Your Partner in Custom Liquid Vitamin Manufacturing: A Founder's Guide

Your expert guide to custom liquid vitamin manufacturing. Learn the process from formula to fulfillment and launch your health brand with confidence.

Get a Free Quote Today!

Get a Free Quote Today!Working with a specialized manufacturer to create a custom liquid supplement is a true partnership. It's like having an extension of your own R&D team—your collaborator from concept through launch, dedicated to turning your unique vision into a top-quality product that speaks directly to your ideal customer.

Bringing Your Liquid Vitamin Vision to Life

Every incredible supplement brand starts with a single, powerful idea.

Maybe you’ve spotted a gap in the market for high-potency vegan D3+K2 drops. Or perhaps you're an entrepreneur tired of seeing kids’ multivitamins loaded with junk and want to create one that actually tastes amazing and is good for them. It could even be a new botanical blend for stress relief that’s far more bioavailable than a standard capsule.

That journey from an initial concept to a bottled, shelf-ready product can feel overwhelming. But when you team up with the right manufacturing partner, it becomes a clear, strategic, and even exciting process. This is where custom liquid vitamin manufacturing truly shines—it’s not about grabbing a generic formula off a shelf, but a deep, collaborative dive into making something exclusively yours.

Why Choose Custom Liquid Vitamins

The demand for personalized and convenient health solutions is on the rise. Today's consumers are savvy; they do their homework and actively look for products that fit their specific dietary needs, ethical standards, and lifestyles.

The market data backs this up. The global liquid vitamins market was valued at USD 28.16 billion in 2025 and is on track to hit USD 42.62 billion by 2032. That’s not a fluke—it’s fueled by a clear preference for supplements that are easier to take and offer better absorption than old-school pills.

For an e-commerce founder or wellness entrepreneur, this is a massive opportunity. Liquid supplements just make sense for so many people.

- Enhanced Bioavailability: The body can absorb nutrients from a liquid far more quickly and efficiently. There’s no solid pill that needs to be broken down first.

- Ease of Use: They are the perfect solution for kids, older adults, or anyone who struggles with swallowing pills.

- Flexible Dosing: A dropper makes it incredibly simple for users to adjust their dosage, which is a huge selling point for anyone seeking a more personalized nutrition plan.

Partnership Mindset: Think of a custom manufacturer as your dedicated R&D partner. We're here to translate your brand's mission into a safe, effective, and marketable liquid supplement, guiding you from initial formula brainstorming through final launch.

To see how other brands have navigated this process, check out Fushi Wellbeing's journey.

Custom Formulation vs Off-the-Shelf Private Label

Deciding between a completely custom formula and a standard private label product is one of the first big crossroads a brand founder reaches. Private label gets you to market fast, but you sacrifice what makes your brand unique. A custom formulation, on the other hand, lets you weave your brand’s DNA right into the product itself.

So, which path is right for you? It really depends on your vision, budget, and long-term goals.

Here’s a direct comparison to help you weigh the options.

| Feature | Custom Formulation (Our Process) | Standard Private Label |

|---|---|---|

| Formula Uniqueness | 100% exclusive to your brand. You own the formula. | Generic formula sold to multiple brands. No exclusivity. |

| Ingredient Sourcing | You can select specific, patented, or branded ingredients. | Limited to the manufacturer's pre-selected stock ingredients. |

| Flavor & Profile | Fully customized to match your target audience's preferences. | Limited to a small selection of standard, pre-developed flavors. |

| Brand Storytelling | Creates a powerful, authentic story around a unique product. | Difficult to differentiate from competitors using the same base. |

| Minimum Order | Higher initial MOQs, but we offer flexible pilot runs. | Generally lower MOQs, making it easier for initial entry. |

| Launch Timeline | Longer (8-12 weeks) due to R&D, sourcing, and testing phases. | Faster (4-6 weeks) as the formula is already developed. |

While a standard private label product can feel like a shortcut, building a custom formula is about creating a true asset for your brand—something that sets you apart and gives your customers a reason to choose you over everyone else.

Crafting Your Unique Formula and Flavor Profile

This is where the magic really happens. It’s the point where we move beyond generic templates and start building your brand’s story right into the bottle. Whether you’re dreaming of a powerful elderberry immune syrup or a gentle, kid-friendly multivitamin, this is the collaborative stage where your vision meets our scientific know-how to create something truly special.

The heart of any great liquid supplement is ingredient synergy. It’s never enough to just throw popular nutrients together. The real art is in making them work in harmony to boost health benefits and, crucially, bioavailability. We spend a lot of time analyzing how different compounds interact, making sure every ingredient elevates the others instead of fighting for absorption.

Pushing the Boundaries of Bioavailability

A fantastic formula is pointless if the body can't actually use it. That's why we’re always focused on advanced delivery systems and extraction methods—we want to ensure your product truly delivers on its promise. Modern custom liquid vitamin manufacturing is all about creating supplements with superior effectiveness, moving far beyond basic liquid solutions.

Two powerful ways we do this are:

- Liposomal Delivery Systems: We wrap active ingredients, like Vitamin C or Glutathione, in a protective lipid (fat) layer. Think of it as a tiny shield that guards the nutrient against harsh stomach acids, allowing it to be absorbed much more effectively into the bloodstream. The result? Massively higher bioavailability compared to a standard liquid formula.

- Advanced Botanical Extraction: Our team uses temperature-controlled, alcohol-free extraction methods. This approach gently draws out the active compounds from herbs and botanicals without damaging their delicate structures. It preserves the full spectrum of an ingredient's benefits, ensuring the final product is as potent and pure as nature intended.

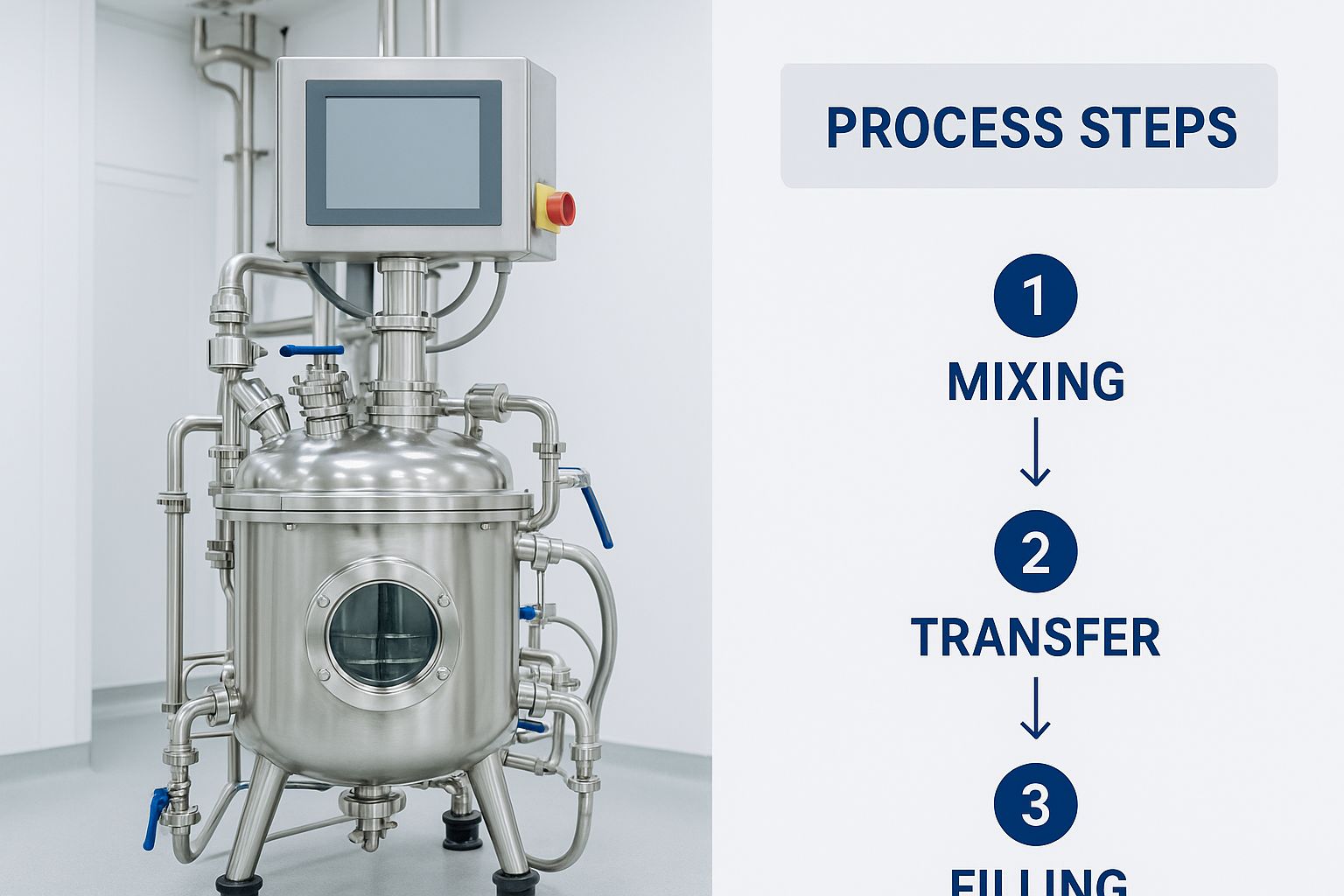

Here’s a quick look at the key steps involved in bringing a formula to life inside a sterile, controlled environment.

This just shows how meticulously each phase, from verifying raw materials to the final homogenization, is managed to produce a consistent, high-quality supplement every single time.

The Art and Science of Flavoring

Let's be honest: even the most effective formula won't succeed if people hate the taste. This is especially true for liquid supplements, where flavor is front and center. Our flavor development process is equal parts art and science, all aimed at creating a delicious profile that keeps customers coming back.

We always start by digging into your target audience. A flavor that works for athletes chugging a post-workout recovery drink will be worlds away from what you'd want in a children's daily vitamin. For example, if we're developing a vegan multivitamin for kids, we might use natural monk fruit and a mix of berry extracts to create a sweet taste that masks any mineral notes—all without adding artificial sweeteners or sugar.

Expert Insight: Our R&D team has a huge library of natural flavors and masking agents to work with. We can skillfully counteract the bitterness of certain botanicals or the metallic tang of minerals, making sure the final product isn't just tolerable, but genuinely enjoyable to take.

For something like a potent herbal tincture, the goal might be completely different. Instead of covering up all bitterness, we might lean into it, complementing the earthy notes with hints of citrus or ginger. This creates a more sophisticated flavor that signals potency to a discerning adult consumer. This ability to fine-tune the taste is a critical part of the custom liquid vitamin manufacturing process.

If you're just starting to think about your product idea, we've got a great resource to help you map things out. You can learn more in our article on starting your own custom liquid supplement brand. It gives a fantastic overview of the journey from a simple concept to a finished product on the shelf.

Guaranteeing Quality and Compliance in Every Bottle

Let's be blunt: a unique formula and a great taste don't mean a thing if the product isn't safe, pure, and potent. In the world of custom liquid vitamin manufacturing, trust is the most valuable ingredient. That trust is built through relentless quality control and complete transparency. For us, this isn't just a final checkpoint; it’s a commitment woven into every single step of our partnership with you.

We operate within a strict framework of credentials that protect your brand and, most importantly, your customers. Our facility is cGMP compliant, UL certified, and FDA-registered. These aren't just acronyms we hang on the wall; they are your absolute assurance that every bottle leaving our facility meets the highest possible industry standards for safety and consistency.

This dedication to quality kicks in the second raw materials hit our loading dock. Nothing enters our production area without first passing a strict quarantine and testing protocol. We meticulously verify every single ingredient for its identity, purity, and potency before it gets the green light for your formula.

Our Comprehensive Quality Control Process

Quality isn't a one-and-done event. It's a continuous process. From the moment we receive your ingredients to the final sign-off, your product moves through multiple checkpoints designed to guarantee its integrity. This systematic approach is what allows you to stand behind your premium liquid supplement with total confidence.

Here’s a look at how we build quality into every batch:

- Raw Material Verification: Every ingredient is immediately quarantined upon arrival. We conduct identity testing to confirm it’s exactly what it's supposed to be and screen it for any potential contaminants before it ever touches our inventory.

- In-Process Checks: As your product is being manufactured, our quality team is right there on the floor. We constantly monitor key parameters like pH, viscosity, and homogeneity to make sure the batch is mixing perfectly and remains consistent from the first bottle to the last.

- Finished Product Analysis: Once your supplement is bottled and sealed, our work still isn't done. We conduct a final round of internal testing to confirm it meets every single specification outlined in your master manufacturing record.

Our Promise of Accountability: For objective, unbiased proof, we send a sample from every single production batch to an independent, third-party laboratory. This lab runs tests for microbial contaminants, heavy metals, and active ingredient potency. The result is a Certificate of Analysis (CofA) that confirms your product is safe and meets its label claims, every time.

This final, independent verification step is completely non-negotiable for us. It gives you, your retailers, and your customers ultimate peace of mind. Choosing the right manufacturing partner is a huge decision, and our guide on finding a reputable supplement manufacturer digs into more key factors you should consider.

Protecting Potency with Advanced Technology

Here's something many brands overlook: some of the most effective ingredients are also the most fragile. Think about probiotics, enzymes, or certain botanical compounds. They can be easily damaged by heat, which drastically reduces their effectiveness. A standard manufacturing process can literally cook the benefits right out of the product your customers are paying for.

This is exactly why we invested in forward-thinking technology like cold-fill processing.

This specialized method lets us manufacture and bottle your liquid supplement in a completely temperature-controlled environment. We avoid the high heat that degrades those sensitive active ingredients. If your formula contains live probiotics for gut health or delicate digestive enzymes, this process isn't just a nice-to-have; it's essential. It ensures those ingredients stay viable and potent, delivering the full health benefits you intended.

This focus on technology is a core part of our partnership mindset. We don't just supply a product—we work with you to protect and enhance the integrity of your unique formula. By combining stringent cGMP protocols with advanced manufacturing techniques, we make sure the quality you designed in the lab is the exact same quality that reaches your customer’s hands.

Scaling Production from Pilot Batches to Full Runs

For a growing brand, flexibility isn't just a nice-to-have; it's a survival tool. The ability to test, pivot, and scale on your own terms is what separates the brands that break out from the ones that stall out. We’ve designed our entire custom liquid vitamin manufacturing process around this reality, acting as your operational partner through every stage of growth.

For a growing brand, flexibility isn't just a nice-to-have; it's a survival tool. The ability to test, pivot, and scale on your own terms is what separates the brands that break out from the ones that stall out. We’ve designed our entire custom liquid vitamin manufacturing process around this reality, acting as your operational partner through every stage of growth.

This journey almost always starts with a pilot batch. Whether you need a small run for investor decks, influencer mailers, or just to test the waters in the real world, starting small is a savvy move. It gives you the chance to validate your unique formula with actual customer feedback before you sink a huge investment into inventory.

Think of it as de-risking your launch. You get invaluable data that lets you iterate. Maybe customers loved the taste but wanted a different consistency. Or perhaps your initial marketing message didn't quite land. A pilot run gives you the answers you need to refine your product and nail your full-scale launch.

From Pilot Run to Commercial Scale

Making the jump from a 500-unit pilot batch to a 50,000-unit commercial run can feel like a leap of faith. The number one question we hear from founders is, "Will the quality be the same?"

Our answer is always an emphatic yes. The process is engineered for predictable, seamless scalability. Quality and consistency aren't afterthoughts; they're built in from day one.

The secret is the Master Manufacturing Record (MMR) we develop for your product during the pilot phase. This isn't just a recipe; it's the definitive blueprint for your formula. It details every single ingredient quantity, mixing time, quality check, and procedure. When it's time to scale up, we aren't reinventing anything—we’re simply executing that same proven blueprint on a larger scale.

Our Commitment to Consistency: We see scaling as a matter of multiplication, not modification. We use the exact same cGMP-compliant procedures, vetted raw materials, and rigorous testing protocols for a full production run as we do for your initial pilot. Your tenth batch will be a perfect match for your first.

Speed and Reliability for E-Commerce Brands

In the hyper-competitive world of e-commerce, speed is everything. Going out of stock can torpedo your momentum, hurt your search rankings, and send your hard-won customers straight to a competitor. We get it. That’s why our operation is built on two core principles: rapid turnarounds and rock-solid reliability.

Our transparent timelines mean you’re never left guessing. From the moment you submit a purchase order, we give you a clear production schedule. This lets you plan your marketing campaigns and manage inventory with confidence. We have a stellar on-time delivery record because we know that hitting your launch date or restocking deadline is completely non-negotiable.

This focus on reliable, high-quality supplement production is something we take immense pride in, ensuring every brand we work with can scale without skipping a beat.

A Look at Scaling in Practice

Let's walk through a real-world scenario we see all the time. Imagine a Shopify brand is launching a new liquid herbal blend for focus.

- The Pilot: They kick things off with a 1,000-unit pilot run to test the market and start collecting testimonials.

- The Feedback: The product sells out in just three weeks. The reviews are fantastic, but a few people mention the dropper makes it hard to get an accurate dose.

- The Pivot: Before placing their first full order, we help them source a new bottle that features a graduated dropper with clear measurement markings.

- The Scale-Up: Now confident they have a winner, they place an order for 20,000 units. The formula and quality are identical to the pilot run, but the packaging has been perfected based on real user feedback.

This is the power of working with a flexible manufacturing partner. We don't just fill bottles; we give you the operational agility to listen to your market and adapt on the fly. It's how you ensure your brand grows smarter, not just bigger.

Putting the Finishing Touches on Your Packaging, Branding, and Fulfillment

A truly great product experience is about so much more than the liquid inside the bottle. It's about the unboxing, the feel of the container in your customer's hand, and the smooth journey from our facility to their front door. These final steps—packaging, branding, and fulfillment—are where your brand’s story and promise of quality really come to life.

As your manufacturing partner, we guide you through these critical final stages with the same hands-on, collaborative approach we take with formulation. This is where we merge your visual identity with smart, functional design to create a product that really pops, especially on a crowded digital shelf.

Choosing Packaging That Protects and Sells

The right packaging has two crucial jobs: it has to safeguard the integrity of your carefully developed formula, and it needs to communicate what your brand is all about in a single glance. We have access to a huge range of flexible packaging solutions, and we’ll help you land on the perfect choice for your specific product and who you're selling to.

We can source a variety of primary packaging options, including:

- Amber or Cobalt Glass Dropper Bottles: These are the gold standard for protecting sensitive liquid formulas from UV light damage, making them perfect for tinctures and serums.

- BPA-Free PET Plastic Containers: A lightweight, shatterproof, and often more budget-friendly option. They’re a great fit for larger volume products or anything designed for on-the-go use.

- Sustainable and Recycled Options: For brands built on an eco-conscious mission, we can source packaging made from recycled materials that align perfectly with your values.

Partnership in Practice: Let's say you're launching a premium anti-aging supplement. We'd probably point you toward a frosted glass bottle with a sleek serum pump to create a feeling of luxury and precision. On the other hand, for a new children's multivitamin, a durable, easy-to-open PET plastic bottle with a tamper-evident cap is the much more practical and safe choice.

Aligning Your Branding with the Technical Details

Once you've picked your bottle, it’s time to dress it up with labels and cartons. Our team works directly with your designers to make sure your creative vision is executed perfectly. We provide the exact die-lines and technical specs, acting as the bridge between your design files and the printing press.

This hands-on process prevents those common and costly mistakes, like a label that’s too big for the bottle or a carton that doesn't quite fit. We make sure every single element, from the font size on the supplement facts panel to the barcode placement, is compliant and perfectly positioned for a polished, professional look.

The market for personalized health products is absolutely booming, largely driven by e-commerce brands that are masters at creating a powerful brand experience. The global personalized vitamins market was valued at USD 4.88 billion in 2024 and is projected to nearly double to USD 9.89 billion by 2030. This is a massive signal that consumers are ready to invest in brands that speak directly to them. You can explore more insights on the growth of personalized nutrition at GrandViewResearch.com.

Making Your Supply Chain Effortless with End-to-End Fulfillment

Our partnership doesn’t have to stop once your product is bottled and labeled. For many of our clients, especially fast-growing e-commerce brands, dealing with logistics is a major headache. That’s why we offer end-to-end fulfillment services to take that entire operational burden off your plate.

From our FDA-registered facility, we can handle it all:

- Secure Warehousing: Your finished product is stored safely in our climate-controlled warehouse.

- Inventory Management: We keep a close eye on your stock levels, giving you real-time data.

- Pick, Pack, and Ship: We can ship orders directly to your customers (D2C), send inventory to Amazon for FBA, or distribute to other retail partners.

Integrating manufacturing and fulfillment creates some serious operational efficiency. You cut down on transit times, minimize product handling, and get a single point of contact for your entire back-end operation. It frees you up to focus on what you're best at: building your brand and connecting with your customers, all while knowing your custom liquid vitamin manufacturing and delivery are in expert hands.

Your Top Manufacturing Questions, Answered

Stepping into a partnership for custom liquid vitamin manufacturing always brings up a few practical questions. As your partner from the first idea to the final launch, we believe in being an open book. This is where we tackle the most common questions we hear from brand founders, giving you the direct, clear answers you need to move forward with confidence.

What’s the Minimum Order Quantity (MOQ)?

We get it. Every brand, especially a new one, has to watch its cash flow and avoid inventory risk. That’s exactly why we’ve built our process to be as flexible as possible. You won't be forced into a massive, high-risk order right out of the gate.

While the exact MOQ depends on the complexity of your formula and the ingredients we need to source, our model is designed to support your growth from day one. We offer accessible pilot run sizes that are perfect for:

- Testing the market: Get your product into the hands of real customers and gather that all-important feedback.

- Kicking off influencer campaigns: Send samples to key opinion leaders to start building some early buzz.

- Nailing investor presentations: Show up with a professional, finished product that proves you’re ready for business.

Our goal is to be your long-term partner. We want to scale seamlessly with you, from that initial test batch all the way up to full commercial runs of 50,000 units or more. The best way to get a precise number for your project? Let’s just have a quick chat about your specific formula.

How Long Does the Whole Process Take?

For fast-moving e-commerce brands, we know that speed and reliability are everything. A typical project, from the moment your formula is locked in to the day your finished product ships out, takes between 8 to 12 weeks.

We don't like surprises any more than you do, so we provide a transparent project timeline right from the start. You're never left in the dark. Here’s a general idea of how that window breaks down:

- Raw Material Sourcing & Testing: 2-4 weeks

- Formulation & Pilot Batching: 2-3 weeks

- Full-Scale Production Run: 2-3 weeks

- Final QA & Third-Party Testing: 1-2 weeks

You'll get consistent updates from our team, so you can plan your marketing and launch activities with total certainty.

Expert Insight: The biggest variable in any timeline is usually sourcing unique or specialized ingredients. By planning ahead and tapping into our vetted supplier network, we can keep your project on the fastest possible track.

Can You Help Source Specialized Ingredients?

Absolutely. Sourcing is one of the most critical—and honestly, time-consuming—parts of the process, and we handle it all for you. Think of our team as an extension of your own R&D and procurement departments.

We’ve spent years building a robust global network of vetted suppliers for even the most specific ingredients. Whether your formula calls for a patented active, an organic botanical from a particular region, or a sustainably harvested nutrient, we manage the entire procurement and qualification process. Every new ingredient, without exception, is put through our stringent cGMP testing protocol for identity, purity, and safety before it ever gets near your formula. This guarantees both quality and a secure supply chain for your brand.

This is more important than ever as consumers flock to e-commerce for tailored health solutions. The U.S. personalized vitamins market was estimated at USD 1.67 billion in 2024 and is projected to triple to USD 5.29 billion by 2033. That growth is fueled by brands like yours offering unique, customized products. You can find out more about the rise of personalized vitamins in the U.S. at GrandViewResearch.com.

What Kind of Testing Do You Perform?

Our entire operation runs on a principle of "trust but verify." Every single production batch undergoes comprehensive, multi-stage testing before it's ever released. Internally, we test for identity (is the ingredient what it claims to be?), purity, and strength.

But we don't just rely on our own results. We send a sample from every single batch to an independent, third-party laboratory for completely unbiased analysis. They test for:

- Microbial Contaminants: Yeast, mold, and harmful bacteria.

- Heavy Metals: Lead, mercury, arsenic, and cadmium.

- Potency: Verifying that the active ingredients meet 100% of your label claim.

Once everything passes with flying colors, you receive a Certificate of Analysis (CofA) for your records. This document is your ultimate guarantee of safety and quality, giving you, your retail partners, and your customers complete confidence in every bottle.

Ready to turn your vision for a custom liquid supplement into a market-ready reality? At Triton Nutra Group, we partner with you at every step, from formula development to fulfillment. Let’s build something exceptional together.