Your Partner in Custom Dong Quai Root Supplements | Private Label & Contract Manufacturing

Partner with a leading Dong Quai Root private label contract manufacturer for quality, reliability, and custom branding solutions. Get started today!

Get a Free Quote Today!

Get a Free Quote Today!Choosing a Dong Quai Root private label contract manufacturer is the most critical decision for your supplement brand. This isn't just about finding a supplier; it’s about forging a strategic partnership. Your partner's commitment to quality, innovation, and compliance is the bedrock of your success.

Finding the Right Manufacturing Partner

When you launch a Dong Quai supplement, you’re not just following a trend—you're entering a market with explosive potential. The global demand for Dong Quai is surging as consumers seek natural solutions for hormonal balance and overall wellness.

This isn't a fleeting moment. The global Dong Quai market hit USD 2.4 billion in 2023 and is projected to reach USD 5.0 billion by 2033. That’s a compound annual growth rate (CAGR) of 7.8%, signaling a massive opportunity for brands that build on a solid foundation.

The Partnership Mindset

The best manufacturing relationships feel less like a transaction and more like a true partnership. You aren't just buying a product; you're entrusting your brand's reputation to another company. A real partner acts as an extension of your team—your R&D partner from concept through launch.

You need a manufacturer who is:

- A Collaborator: They should be eager to work with you, bringing their R&D insights to the table to perfect your formula.

- A Problem-Solver: Challenges are inevitable. A great partner proactively finds solutions instead of just dropping problems in your lap.

- Invested in Your Success: Their ultimate goal is to help you create a best-in-class product that customers love and return for.

A great private label manufacturer doesn't just ask, "What do you want to make?" They ask, "What problem are you solving for your customer?" This shift in perspective is the difference between a simple supplier and a strategic growth partner.

Key Evaluation Pillars

To find a top-tier partner, look beyond the price-per-bottle. Your vetting process should be built on three core pillars that protect your brand and set you up for success. Before diving in, it’s worth getting a solid understanding of private labeling to know what to expect.

First, Quality and Compliance are non-negotiable. Your manufacturer must operate from an FDA-registered, cGMP-compliant, and UL-certified facility. Think of these certifications not as website logos, but as your brand's insurance policy against recalls and regulatory headaches.

Second, you need Customization and Flexibility. A one-size-fits-all approach leads to a generic product. The right partner can handle small pilot runs for market testing and scale to full production without a dip in quality. They should offer flexibility in formulas, flavoring, and packaging to make your product truly unique.

Our guide on choosing the right liquid supplement supplier takes a much deeper look into these crucial factors.

To help you stay organized, here's a quick checklist summarizing what to look for.

Key Manufacturer Evaluation Checklist

Use this table as a quick reference to ensure you're asking the right questions as you vet potential manufacturing partners for your Dong Quai supplement.

| Criteria | Why It Matters | What to Look For |

|---|---|---|

| Certifications | These are non-negotiable proof of quality and safety. They protect your brand and your customers. | FDA-registered, cGMP-compliant, and UL-certified facility. Ask for proof. |

| Ingredient Sourcing | The final product is only as good as its raw materials. Traceability is key to potency and safety. | Transparent sourcing practices, Certificate of Analysis (CoA) for every ingredient. |

| In-House R&D Team | An R&D team helps refine your formula, improve flavor, and ensure stability. | A dedicated team of scientists and formulators, not just a sales rep. |

| Scalability | You need a partner who can support you from a small test batch to large-scale production runs. | Ask about their capabilities for pilot runs and their maximum production capacity. |

| Minimum Order Quantity (MOQ) | A high MOQ can be a barrier for new brands. Flexibility here shows they support emerging businesses. | Reasonable MOQs that align with your launch strategy and budget. |

| Communication | Clear, proactive communication is the foundation of a good partnership and avoids costly mistakes. | A dedicated point of contact who is responsive, knowledgeable, and transparent. |

Vetting a partner thoroughly using these pillars will pay dividends, ensuring you build your brand on a foundation of quality and trust from day one.

Decoding Quality and Compliance Standards

When vetting a Dong Quai Root private label contract manufacturer, your first conversation must be about quality and compliance. These standards are the absolute bedrock of your business, protecting your brand, your customers, and your investment.

Think of it this way: certifications are your brand's insurance policy. They offer undeniable, third-party proof that a manufacturer isn’t cutting corners. A missing credential isn't a small detail—it's a giant red flag that can lead to costly recalls, regulatory actions, and damage to your brand reputation.

The Non-Negotiable Certifications

As a brand owner, some certifications are table stakes. If a potential partner can’t provide proof of these, walk away. No excuses.

- cGMP (Current Good Manufacturing Practices): This is the gold standard. Enforced by the FDA, cGMP dictates everything from raw material handling to final product testing and packaging, ensuring every bottle is made under the proper conditions.

- FDA-Registered Facility: This is the bare minimum. It means the manufacturer is on the FDA's radar and subject to inspection. An unregistered facility is not a legitimate U.S. supplement producer.

- UL Certified (or similar third-party audit): While cGMP is a government regulation, a UL certification shows a manufacturer has voluntarily paid for and passed rigorous independent audits. It’s a proactive step that proves they go above and beyond.

A manufacturer who proudly showcases these certifications has invested heavily in the systems needed to produce your Dong Quai supplement correctly, every single time. That’s the kind of consistency that builds ironclad customer trust.

Why Third-Party Testing Is Your Ultimate Safety Net

Even the best in-house lab can have blind spots. Real quality assurance comes from an unbiased, outside source. A top-tier contract manufacturer doesn't just do their own checks; they consistently send product batches to independent, third-party labs for analysis.

This external verification does two critical things:

- It Verifies Purity: The lab screens for contaminants like heavy metals, pesticides, and microbes. A contaminated batch could be devastating to your brand's reputation.

- It Confirms Potency: The lab confirms that the amount of active compounds—like alkylphthalides in Dong Quai—is exactly what your label claims. Mislabeled potency is a fast track to an FDA warning letter.

Imagine launching your product, only to have a random test reveal it contains half the Dong Quai extract promised on the bottle. This isn't a hypothetical; it has tanked brands. Third-party testing is your essential shield against this kind of disaster.

When you're vetting a Dong Quai Root private label contract manufacturer, don't be shy. Ask to see their Certificates of Analysis (CoAs) for both raw ingredients and finished products. A transparent, confident partner will provide them without hesitation. That's how you know their commitment to quality is real.

Bringing Your Unique Dong Quai Formula to Life

A true manufacturing partner does more than fill bottles—they should be your innovation engine. This is where you move beyond a generic product and create a liquid Dong Quai supplement that stands out. It’s your chance to craft a unique formula with a specific flavor, viscosity, and bioavailability that speaks directly to your ideal customer.

The difference between a lackluster herbal supplement and an exceptional one often comes down to lab technology. Dong Quai root contains delicate, volatile compounds like alkylphthalides and ferulic acid. Old-school, high-heat extraction methods can degrade these vital components, leaving you with a less effective product.

This is exactly why we leverage forward-thinking processes.

- Modern Botanical Extraction: We use advanced, temperature-controlled extraction methods. This gentle process protects the full spectrum of active compounds, ensuring your final product delivers the potency your customers expect.

- Cold-Fill Processing: Instead of pasteurizing formulas with high heat—which can destroy nutrients and alter flavor—we use cold-fill technology. This innovative approach preserves the formula's integrity, taste, and nutritional value, a non-negotiable for sensitive botanicals like Dong Quai.

From a Simple Idea to a Finished Product

Let's look at a real-world example. A wellness startup approached us with an idea: a Dong Quai blend for women's post-workout recovery. Their vision was to pair its traditional properties with botanicals that aid muscle relaxation and hormonal balance after a tough gym session.

They had a great concept but needed a Dong Quai Root private label contract manufacturer to bring it to life.

We immediately became their R&D partner. Our formulation team brainstormed synergistic ingredients, landing on peony root for muscle relaxation and goji berry for antioxidant support. We then created small pilot batches, fine-tuning the natural sweetener levels until the flavor was perfect—earthy and pleasant, with no artificial aftertaste.

The collaboration was seamless. We went from a whiteboard concept to a shelf-ready, market-tested product with rapid turnaround. It demonstrated what a true partnership looks like: combining their brand vision with our scientific and production expertise.

Dong Quai Product Format Comparison

The format you choose for your Dong Quai supplement impacts both manufacturing and customer connection. A liquid tincture offers different benefits than a capsule, powder, or gummy. This is a strategic choice based on your target audience.

To help you decide, here's a quick comparison of common formats.

| Product Format | Manufacturing Complexity | Consumer Appeal | Ideal Use Case |

|---|---|---|---|

| Liquid Tincture | Moderate | High bioavailability, fast-acting, easy to adjust dosage. | Brands targeting rapid relief or consumers who dislike swallowing pills. |

| Capsules | Low | Tasteless, convenient, precise dosage. | Mass-market appeal, easy to stack with other daily supplements. |

| Powders | Moderate | Flexible dosing, can be mixed into smoothies or drinks. | Active lifestyle brands, customers who prefer functional beverages. |

| Gummies | High | Excellent taste, fun and easy to take. | Brands targeting younger demographics or those with pill fatigue. |

Ultimately, developing a unique formula is about more than an ingredient list. It’s about leveraging your manufacturer's expertise in processing, flavoring, and formatting to create a product that solves a real problem for your customers and builds lasting brand loyalty.

Bringing Your Dong Quai Supplement from Concept to Market

Taking a product from idea to a physical bottle can feel overwhelming. Many manufacturers keep their process a secret, but we believe in pulling back the curtain.

As your Dong Quai Root private label contract manufacturer, we see the production journey as a clear, collaborative roadmap. Our entire process is built on transparency, proactive communication, and on-time delivery.

It begins with a deep dive into your formula. Our R&D experts work with you to nail down the vision. Once locked, our sourcing team meticulously vets every raw material supplier, demanding a Certificate of Analysis (CoA) for every batch of Dong Quai root to confirm its identity, purity, and potency before it enters our facility.

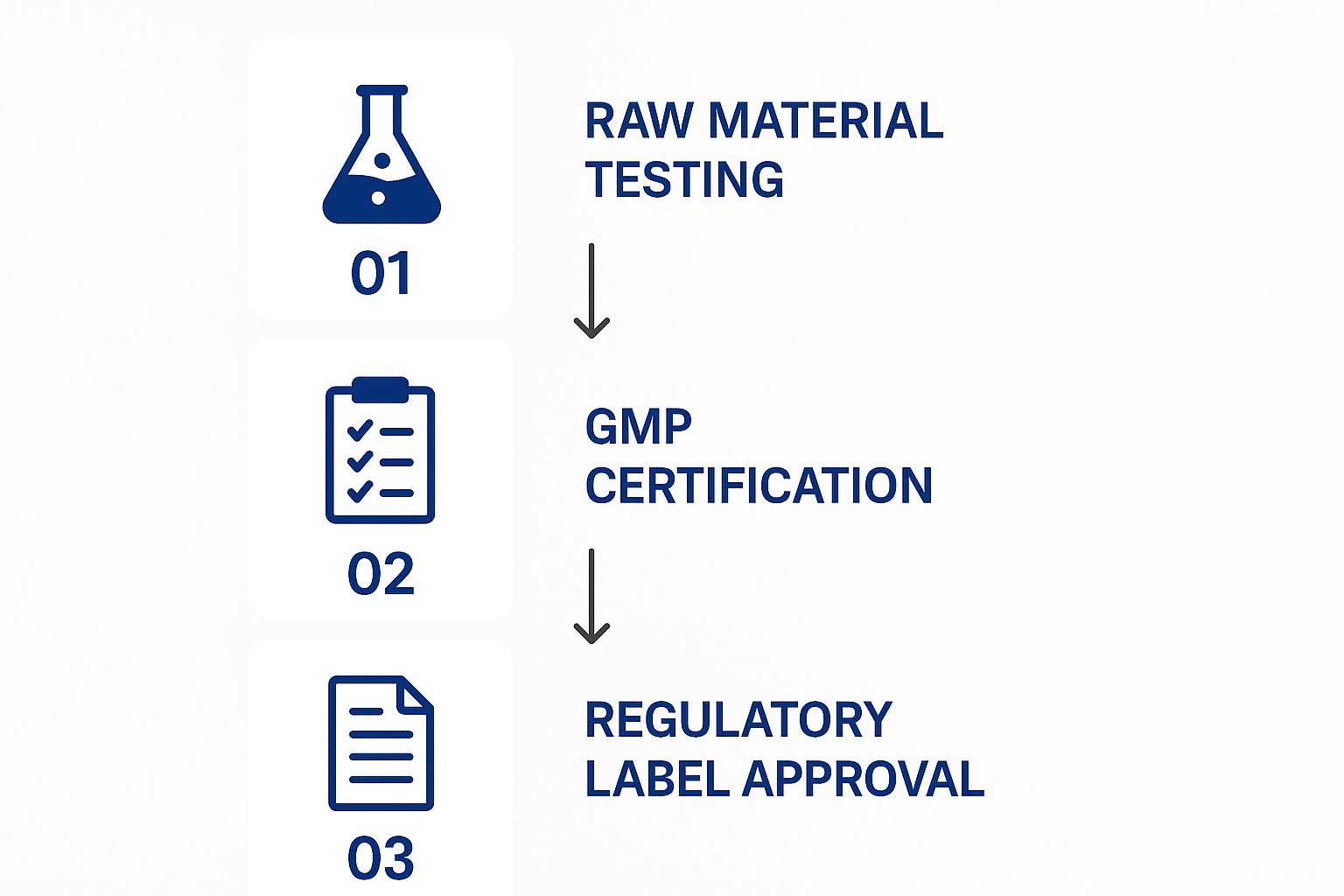

This infographic breaks down the core compliance checkpoints every batch of your product will go through.

This structured workflow ensures that from raw ingredient sourcing to final label application, your supplement is built on a foundation of verified quality and strict compliance.

From Pilot Batch to Full-Scale Production

With raw materials approved, we move to the pilot batch: a small, controlled run for your final sign-off. You’ll sample the product to confirm the flavor, color, and texture meet your exact specifications, eliminating surprises before we scale up.

While you review the pilot batch, our teams move on other critical tasks in parallel:

- Label & Packaging Compliance: Our regulatory specialists review your label design to ensure it meets all FDA guidelines, saving you from the cost and hassle of reprints or compliance issues.

- Production Scheduling: We map out the complete timeline for your full production run, providing a reliable launch date to anchor your marketing and sales strategies.

This isn't just about manufacturing; it’s about setting you up for a successful launch. A true partner manages the complex logistics and provides proactive updates, so you can focus on what you do best: building your brand.

Final Checks and Getting to Market on Time

Once you approve the pilot batch, we accelerate. Your full production run is scheduled in our cGMP-certified, FDA-registered facility. Here, our advanced cold-fill technology and precision batching systems ensure every bottle is identical to the last.

Before anything leaves our facility, it undergoes a final, rigorous Quality Assurance (QA) screening. This includes sending samples for third-party lab testing, which provides an unbiased confirmation of your product's potency and purity.

The Dong Quai market is heavily focused on women's health, driving roughly 70% of all sales. E-commerce now accounts for over 40% of total revenue for private label brands. We get the urgency. Our process is designed for speed and reliability, ensuring your product is delivered on time, every time, ready to capture the market. For more industry context, you can explore further insights on Expert Market Research.

Critical Questions to Ask Any Manufacturer

Signing with a private label manufacturer is a serious commitment. Before you do, you need to dig deeper than the price-per-unit. Asking the right questions reveals a company’s true capabilities, dedication to quality, and whether they genuinely operate with a partnership mindset.

Think of this as your final interview. The answers will tell you everything you need to know about working with them.

Uncovering Sourcing and Quality Protocols

Your supplement's integrity starts and ends with the raw Dong Quai root. You need absolute confidence in your manufacturer’s supply chain. Vague answers here are a massive red flag.

Ask directly:

- “Walk me through your sourcing and verification process for Dong Quai root. How do you qualify a new supplier?”

- “Can you provide a Certificate of Analysis (CoA) for a recent batch of Dong Quai from both the raw material supplier and a third-party lab?”

- “How do you guarantee batch-to-batch consistency for key active compounds like alkylphthalides?”

A top-tier partner will proudly explain their robust verification process and provide documentation to prove their ingredients are pure and potent.

A confident manufacturer won’t just tell you they value quality; they'll show you the paperwork. If they hesitate to share CoAs or third-party test results, it’s a clear sign their quality systems aren't as solid as they claim.

Gauging Flexibility and Partnership

Your needs will evolve. You might start with a small pilot run and scale to massive orders a year later. You need a partner who can grow with you. These questions test their flexibility and commitment to your success.

Get specific about your working relationship:

- “What are your Minimum Order Quantities (MOQs) for an initial pilot run and a full-scale production run?”

- “Who will be my dedicated point of contact, and what is your standard process for project communication?”

- “How do you handle unexpected challenges, like a raw material delay or a formulation issue?”

A true partner gets it. They offer flexible MOQs to support startups and have a clear communication system. They can describe how they solve problems collaboratively, not just report bad news. For a deeper dive on the manufacturing relationship, check out our guide to nutraceutical contract manufacturing.

Arming yourself with these questions helps you cut through the sales pitch and evaluate any Dong Quai Root private label contract manufacturer on the criteria that truly matter for a successful, long-term partnership.

Your Private Label Manufacturing FAQs

Starting a new supplement launch always brings up questions. We get it. As your potential Dong Quai Root private label contract manufacturer, we believe in being an open book. Let's tackle some of the most common questions we hear from health and wellness entrepreneurs.

Our goal is to give you the clarity you need to move forward with confidence.

How Is My Custom Formula Protected?

This is a critical question, and the answer should be simple: with a rock-solid Non-Disclosure Agreement (NDA). Before discussing the details of your proprietary blend, we sign a mutual NDA. This legally binding document protects your unique formula, ingredient ratios, and innovative ideas. They remain your exclusive intellectual property.

We see ourselves as your trusted production partner, not a competitor. Your formula's success is your brand's success, and we are committed to protecting it.

What Factors Influence the Cost Per Unit?

Several key variables affect the final per-unit price. Understanding them helps you balance premium quality with your budget.

- Raw Material Quality: The grade and sourcing of the Dong Quai root is a major cost driver. Certified organic or wild-harvested roots command a higher price than standard grades.

- Formula Complexity: A simple Dong Quai tincture is less expensive to produce than a complex formula with other premium botanicals or proprietary extracts.

- Order Volume: This is a big one. Larger production runs almost always lower the cost-per-unit, thanks to economies of scale in sourcing, setup, and labor.

What Is a Typical Production Timeline?

From finalizing your concept to receiving the finished product, a standard timeline is typically 8-12 weeks. This can vary based on formula complexity and the sourcing time for unique raw materials.

A true partner will provide a transparent project plan with clear milestones, so you're never left wondering about progress. You can get a better feel for this process in our comprehensive guide for starting your own private label brand.

Remember, manufacturing is one piece of the puzzle. Building a brand requires its own game plan. It's smart to start thinking about strategies for boosting private label brand success now, so you’re ready for a powerful launch.

Ready to turn your vision for a market-leading Dong Quai supplement into reality? The team at Triton Nutra Group is here to be your dedicated R&D and manufacturing partner. Request a free quote today!