How Are Vitamins Manufactured? A Founder's Guide to Production

Learn how are vitamins manufactured, from raw ingredients to finished supplements. A comprehensive guide on production, quality, and best practices.

Get a Free Quote Today!

Get a Free Quote Today!Ever wonder what it takes to turn raw ingredients into the polished vitamin bottle on a retail shelf? The journey is a finely tuned dance of science, technology, and uncompromising quality control. For any brand founder, understanding this process isn't just interesting—it's critical for making strategic decisions that define your product's quality and success.

The Journey from Concept to Bottle

Think of vitamin manufacturing like a high-stakes culinary operation. A master chef doesn't just toss ingredients into a pot. They meticulously source, measure, blend, and test to create a perfect, repeatable result. It's the same disciplined approach we use to create high-quality liquid supplements. From raw material to market-ready product, every step is designed to build consumer trust.

This guide is your backstage pass. We'll walk you through the entire production lifecycle, giving you the insider knowledge you need to be an effective partner with your manufacturer. For entrepreneurs in the health and wellness space, this roadmap will arm you with the insights needed to build a powerhouse supplement brand.

From Blueprint to Bottle

The process is far more than mixing powders and liquids. It’s a disciplined, systematic approach built to guarantee safety, potency, and consistency in every bottle that leaves our cGMP, UL certified, and FDA-registered facility. Our job as your manufacturing partner is to translate your vision into a tangible, compliant, and effective product.

Here are the key stages we navigate together:

- Sourcing Pristine Materials: It all starts here. We vet and acquire high-purity raw ingredients from a trusted global supply chain. No compromises.

- Precision Formulation: This is where the magic happens. We carefully weigh and blend active vitamins with functional ingredients to perfect your unique formula.

- Navigating Quality Control: We run a battery of rigorous tests at multiple checkpoints. This ensures the final product is safe, potent, and delivers exactly what the label promises.

- Packaging and Fulfillment: The final leg involves bottling, labeling, and prepping your product for shipment, all while ensuring stability and shelf-life.

Think of us as your R&D partner from concept through launch. We handle the technical complexities so you can focus on building your brand. Our goal is to make the journey from idea to finished product transparent and reliable.

Understanding these steps is the first move in starting your own custom liquid supplement brand. It shifts you from being just a brand owner to an informed collaborator, capable of making smarter decisions about your product's future.

Sourcing Your Core Ingredients

The quality of your finished liquid supplement is decided long before the first bottle hits the production line. It begins with the rigorous sourcing of raw materials. Like a master chef who insists on hand-selecting the freshest produce, we know the foundation of a premium vitamin is the purity and potency of its ingredients.

This first step is non-negotiable for building brand trust. Every ingredient entering our UL certified, FDA-registered facility is chosen to meet our exacting standards. This commitment ensures your product’s integrity is locked in from the start, setting the stage for a safe, effective supplement your customers will love.

Natural vs. Synthetic Sourcing

Vitamin compounds come from two primary origins: extracted from a natural source or created in a lab. Understanding the difference is key to making smart decisions about your formula, marketing message, and price point. Each path has its own trade-offs in cost, purity, and consumer perception.

-

Natural Extraction: This process isolates vitamins directly from organic sources like plants, minerals, or animal tissues. A classic example is extracting Vitamin C from acerola cherries. While "natural" is a huge draw for consumers, this method is often more expensive and can yield lower concentrations.

-

Synthetic Production: Here, vitamins are built in a controlled lab environment through precise chemical synthesis or microbial fermentation. These lab-made vitamins are chemically identical to their natural counterparts. The advantages? Higher purity, greater stability, and cost-effectiveness, enabling a more accessible price for your customers.

The choice isn't about one being "better." It’s about aligning your sourcing strategy with your brand promise. We partner with you to walk through these options, ensuring the chosen ingredients meet your quality standards and business goals.

The Foundation of a Reliable Supply Chain

Knowing how a vitamin is made is one thing; knowing where it comes from is everything. A transparent, managed supply chain is the backbone of a reputable supplement brand. You need a partner who guarantees traceability and quality at every turn.

This is why we use a strict vendor qualification protocol. Before any supplier is approved, they undergo a thorough vetting process to confirm they meet our stringent cGMP (current Good Manufacturing Practices) standards. This involves audits, documentation reviews, and requiring certificates of analysis (COA) for every batch of raw material.

A Certificate of Analysis (COA) is a document from the supplier confirming an ingredient's identity, purity, and potency. It's our first line of defense in quality control, proving what we ordered is exactly what arrived—free from contaminants.

This painstaking approach creates an unbroken chain of custody, from the material's origin to our facility. This traceability isn't a "nice-to-have"; it’s fundamental to building a brand people trust without a second thought.

This process is essential in a massive global industry. With global demand for dietary supplements projected to hit $118.9 billion by 2025, and major production hubs like China dominating the market, a rock-solid supply chain is non-negotiable. You can learn more about the scale of the global vitamins market from this report. This growth reinforces how critical a reliable supply chain is for ensuring consistent quality.

How the Magic Happens: Core Vitamin Production Methods

Once premium raw materials are sourced and verified, the real transformation begins. This is where we take those compounds and turn them into active, potent vitamins ready for your final formula. Think of this stage as an industrial kitchen where raw ingredients are expertly refined.

Understanding how vitamins are made at this level empowers you to make smarter decisions about your product's effectiveness, cost, and market position. As your partner, we use key production methods, each selected to achieve the best quality and stability for specific vitamins.

Let's pull back the curtain on the three primary techniques. We'll explain not just what they are, but why a certain method is the gold standard for a particular nutrient. This is the science that separates a good liquid supplement from a great one.

Chemical Synthesis: Building Vitamins Molecule by Molecule

Chemical synthesis is all about precision. It's the process of building a vitamin's molecular structure from the ground up in a controlled lab. Our chemists use specific chemical reactions to assemble simpler molecules into the exact structure of the needed vitamin. The final product is a bio-identical compound—a perfect chemical match to its natural cousin.

This method offers serious advantages for your brand:

- High Purity: The controlled environment minimizes contaminants, resulting in an incredibly pure final product.

- Rock-Solid Consistency: Every batch is identical to the last. This guarantees reliable dosage and potency in every bottle.

- Cost-Effectiveness: For many vitamins, large-scale synthesis is more economical than extraction, helping make your product more accessible.

Vitamin C (ascorbic acid) is a classic example. While you can get it from oranges, synthesizing it is the only practical way to produce the high-potency, stable doses consumers expect from a quality supplement.

Microbial Fermentation: Using Nature's Tiny Factories

Not all vitamins are easy to build. For more complex molecules, we turn to nature's microscopic powerhouses: microorganisms. Microbial fermentation uses specific strains of bacteria, yeast, or algae as tiny, ultra-efficient bioreactors. We place these microbes in a controlled environment, feed them a nutrient-rich substrate, and let their natural metabolic processes produce the target vitamin.

Think of it like brewing kombucha, but on a highly scientific scale. We create the perfect conditions for these organisms to thrive and churn out what we need. This process is essential for vitamins with intricate structures that are difficult or impossible to create through chemical synthesis.

Partnership Insight: This is where manufacturing expertise shines. Choosing the right microbial strain, dialing in the perfect fermentation conditions, and purifying the final product are critical steps. Each directly impacts the quality of the vitamin in your formula.

Vitamin B12 is the perfect example. Its molecular structure is so complex that chemical synthesis isn't practical. Instead, specialized bacteria produce it through fermentation. The global market for this single ingredient was valued at around $295.4 million in 2024 and continues to grow. You can explore more about the Vitamin B12 market trends here.

Natural Extraction and Advanced Bioconversion

For brands leaning into a "whole food" or "plant-based" story, natural extraction is the way to go. This method isolates vitamins directly from their original source, whether botanicals, fruits, or animal tissues. For instance, Vitamin E is often extracted from sunflower oil.

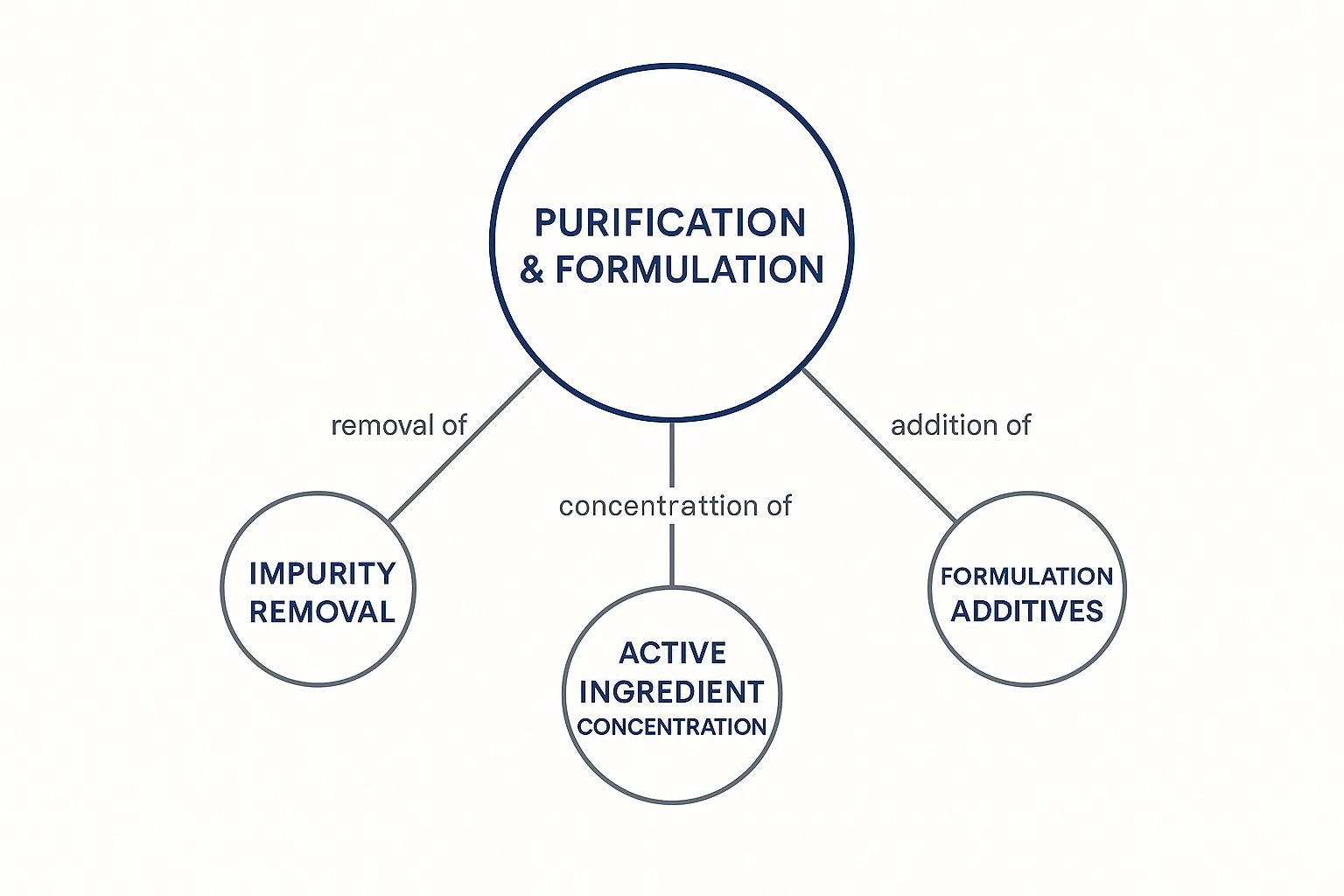

Of course, it’s not as simple as squeezing a plant. This method requires advanced purification steps to concentrate the vitamin and remove unwanted compounds. The infographic below breaks down the key stages in refining any raw vitamin compound after it’s produced.

As you can see, it doesn't matter if a vitamin is synthesized, fermented, or extracted. It always undergoes rigorous purification to ensure it’s clean, concentrated, and ready for your custom formula.

We also use forward-thinking techniques like enzymatic bioconversion. This process uses specific enzymes as biological catalysts to convert a precursor molecule into a more bioavailable form of a vitamin. It's a sophisticated approach that blends nature and science, allowing us to create superior ingredients that make your product stand out.

Crafting Your Unique Product Formula

This is where your brand's vision becomes a tangible, shelf-ready product. Once raw vitamins are sourced and purified, we move to precision formulation. Think of it as creating the master recipe for your supplement, where every ingredient is chosen for a specific purpose.

We don't just take orders; we act as an extension of your team. Our job is to translate your goals into a stable, effective, and appealing liquid formula. It’s a process that goes beyond just mixing in active ingredients; we're building the entire customer experience.

Combining Actives and Functional Ingredients

Creating a standout liquid supplement is like being a master chef. Your active vitamin is the star, but it needs a strong supporting cast. We carefully weigh and blend your chosen vitamins with functional ingredients, each playing a vital part in the final product's performance.

These supporting players, often called excipients, are non-negotiable for a successful formula:

- Stability: Preservatives and antioxidants protect the formula from breaking down, ensuring potency from the first dose to the last.

- Experience: This is about the senses. Natural flavors, sweeteners, and coloring agents create the taste and look that will connect with your audience.

- Consistency: Emulsifiers and suspending agents ensure every drop delivers a uniform, reliable dose. No settling, no separation.

Our R&D team works with you to perfect the mix. Whether your brand is all-natural, sugar-free, or allergen-friendly, we ensure the final formula not only works but reflects what you stand for.

Your R&D Partner from Concept to Launch

We believe true partnership means acting as a seamless extension of your team. You don’t need an in-house lab or a team of chemists; we are your dedicated formulation experts, from the first call to the final sample approval. Our R&D process is designed to be transparent and collaborative.

We believe that how vitamins are manufactured should be a collaborative journey, not a black-box process. You bring the vision; we provide the scientific expertise, cGMP-compliant facility, and state-of-the-art technology to bring it to life safely and effectively.

This approach gives us the agility to get things right. We help you navigate ingredient interactions, dosage accuracy, and flavor profiles, ensuring the product we create is one you are proud to put your name on.

This table shows how our collaborative process breaks down, giving you a clear picture of how we build your custom formula together.

Key Stages in Custom Vitamin Formulation

| Stage | Your Role (The Brand) | Our Role (The Manufacturing Partner) | Key Outcome |

|---|---|---|---|

| 1. Concept & Vision | Define your target audience, desired benefits, and key selling points. Share your brand identity. | Listen, ask clarifying questions, and provide initial feedback on feasibility and ingredient pathways. | A clear project brief and a shared understanding of the product's purpose. |

| 2. Ingredient Selection | Provide input on key active ingredients and preferences (e.g., vegan, organic, non-GMO). | Recommend specific vitamin forms and complementary excipients for stability, taste, and bioavailability. Source and vet suppliers. | A preliminary list of all active and inactive ingredients for the formula. |

| 3. Prototype & Sampling | Taste and evaluate initial lab samples for flavor, color, and texture. Provide direct feedback for revisions. | Develop 1-3 benchtop prototypes based on the agreed-upon ingredients. Iterate on the formula based on your feedback. | An approved "gold standard" sample that meets all sensory and efficacy targets. |

| 4. Final Formula Lock-In | Give final approval on the formula, solidifying the recipe for production. | Finalize all ingredient specifications, dosage levels, and manufacturing instructions. Document the master formula in our cGMP system. | A locked-in, production-ready master formula for your unique supplement. |

As you can see, your vision and feedback are the driving forces. We provide the technical guardrails and scientific know-how to ensure the final product is effective and perfectly aligned with your brand.

Flexibility for Every Stage of Growth

We get it—a startup has different needs than an established brand. Our manufacturing process is built for flexibility. We’re equipped to handle everything from small pilot batches to full-scale commercial runs.

- Pilot Batches: Want to test a new flavor or run a small market trial? Our pilot runs let you produce a smaller quantity with lower upfront investment. It's the perfect way to get real-world feedback.

- Full-Scale Production: When you’re ready for a major launch, we can seamlessly ramp up production to meet demand while maintaining the exact same quality standards. Our rapid turnaround times mean you never miss a market opportunity.

This flexibility allows you to grow at your own pace, knowing you have a manufacturing partner ready to scale alongside you.

Ensuring Purity and Potency with Quality Control

For any supplement brand, trust is everything. After we’ve perfected the formulation, our focus shifts to a relentless process of quality control and compliance. This isn’t a final inspection; it’s a rigorous system woven into every step of production, designed to build and protect that trust.

Think of it like an airline's pre-flight, in-flight, and post-flight safety checks. We operate with the same diligence. It’s how we ensure every bottle leaving our facility is safe, pure, and delivers exactly what your label promises. This deep commitment to quality is what separates a good product from a great brand.

The Role of cGMP in Manufacturing

You’ve likely seen the term cGMP. It stands for current Good Manufacturing Practices, and it’s the FDA's official rulebook for how supplements must be made. This covers everything from equipment sanitation and staff training to the air quality in our blending rooms.

Following cGMP means we have a documented, repeatable process that guarantees consistency. It prevents contamination, mix-ups, and errors. As a UL certified, FDA-registered facility, adhering to these standards is the core of our promise to you.

Our Multi-Stage Quality Checkpoints

Effective quality control is a series of critical checkpoints designed to catch potential issues long before they impact the final product.

Here’s how we build testing into the entire process:

- Raw Material Analysis: Every ingredient that arrives is immediately quarantined. We test it to verify identity, purity, and potency, cross-referencing its Certificate of Analysis to ensure it’s free from heavy metals, microbes, and other contaminants.

- In-Process Checks: While blending and formulating, we constantly pull samples to monitor key parameters like viscosity, pH, and homogeneity. This ensures every batch is perfectly mixed and every drop contains a uniform dose.

- Final Product Testing: After the product is bottled and sealed, it undergoes one last round of comprehensive testing. We confirm the final potency matches the label claim and run a final screen for contaminants.

Partnership Insight: We take it one step further. We send a sample from every single batch to an independent, third-party lab for verification. This unbiased analysis provides an extra layer of assurance, giving you and your customers complete confidence in the product's purity and potency.

This meticulous approach to quality supplement production is how we safeguard your brand's reputation and protect your customers.

Preparing for the Unexpected in the Supply Chain

While we control every variable inside our facility, the global vitamin market can be unpredictable. The complex methods of vitamin manufacturing mean supply chains are sometimes vulnerable to disruptions.

For instance, the market for key vitamins can be rocked by supply chain breakdowns. In 2024, a major European vitamin E producer had to halt production after an explosion, sending ripples through the global supply chain. Incidents like this show how even the most buttoned-up manufacturing processes can be impacted. You can learn more about how market dynamics impact the vitamin industry here.

As your manufacturing partner, our deep industry relationships and proactive sourcing strategies help us anticipate and navigate these risks. We work to secure a stable supply of ingredients for your brand. We don't just react to market shifts; we plan for them, giving you the stability to grow your business without interruption.

From Our Production Line to Your Customers' Hands

This is where it all comes together. The final step transforms your expertly crafted liquid formula into a premium, market-ready product. This "last mile" of production, with its precision packaging and reliable delivery, ensures the quality you’ve invested in reaches your customers perfectly intact.

Getting this stage right is as important as the formulation itself. The right choices here protect your product, define your brand experience, and shape your customers' perception of quality.

Protecting Potency with Smart Packaging

Great packaging does more than catch the eye. For liquid supplements, it's a vital component of product stability—a shield protecting sensitive ingredients from light, air, and temperature changes.

We’ll guide you in selecting the ideal packaging that fits your formula's needs and your brand's unique look. This is a strategic choice that directly impacts shelf life and potency.

Our flexible packaging solutions are designed with protection in mind:

- Amber Glass Bottles: The gold standard for a reason. Amber glass is fantastic at blocking the UV rays that can break down light-sensitive compounds.

- Specialized Seals: We use tamper-evident and induction-sealed caps to create an airtight barrier. This prevents oxidation and guarantees product safety for your customers.

- Customizable Designs: Your packaging is a core part of your brand. From bottle shape to label finish, we offer a suite of options to ensure your product looks exactly as you envisioned.

Speed and Reliability in Fulfillment

Our job isn't done when your product is bottled. In e-commerce and retail, speed and reliability are everything. A missed deadline can mean lost sales and unhappy customers. Our fulfillment process is built to be transparent, efficient, and dependable.

We are more than just a manufacturer; we're the reliable partner you need to launch successfully and on schedule. Our streamlined fulfillment and on-time delivery record mean you can build your business with confidence, knowing your inventory is in capable hands.

From the moment you place an order, you get a clear production timeline. Our team handles all logistics—bottling, labeling, and packing—with precision, getting your products ready for shipment to your warehouse or a fulfillment center like Amazon FBA. It’s a true partnership, ensuring a smooth journey from our facility to your customers.

Got Questions About Vitamin Manufacturing? We've Got Answers.

When diving into private-label supplements, a few practical questions always come up. As your partner, we believe in being upfront. Here are clear, straightforward answers to the questions we hear most from brand founders.

What Is a Typical Lead Time for a Custom Vitamin Order?

Count on about 8 to 12 weeks from the moment we lock in your unique formula to the day your product ships.

This realistic timeline covers every crucial step: sourcing and testing raw ingredients, running a pilot batch for your approval, moving to full-scale production in our cGMP facility, and a final comprehensive quality check by a third-party lab.

We’ll provide a detailed production schedule at the start, so you know exactly what to expect and can plan your launch with confidence.

What Are Your Minimum Order Quantities?

We’re set up to help brands win, whether you're starting out or scaling up. While we have competitive MOQs for full production runs, we also offer flexible options for smaller pilot batches. This lets you test a new product idea in the market without a massive upfront investment.

Our goal is to grow with you. We’ve designed our services to scale alongside your business, making the jump from a startup launch to a best-selling product line seamless.

How Is My Custom Formula Kept Confidential?

Your formula is your most valuable asset. We treat it that way. Every partnership begins with a rock-solid non-disclosure agreement (NDA). This is our legal guarantee that your unique formula, ingredient ratios, and proprietary methods remain completely confidential.

Simply put, your custom blend belongs to you and you alone. We operate with total integrity and see ourselves as a trusted extension of your team.

Can You Source Unique or Innovative Ingredients?

Absolutely. Our R&D and sourcing teams are always hunting for what's next, from cutting-edge botanical extracts to clinically-studied branded compounds. We tap into our extensive network of qualified global suppliers to track down specialty ingredients that match your brand’s vision.

This commitment is a huge piece of the puzzle when figuring out how to start a supplement business that gets noticed. As your dedicated R&D partner, we ensure even the rarest ingredients meet our tough standards for quality and compliance.

Ready to turn your vision for a high-quality liquid supplement into a reality? The team at Triton Nutra Group is here to partner with you from concept to launch, bringing the expertise, flexibility, and quality assurance you need to succeed.