small pilot run to test the market, then seamlessly scale to full production as your brand grows. We offer flexible run sizes to match your needs, ensuring your supply chain is always reliable.

A partnership with the right contract manufacturer is about more than production. It’s about gaining a collaborator who is as dedicated to your brand's quality, compliance, and success as you are.

The demand for high-quality health products isn't just growing; it's exploding. The global nutraceutical contract manufacturing services market is projected to skyrocket from an estimated USD 187.6 billion in 2025 to USD 585.2 billion by 2035. That's a compound annual growth rate (CAGR) of 12.1%.

This trend makes one thing clear: forward-thinking brands are relying on expert manufacturing partners to meet surging consumer demand with speed and reliability. By choosing the right partner, you position your brand to capture a piece of this expanding market. You can learn more about the nutraceutical market growth and see just how big the opportunity is.

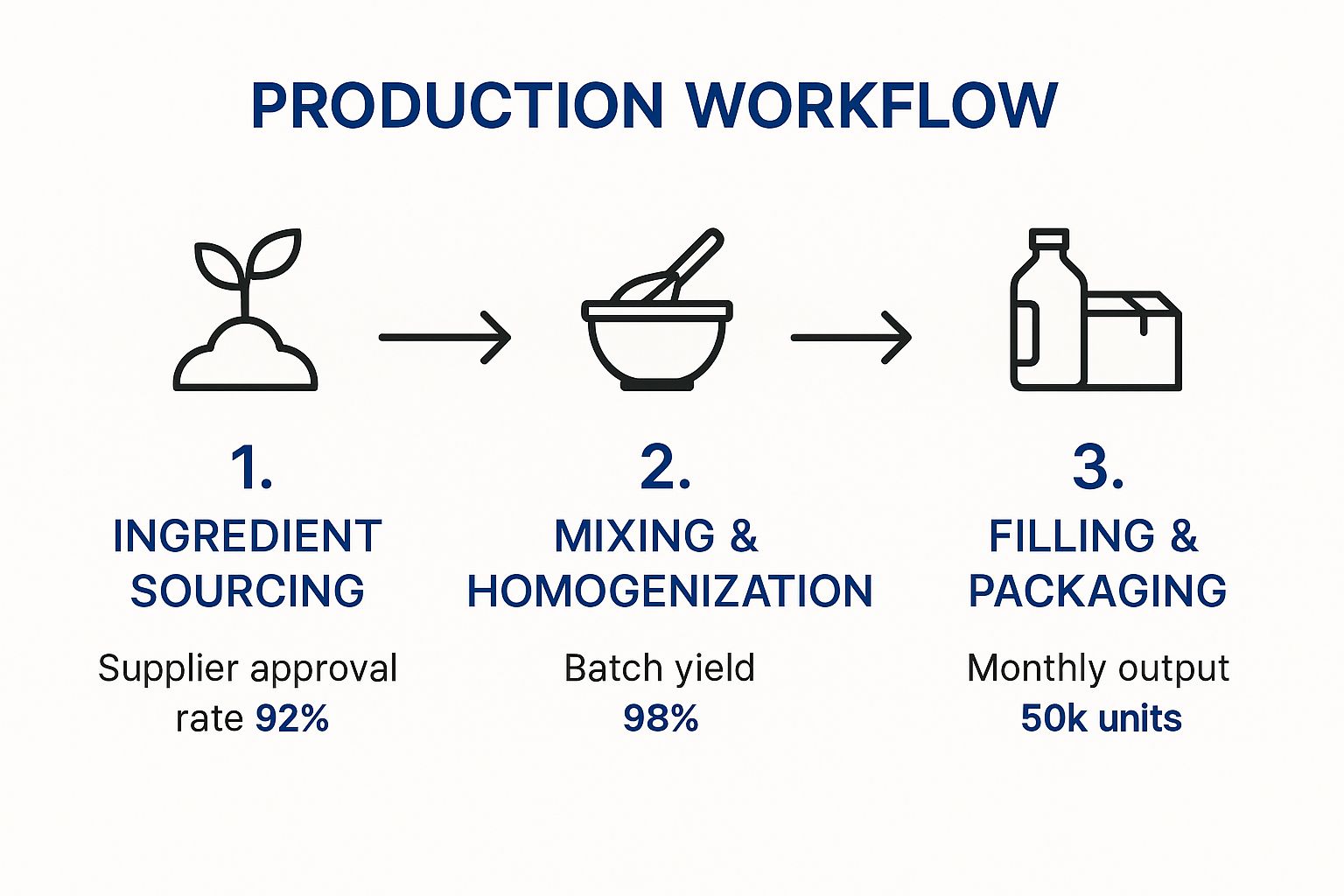

The Production Journey: From Concept to Completion

Turning your vision for a liquid supplement into a shelf-ready product is a precise, highly controlled journey. Every stage is engineered to guarantee quality, safety, and consistency. We believe in total transparency, so we're pulling back the curtain to show you exactly how we transform your concept into a finished product your customers will trust and love.

This journey is our proven roadmap for success. It starts with the building blocks of your formula and doesn't end until we have a fully tested, packaged product that meets the highest cGMP standards in the industry, delivered on time.

Stage 1: Sourcing and Verifying Raw Materials

The integrity of your finished supplement begins with the purity of its ingredients. This first stage is the most critical, as the quality of raw materials directly dictates your product's efficacy and safety. We don’t just order ingredients; we meticulously vet every supplier through a rigorous qualification process.

Here’s our approach to quality and compliance:

- Supplier Audits: We partner exclusively with reputable, GMP-audited suppliers who provide comprehensive documentation verifying the identity, purity, and origin of every botanical, vitamin, and mineral.

- Material Quarantine and Testing: Upon arrival, all raw materials are placed in quarantine. Our in-house quality control team performs identity tests to confirm they are exactly what they claim to be, free from adulterants.

- Full Traceability: We maintain meticulous records for every lot number, creating a transparent chain of custody from the source to your finished bottle. This ensures complete accountability and traceability.

This strict process ensures that only the absolute best, fully verified ingredients make it into your formula.

Stage 2: Pilot Batching and Flavor Perfection

Before committing to a full-scale production run, we move to the pilot batching phase—your product's dress rehearsal. We create a small, test-sized batch of your liquid supplement to ensure every aspect of the formula is dialed in perfectly.

This is where formulation art meets science. This crucial step allows us to:

- Confirm Flavor and Texture: We fine-tune the flavor profile to meet your brand’s standards and appeal to your target customer, applying sophisticated flavor-masking techniques for potent herbal formulas.

- Verify Ingredient Interactions: We confirm all active ingredients remain stable and bioavailable when combined in the final liquid matrix.

- Finalize Specifications: The pilot batch locks in the final specifications for color, viscosity, and sensory attributes. This becomes the "gold standard" against which all future production runs are measured.

Your approval is paramount. We don’t proceed until you are 100% satisfied with the taste, feel, and appearance of your product.

Stage 3: Full-Scale Production and Quality Control

Once the pilot batch receives your approval, we transition to full-scale production, where precision and consistency are paramount. Our cGMP-certified facility is equipped with advanced blending and homogenization equipment specifically for liquid supplement contract manufacturing.

Ingredients are weighed with calibrated precision and introduced into blending tanks according to a validated Master Manufacturing Record (MMR). Throughout the blending process, our quality control team conducts constant in-process checks, monitoring key parameters like pH, viscosity, and homogeneity. This ensures every drop of liquid is consistent from the first bottle to the last, reflecting our commitment to reliability.

We are custodians of your brand's reputation. Our rigorous in-process quality checks are not just a regulatory requirement; they are our promise that every unit we produce upholds the quality your customers demand.

Stage 4: Bottling, Packaging, and Final Testing

The final stage involves carefully moving the finished liquid into your chosen packaging. Our automated filling lines handle various bottle sizes and types with precision, ensuring accurate fill weights while minimizing environmental exposure. We utilize innovative cold-fill technology to protect heat-sensitive ingredients, preserving your formula's potency.

Once bottled and sealed, each unit is labeled and coded with a lot number and expiration date for complete traceability. But our commitment to quality doesn't stop there. We send samples from every finished batch to an independent, third-party laboratory.

This final verification tests for:

- Potency: To confirm active ingredients meet label claims.

- Purity: To ensure freedom from heavy metals and other contaminants.

- Microbial Limits: To guarantee the product is free from harmful bacteria.

Only after receiving a passing Certificate of Analysis (COA) from this impartial lab do we release the product for shipment. This final, unbiased validation provides ultimate assurance that your supplement is safe, potent, and ready to build your brand’s legacy.

Creating a Winning Liquid Supplement Formula

The secret to a standout liquid supplement isn't just the ingredient list—it's how everything works together to deliver results and a positive customer experience. Unlike pills, liquids present unique formulation challenges and opportunities.

This process blends science and art. We ensure every ingredient is stable, delivers tangible benefits, and creates a pleasant taste. This is where a true liquid supplement contract manufacturing partner excels, acting as your R&D collaborator to create an innovative and effective product.

Our job is to solve the complex puzzles of liquid formulas, from protecting delicate botanicals to masking the taste of potent herbs. The goal is simple: create a product that works and is desirable in a crowded market. You bring the vision; we bring the deep scientific know-how to make it a reality.

Mastering Bioavailability and Ingredient Stability

An incredible ingredient list is useless if the body can't absorb it. Bioavailability—the amount of an active ingredient the body can use—is everything for liquids.

We engineer our formulas for maximum absorption and stability:

- Advanced Botanical Extraction: We use specialized, temperature-controlled methods to gently extract active compounds from botanicals, avoiding harsh solvents to keep the final extract potent and pure.

- Ingredient Synergy: Our formulators are experts in how ingredients interact. We pair vitamins, minerals, and botanicals that enhance each other's absorption, creating a formula that is more powerful than the sum of its parts.

- pH Optimization: The pH level of a liquid can impact the stability of ingredients like Vitamin C. We carefully balance every formula to the ideal pH, protecting ingredient integrity from our facility to your customer's shelf.

The Art and Science of Flavoring

Let's be direct: if your supplement tastes bad, customers won't re-purchase. Flavor is your product's first impression and a critical factor for loyalty, especially for tinctures and wellness shots.

Masking the strong notes of functional ingredients is a challenge our R&D team thrives on.

- Identify the Off-Notes: We first analyze the base formula to pinpoint the exact flavor challenges—is it bitter, metallic, or earthy?

- Strategic Flavor Pairing: Instead of simply adding sugar, we use sophisticated natural flavor systems to complement and neutralize unwanted tastes. Think of how citrus can cut a metallic taste or how berry notes can balance earthy herbs.

- Custom Sweetener Systems: We create custom blends of natural, non-sugar sweeteners like stevia, monk fruit, and allulose to achieve the perfect level of sweetness health-conscious consumers want, without the guilt.

Your formula is your brand’s unique fingerprint. As your R&D partner, our mission is to help you create a custom formula that is not only effective and stable but also offers a flavor experience that builds true customer loyalty.

Customization for Modern Dietary Demands

Today’s consumers know what they want and what they want to avoid. A one-size-fits-all product is no longer enough. Our team specializes in crafting custom formulas that meet the specific criteria your audience demands.

We have extensive experience developing products that are:

- Vegan or Plant-Based

- Non-GMO Project Verified

- Certified Organic

- Sugar-Free or Keto-Friendly

- Allergen-Free (e.g., gluten-free, soy-free)

This flexibility means your product can confidently target niche markets while staying true to your brand's core values. For a closer look at the steps involved, check out our guide on how to create a supplement formula. Our process is designed to turn your big idea into a winning product.

Navigating Quality and Regulatory Standards

In the supplement industry, trust is your most valuable currency. Customers need absolute confidence that your product is safe, pure, and delivers what the label promises. This trust isn't built on marketing—it's forged in a facility that embodies a culture of quality.

Understanding these standards is a non-negotiable part of protecting your business and your customers. This is where partnering with a top-tier liquid supplement contract manufacturing facility becomes your greatest asset. We act as your compliance shield, ensuring every bottle that leaves our facility reflects your brand’s commitment to excellence.

This dedication to quality and compliance is more important than ever. The global contract manufacturing market for dietary supplements was valued at USD 59.63 billion in 2024 and is expected to rocket to USD 121.2 billion by 2030. With over 74% of U.S. adults taking supplements, the demand for trusted products is at an all-time high. You can explore more on this incredible growth and learn about the supplement contract manufacturing market trends.

The Foundation of cGMP and FDA Registration

You'll often hear the terms "cGMP certified" and "FDA-registered." Let’s clarify what these mean for your product.

-

FDA-Registered Facility: This means the U.S. Food and Drug Administration is aware of our facility, our products, and our subjection to their inspections. It is the baseline for operating legally and transparently.

-

cGMP Certified: This is where the true commitment to quality shines. Current Good Manufacturing Practices (cGMP) are rigorous guidelines governing every aspect of production. We are UL certified, demonstrating our adherence to these high standards.

cGMP isn't just a certificate on our wall; it's the operational DNA of our facility. It dictates how we train staff, maintain equipment, validate processes, and document every action to ensure your product is consistent, safe, and pure—every single time.

Our Multi-Stage Quality Control Protocol

Compliance is a continuous process woven into every stage of production. From raw material arrival to final shipment, your product is under constant scrutiny. This proactive approach prevents issues before they start, guaranteeing the final product meets the highest standards of quality.

Our protocol includes several key checkpoints:

- Raw Material Verification: Every ingredient is quarantined upon arrival. We test it for identity, purity, and contaminants before it is approved for use. No exceptions.

- In-Process Checks: During manufacturing, our team constantly monitors critical parameters like pH, viscosity, and homogeneity to ensure perfect batch consistency.

- Finished Product Testing: We don’t just rely on our internal labs. We send samples from every finished batch to an independent, third-party laboratory for unbiased verification.

This final, third-party testing provides a Certificate of Analysis (COA) that validates the product's potency (it contains what the label claims) and purity (it’s free from heavy metals, microbes, and other contaminants). This commitment to verifiable quality provides ultimate peace of mind. For a deeper dive into what this involves, review our detailed guide on dietary supplement manufacturing requirements.

Getting a Handle on Your Production Costs

A successful partnership begins with a clear understanding of your investment. In liquid supplement manufacturing, several key factors determine your final cost per unit. Our goal is to provide full transparency into this pricing so you can build a solid budget and see exactly where your investment goes.

Think of it like building a custom product. A standard model has a certain price, but when you add premium ingredients, custom flavors, and unique packaging, the cost adjusts accordingly. Every choice, from the ingredients inside the bottle to the label on the outside, shapes the final investment.

Core Cost Drivers in Liquid Manufacturing

Your product's final price reflects its complexity and production volume. We provide a detailed, line-item quote for every project, driven by a few key variables. Understanding these helps you make strategic decisions that align your product goals with your budget.

Here are the main factors that determine your per-unit price:

- Raw Ingredient Complexity: Sourcing a rare, certified organic botanical extract will be more expensive than using common vitamins. The purity and potency of your ingredients are the foundation of your product's quality and a primary cost factor.

- Batch Size (MOQ): Minimum Order Quantity (MOQ) is a key concept. Larger production runs unlock significant economies of scale, dramatically lowering your cost per unit. We offer flexible run sizes, from pilot batches to full-scale production, to support your brand's growth.

- Formulation & R&D: A straightforward formula using existing ingredients will be more cost-effective than a completely custom blend requiring extensive R&D, flavor masking, and stability testing. Our team helps you find the sweet spot between innovation and cost efficiency.

We believe in upfront, transparent pricing with zero hidden fees. Your quote will clearly break down every cost, from raw materials to final third-party testing, so you can plan your launch with total confidence.

The Impact of Testing and Packaging

Beyond the formula itself, two other key areas influence your budget: ensuring your product is safe, compliant, and has strong shelf appeal.

- Specialized Testing Requirements: Standard third-party testing for potency and purity is included in our process. However, some brands seek additional certifications like Non-GMO Project Verified or specific allergen testing. These add to the cost but can be powerful marketing assets.

- Packaging Choices: Your packaging is a crucial part of your brand's first impression. A standard plastic bottle is the most budget-friendly option. Custom-colored glass bottles, unique droppers, or printed boxes will increase the per-unit price. We can help you source packaging that fits both your brand aesthetic and your budget.

To give you a clearer picture, here’s a breakdown of the primary factors and how they typically affect your overall cost.

Primary Cost Factors in Liquid Supplement Production

| Cost Factor | Description | Impact on Price (Low to High) |

|---|---|---|

| Raw Materials | The specific vitamins, minerals, herbs, and other active ingredients used in the formula. | Sourcing common, widely available ingredients keeps costs low. Rare, organic, or trademarked ingredients increase the price significantly. |

| Batch Size (MOQ) | The total number of units produced in a single production run. | Larger runs (5,000+ units) create major economies of scale, leading to a much lower cost per unit. Small pilot runs have the highest per-unit cost. |

| Formulation R&D | The work required to develop a new, stable, and effective custom formula. | Using a pre-existing "stock" formula is the most cost-effective. A fully custom formula requiring flavor development and stability testing is a larger upfront investment. |

| Packaging | The primary bottle, cap, dropper, and any secondary packaging like boxes or inserts. | Standard plastic bottles and caps are the most economical. Custom glass, unique closures, and multi-component packaging are on the higher end. |

| Third-Party Testing | Independent lab verification for purity, potency, and safety. | Standard testing is a baseline cost. Additional certifications (e.g., NSF, Informed-Sport, Non-GMO) add to the total cost but also add value. |

| Labeling & Design | The cost associated with printing and applying labels to the bottles. | Simple, one-color labels are inexpensive. Complex, multi-panel labels or screen printing directly onto the bottle will increase the price. |

Ultimately, we are your partner in finding the perfect balance between an incredible product and a cost structure that fuels your success. By understanding these variables, you can make informed choices that set your brand up for profitable, long-term growth.

Choosing the Right Manufacturing Partner

Selecting a manufacturing partner is the single most important decision for your supplement brand. This is not just about finding a company to fill bottles; you are choosing a collaborator who will guard your brand’s reputation and act as an extension of your team. The right partner becomes your R&D department, your compliance shield, and your production powerhouse.

This choice is the foundation of your success. The market for nutraceutical contract manufacturing services was valued at a massive USD 198.34 billion in 2025 and is expected to rocket to USD 386.6 billion by 2033. This growth highlights how much brands rely on expert partners to scale efficiently while maintaining brand control. To better understand this trend, you can discover more insights on the nutraceutical market's expansion.

Verifying Quality and Compliance Credentials

Your first step should be to vet a potential partner's quality and compliance credentials. These are non-negotiable and reveal the professionalism of their operation. Don't just take their word for it—ask for the documentation.

Here are the essentials to verify:

- cGMP Certification: Ask to see their current Good Manufacturing Practices (cGMP) certificate from a reputable third-party auditor like UL or NSF. This proves their commitment to strict operational standards.

- FDA Registration: Confirm they are an FDA-registered facility, showing they are on the federal radar and subject to inspection.

- Third-Party Testing Protocols: Ask about their process for independent lab testing. A quality partner will be transparent about how they verify the potency and purity of every batch.

Assessing Capabilities and Flexibility

After confirming their commitment to quality, ensure their capabilities align with your brand's needs—both now and in the future. A partner who can't scale with you will eventually limit your growth.

The ideal partner doesn't just ask, "What do you want to make?" They ask, "Where do you want to go?" Their job is to offer the operational flexibility that fuels your brand's ambition, from a small pilot launch to a full-scale market takeover.

Assess their operational flexibility by asking about:

- Run Sizes: What are their Minimum Order Quantities (MOQs)? Can they accommodate small pilot batches for market testing and large production runs as your sales climb?

- Technical Expertise: Do they have experience with your specific ingredients? Inquire about their capabilities with advanced botanical extractions or complex flavor-masking challenges.

- Packaging Solutions: What are their options for bottling, capping, and labeling? Ensure they can deliver packaging that protects your formula and aligns with your brand aesthetic.

Evaluating Communication and Partnership Mindset

Finally, look beyond the machinery and certificates to evaluate the people. You are entering a long-term relationship that requires clear, transparent communication. Their approach in your initial conversations is a strong indicator of how they will manage your project.

A true partner is invested in your success. They should provide a dedicated project manager, offer transparent timelines, and proactively keep you informed. For a complete list of questions to ask, check out our guide on choosing the right partner for your brand. Choosing wisely sets you up for a smooth, reliable, and profitable journey from idea to finished product.

Have Questions About Making a Liquid Supplement? We've Got Answers.

Entering the world of private label supplements can bring up a lot of questions. As your potential partner in liquid supplement contract manufacturing, we believe in being clear and direct. Here are honest answers to the most common questions we hear from entrepreneurs and brand managers.

What’s the Minimum Order Size?

"How much do I have to order?" is often the first question, and it's critical for managing startup costs. The Minimum Order Quantity (MOQ) isn't a single number; it depends on the complexity of your formula.

A straightforward blend of common vitamins will have a lower starting point than a custom formula requiring rare botanical extracts. The availability and lead times of raw materials are major factors.

We understand that launching a new brand requires flexibility. That's why we offer smaller pilot batches, perfect for testing the market before committing to a larger run. The best way to get a specific number is to discuss your product idea with our team. We’ll help you map out a production plan that aligns with your launch strategy and budget.

How Long Does It All Take?

Speed to market is crucial. A reliable timeline is essential for planning your launch and marketing campaigns. From the moment we finalize your formula to the day the finished products ship, you can generally expect the process to take between 8 to 16 weeks.

Here’s a rough breakdown of that timeline:

- Formulation & Flavoring: Perfecting the taste and ingredient profile typically takes 1-4 weeks, depending on complexity.

- Sourcing Ingredients: Procuring and verifying all raw materials can take anywhere from 2-6 weeks.

- Production & Testing: Manufacturing, bottling, and third-party lab verification usually requires 4-6 weeks.

We won't leave you guessing. We provide a clear project schedule with key milestones from the start. Your dedicated project manager ensures transparent communication and on-time delivery, so you can plan with confidence.

Can You Help Me with the Label?

Absolutely. While you focus on creating a stunning brand design, we act as your regulatory guide to ensure every detail on your packaging is compliant.

Our in-house compliance experts will review your label artwork to ensure it meets all FDA guidelines. We check for:

- Accuracy of the Supplement Facts panel.

- Inclusion of all required disclaimers.

- A thorough review to ensure no unapproved health claims are made.

We also offer a wide range of bottling and packaging options that protect your product and make it stand out on the shelf. You can launch with peace of mind, knowing your supplement is fully compliant and ready for your customers.

Ready to transform your liquid supplement idea into a market-ready product? At Triton Nutra Group, we are more than a manufacturer—we are your partner, invested in your success from concept to completion. Let our expertise in formulation, compliance, and production help you launch a brand that earns customer trust. Request a free quote today and let’s build something incredible together.