Your Partner's Guide to Dietary Supplement Packaging

Discover the essentials of dietary supplement packaging. Our guide covers materials, FDA compliance, and choosing the right manufacturing partner.

Get a Free Quote Today!

Get a Free Quote Today!Choosing the right dietary supplement packaging isn't just about picking a container. It’s a critical business decision that impacts product integrity, regulatory compliance, and how your brand stands out on a crowded digital shelf. For e-commerce founders and brand managers in the health and wellness space, think of it as your product's first—and most important—handshake with the customer.

Your Guide to Strategic Supplement Packaging

Your packaging is your silent salesperson. It’s the first physical interaction a customer has with your product, making it a powerful tool for building trust and communicating the quality of your liquid herbal supplements before they even try what’s inside.

This isn’t just about a box or a bottle; it’s a strategic asset. The global dietary supplement packaging market was valued at around USD 23.79 billion in 2024 and is expected to hit USD 35.42 billion by 2032. This rapid growth highlights how critical packaging has become in a competitive industry. You can discover more insights about dietary supplement packaging trends to see where the market is headed.

In this guide, we'll break down everything you need to know, from advanced material selection to FDA labeling, so you can make informed decisions. As a cGMP, UL certified, and FDA-registered facility, we're not just a supplier; we're your R&D partner from concept through launch. We’ll help you navigate the process and avoid common pitfalls.

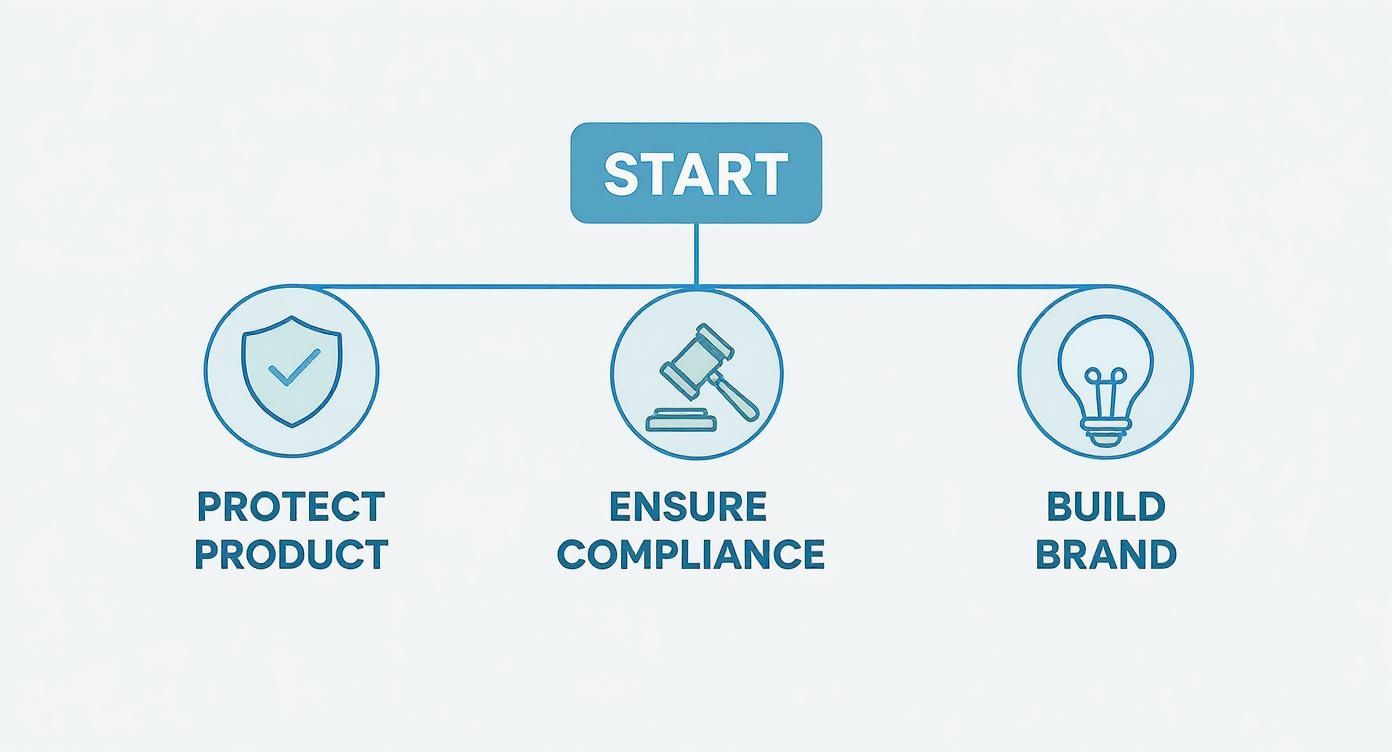

Core Pillars of Packaging Success

To build a product that lasts, your packaging strategy must nail three essential functions. Get these right, and you're well on your way.

-

Product Protection: First and foremost, the package must maintain the stability and efficacy of your formula. From the moment it leaves our facility to when it lands in your customer's hands, it has to be safeguarded from degradation by light, moisture, and oxygen. Our expertise in botanical extraction and cold-fill technology ensures your formula starts pure and stays potent.

-

Regulatory Compliance: This part is non-negotiable. Your packaging must meet all legal requirements, which means accurate labeling, tamper-evident seals, and full adherence to cGMP standards. This protects your customers and shields your business from serious liability. Our commitment to quality and compliance is unwavering.

-

Brand Communication: Your packaging has to tell your brand’s story at a glance. The materials you choose, the design you land on, and the unboxing experience all work together to broadcast your values—whether that's clinical precision, all-natural purity, or cutting-edge innovation.

Your packaging is the bridge between your formula and your customer. It must be strong enough to protect the product, clear enough to meet regulations, and compelling enough to build a loyal following.

Ultimately, getting your supplement packaging right requires a holistic view. It's a true partnership between your vision and our manufacturing expertise, ensuring every choice—from the type of plastic resin in the bottle to the finish on the label—serves your brand’s long-term goals.

Before we dive into specific packaging types, let's look at the key strategic factors you'll need to weigh. Use this as a quick-reference checklist to keep your priorities in order.

Key Packaging Considerations at a Glance

| Factor | Why It Matters for Your Brand | Example Question to Ask |

|---|---|---|

| Product Stability | Does the packaging protect your formula from degradation caused by light, moisture, or air? | "Is this material's oxygen barrier sufficient for my probiotic formula?" |

| Regulatory & Labeling | Does it meet FDA, cGMP, and other legal requirements, including tamper-evident and child-resistant features? | "Does my label design leave enough space for the full Supplement Facts panel and required disclaimers?" |

| Brand Storytelling | Does the look and feel align with your brand's identity and appeal to your target customer? | "Does a sleek glass bottle better communicate our premium positioning than a standard plastic pouch?" |

| Fulfillment & Logistics | Is the packaging durable, lightweight, and compatible with your sales channels (e.g., Amazon FBA)? | "Will this container survive a 3-foot drop test, and what are its dimensional weight shipping costs?" |

| Cost & MOQs | What is the per-unit cost, and does the minimum order quantity fit your budget and sales forecast? | "Can we start with a lower MOQ for our initial pilot run and get better pricing as we scale?" |

| Sustainability | Does the packaging use recycled materials or offer a responsible end-of-life option for your customers? | "Is there a post-consumer recycled (PCR) plastic option available for these bottles?" |

| Lead Times | How long will it take to source, print, and receive your packaging components? | "What is the lead time for custom-printed pouches, and how does that fit into our overall production timeline?" |

Thinking through these factors upfront will save you from costly mistakes and headaches down the road. Every decision you make here has a ripple effect on your supply chain, budget, and brand perception.

Selecting the Right Packaging Materials and Formats

Deciding on the right container for your liquid supplement is one of the most critical choices you'll make. This isn’t just about picking a bottle; it’s about protecting the formula you’ve invested in, shaping your customer’s perception, and managing your bottom line.

As your manufacturing partner, our job is to guide you through the options. We don't just show you a catalog. We analyze your specific formula, your target audience, and your business goals to find the packaging solution that actually works for you. This is a collaborative process, not just a logistical decision.

Comparing Glass and Plastic Containers

The first fork in the road is almost always glass versus plastic. Each material brings its own set of pros and cons, especially for sensitive liquid herbal extracts that can be easily affected by their environment.

-

Glass Bottles (Amber, Cobalt, Clear): Nothing says "premium" like glass. It has a high-quality feel that instantly connects with discerning consumers. For product protection, amber and cobalt glass are the gold standard for blocking UV radiation, which can quickly degrade the active compounds in botanicals. Think of an amber bottle as built-in sunglasses for your supplement—it preserves potency and extends shelf life. Glass is also infinitely recyclable and chemically inert, meaning it won't leach anything into your product. The main drawbacks? It's heavier, which increases shipping costs, and it can break.

-

Plastic Bottles (PET & HDPE): Today’s plastics are incredibly versatile and tough. PET (polyethylene terephthalate) is prized for its glass-like clarity and strength, making it a great option if you want to showcase a brightly colored liquid. HDPE (high-density polyethylene) is more opaque and rigid, offering solid chemical and impact resistance. Both are lightweight, shatter-resistant, and more budget-friendly—a huge win for e-commerce brands managing shipping weights and breakage. The key is ensuring the plastic has the right barrier properties to prevent oxidation from compromising your formula.

This decision often comes down to what you're trying to achieve with your brand.

As this flowchart shows, every packaging choice should be rooted in one of three core pillars: protecting the product, ensuring compliance, or building the brand.

Choosing the Right Format and Dispenser

Once you've settled on a material, the next step is choosing the format. This is all about the customer experience—how they will use your product every day. The right format can make your product a seamless part of their routine and a real point of difference from competitors.

For liquid supplements, you'll typically see a few popular options:

- Boston Round Bottles with Droppers: The classic setup for tinctures and herbal extracts for a reason. It allows for precise, measured dosing, and a calibrated glass dropper adds a touch of scientific accuracy that builds consumer trust.

- Bottles with Pump Tops: Perfect for lotions, serums, or any liquid that's a bit thicker. A pump delivers a consistent, controlled amount with every press, making it easy and mess-free.

- Single-Serving Sachets or Stick Packs: These are all about convenience and portability. They're fantastic for on-the-go lifestyles, travel, or sampling programs. Plus, each dose is perfectly measured and protected until use.

- Sprayers: Fine-mist sprayers are the go-to for oral supplements or throat sprays, offering direct and simple application.

The best format is the one that fits how your product is used and how your customer lives. A high-potency sleep formula is a natural fit for a dropper, while a daily energy shot makes more sense in a single-serving pack.

Material safety is non-negotiable. We ensure every component that touches your product is food-grade and contaminant-free. Part of our quality assurance process involves understanding complex VOC product emission testing methods to guarantee no harmful compounds migrate from the packaging into the supplement. When you partner with us, we handle that compliance burden, so you can be confident your packaging is as safe as it is effective.

Navigating FDA Labeling and Compliance

You can have a groundbreaking formula and a beautiful bottle, but if your label isn't compliant, your launch is dead in the water. This is where many promising brands get tripped up, facing expensive delays or even legal challenges.

Think of your label less as a marketing flyer and more like a legal document. It demands precision, total accuracy, and a solid understanding of FDA regulations.

Your product’s label falls under the authority of the Dietary Supplement Health and Education Act (DSHEA), which lays out strict rules for what you must say and how you must say it. As your partner, our job is to cut through this complexity and shield you from regulatory risk. We ensure every piece of your dietary supplement packaging meets every legal standard, so you can go to market with confidence.

The Anatomy of a Compliant Label

Every supplement label has several required components that must be present and formatted correctly. These aren't suggestions; they're federal requirements designed to keep consumers safe and informed. Let’s walk through the essential elements on the Principal Display Panel (the front of your package) and the information panel.

- Statement of Identity: This clearly answers the question, "What is this?" Think "Herbal Supplement" or "Vitamin D Dietary Supplement." It must be front and center.

- Net Quantity of Contents: This tells your customer exactly how much product is inside, listed in both metric and U.S. customary units (e.g., 60 Capsules or 2 fl oz (59 mL)).

- Name and Place of Business: Your label must show the name and address of the manufacturer, packer, or distributor.

These foundational pieces set the stage for the most important part of your label—the Supplement Facts panel.

Mastering the Supplement Facts Panel

The Supplement Facts panel is the heart of your label's compliance. It’s a standardized format that lets consumers see exactly what’s in your product and how much. Ever since the FDA's Dietary Supplement Labeling Guide was published, this panel has become a non-negotiable, highly regulated feature.

The FDA gets specific on everything from font size to line thickness to ensure it's readable. Read the full details from the FDA to see just how detailed the requirements are.

To help you get organized, here’s a quick checklist of what you'll need to include on your label.

FDA Labeling Checklist For Dietary Supplements

This table breaks down the must-have legal requirements versus the optional (but often smart) marketing elements for your label design.

| Label Component | Requirement Level | Best Practice Tip |

|---|---|---|

| Statement of Identity | Mandatory | Be clear and direct (e.g., "Vitamin C Supplement"). Avoid vague or misleading terms. |

| Net Quantity of Contents | Mandatory | Display prominently on the front panel in both metric and U.S. customary units. |

| Supplement Facts Panel | Mandatory | Follow FDA formatting rules precisely. Use a professional designer familiar with these rules. |

| Ingredients List | Mandatory | List all "Other Ingredients" (inactive ones like fillers) below the Supplement Facts panel. |

| Name & Address of Business | Mandatory | This builds trust and is required for regulatory contact. A PO Box is generally not sufficient. |

| Health/Structure/Function Claims | Optional | All claims must be truthful and not misleading. You must have scientific evidence to back them up. |

| "Free-From" Claims (e.g., Gluten-Free) | Optional | If you make a claim like this, you must be able to prove it with testing and documentation. |

| Third-Party Certifications (e.g., Non-GMO) | Optional | These logos can build significant consumer trust but require a rigorous certification process. |

While the mandatory items are non-negotiable, the optional claims are where you can strategically position your brand—as long as you have the data to support them.

The Supplement Facts panel itself must include:

- Serving Size: The recommended amount to take at one time.

- Servings Per Container: The total number of servings in the package.

- Dietary Ingredients: A full list of all active ingredients.

- Amount Per Serving: The quantity of each ingredient in one serving.

- % Daily Value (%DV): How much a nutrient in a serving contributes to a total daily diet.

Any inactive ingredients, like flow agents or capsules, must be listed separately below the panel under the heading "Other Ingredients." Getting this right can feel overwhelming, which is why our team provides in-depth guidance. To dig even deeper, check out our complete breakdown of the dietary supplement labeling guidelines.

Beyond the Panel: cGMP and Consumer Safety

Compliance isn't just about what's printed on the label. It’s also about the physical integrity of the packaging itself. This is where Current Good Manufacturing Practices (cGMP) are critical.

cGMP regulations are the bedrock of product safety. They mandate that your packaging operations prevent mix-ups, contamination, and errors, ensuring the label on the bottle perfectly matches the product inside.

This is why tamper-evident seals are an absolute must. A tamper-evident seal—like the foil liner under a cap or a plastic shrink band around the lid—gives the customer visible proof that the product hasn't been touched since it left our facility.

It’s a simple feature that builds tremendous trust and is a core part of our cGMP-compliant process. As your partner, we handle these details, making sure every single unit that ships from our UL certified, FDA-registered facility is safe, compliant, and ready to build your brand’s reputation.

Optimizing Packaging for E-commerce and Retail

Selling your supplements online is a different ball game than stocking them on a physical shelf. When you’re shipping direct-to-consumer, your packaging must do more than just look good—it needs to be tough enough to survive the journey from our warehouse to your customer's door. We plan for your entire supply chain from day one.

The digital shelf demands a unique approach. In a store, customers can pick up a bottle and feel its weight. Online, your first impression is a photo. Your packaging needs to pop on screen and be structurally sound enough for shipping. It has to handle drops, vibrations, and temperature shifts without breaking a sweat (or a seal).

Mastering Amazon FBA and Third-Party Logistics

Platforms like Amazon FBA (Fulfillment by Amazon) have their own strict rules. Get them wrong, and you're looking at rejected inventory or surprise fees. It can feel like navigating a minefield, but we’re here to guide you.

Here’s what you need to get right for e-commerce:

- Barcode Standards: Every unit requires a scannable barcode, usually a UPC or an Amazon-specific FNSKU label. We ensure these are printed clearly and positioned correctly to avoid scanning headaches at the fulfillment center.

- Shipping Durability: Your product has to survive a drop test. This means choosing bottles and caps that won't crack or leak under pressure. We often recommend adding extra security, like shrink bands or induction seals, to keep everything locked down.

- Multipacks and Bundles: Selling a 3-pack? It needs to be packaged as a single unit ready for sale. We create custom-kitted sets for you, complete with a "Sold as a Set" or "Do Not Separate" label so warehouse staff don't accidentally break them apart.

Selling supplements on Amazon is a specialized skill. If that's your primary channel, it pays to do your homework. We highly recommend checking out a complete guide on how to sell supplements on Amazon to get a handle on its unique challenges.

The Power of the Unboxing Experience

For any e-commerce brand, the shipping box is your new storefront. That moment of unboxing is the first real, physical interaction a customer has with your brand. It's a golden opportunity to make a connection, reinforce your quality, and earn rave reviews.

In e-commerce, the shipping box isn't just for protection; it's the stage for your brand's first impression. A thoughtful unboxing experience transforms a simple delivery into a rewarding brand moment.

Consider using secondary packaging, like a custom-printed mailer or branded tissue paper. It does more than just protect the bottle; it crafts a premium, memorable experience. It signals that you care about the details. This small investment can have a huge impact on how customers perceive your brand's value.

As your partner, we ensure your packaging is ready for any sales channel. Whether it's ensuring you're FBA compliant or designing an unboxing experience that gets people talking, we build a packaging strategy that aligns with your business goals. To dive deeper into the world's biggest online marketplace, take a look at our guide on how to sell supplements on Amazon. We bring the reliability and expertise you need to win online.

Getting Real About Packaging Costs and Sustainability

Picking the right packaging is a balancing act. You're juggling budget, brand values, and the realities of manufacturing and shipping. Every choice, from material to design, hits your bottom line. As your manufacturing partner, we provide full transparency on these costs so you can make smart decisions that work for your wallet and your brand’s mission.

This is where a true partnership matters. We don't just give you a menu of options; we help you weigh the pros and cons of each. We'll break down how your material choices, order size, and design complexity affect your final per-unit cost. No surprises, just clear information.

What’s Really Driving Your Packaging Costs?

Your packaging cost isn’t a random number. It’s the result of a few key factors. Understand these, and you can pull the right levers to hit your target cost-of-goods-sold (COGS) without cheapening your product.

Here are the big drivers that will shape your budget:

- Material Selection: Glass almost always has a higher upfront cost than plastic. Even within plastics, specialty resins with extra-strong barrier properties will carry a premium.

- Order Volume: This is a major factor. Your minimum order quantity (MOQ) significantly impacts your price. Larger orders mean better per-unit pricing because we can run our equipment more efficiently.

- Customization and Complexity: A standard amber bottle is a cost-effective workhorse. A custom-molded container in a unique brand color will cost more. The same goes for printing; a simple pressure-sensitive label is cheaper than multi-color screen printing or an embossed logo.

We understand that not everyone is ready for a massive production run out of the gate. That's why we offer flexible run sizes, from smaller pilot batches to full-scale production. This lets you test the market without a huge financial commitment and scale up smoothly as you grow.

The Shift to Sustainable Packaging

Today's customers want more than just a great product. They want to buy from brands that share their values. More shoppers are actively looking for eco-friendly packaging. For modern brands, sustainability isn't an afterthought—it's a core part of their identity.

But switching to greener options requires a realistic look at the costs and benefits. Here are two popular paths:

- Recycled PET (rPET): A fantastic option for cutting down on virgin plastics. It’s made from post-consumer recycled materials and performs almost identically to standard PET. The trade-offs? It usually comes with a slightly higher price tag and can sometimes have minor inconsistencies in clarity.

- Glass: As a material that can be recycled forever, glass is a champion of sustainability. It also has a premium feel that can help justify a higher price point for your product. The downside is its weight, which increases shipping costs and its carbon footprint during transit.

Choosing sustainable packaging is an investment in your brand's story. It signals your values to a market that's paying close attention. But that choice must be balanced with practical considerations like cost, performance, and supply chain reliability.

Planning for Supply Chain Realities

The packaging you choose affects more than your costs; it has a huge impact on your production timeline. Specialty materials or custom-made components will have longer lead times than standard, in-stock options. Getting this right is critical for a smooth product launch.

For example, custom-colored glass bottles from an overseas supplier can easily take 12-16 weeks. In contrast, standard amber PET bottles might be ready in just 2-4 weeks. That's a massive difference that can seriously affect your time-to-market.

This is another area where we act as your partner. We provide transparent timelines from the start. We’ll help you map out the entire schedule, accounting for the lead time on every single component—from the bottle and cap to the label and shipping box. This proactive planning prevents last-minute emergencies and ensures we hit your launch date.

How to Choose Your Manufacturing Partner

Getting your dietary supplement packaging right is only half the battle. The other half is choosing the right partner to bring your product to life.

Don't think of your manufacturer as just a vendor. They are an extension of your team—the operations expert handling the complex logistics so you can focus on building your brand. A great partner accelerates your growth; a bad one becomes a constant bottleneck.

This is a critical decision. It means looking past the price quote and digging into their credentials, capabilities, and philosophy. This is how you find a true collaborator, not just an order-taker.

Vetting Credentials and Certifications

First, verify their qualifications. Credentials are your first line of defense against quality control issues and regulatory headaches. They are objective proof that a manufacturer holds themselves to the highest industry standards.

Look for these key certifications:

- cGMP Compliance: Current Good Manufacturing Practices are the absolute foundation of supplement quality. A cGMP-certified facility proves they have robust systems to prevent contamination, mix-ups, and errors.

- FDA-Registered Facility: This confirms the manufacturer operates under the oversight of the U.S. Food and Drug Administration. It’s a non-negotiable requirement for any supplement sold in the U.S.

- UL Certification: An independent, third-party certification from a group like UL Solutions demonstrates an even deeper commitment to safety and quality control, often involving rigorous facility audits that go beyond standard requirements.

These aren't just logos for a website. They are your guarantee that your products will be made safely and consistently, batch after batch.

Finding a Partner Who Can Scale With You

Your business will evolve, and you need a manufacturing partner who can keep up. Look for flexibility in production volume. A partner who only does massive runs is useless to a startup, but one who can't handle larger orders is a dead end for a growing brand.

A true partner meets you where you are. They should offer the flexibility for small pilot batches when you're testing a new product, then seamlessly scale up to full production as your sales explode—all without ever sacrificing quality.

This flexibility is everything. It lets you launch new formulas without betting the farm on a massive inventory run. We are set up to handle everything from initial R&D batches to large-scale manufacturing, paving a smooth road for your growth. For more on this, check out our in-depth guide on finding a reputable supplement manufacturer for your business.

Beyond Manufacturing: The Partnership Mindset

At the end of the day, you're looking for more than a factory. You need a strategic ally—an R&D partner who’s with you from the initial concept all the way through launch.

The best manufacturers offer support that goes way beyond the production line. This could mean in-house stability testing to confirm your product's shelf life or expert guidance on formulation to dial in efficacy and flavor.

This partnership mindset is built on a foundation of Quality, Customization, and Reliability. It's about having a dedicated team you can call for advice, transparent timelines you can count on, and the confidence that every unit they ship proudly represents your brand’s promise of excellence.

Your Top Supplement Packaging Questions, Answered

Jumping into the world of supplement packaging always brings up a few key questions. We get it. You have a vision, and now you need to figure out the practical side of things. Here are the straight answers to the most common questions we hear from brand owners like you.

What’s a Realistic Minimum Order Quantity (MOQ)?

This is a big one, and the honest answer is: it depends. Minimum order quantities, or MOQs, vary widely based on how custom you want to get. A fully custom-colored glass bottle, for example, will have a much higher barrier to entry than a standard amber PET bottle we keep in stock.

But we know every brand has to start somewhere. That’s why we offer flexible run sizes designed to help your business grow. We can kick things off with small pilot batches so you can test the market, prove your concept without a huge financial leap, and then easily scale up to full production when you’re ready.

How Long Does This Whole Packaging Thing Take?

The timeline from "go" to "goods in hand" hinges on a few moving parts. We need to finalize your label design, source the exact bottles and caps you’ve chosen, and factor in our production schedule.

A solid timeline is everything for a smooth launch. Realistically, you should plan for the entire process—from design approval to receiving your finished products—to take between 6 to 12 weeks.

We're all about speed and reliability, so we provide a transparent timeline from the start. We’ll map out every step so you know exactly what’s happening and when, which lets you line up your marketing and lock in a launch date without any guesswork.

What Kind of Quality Testing Do You Do?

For us, quality and compliance are the foundation of everything we do. We run a series of rigorous tests to ensure your supplement packaging not only protects your formula but also meets every safety standard.

Our quality assurance process is locked down and includes:

- Compatibility Testing: We make sure your liquid formula and the packaging materials work together perfectly, with no leaching or degradation over time.

- Stability Testing: We confirm your product stays potent, pure, and physically stable for its entire shelf life within its final container.

- cGMP Adherence: Every step of our process adheres to strict cGMP (Current Good Manufacturing Practices) to eliminate any risk of contamination or labeling mix-ups. This is confirmed by our third-party certifications.

This obsessive attention to detail means you can rest easy, knowing your product is safe, stable, and completely ready for your customers.

At Triton Nutra Group, we’re more than just a manufacturer—we’re the strategic partner you need to build a standout supplement brand. From untangling tricky regulations to picking that perfect bottle, we have the expertise and support to bring your vision to life.

Ready to get started? Request a free consultation and quote today and let's build something great together.