Create Your Own Supplement Formula From Scratch

Learn how to create your own supplement formula. This guide covers concept, R&D, manufacturing, and launch for brand founders and e-commerce entrepreneurs.

Get a Free Quote Today!

Get a Free Quote Today!Ready to move beyond a simple idea and create your own supplement formula? This journey is about turning a concept into a tangible, science-backed product that resonates with your target market. It starts with a deep understanding of your customer, strategic ingredient selection, and finding a manufacturing partner who acts as an extension of your team. This process involves strategic R&D, navigating compliance, and rigorous testing to ensure what you create is both safe and effective. It’s the only way to build a unique brand, not just another "me-too" product.

Your Idea Is the First Ingredient

Every successful supplement begins as a solution to a real problem. Long before a single ingredient is ordered or a bottle gets filled, there's a core idea—a vision for improving someone's health. For brand founders, this initial concept is the most critical ingredient you'll ever have. It's what separates a category-defining product from one that just gets lost on the shelf.

The goal isn't just to make a supplement; it's to make your supplement. This means steering clear of generic, off-the-shelf options and committing to a custom formulation process. Instead of picking from a pre-made menu, you get to build your product from the ground up. You call the shots on every active ingredient, its precise dosage, and even the delivery system and flavor profile.

This is the path that gives you total control to build a brand that actually stands out. It’s the difference between just selling a product and truly owning a formula.

From Concept to Custom Formula

Bringing an idea into the real world requires a clear framework. The most successful entrepreneurs start by asking pointed questions that lay the groundwork for a powerful and marketable formula.

Before you go any further, think through these foundational pillars. Getting these right from the start saves time, money, and headaches later.

The Four Pillars of Successful Supplement Formulation

Bringing a new supplement to life is a complex process, but it can be broken down into four key areas of focus. Nailing these pillars is essential for transforming your initial concept into a market-ready product that resonates with customers and stands on solid scientific ground.

| Pillar | What It Means For Your Brand | Key Action |

|---|---|---|

| Problem-Solving Focus | Your product must address a specific, well-defined need. | Move beyond broad claims like "energy booster." Instead, target something like "afternoon focus without jitters for remote workers." |

| Audience Definition | You need to know exactly who you're formulating for. | A product for elite athletes will have vastly different ingredients and potencies than one for busy parents needing better sleep. |

| Brand Differentiation | Your formula must have a unique selling proposition (USP). | This could be a novel ingredient combination, a superior delivery format (like a liquid tincture), or ethically sourced botanicals. |

| Manufacturing Partnership | You need more than just a factory; you need a collaborator. | Find a partner who acts as an extension of your R&D team, providing scientific and regulatory guidance from start to finish. |

Focusing on these four pillars will give your brand a defensible position in the market and a much clearer path to launch.

Our Partnership Mindset: Finding a manufacturing partner who understands this vision is essential. You need a collaborator who acts as your R&D partner from concept through launch, not just an order-taker. They should provide the scientific and regulatory expertise to translate your idea into a compliant, shelf-stable, and effective final product.

The demand for this level of personalization is exploding. The global dietary supplements market was valued at a staggering $192.65 billion in 2024 and is on track to hit $414.52 billion by 2033. This incredible growth is being driven by consumers who are tired of generic options and are actively seeking nutrition solutions tailored to their specific needs—something private-label products often can't deliver. You can explore the data behind this expanding market to fully grasp the opportunity here.

Choosing to create your own supplement formula is a serious commitment to quality and innovation. It’s a strategic decision that empowers you to build a defensible brand, create real customer loyalty, and make a genuine impact. With the right idea and the right partner, you can absolutely navigate the path from a simple concept to a market-ready success.

Crafting Your Custom Formula Blueprint

To create your own supplement formula that makes an impact, you have to think beyond stringing together a few popular ingredients. The best products—the ones that truly take off—are born from a deep understanding of a specific customer need. This is where your market research converges with strategic formulation decisions to form the very core of your product.

It all starts with pinpointing a profitable niche. Look for the gaps in the market. What pain points are being overlooked? For instance, don't just create another generic "sleep aid." Think about a formula designed specifically for shift workers who struggle to reset their circadian rhythm without feeling groggy the next day. Instead of a broad "immune booster," why not a liquid tincture for targeted seasonal sinus support?

Letting genuine consumer problems guide every decision is the secret sauce. This targeted approach doesn't just supercharge your marketing; it ensures your product has a built-in audience eager for a solution.

The Art of Ingredient Selection

Once you've locked in on a clear problem to solve, choosing your ingredients becomes a strategic exercise, not a guessing game. The objective is to build a formula where every single component works synergistically to deliver a very specific outcome.

It’s a balancing act. You want to mix innovative, exciting ingredients with those tried-and-true, clinically-proven staples. A novel botanical extract might generate buzz, but pairing it with a well-researched vitamin or mineral builds the credibility and trust you need for long-term success. As your R&D partner, we help brands navigate this balance every day, ensuring their formula is both effective and marketable.

Here’s a breakdown of how we approach building a synergistic formula:

- Primary Actives: These are the heavy hitters—the ingredients that directly tackle the core problem your product is designed to solve. For a cognitive enhancer, this might be Citicoline or Bacopa Monnieri.

- Supporting Nutrients: Think of these as the supporting cast. They complement the primary actives, often by boosting absorption or offering secondary benefits. A classic example is adding Black Pepper Extract (as BioPerine®) to enhance the bioavailability of other botanicals like Turmeric.

- Flavor and System Ingredients: For liquids, these are absolutely essential for a great user experience. We use natural flavor systems and stabilizers to make sure the product not only tastes great but also stays shelf-stable, all without compromising the integrity of the active ingredients.

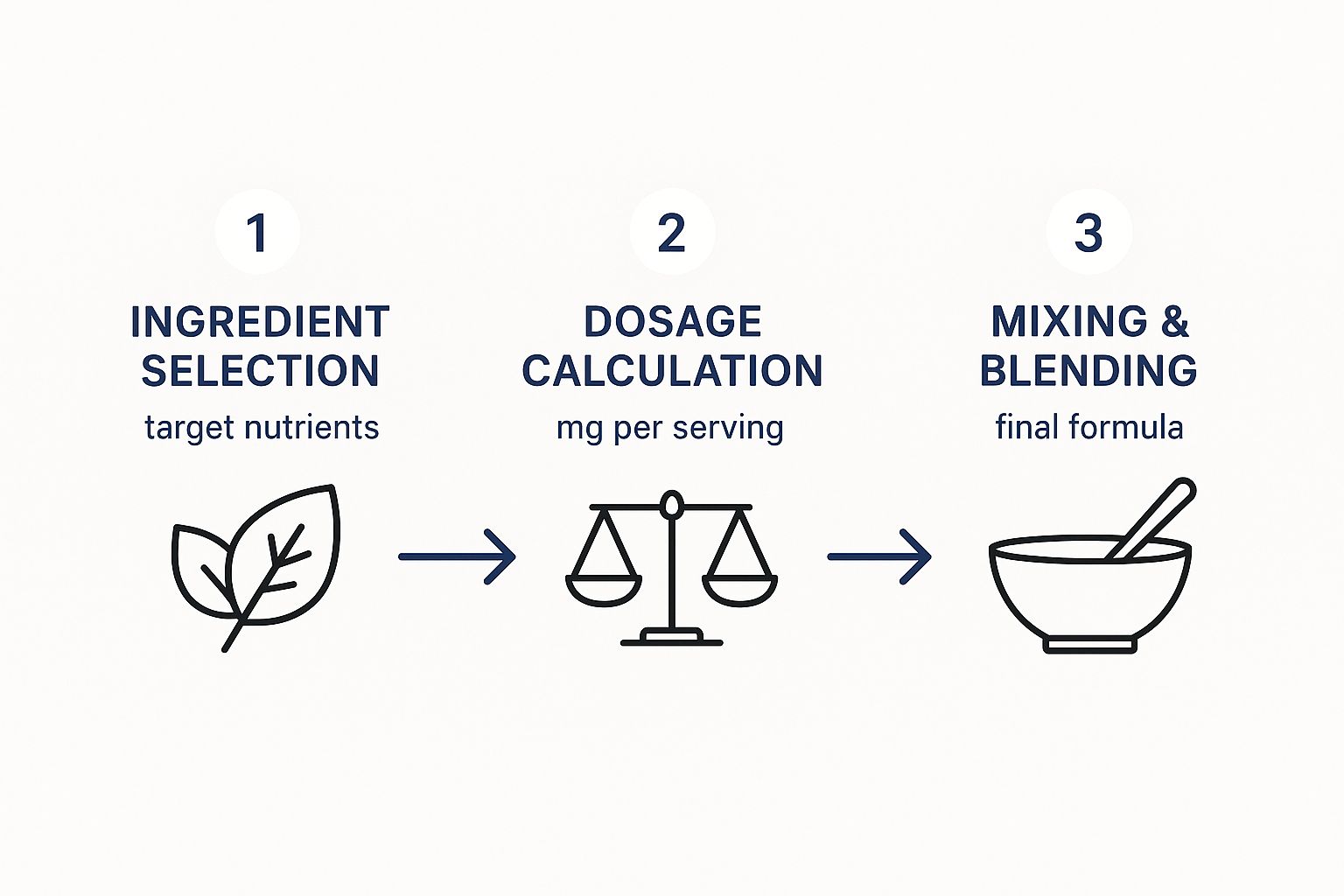

This visual really captures the methodical flow from an ingredient list to a finished formula.

As the infographic shows, it’s a clear progression: select the core nutrients, determine the precise dosage, and then finalize the blending process. This is the foundation of high-quality, repeatable manufacturing.

Choosing the Right Delivery System

The decision between a liquid, powder, or capsule is a major one. It affects everything from bioavailability and user experience to manufacturing costs and scalability. While capsules are common, liquid supplements have distinct advantages, especially for certain formulas and target demographics.

For many active ingredients, liquids can offer superior absorption because they don't need to be broken down in the digestive system first. This makes them ideal for consumers who want faster effects or for the many people who have trouble swallowing pills—a market segment that’s much larger than most founders realize.

Insider Tip: Your delivery system is a core part of your brand identity. A sleek, modern liquid tincture can communicate a premium, forward-thinking message that immediately sets you apart from a sea of generic white capsules. It's a key part of your product's story.

This choice also has a major impact on manufacturing. Our innovative cold-fill technology, for instance, is engineered specifically for liquids. It preserves the potency of heat-sensitive botanicals and probiotics that would be degraded in standard manufacturing. It’s this kind of technical detail that turns a good idea into a great product.

Market trends confirm the growing demand for well-formulated products. The global dietary supplements market is projected to swell from roughly $203.42 billion in 2025 to over $402.20 billion by 2034. This explosive growth is being driven by consumers actively seeking out preventive health solutions, making it an ideal time to launch a thoughtfully crafted formula.

Turning your vision into a precise, scientifically-backed formula is one of the most exciting parts of this journey. To see how these steps fit into the bigger picture, take a look at our guide on starting your own custom liquid supplement brand. It’s this formula blueprint that will guide production and become the bedrock of your brand’s success.

Finding the Right Manufacturing Partner

Choosing who will physically produce your product is the single most important decision you'll make on your journey to create your own supplement formula. This isn’t about finding a factory to fill bottles. It’s about selecting a true partner who becomes an extension of your R&D team.

The right manufacturer brings more than just equipment to the table. They bring deep expertise, bulletproof quality systems, and a collaborative spirit that can make or break your brand.

A great partner doesn't just take your order. They challenge your assumptions, offer smarter solutions, and provide the guardrails that keep your product safe, compliant, and effective. They see your vision and have the technical chops to bring it to life, protecting you every step of the way.

The Non-Negotiable Certifications

Before you even discuss your formula, you need to vet a potential partner’s credentials. Certain certifications are the absolute bare minimum for operating legally and safely in the supplement industry. Think of these as your brand's insurance policy against a quality control nightmare.

Here are the absolute must-haves:

- cGMP Certified: Standing for Current Good Manufacturing Practices, this is an FDA-enforced standard. It ensures the manufacturer follows strict procedures for identity, purity, strength, and composition. It’s the bedrock of quality.

- FDA Registered Facility: This means the Food and Drug Administration is aware of the facility and its operations. It’s a basic prerequisite for legally manufacturing dietary supplements in the United States.

- UL Certified: Third-party organizations like UL go a step further than cGMP. They audit facilities against their own rigorous standards for quality and safety, giving you an extra layer of verification and trust.

These aren't just logos on a website; they are hard-earned proof of a deep commitment to quality that will directly impact your final product and protect your brand.

Beyond the Basics: Evaluating True Partnership Potential

Once you've confirmed the essential certifications are in place, the real evaluation begins. This is where you separate the order-takers from the true R&D partners. The best manufacturers are forward-thinking, flexible, and genuinely invested in your success.

You're looking for a partner who can innovate right alongside you. For example, if you're working with a delicate liquid formula full of sensitive botanicals, the manufacturing technology is critical. Standard heat-based pasteurization can destroy the very compounds your customers are paying for.

Our Commitment to Innovation: We invested in advanced cold-fill technology for this exact reason. It allows us to produce shelf-stable liquid supplements without subjecting heat-sensitive ingredients to damaging temperatures, preserving the full potency of your formula from batching to bottling.

This commitment to advanced processes is a huge indicator of a quality partner. The same goes for their botanical extraction methods. Do they use standard alcohol-based extractions, or do they offer more advanced, temperature-controlled methods that yield a cleaner, more potent final ingredient? These details matter. A lot. Our guide on finding a reputable supplement manufacturer dives deeper into what to look for.

Flexibility from Pilot to Scale

Your production needs will change as your brand grows. A partner who can only handle massive, 50,000-unit runs is a poor fit for a startup that needs to test the market first. You need a manufacturer with the flexibility to support your entire journey.

Assess their flexibility across these key areas:

- Run Sizes: Can they support a small pilot batch of just a few hundred units? This is vital for finalizing your flavor and getting market feedback without a huge upfront investment. As you grow, can they scale with you to full production runs without sacrificing quality?

- Customization: How deep does their customization go? Beyond the formula, can they help you dial in a unique flavor profile using natural systems? Can they accommodate specific bottle types, caps, and custom packaging to help your brand stand out?

- Turnaround Times: In e-commerce, speed and reliability are everything. Ask for their typical lead times for both initial runs and reorders. A great partner provides transparent timelines and has a proven track record of on-time delivery, so you never have to deal with costly stockouts.

The ideal partner can seamlessly transition with you from a garage startup to an established product line. They offer the infrastructure to scale and the collaborative spirit to feel like part of your team, providing expert guidance from your first pilot batch to your hundredth full-scale production run. That partnership mindset is the ultimate key to long-term success.

Fine-Tuning Your Formula for Market Success

A brilliant formula is a fantastic starting point, but it's only half the journey. If you create a supplement formula from scratch that’s scientifically sound but tastes awful or loses potency on the shelf, it’s destined to fail. This is the stage where we polish every detail to turn a good product into one that customers will enjoy using and buy again and again.

This refinement process is what transforms a lab concept into a product people love. It’s where you dial in the flavor, lock down its stability, and get the final, undeniable proof of its quality through rigorous testing. Skipping these steps is a gamble no serious brand can afford to take.

Think of it as the final quality gate before your product goes public. It’s about protecting your customers, your reputation, and your investment.

Perfecting the Flavor Profile

For any liquid supplement, flavor isn't a bonus feature; it's a core component. You can have the most potent blend of botanicals, but if your customers dread taking it, they won't stick with it. The goal is to develop a flavor system that works with your active ingredients, not just mask them with artificial sweeteners.

This is a delicate balance of art and science. We’ll work closely with you to:

- Select Natural Flavor Systems: We lean on natural fruit extracts, essences, and sweeteners like stevia or monk fruit to build a clean, appealing taste.

- Balance Actives and Flavors: Some ingredients, especially herbal extracts, have strong tastes. Our R&D team is skilled at finding the perfect flavor pairings to harmonize these notes, creating a pleasant experience without watering down the potency.

- Conduct Sensory Panels: We use internal taste tests during pilot batches to get real-world feedback, allowing us to make precise tweaks until the flavor is just right.

The Critical Role of Stability Testing

How can you be certain your product is just as effective on its expiration date as it was the day it was made? The answer is stability testing. This is a non-negotiable process that determines your product's shelf life and serves as a cornerstone of cGMP compliance.

Stability testing involves putting finished products into controlled chambers that mimic different environmental conditions—like high heat and humidity—over an extended period. We pull and test samples at set intervals to confirm that the product's key attributes remain exactly where they need to be.

A Real-World Example of Our Partnership: A client had a new formula with a sensitive vitamin complex. Our accelerated stability testing showed a 15% potency drop after the equivalent of six months at a high temperature. This discovery allowed us to reformulate with a more stable vitamin version before the first production run ever started, safeguarding the product's integrity and the brand's promise to its customers.

This is your guarantee that the product stays safe, potent, and stable from the production line to the customer's cabinet.

Third-Party Testing: The Ultimate Proof of Quality

In this industry, trust is your most valuable currency. While our in-house testing is exhaustive, we mandate comprehensive third-party testing for every single batch we produce. This provides independent, unbiased verification that your product is pure, potent, and safe.

An independent, ISO-accredited lab receives a sample from your finished batch and tests for:

- Potency: Does the product contain the exact amount of each active ingredient claimed on the label?

- Purity: Is the product free from contaminants like heavy metals, microbes, and other pathogens?

The resulting Certificate of Analysis (CofA) is your definitive proof to customers, retailers, and regulators that your product is exactly what you say it is. It's an incredibly powerful tool for building consumer confidence. As you refine your supplement and prepare for launch, you'll find that developing a comprehensive business plan is essential for mapping out these critical marketing and quality strategies.

Before launching, it's essential to understand the different types of testing your product will undergo.

Essential Testing Protocols for Your Supplement

This table breaks down the critical tests your supplement must pass to ensure it meets the highest standards for safety, quality, and regulatory compliance.

| Test Type | Purpose | Why It's Non-Negotiable |

|---|---|---|

| Microbial Testing | To detect harmful microorganisms like E. coli, Salmonella, and mold. | Ensures the product is safe to consume and won't make customers sick. This is a fundamental consumer safety requirement. |

| Heavy Metal Analysis | To screen for toxic metals such as lead, mercury, arsenic, and cadmium. | Protects consumers from long-term health risks associated with heavy metal exposure and is a key part of regulatory compliance. |

| Potency Verification | To confirm the amount of each active ingredient matches the label claim. | This is the foundation of your product's efficacy and your brand's credibility. It ensures your customers get what they paid for. |

| Stability Testing | To determine the product's shelf life and ensure it maintains its quality over time. | Guarantees the product remains safe and effective until its expiration date, protecting both the consumer and your brand's reputation. |

Each of these tests provides a layer of assurance, building a fortress of quality around your product and brand.

This intense focus on quality is vital for success, especially for brands eyeing global markets. For example, the dietary supplements market in the Asia Pacific region is exploding, projected to hit $143,624 million USD by 2033 with a staggering 9.803% CAGR. To compete in dynamic markets like that, you need airtight quality documentation.

By meticulously refining the user experience and verifying every detail through rigorous testing, you create a product that doesn't just sell—it earns loyalty.

Preparing for a Successful Product Launch

You've done it. Your custom supplement formula is tested, refined, and perfected. The science is solid, the taste is dialed in, and you’ve confirmed its stability.

Now it's time to bridge the gap between having a fantastic product and a market-ready brand. This final stage is all about logistics and presentation—the details that make or break a launch.

This is where your product gets its identity. We’ll walk through the essentials of packaging and labeling, ensuring your design isn't just eye-catching but also perfectly compliant with all FDA regulations. A powerful design grabs attention, but a compliant label builds trust and protects your business.

Ultimately, this phase is about building a foundation for long-term growth. From the label on the bottle to the supply chain that keeps it in stock, these preparations position your brand as a reliable and professional player in a competitive space.

Nailing Your Packaging and Label Design

Think of your packaging as the first handshake with a potential customer. It has to instantly communicate your brand's story, its quality, and what makes it special. But looking good is only half the battle; it must also be meticulously compliant.

We see ourselves as your partner in this process, ensuring your creative vision fits squarely within the FDA's strict requirements. This isn't just about avoiding a warning letter; it’s about establishing your brand's integrity from the first impression.

A few things to keep in mind for your packaging:

- Brand Cohesion: Your label design, bottle choice, and even the cap should all work in harmony to reinforce your brand. A minimalist design might signal scientific precision, while earthy tones could convey natural origins.

- Durability and Function: The packaging has a job to do. It must protect your liquid formula from light and air, which can degrade sensitive ingredients. We’ll help you select materials that preserve shelf life and also feel premium in the customer's hand.

- Regulatory Review: Before a single label is printed, our team gives it a thorough compliance review. We check everything from the font size on the Supplement Facts panel to the exact wording of your product claims.

Crafting a Flawless Supplement Facts Panel

The Supplement Facts panel is the most scrutinized part of your label. This isn't a marketing tool—it's a legal document that has to be 100% accurate. One small error can undermine customer trust and attract unwanted regulatory attention.

Crafting this panel is a precise science, and we'll guide you through every line item to make sure it's clear, correct, and fully compliant with FDA guidelines.

Here are the key components we help you get right:

- Serving Size and Servings Per Container: These must be clearly stated and accurately reflect how the product is meant to be used.

- Ingredient Listing: All dietary ingredients have to be listed with their proper names and the exact quantity per serving. If you have a proprietary blend, it has its own specific formatting rules.

- Percent Daily Value (%DV): These values must be calculated based on the FDA's established standards for required nutrients.

- Other Ingredients: Any non-dietary ingredients—like natural flavors, purified water, or stabilizers—must be listed in descending order by weight.

An accurate Supplement Facts panel is non-negotiable. It’s the ultimate statement of transparency between your brand and your customer. Getting it right is a core element when you create your own supplement formula and is fundamental to building a trustworthy reputation.

Establishing a Reliable Supply Chain

With your product and packaging finalized, the focus shifts to operations. A reliable supply chain is the engine that will power your brand's growth. Without it, even the most incredible product will fail due to stockouts and broken customer promises.

As your manufacturing partner, we see ourselves as the first and most critical link in that chain. We are committed to speed and reliability, providing transparent timelines and an excellent on-time delivery record. This lets you manage your inventory with confidence, knowing that reorders will arrive when you expect them.

This partnership is crucial for scaling your business effectively. We support your growth with flexible production run sizes, allowing you to move seamlessly from a small pilot launch to full-scale production as demand grows. This approach keeps you from tying up too much capital in inventory early on while ensuring you can meet a sudden surge in orders.

To give your supplement the strong market entry it deserves, you need a smart launch plan. This compelling case study on developing a perfect go-to-market strategy for a new consumer product shows just how critical this is. Planning these logistics with your manufacturer from the start ensures you can actually meet the demand you work so hard to create.

Common Questions About Custom Formulation

Diving into creating a supplement from the ground up naturally brings up questions. This is a detailed process, and the decisions you make now will shape your brand for years. As the R&D partner for countless health and wellness entrepreneurs, we've heard just about every smart question there is.

Here are the clear, insider answers you need to move forward with confidence. We’ll get into the nitty-gritty of timelines, potential hidden costs, and the manufacturing steps that really matter.

How Long Does a Custom Formula Really Take?

"How long will this take?" It’s almost always the first question, and for good reason. From that first idea to having finished bottles ready to ship, the process can seem overwhelming.

For a completely new liquid supplement built from scratch, a realistic timeline is 12 to 20 weeks.

This isn't one long waiting period; it's broken into distinct phases:

- R&D and Ingredient Sourcing (4-6 weeks): This is the creative heart of the project. We finalize your formula and start securing high-quality raw materials. If you’re set on a rare botanical, this phase can sometimes stretch.

- Pilot Batch and Flavor Development (4-6 weeks): Here, we create a small-scale run to get the taste and mouthfeel just right. This is where you get to sample the product and give the final sensory approval.

- Stability Testing (at least 4 weeks for accelerated testing): This is a non-negotiable step that determines your product's shelf life and ensures it stays effective and safe.

- Initial Full-Scale Production Run (4-6 weeks): Once you’ve signed off on everything, we schedule your first market-ready production, providing a transparent timeline for completion.

This timeline can be shorter if you're adapting one of our existing base formulas. But for a truly custom product, building this window into your launch plan is key to a smooth process.

What Is a Pilot Batch and Why Is It So Important?

A pilot batch is a small, trial production run of your new formula, typically between 50 and 500 units. It’s the single most important risk-management step you can take before committing to a full-scale order.

Think of the pilot batch as your final dress rehearsal. It’s your last chance to make crucial adjustments to the flavor, consistency, and even the fill level of the bottle before investing in thousands of units. Skipping this step to save a few weeks is a classic rookie mistake that can cost you dearly.

The pilot run lets you test your formula in a real manufacturing environment, not just a lab beaker. It also gives you physical samples for product photography, influencer mailings, and final approval from stakeholders. It's a small investment that delivers massive value and peace of mind.

Can I Supply My Own Proprietary Ingredients?

This question comes up a lot, especially from brands who've invested in developing or sourcing a unique, signature ingredient. The short answer is: it depends on the manufacturer's quality systems.

As a cGMP and UL certified facility, we operate with an incredibly strict and traceable supply chain. We have a network of vetted raw material suppliers we trust to guarantee quality and compliance. That said, we do have a robust process for qualifying an outside ingredient if it’s proprietary to your brand.

If you want to supply an ingredient, you'll need to provide a complete Certificate of Analysis (CofA) from your supplier. From there, we'll conduct our own independent, third-party verification testing to ensure it meets our rigorous standards for purity and potency before it ever enters our facility.

Ready to stop wondering and start creating? The team at Triton Nutra Group is your dedicated R&D partner, ready to guide you from concept to a market-ready liquid supplement. Request a quote today and let's build your formula together.