Private Label Liquid Bariatric Vitamins Guide

Launch your brand with private label liquid bariatric vitamins. This guide covers formulation, manufacturing, and choosing the right partner for success.

Get a Free Quote Today!

Get a Free Quote Today!For weight-loss surgery patients, the journey to a healthier life is a lifelong commitment. A critical piece of that puzzle is nutrition, and that’s where liquid bariatric vitamins come in. They aren't just another supplement; they're a daily necessity.

Surgical changes to the digestive system make it incredibly difficult for patients to absorb nutrients from traditional pills. For e-commerce founders and health-and-wellness entrepreneurs, this presents a unique opportunity: serve a dedicated, rapidly expanding community with a product they truly need. This guide is for you—the brand builder researching private-label manufacturing. We'll walk you through the process and show you how a strategic partnership can help you launch a successful product line.

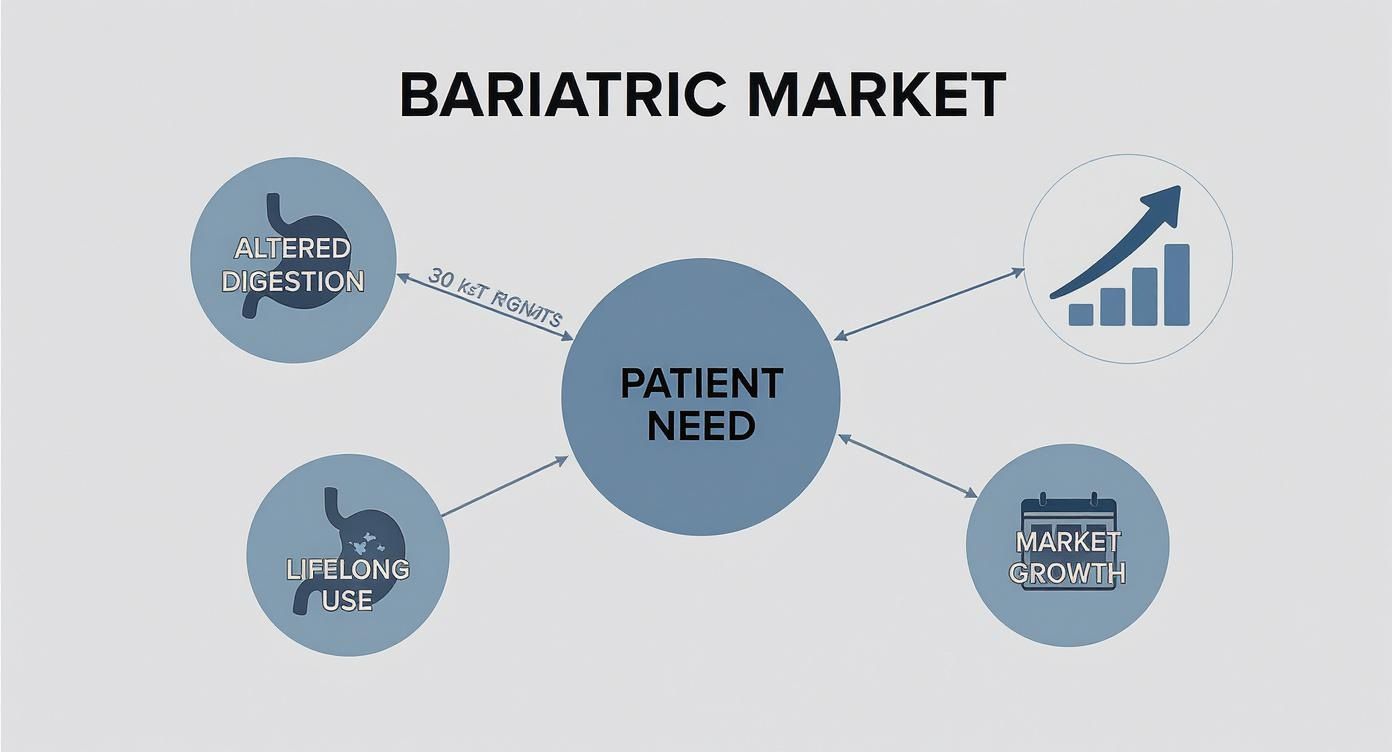

Why Liquid Bariatric Vitamins Are a Market Opportunity

If you're an e-commerce founder or a supplement brand manager, understanding the "why" behind liquid bariatric vitamins is key. This isn't about a fleeting wellness trend. The demand is rooted in a permanent, physiological need created by procedures like gastric bypass or sleeve gastrectomy.

These surgeries fundamentally alter how the body processes nutrients. The stomach is smaller, and parts of the small intestine—where most nutrient absorption happens—are often bypassed. Because of this, digesting solid pills can be difficult and, more importantly, ineffective. Patients simply can't get the essential vitamins and minerals needed to avoid serious health problems. For them, a liquid option isn't a preference; it's a necessity.

A Dedicated and Lifelong Customer Base

Most supplements are tied to temporary goals, like boosting energy for a few months. Bariatric vitamins are different. They are a lifelong commitment.

Doctors and dietitians stress that daily supplementation is non-negotiable for long-term health, helping to prevent debilitating conditions like anemia and osteoporosis. This creates a highly motivated customer base that relies on a consistent, predictable supply.

A brand that delivers a high-quality, easy-to-take liquid bariatric vitamin isn't just making a sale. You're building a genuine, long-term relationship with someone who depends on your product every single day.

Tapping into a Growing Market

The need for these specialized supplements is growing right alongside the number of bariatric surgeries performed each year. As more people seek effective, long-term solutions for obesity, the demand for post-operative nutritional support has exploded.

The global market for liquid vitamins, which includes these bariatric formulas, is already massive and expanding. This points to a clear and sustainable path forward for your brand. Entering this space offers serious advantages:

- Medical Necessity: You’re providing a solution to a critical health need. This builds immediate trust and authority.

- High Adherence: Patients are medically required to take these supplements for life, which means consistent, predictable demand.

- A Focused Niche: The general multivitamin market is incredibly crowded. This specialized area has fewer competitors, giving new brands a real chance to stand out.

Ultimately, launching a private-label line of liquid bariatric vitamins is a smart, strategic move. It allows your brand to serve a dedicated, high-growth segment of the health industry. To get a better handle on the core benefits of this format, check out our guide on whether liquid vitamins are better than pills.

Crafting a Liquid Vitamin Formula That Truly Works

Creating an effective liquid bariatric vitamin is more than just mixing nutrients in water. It’s a delicate balance of science and formulation artistry. For brand owners, getting these details right is what separates a forgettable product from one that builds a loyal, lifelong customer base.

The biggest hurdle is bioavailability. After bariatric surgery, a patient's digestive system is fundamentally changed. The body must absorb essential nutrients quickly and completely from a small liquid dose. This isn't easy. It demands we select the most soluble, readily absorbed forms of every vitamin and mineral and ensure they stay potent once suspended in liquid.

This is where understanding the market becomes crucial. Patient needs are the driving force behind the demand for these highly specialized supplements.

As you can see, the physiological changes from surgery create a non-negotiable need for lifelong supplementation. This reality fuels market growth and highlights the opportunity for products formulated with genuine expertise.

The Art and Science of a Great-Tasting, Stable Formula

Here’s a hard truth: even the most nutritionally sound formula is a failure if patients can't stand taking it. This is where the "art" of formulation truly shines, and it boils down to nailing three critical factors.

- Taste is Everything: B-vitamins have a notoriously strong, metallic taste. A top-tier R&D team doesn't just mask these flavors; they use sophisticated flavor systems to neutralize the off-notes entirely, all without loading the product with sugar. The goal is a pleasant taste that makes daily compliance a breeze.

- Getting the Texture Just Right: The liquid's thickness—its viscosity—has to be perfect. Too thin, and it’s a pain to measure accurately. Too thick, and it’s like swallowing syrup. We aim for a smooth, consistent texture that makes dosing simple and accurate.

- Keeping it Safe and Shelf-Stable: A reliable preservative system is essential for preventing microbial growth. The modern approach, and the one we use, is to lean on natural preservatives that protect the product's integrity without introducing unwanted chemicals.

Better Technology for a Better Product

How ingredients are handled is just as critical as what goes into the bottle. As your manufacturing partner, we use advanced processing techniques to protect nutrient potency from start to finish.

A prime example is our cold-fill technology. Traditional hot-fill methods can degrade heat-sensitive nutrients like Vitamin C and B-complex vitamins. Our cold-fill process bypasses that problem entirely, preserving the full strength of these delicate ingredients so your customers get the maximum impact from every dose.

This obsession with quality carries over to how we source botanicals. We use proprietary, alcohol-free, temperature-controlled extraction methods that gently pull active compounds from raw materials. The result? Cleaner, more potent, and more bioavailable extracts that will make your liquid bariatric vitamins stand out.

Key Nutrient Profiles for Liquid Formulas

When formulating for post-bariatric patients, you have to be laser-focused on the specific nutrients that are notoriously difficult to absorb after surgery. A superior formula doesn't just include the right nutrient; it includes the right form of that nutrient.

Below is a quick look at some of the most critical nutrients and the forms we prioritize for maximum absorption in a liquid base.

Key Nutrient Requirements for Post-Bariatric Patients

| Nutrient | Post-Bariatric Daily Need | Optimal Form for Liquid Bioavailability | Formulation Consideration |

|---|---|---|---|

| Vitamin B12 | 350-1000 mcg | Methylcobalamin | This active form bypasses the need for intrinsic factor, which is significantly reduced post-surgery. |

| Iron | 45-60 mg | Ferrous Gluconate | A gentler, more easily tolerated form that minimizes the risk of common GI upset. |

| Calcium | 1200-1500 mg | Calcium Citrate | Crucially, this form doesn't require stomach acid for absorption, a key advantage for bariatric patients. |

| Vitamins A, D, E, K | Varies | Micellized/Emulsified Forms | These fat-soluble vitamins must be broken into microscopic droplets to be absorbed in a liquid without normal digestive fat processing. |

Balancing these complex needs is no simple task. It requires deep scientific knowledge and hands-on experience. For a deeper dive, check out our complete guide to nutraceutical formulation development. Ultimately, finding a manufacturing partner who lives and breathes this science is the single most important step toward launching a successful bariatric supplement.

Meeting Quality and Regulatory Standards

When you're selling liquid bariatric vitamins, trust is everything. Your customers—and their doctors—are investing in a product vital to their long-term health. Navigating the web of manufacturing quality and regulatory compliance is more than a box-checking exercise. It's the bedrock of your brand's reputation.

Choosing a manufacturing partner isn't about finding someone who can just follow a recipe. You need a partner who lives and breathes quality, ensuring every bottle that leaves their facility is safe, potent, and pure. This commitment begins with a few non-negotiable credentials.

Decoding the Alphabet Soup of Compliance

You'll see terms like cGMP, UL, and FDA-registered, but what do they really mean for your brand? Think of them as a multi-layered shield protecting your business and your customers.

- cGMP (Current Good Manufacturing Practices): This is the FDA's gold standard for quality. A cGMP-certified facility sticks to rigid protocols for every step of the process—from sourcing raw materials to testing the final product. It’s your guarantee of consistency and quality.

- UL Certification: This adds another powerful layer of trust. UL is a globally respected third-party organization that audits facilities to ensure they exceed cGMP standards. It’s an independent stamp of approval signaling a serious commitment to excellence.

- FDA-Registered Facility: While the FDA doesn't "approve" dietary supplements, manufacturers must register their facilities with the agency. This opens them to inspections, holding them accountable to federal law.

When you partner with a facility that holds these credentials, you're buying peace of mind. You can tell your customers their vitamins are produced in an environment that puts their safety first.

A Rock-Solid Quality Control Process from Start to Finish

True quality is woven into every stage of production. A reliable partner should have a transparent and tough quality control (QC) process.

It starts with meticulously vetting every raw material supplier. Each ingredient must arrive with a Certificate of Analysis (COA), a document verifying its identity, purity, and potency. But we don't stop there—we run our own in-house tests to confirm everything checks out.

The commitment to quality is a partnership. By holding our suppliers to the highest standards, we ensure your formula's integrity from the ground up. This isn't just good practice; it's how you build a brand that consumers trust for life.

With over 250,000 bariatric procedures performed annually in the U.S. alone, the demand for trusted, high-quality liquid vitamins is crystal clear. The global market for these products is expanding rapidly, underscoring the need for impeccable quality.

Finally, after your product is formulated, blended, and bottled, it undergoes one last crucial step: third-party testing. We send samples to an independent, accredited lab. This gives you unbiased proof that the formula meets its label claims for potency and is free from contaminants. This final report is your ultimate seal of quality, giving you and your customers complete confidence. Our guide on dietary supplement manufacturing requirements dives deeper into these essential steps.

From Handshake To Finished Product: Your Private Label Journey

So, you have an idea for a liquid bariatric vitamin. Now what? Turning that concept into a market-ready product can seem daunting, but it doesn't have to be. The key is finding a partner who follows a structured, transparent process—one who treats your vision like it’s their own.

We’ve refined our private label process into a clear, collaborative roadmap. We act as an extension of your team, handling the manufacturing complexities so you can focus on building your brand.

Stage 1: The Initial Spark - Consultation and Formulation

Every great product begins with a conversation. We get into the weeds of your brand vision, target audience, and goals for your liquid bariatric vitamins. We’ll talk through nutrient profiles, ingredient sources, flavor goals, and packaging ideas.

From there, our R&D experts get to work. They translate your ideas into a formula that’s scientifically sound, effective, and stable. We obsess over the details, like using the most bioavailable forms of each nutrient—think methylcobalamin for B12 and calcium citrate—to give your customers the best chance at absorption.

Stage 2: Making It Yours - Flavoring and Packaging Design

With the core formula locked in, we move to flavor. Taste is everything for patient compliance. We’ll create several flavor samples for you to test until we nail it. Our specialists are experts at masking the metallic aftertaste of minerals and vitamins, creating a pleasant experience that keeps customers coming back.

At the same time, we sort out packaging. Whether you have your own components or need guidance, we ensure everything works with our production lines and meets regulatory standards. This is where your brand’s personality begins to shine.

Stage 3: Liftoff - Pilot Runs and Full-Scale Production

Before you commit to a massive order, we offer smaller pilot batches. This lets you test the market, get customer feedback, and make final tweaks with minimal risk. It's a game-changer for new brands.

We’re not just a supplier; we're your R&D partner from concept through launch. That means we adapt to your needs. We support your growth with flexible run sizes, from pilot batches to full-scale production. You can grow your business with confidence.

Once you give the green light, we start full-scale production in our cGMP, UL-certified, and FDA-registered facility. We know deadlines are critical, so we provide transparent timelines and stick to them. Our rapid turnaround and on-time delivery record mean you can plan your launch with certainty.

Successfully launching a brand also requires a smart marketing plan. Looking into effective content marketing strategies is a great place to start as you prepare.

Our job is to provide the expertise, quality, and reliability you need to turn your idea into a success story.

Private Label Timeline: A Realistic Overview

| Phase | Key Activities | Estimated Duration |

|---|---|---|

| 1. Discovery & Quoting | Initial consultation, defining product specs, providing initial quote. | 1-2 weeks |

| 2. Formulation & R&D | Developing the base formula, sourcing raw materials, initial lab samples. | 2-4 weeks |

| 3. Flavoring & Sampling | Creating and sending flavor samples, gathering feedback, finalizing taste profile. | 1-3 weeks |

| 4. Packaging & Labeling | Finalizing bottle/cap selection, label design approval, sourcing components. | 2-4 weeks |

| 5. Pilot Run (Optional) | Producing a small test batch for market validation. | 3-4 weeks |

| 6. Full Production | Scheduling, blending, bottling, and final QC checks. | 4-6 weeks |

| 7. Final Testing & Shipping | Third-party lab testing for final verification, preparing for shipment. | 1-2 weeks |

| Total Estimated Time | (Without Pilot Run) | 11-21 weeks |

| Total Estimated Time | (With Pilot Run) | 14-25 weeks |

These are estimates. The complexity of your formula and the speed of your feedback can shift the timeline, but this provides a solid framework for planning your launch.

How to Choose the Right Manufacturing Partner

Picking a manufacturing partner is the single most important decision you'll make for your supplement brand. It directly impacts your product quality, brand reputation, and ability to scale. You’re not just looking for a supplier; you're looking for a true partner—an extension of your team who guides you with real-world expertise.

A great partner doesn’t just fill orders. They anticipate problems, suggest smart solutions, and operate with transparency that lets you build your business with confidence.

Verifying the Non-Negotiables: Certifications and Compliance

Before talking formulas or pricing, verify a potential partner's credentials. They are hard-earned proof of a commitment to safety and quality.

Here’s what you need to ask for, no exceptions:

- Current Good Manufacturing Practices (cGMP): This is the baseline. A cGMP-certified facility follows strict, FDA-enforced standards for every step of production.

- UL Certification: This takes quality assurance a step further. UL is a highly respected third party that independently audits and verifies cGMP compliance, adding a crucial layer of unbiased validation.

- FDA-Registered Facility: Your partner must be registered with the FDA, making them accountable to federal regulations and subject to official inspections.

These credentials are your brand's shield. They protect you from liability and give your customers the quality assurance they expect.

Assessing R&D and Formulation Capabilities

Your vision for a standout line of liquid bariatric vitamins needs a partner with serious R&D muscle. A top-tier manufacturer doesn't just follow your recipe; they work with you to perfect it. Their team should be a source of expert advice on everything from bioavailability and flavor masking to creating stable, effective formulas.

When vetting a partner, ask pointed questions about their process. How do they tackle the strong taste of B-vitamins? What are their methods for keeping fat-soluble vitamins bioavailable in a liquid? A true expert will have confident, science-backed answers ready.

Your manufacturer should be your outsourced R&D team. Their ability to innovate on flavor, texture, and stability is what will make your product shine. They should be as invested in creating a superior product as you are.

Demanding Flexibility and Transparent Communication

As a growing brand, you need a partner who can adapt. One of the biggest hurdles can be the minimum order quantity (MOQ). A manufacturer focused only on massive runs can shut out new brands. Look for a partner who offers flexible run sizes, including smaller pilot batches. This lets you launch with less risk and scale up as sales climb.

This flexibility must be matched with clear, consistent communication. You should get transparent timelines, proactive updates, and a direct line to your project manager. This partnership mindset makes the journey from concept to launch smooth. As the market for liquid vitamins continues to grow, having a reliable partner is non-negotiable. You can read more about these global market trends to fully grasp the opportunity ahead.

The Nuts and Bolts of Launching Your Vitamin Line

Stepping into the private label world with a specialized product like liquid bariatric vitamins can feel like a massive leap. If you're an entrepreneur or brand manager, you likely have practical, bottom-line questions that need straight answers.

We get it. Here are the most common business-critical questions we hear from founders just like you, with straightforward insights to help you move forward.

What Are the Typical Minimum Order Quantities?

Let's start with the big one: the minimum order quantity (MOQ). For new brands, this is often a major hurdle. A good manufacturing partner knows that flexibility is key. That's why we champion small-scale pilot runs, letting you test your product in the market without a huge financial risk before you scale.

For full-scale production, MOQs can vary depending on formula and packaging complexity. We've designed a tiered approach to support your brand at any stage. It allows startups to get off the ground affordably while giving established brands the capacity to grow. Our goal is to be a partner in your growth, not a barrier to entry.

How Long Does It Take to Develop a New Liquid Vitamin?

Bringing a new product to market is a journey, and you need a predictable timeline. From our initial consultation to your finished product, the entire process for a new liquid bariatric vitamin typically takes 12 to 20 weeks. This timeframe ensures we don't cut corners on quality.

We provide a transparent project timeline from the start, breaking down each phase:

- R&D and Formula Finalization: 4–6 weeks

- Raw Material Sourcing and Verification: 2–4 weeks

- Stability Testing and Quality Control: 4–6 weeks

- Full Production and Bottling: 2–4 weeks

Our project managers keep you updated at each stage. This commitment to a reliable schedule and rapid turnaround means we get your product to market on time, every time.

Can I Use My Own Ingredients or Packaging?

Absolutely. We see ourselves as an extension of your team, and that means we're built for customization. If you have a proprietary ingredient, we can integrate it into your formula, provided it meets our strict quality standards and comes with a Certificate of Analysis (COA).

The same goes for packaging. You are welcome to supply your own branded bottles, caps, and labels. Our team will work with you to ensure everything is compatible with our production lines and meets regulatory requirements. This collaborative approach makes sure the final product is a true reflection of your brand.

Your brand's identity is its greatest asset. Our role is to provide the manufacturing expertise and flexibility needed to bring that identity to life, whether through a custom ingredient or unique packaging.

What Support Do You Offer for Flavor Development?

In the world of liquid bariatric vitamins, flavor is everything. Daily adherence is critical for patients, and an unpleasant taste is the fastest way to lose a customer. That's why our in-house R&D team includes dedicated flavor specialists who are masters at creating products people enjoy taking.

The process kicks off with a detailed consultation to nail down your target flavor profile. From there, we develop multiple flavor samples for your team to test. We'll keep iterating until we land on a taste your customers will love. We're particularly skilled at masking the strong notes from vitamins and minerals and can work with natural sweeteners to align with your brand’s clean-label promise.

Ready to turn your vision for a premium liquid supplement into a market-ready reality? The team at Triton Nutra Group is here to be your dedicated partner from concept through launch. Request your free quote today and let's build something exceptional together.