Partnering with Your Goldenrod Private Label Contract Manufacturer: A Founder's Guide

Find the best Goldenrod private label contract manufacturer for your herbal brand. Expert tips to successfully launch your supplement from concept to sale.

Get a Free Quote Today!

Get a Free Quote Today!Launching a new supplement brand is a massive undertaking. Of all the decisions you'll make, none is more critical than choosing the right manufacturing partner. This isn't just about finding a factory to fill bottles; it's about securing a collaborator who is as obsessed with quality, compliance, and innovation as you are. For e-commerce founders and brand managers in the health and wellness space, looking past the price tag to find a true partner is the secret to long-term success.

Choosing a Partner, Not Just a Supplier

When you’re searching for a Goldenrod private label contract manufacturer, it’s tempting to focus on unit cost and lead times. We get it. Those numbers matter, but they don't tell the whole story. The brands that truly win are built on strong, collaborative relationships with their manufacturing partners.

Think of it this way: your manufacturer is the ultimate guardian of your product's quality. By extension, they hold your brand's reputation in their hands. A true partner understands this. They invest in your success because it’s tied directly to their own. They become your R&D partner, your compliance gurus, and your operational backbone, all in one.

The Partnership Mindset

So, what’s the real difference? A supplier fills an order. A partner is in the trenches with you from concept through launch. This partnership mindset is your secret weapon for navigating the crowded wellness market.

What does this actually look like?

- Shared Expertise: They offer insights on ingredient synergy, keep you ahead of market trends, and suggest innovative botanical extraction methods to make your formula stand out.

- Compliance Guidance: A great partner guides you through the maze of requirements for an FDA-registered, UL certified, and cGMP-compliant facility. They handle the red tape so you can focus on your brand.

- Proactive Problem-Solving: Instead of waiting for things to go wrong, they anticipate potential production or packaging snags and bring you solutions before they become expensive delays.

This collaboration is everything. When you're vetting a private label contract manufacturer, look for one that lives and breathes quality and reliability. This is the foundation for building customer trust with the people who buy your product. A cheap supplier who cuts corners will eventually crater your brand's credibility. It’s simply not worth the risk.

Your manufacturer should be your first line of defense for quality control. Their commitment to third-party testing and transparent processes protects your investment and ensures your goldenrod supplement is safe, potent, and effective.

From Concept to Shelf-Ready Reality

The right partner makes the journey from a brilliant idea to a market-ready product feel seamless. They offer the flexibility to start with small pilot runs to test the market, then smoothly scale up to full production as your brand takes off. This adaptability is invaluable for both startups and established brands.

They should be ready to work with you on every detail—from perfecting the formula and flavor profile to selecting the right bottle and designing a killer label. This level of customization ensures the final product is a perfect reflection of your brand's vision.

At the end of the day, you're not just buying a product. You’re investing in a relationship that will power your brand's growth for years to come.

Vetting Your Manufacturing Partner: A Step-by-Step Guide

Alright, you’ve shortlisted potential manufacturing partners. Now the real work begins. It’s time to look past the slick websites and start the serious business of vetting.

This isn’t a step you can afford to skip. Properly investigating a Goldenrod private label contract manufacturer is how you protect your brand, your investment, and—most importantly—your future customers. You're not just buying a product; you're entrusting your reputation to them.

Beyond the Acronyms: What Certifications Really Mean

Any manufacturer you're considering should have baseline certifications like cGMP, UL certified, and be an FDA-registered facility. But these are just the ticket to the game. You need to understand what they actually represent so you can ask smarter questions.

-

cGMP (Current Good Manufacturing Practices): These are the FDA-enforced rules ensuring a manufacturer has the systems to design, monitor, and control their entire process. Think of it as the foundation for quality. A great follow-up question is, "Can you share your cGMP audit history?" A partner confident in their quality will be transparent.

-

UL Certified: This means a respected third party, Underwriters Laboratories, has audited the facility against specific quality and safety standards, adding another layer of trust.

-

FDA-Registered: This is a fundamental requirement. It means the facility is on the FDA's radar and is subject to inspection. It is not an endorsement from the FDA, but a manufacturer operating legally in the US must have it.

A true partner sees these credentials as the bare minimum—a starting point for a deep-seated commitment to quality, not just a collection of logos for their website.

The Vetting Scenario: A Tale of Two Manufacturers

Let's play this out. Imagine you're vetting two potential partners for your new goldenrod tincture.

Manufacturer A is an open book. They walk you through their process, providing full documentation on raw material sourcing, complete with Certificates of Analysis (COAs) for each botanical lot. They openly discuss their third-party testing protocols for potency and purity and even offer a virtual tour of their facility.

Manufacturer B, on the other hand, is cagey. Ask about sourcing, and you get a vague answer like, "we use premium global suppliers." Their testing info is limited to "in-house QC checks." They seem more focused on getting you to sign a contract than proving their quality.

The choice is clear. Transparency isn't a nice-to-have bonus; it's a direct reflection of a partner's integrity and reliability. Vague promises are a giant red flag.

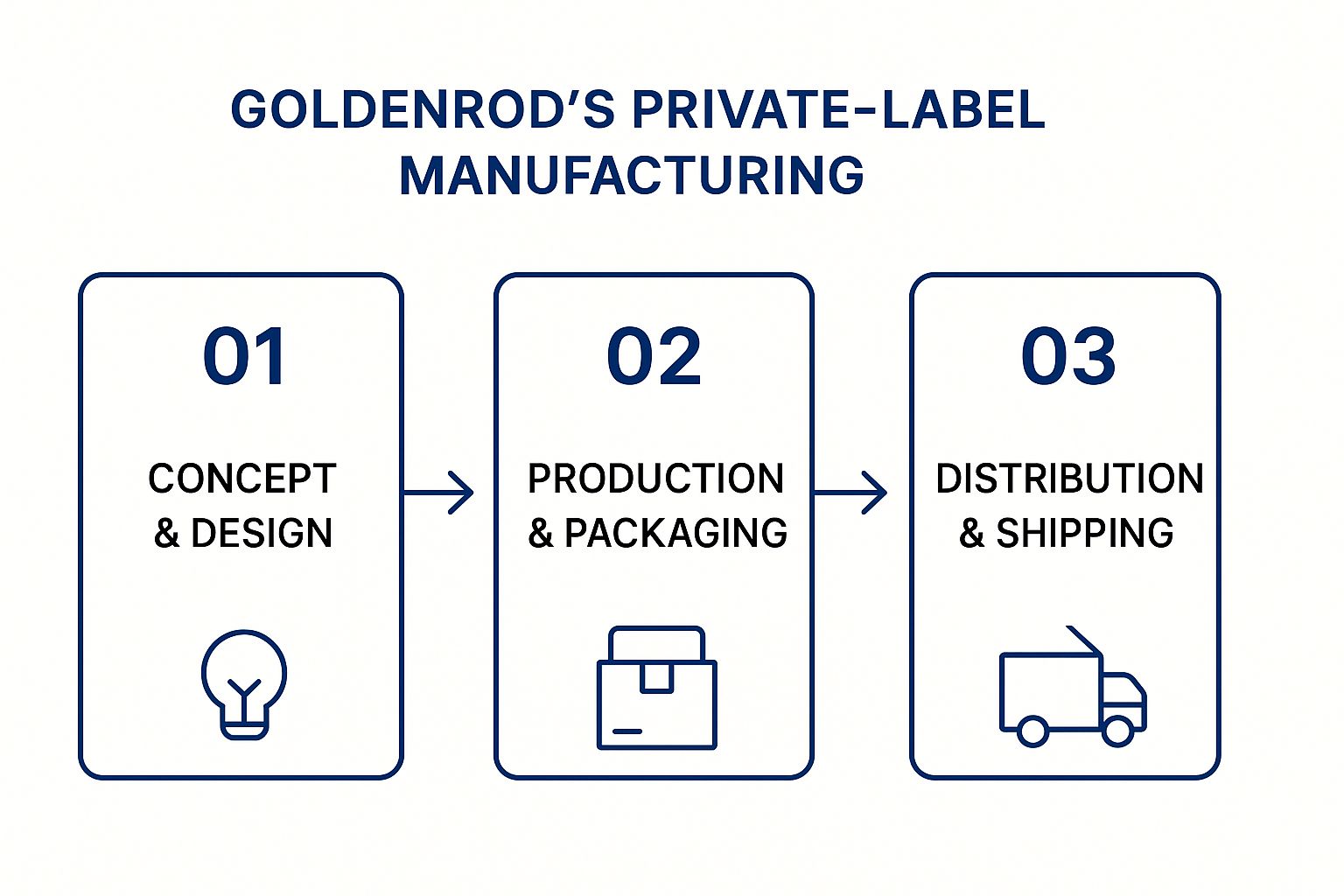

This process flow shows you what it looks like when you find a transparent partner who can take your idea and make it a reality.

A well-defined process, from initial concept to shipping, is your best defense against surprises and ensures quality is baked in at every single step.

Key Questions to Uncover the Truth

To really understand who you're dealing with, you need to dig in with pointed questions. Here are the non-negotiables you should be asking every potential Goldenrod private label contract manufacturer.

Expert Tip: Never just accept a "yes." Always ask for proof. Request redacted COAs from recent batches, sample quality control reports, or a copy of their latest third-party audit certificate. A partner who stands by their quality will have this information ready.

Questions About Sourcing and Raw Materials:

- Where exactly do you source your goldenrod (Solidago virgaurea)? Can you trace it back to its origin?

- What documentation, like COAs, do you require from your raw material suppliers?

- How do you test incoming raw materials before they enter the production line?

Questions About Testing and Quality Control:

- Do you use third-party labs to test finished products? Which ones?

- What is the full panel of tests you run (e.g., identity, potency, heavy metals, microbial)?

- What is your process if a batch fails a quality check?

This intense focus on partnership and quality is driving major shifts in the industry. For a bird's-eye view of the whole journey, our comprehensive guide for starting your own private label liquid supplement brand is a great resource. Making the right choice here sets the stage for everything that comes next.

Bringing Your Custom Formula to Life

This is where the real fun begins. After the research and vetting, you get to the most exciting part: turning your idea for a goldenrod supplement into a tangible product. A genuine Goldenrod private label contract manufacturer is much more than an order-taker. They are your in-house R&D department, helping you navigate the decisions that will define your product.

Imagine an e-commerce founder launching a new goldenrod tincture. Their vision is to create something special that carves out its own space in a crowded market. That process doesn't start on a bottling line; it starts with a conversation. This is where your manufacturer's hands-on experience becomes your most valuable asset.

Navigating From Stock Formulas to Custom Blends

One of the first conversations you'll have is about your formula. A good partner will clearly lay out the possibilities, explaining the trade-offs between speed-to-market, cost, and brand differentiation.

Your options generally fall into three buckets:

- Stock (or "White Label") Formulas: These are tried-and-true formulas that are pre-developed and tested. It's the quickest way to get a product on the shelf, perfect for testing a new concept.

- Modified Stock Formulas: Perhaps you like a base formula but want a unique twist, like adding echinacea for immune support. This path offers customization without the full R&D timeline.

- Fully Custom Formulas: This is for the brand with a one-of-a-kind vision. You'll work directly with their formulators to build a proprietary blend from the ground up, giving you a powerful competitive advantage.

An experienced manufacturer will do more than just mix what you ask for. They'll provide critical feedback on ingredient synergy—making sure your chosen botanicals work well together—and help foresee any stability or regulatory hurdles. For a deeper look at this, our guide on how to create a supplement formula is a great resource.

The table below breaks down the key stages where you'll collaborate with your manufacturing partner to tailor the product to your brand's specific needs.

Private Label Customization Options

| Customization Stage | Key Decisions & Options | Partner's Role |

|---|---|---|

| Formula Development | Stock, Modified Stock, or Fully Custom. Selection of active ingredients and dosages. | Provide formulation expertise, advise on ingredient synergy, ensure regulatory feasibility, and create sample batches for approval. |

| Flavor Profile | Natural sweeteners (stevia, monk fruit), masking agents, and flavor selection (e.g., citrus, berry, mint). | Offer a library of flavor options, create and ship flavor samples for tasting, and provide guidance on achieving a palatable final product. |

| Primary Packaging | Bottle material (glass vs. plastic), color (clear, amber), dropper type (calibrated, bulb), and cap (child-resistant, tamper-evident). | Source and present various packaging options, advise on material suitability for product stability, and ensure component compatibility. |

| Secondary & Labeling | Carton/box design, insert creation, and label design. | Provide dielines for designers, review label content for FDA compliance (Supplement Facts, disclaimers), and ensure print quality. |

| Production Volume | Pilot batch size (e.g., 500 units) for launch or scalable runs for established demand. | Offer flexible minimum order quantities (MOQs), provide clear cost structures for different volumes, and plan for future scalability. |

This collaborative process is what separates a true partner from a simple supplier, turning a standard product into something that is uniquely yours.

The Art and Science of Flavor and Packaging

With your formula finalized, the focus shifts to the consumer experience. For a liquid supplement like a goldenrod tincture, the flavor profile is absolutely critical. Your manufacturer should be ready to send you samples with different natural flavors and sweeteners until you find the perfect taste.

At the same time, you'll decide on packaging that not only protects your product but also tells your brand's story on a crowded shelf. This involves:

- Primary Packaging: The bottle holding the tincture. Will it be classic amber glass or a modern plastic? Does it need a calibrated dropper for precise dosing?

- Secondary Packaging: The box the bottle sits in. This is valuable real estate for branding and highlighting key benefits.

- Labeling: This is part science, part art. The design must be eye-catching, but it also must be 100% compliant with FDA regulations for supplement facts and disclaimers.

A manufacturer’s ability to handle this complexity is what allows brands to thrive. We see this across the industry. For instance, one private label manufacturer, Goldenrod Corporation, grew its team by 147% in one year to keep up with demand. Its journey shows how agile manufacturers are scaling to support private label brands. You can see more on this in the data published about the company’s expansion.

Insider Tip: Never underestimate the power of packaging. We once worked with a client whose sales shot up after they switched from a standard bottle to a UV-protected amber glass bottle with a calibrated dropper. It didn't change the formula, but it signaled a higher level of quality and precision.

Flexible Run Sizes for Smart Growth

Perhaps the most important thing a modern Goldenrod private label contract manufacturer can offer is flexibility in production runs. Not every new brand is ready to commit to a 100,000-unit order from the start.

A real partner gets that. They support your growth journey, no matter the stage.

First, you'll want to do pilot batches. These small runs—sometimes as low as a few hundred units—are perfect for testing the market, seeding products with influencers, or landing your first retail accounts without sinking cash into inventory.

Then, as sales pick up, you need to be able to scale production seamlessly. Your partner should have the capacity to grow with you, ensuring the 50,000th bottle is as perfect as the first. This ability to start small and scale smart is a massive advantage for entrepreneurs.

Technology, Timelines, and Transparency: The Modern Manufacturing Process

Once you’ve locked in your custom formula, your focus shifts to two big questions: How fast can I get my product, and can I trust the process? In modern supplement manufacturing, the answer to both lies in technology. The journey from purchase order to shipped pallet isn't a black box; it’s a carefully choreographed process powered by smart systems.

A top-tier Goldenrod private label contract manufacturer invests in technology that creates a better product and guarantees it arrives on time. This is the real test of a reliable partner. It’s what ensures the 10,000th unit is identical to the first and that you can hit your launch date with confidence.

The Tech That Safeguards Your Supplement

The quality of a liquid herbal supplement is fragile. The very botanical compounds that make them effective can be damaged by heat, pressure, or improper handling. This is where a manufacturer's technology becomes your brand's secret weapon.

Two innovations are critical:

- Advanced Botanical Extraction: Old-school methods often rely on high heat, which can destroy the delicate phytochemicals your customers are paying for. We use forward-thinking, temperature-controlled extraction that gently preserves the full spectrum of active compounds, ensuring your product delivers on its promise.

- Cold-Fill Processing: Similarly, the bottling stage can degrade sensitive formulas. Our cold-fill technology means we don’t have to pasteurize your product with heat during bottling. This protects the integrity of the finished liquid, a game-changer for complex herbal blends.

You can't compromise on this level of technology if you want a premium product. It's the physical proof of a manufacturer's dedication to quality.

We see ourselves as your R&D partner from concept through launch. Our investment in technology is a direct investment in your brand’s success. We know that what we do in our facility builds lasting trust between you and your customers.

Cracking the Code on Production Timelines

Getting a handle on the production timeline is key to mapping out a smart launch strategy. A partner worth their salt will provide a clear, step-by-step schedule.

Here’s a typical timeline for a private label run to give you a feel for the process:

| Stage | Duration | Key Activities |

|---|---|---|

| 1. Onboarding & PO | 1-3 Business Days | We finalize your quote, execute agreements, and issue your official Purchase Order. |

| 2. Raw Material Sourcing | 5-15 Business Days | We procure all raw materials. Every ingredient undergoes rigorous inbound quality testing and verification. |

| 3. Compounding & Blending | 2-4 Business Days | Your unique formula is blended with precision in a controlled cGMP environment. |

| 4. QC & Lab Testing | 3-7 Business Days | Samples from the master batch go to a third-party lab to confirm potency, purity, and safety. No exceptions. |

| 5. Production & Bottling | 3-5 Business Days | Once approved, the batch hits our production lines to be bottled, capped, and labeled. |

| 6. Final Release & Shipping | 1-2 Business Days | Your finished goods get one last quality review before being packed and shipped to you. |

This process highlights how specialized efficiency fuels the contract manufacturing sector, which is growing at a healthy 5-7% annually. It’s especially true for small to mid-sized manufacturers—those often doing between $1 million and $10 million in revenue—that shine by offering these customized, high-touch solutions. For brands, this can translate into significant cost savings. You can dig into more of these market dynamics and company scales if you’re curious.

Transparent communication is the bedrock of a solid manufacturing relationship. Your partner should provide proactive updates at every stage. You should never be left wondering what’s going on with your investment. That clarity and reliability free you up to focus on what you do best: building your brand.

Building a Partnership That Fuels Growth

Getting your first product launched feels like crossing the finish line, but it’s really just the starting gun. The real opportunity begins as you scale the brand, react to the market, and plan your next move.

Getting your first product launched feels like crossing the finish line, but it’s really just the starting gun. The real opportunity begins as you scale the brand, react to the market, and plan your next move.

This is where you'll see the massive difference between a simple supplier and a true manufacturing partner.

Your relationship with your Goldenrod private label contract manufacturer has to be more than transactional. The best partners become genuinely invested in your success. They act less like a vendor and more like a strategic ally, helping you see around corners.

More Than Just a Production Line

A proactive partner brings value long after your first batch ships. They don’t just wait for your next purchase order. They come to you with ideas and insights that can become your next big win.

What does that look like in the real world?

- Spotting Market Trends: They might call you and say, "We're seeing a huge spike in demand for botanicals that complement goldenrod. Have you thought about a new combination formula?" This gets you ahead of the curve.

- Suggesting Line Extensions: Based on your tincture's success, they could propose complementary products—maybe a goldenrod-infused throat spray or a lower-dose children's version. These are natural ways to grab more market share.

- Navigating Regulatory Changes: When the FDA quietly updates a labeling rule, a great partner is on it. They’ll let you know immediately and help you adapt, saving you from headaches and costly mistakes.

An Extension of Your Team

In the film and TV world, a "goldenrod" script is a late-stage revision triggered by an unexpected problem. The "goldenrod" pages are the fix that keeps the whole project from derailing.

Your manufacturing partner should be your "goldenrod" solution—the reliable problem-solver who keeps your brand moving forward, no matter what challenges pop up.

A truly integrated partnership means your manufacturer is as committed to your brand's future as you are. They celebrate your wins and actively work to prevent losses, becoming a seamless extension of your own team.

This collaborative spirit frees you up to do what you do best: grow the business. When you have a solid partnership with your Goldenrod private label contract manufacturer, you can focus on marketing, sales, and implementing top customer retention strategies for e-commerce success, knowing your production is in expert hands.

Ultimately, this is about finding a partner who can grow right alongside you. You need someone who can handle a small pilot batch of 500 units just as easily as they can a full-scale run of 50,000. That scalability is non-negotiable. It ensures that as your brand’s reputation grows, your operations can keep up without a hitch. You’re not just manufacturing a product; you’re building an enterprise built to last.

Your Goldenrod Manufacturing Questions Answered

Diving into the world of private label manufacturing can feel like learning a new language. You have a vision for a fantastic goldenrod supplement, but a thousand questions stand between your idea and a product on the shelf.

As a dedicated Goldenrod private label contract manufacturer, we get these questions every day from sharp founders and brand managers just like you. We've compiled the most common ones here to give you clear, direct answers and demystify the process.

What Is the Realistic Timeline From Idea to Shipped Product?

This is almost always the first question we’re asked. While every project is unique, a typical timeline from a signed purchase order to your product shipping out the door is usually 4-8 weeks.

What can shift that timeline? A few key things:

- Raw Material Availability: Sourcing and verifying top-notch goldenrod and other botanicals can sometimes add time, especially for rare ingredients.

- Formula Complexity: A straightforward, single-ingredient tincture will move faster than a complex blend that needs extensive stability testing.

- Packaging Lead Times: Custom-designed bottles or unique dropper caps can have longer lead times. We always flag this early in the process.

We provide a transparent project schedule so you always know exactly where your product is in the process, from sourcing and third-party lab testing to final bottling.

How Do I Protect My Proprietary Formula?

Your custom formula is your secret sauce—your brand's most valuable intellectual property. Protecting it is our top priority. This is handled professionally through a Non-Disclosure Agreement (NDA).

Before we discuss the specifics of your blend, we execute a mutual NDA. This legally binding contract guarantees every detail of your formula remains completely confidential. For us, this isn't optional; it's a standard part of building a partnership based on trust.

Trust is the foundation of our business. Your formula is as safe with us as it would be in your own vault. We are your production partner, not your competitor.

Can You Help Me Make My Product Compliant for Amazon or Shopify?

Absolutely. This is a huge part of what we do. Navigating the specific compliance rules for major e-commerce platforms is a critical service we provide.

For instance, getting a product ready for sale on Amazon FBA almost always requires:

- A valid Certificate of Analysis (COA) from an accredited third-party lab.

- Proof the product was made in a cGMP (Current Good Manufacturing Practices) facility.

- Labeling that is 100% compliant with FDA regulations.

We walk you through this entire process. We ensure your labels are right and you have all the necessary documentation before you launch. This prevents listings from getting flagged or taken down, saving you time, money, and stress.

What Does "Turnkey Solution" Actually Mean?

You’ll hear the term “turnkey” thrown around a lot. Simply put, it means we can handle every step of the manufacturing process for you. You come to us with an idea (the "key"), and we deliver a finished, market-ready product (you can "turn the key" and start selling).

Our turnkey service covers it all:

- Formulation: We help develop a new formula from scratch or refine an existing one.

- Sourcing: We procure and test all raw materials and packaging.

- Production: We do all the blending, bottling, and labeling in our cGMP facility.

- Compliance: We ensure your product meets all regulatory standards.

- Fulfillment: We can even store inventory and ship orders directly to your customers.

This end-to-end management frees you to focus on marketing, sales, and growing your brand, knowing the operational side is in expert hands.

Do I Need to Understand All the Technical Jargon?

Not at all. While knowing the basics is helpful, you don’t need to be a formulation scientist to launch a successful supplement. Our job is to translate technical complexities into clear business decisions. We explain the why behind our recommendations, whether we’re discussing a specific extraction method or a type of preservative.

Think of it this way: a "goldenrod" script revision in the film industry is a critical change made to solve a production problem. We see our role similarly. We're here to be your expert problem-solvers. Your job is to hold the vision; our job is to handle the technical execution to bring it to life flawlessly.

Ultimately, choosing the right Goldenrod private label contract manufacturer comes down to finding a partner you can trust—one who will manage the intricate details, give you honest answers, and stand proudly by the quality of the product that has your name on it.

Ready to turn your vision for a goldenrod supplement into a market-ready reality? The team at Triton Nutra Group is here to be your expert partner every step of the way. Let's discuss your project and get a no-obligation quote. Start your journey with us today!