Choosing a Contract Manufacturer for Nutritional Supplements: Your Ultimate Guide

Learn how to find and vet a contract manufacturer nutritional supplements partner who delivers on cGMP quality, custom formulation, and helps scale your brand.

Get a Free Quote Today!

Get a Free Quote Today!Choosing the right contract manufacturer for nutritional supplements is one of the most critical decisions you'll make for your brand. This isn't just about finding a factory; it's about securing a true partner who understands your vision and can transform it into a compliant, high-quality product ready to dominate the market. This guide is your insider's roadmap to finding that perfect fit—a partner who nails it on quality, customization, and reliability.

Finding the Right Partner to Launch Your Supplement Brand

If you're an e-commerce founder or brand manager in the health and wellness space, you know the path from concept to customer is loaded with hurdles. You’re juggling complex regulations, guaranteeing top-notch quality, and figuring out how to scale without burning through capital. This is where a specialized contract manufacturer becomes more than a supplier—it becomes your strategic advantage.

Outsourcing production lets you focus on your superpowers: building your brand, marketing your product, and connecting with customers. Instead of sinking huge amounts of capital into equipment and regulatory experts, you get immediate access to a team that lives and breathes supplement manufacturing.

The Value of a True Partnership

The best manufacturing relationships are far more than client-vendor transactions. Your manufacturer should feel like an extension of your own team—Your R&D partner from concept through launch. That partnership mindset is what separates a decent manufacturer from a great one.

A true partner brings immense value to the table:

- Deep Expertise: You gain immediate access to chemists, formulators, and QA specialists who know the ins and outs of tricky ingredients like botanical extracts and liquid supplements.

- Regulatory Peace of Mind: You can launch with confidence knowing your product is made in a cGMP, UL certified, and FDA-registered facility, taking a massive compliance headache off your plate.

- Flexibility to Scale: They give you the freedom to start with smaller pilot runs and then smoothly ramp up to full-scale production as your sales take off.

The demand for these services is booming. The dietary supplements contract manufacturing market hit USD 59.63 billion in 2024 and is projected to more than double, reaching USD 121.2 billion by 2030. This explosive growth shows just how essential these partnerships have become for brands. You can dig into more data on this market expansion to see why this industry is white-hot.

Your contract manufacturer shouldn't just be an order-taker. They should challenge your ideas, suggest innovative solutions like cold-fill technology to protect delicate ingredients, and provide transparent timelines you can actually count on.

This guide gives you an insider's view of finding that ideal partner. We'll walk through actionable steps to vet potential manufacturers, navigate the custom formulation process, and launch a product that shines.

How to Vet Potential Manufacturing Partners

Finding the right contract manufacturer for your supplements is a high-stakes interview process, and for good reason. Before you draft that first email, you need absolute clarity on what you're building. Who is your customer? Will a liquid herbal tincture resonate more with them than a capsule? What unique botanical extracts will set your brand apart?

Answering these questions gives you a powerful framework. With that clarity, you can shift from simply "searching for suppliers" to strategically vetting true partners. Your first outreach isn't just about getting a price; it’s a test of their expertise, flexibility, and communication.

The Non-Negotiables of Quality and Compliance

Your brand's reputation is built on the quality of your product. This makes your manufacturer's credentials the first and most critical checkpoint. There is zero room for compromise here.

Before you discuss capabilities, verify their core compliance documents.

- cGMP Certification: Current Good Manufacturing Practices are the bedrock of supplement safety and quality. This isn't a "nice-to-have"—it's a federal requirement enforced by the FDA.

- FDA-Registered Facility: This confirms the manufacturer is on the FDA's radar and subject to inspection, adding a crucial layer of accountability.

- Third-Party Certifications: Look for seals from respected independent bodies like UL or NSF. These certifications often go beyond basic cGMP, signaling a manufacturer’s commitment to exceeding industry standards.

A partner’s certifications are a direct reflection of their operational discipline. If a potential contract manufacturer hesitates to provide documentation for their cGMP, UL, or FDA registration, consider it a major red flag and walk away.

This is also the time to ask pointed questions about their quality assurance (QA) team. Who's in charge? What's their background? A strong QA department, staffed with experienced chemists and technicians, is your best defense against contamination, ingredient inconsistencies, and compliance headaches. For a deeper dive, check out our guide on finding a reputable supplement manufacturer and other key considerations.

Beyond the Basics: Gauging True Partnership Potential

Once a manufacturer clears the essential compliance hurdles, the real evaluation begins. This is where you separate order-takers from genuine collaborators who will help you innovate and scale. A detailed Request for Proposal (RFP) is your best tool for digging deeper.

Your RFP should do more than just ask for a quote. Use it to gauge their expertise and flexibility.

- Ask about their R&D Process: How do they approach custom formulations? Can they share examples of innovative solutions they've developed, like using advanced cold-fill technology to preserve delicate botanicals?

- Inquire about Sourcing Transparency: Where do their raw materials come from? What's their process for vetting suppliers and demanding Certificates of Analysis (COAs) for every ingredient?

- Clarify Run Size Flexibility: Can they support a small pilot run for your launch and then scale up to full production as you grow? A partner who understands the startup journey and is willing to grow with you is invaluable.

The quality of their responses reveals their commitment to partnership versus just fulfilling an order. To help you stay organized, use this checklist to score each potential partner and make a data-driven decision.

Contract Manufacturer Vetting Checklist

| Vetting Criteria | What to Look For | Red Flags to Avoid |

|---|---|---|

| Certifications | cGMP, FDA-Registered, UL/NSF, Organic, etc. | Missing or expired certifications; hesitation to provide documents. |

| Quality Control (QC) | In-house lab, experienced QC team, detailed testing protocols. | Vague answers on testing; no dedicated QC staff. |

| R&D Capabilities | In-house formulators, experience with unique ingredients & innovation. | Only offers stock formulas; limited R&D support. |

| Sourcing Transparency | Clear supplier vetting process, provides COAs for all ingredients. | Obscure sourcing information; unwilling to share COAs. |

| Production Flexibility | Accommodates small pilot runs and large-scale production. | High MOQs only; inflexible production scheduling. |

| Communication Style | Responsive, clear, and provides a dedicated account manager. | Slow response times; vague or evasive answers. |

| Industry Experience | Proven track record with brands similar to yours (e.g., liquid herbals). | New to the industry; no relevant case studies or references. |

After comparing candidates using this checklist, you'll have a much clearer picture of who rises to the top as a true potential partner.

The market for these services is incredibly dynamic. North America leads the dietary supplement contract manufacturing market, which is projected to grow by USD 46.35 billion between 2025 and 2029. This growth is driven by manufacturers investing in advanced technology and maintaining rigorous quality controls. You can explore more insights on this rapidly expanding market. Partnering with the right group isn't just a sourcing decision; it's a strategic move for your brand's future.

Bringing Your Custom Formulation to Life

This is where your unique product idea becomes a tangible reality. The formulation and R&D process is more than just mixing ingredients; it’s a creative partnership where your brand’s identity is forged.

When you work with the right contract manufacturer for nutritional supplements, you’re not just handing over a recipe. You’re starting a collaboration to build something exceptional from the ground up. The first big decision is whether to go with a stock private-label formula or create something entirely custom.

Private Label vs. Custom Formulation: A Strategic Choice

A private-label (or "white-label") product is an off-the-shelf formula a manufacturer has already developed. You simply add your own branding.

The main advantage is speed-to-market. The R&D is done, and you can launch in a fraction of the time with lower Minimum Order Quantities (MOQs), reducing upfront financial risk. The trade-off is a lack of uniqueness; your product will be functionally identical to others, meaning you compete almost entirely on branding and price.

A custom formulation, on the other hand, is developed exclusively for your brand. You work directly with the manufacturer's R&D team to pick every ingredient, fine-tune dosages, and perfect the flavor profile of your liquid supplement. This is your chance to truly innovate. While it requires more time and a larger initial investment, the result is a one-of-a-kind product that you own outright—a massive competitive advantage.

We position ourselves as your R&D partner from concept through launch. The goal isn't just to make a product; it's to create the best possible version of your product, leveraging our expertise in botanical extraction and formulation science to bring your vision to life.

The Collaborative R&D Process

Once you decide on a custom formula, the partnership kicks into high gear. A great manufacturer will guide you through a transparent, step-by-step development process.

Here’s what that collaboration looks like:

- Ingredient Profiling and Sourcing: You’ll work with formulators to select potent, science-backed botanical extracts. A manufacturer’s sourcing transparency is critical here. They must provide a Certificate of Analysis (COA) for every raw material to prove its identity, purity, and potency.

- Dosage and Efficacy: The R&D team helps determine the perfect dosage for each active ingredient to ensure your product is effective and your marketing claims are supported.

- Flavor and Palatability: For liquid supplements, taste is paramount. Your partner will develop multiple flavor samples, letting you give direct feedback to perfect the profile for your target customer.

- Pilot Batch and Stability Testing: Before a massive production run, a small pilot batch is created. This sample serves as the "gold standard" for final approval and undergoes stability testing to ensure the product maintains its potency and quality over its entire shelf life.

This methodical approach eliminates surprises and de-risks your launch, ensuring the final product is precisely what you envisioned.

Supply Chain Transparency: The Foundation of Trust

A custom formula is only as good as its raw ingredients. A transparent, ethical sourcing strategy isn't a "nice-to-have"—it's a requirement. Your contract manufacturer must have a robust supplier qualification program, deeply vetting every farm and raw material provider.

This commitment to quality should extend to their technology. We rely on advanced, temperature-controlled extraction methods and cold-fill technology. This modern approach avoids high heat that can degrade sensitive vitamins and botanical compounds, ensuring your final product delivers maximum potency and efficacy. This dedication to quality—from sourcing to bottling—is what separates a simple supplier from a genuine manufacturing partner.

Mastering Quality Control and Regulatory Compliance

When you're building a supplement brand, especially in a competitive space like liquid herbals, quality and compliance are the bedrock of your reputation and customer trust.

You have to prove your product's safety, purity, and potency with every bottle. This is where your relationship with a contract manufacturer for nutritional supplements becomes a critical part of your business. A great partner’s dedication to quality is a daily discipline, starting the moment raw materials arrive and not ending until your finished product is sealed and ready for fulfillment.

Deconstructing cGMP and FDA Registration

"cGMP" and "FDA-registered" are more than just buzzwords; they are your assurance of quality.

Current Good Manufacturing Practices (cGMP) are the standards mandated by the FDA for how products are made, tested, and stored. It's the law. A cGMP-certified facility lives by these strict protocols:

- Facility Cleanliness: Documented procedures for sanitizing all equipment and production areas to prevent cross-contamination.

- Personnel Training: Every team member is trained on proper material handling and safety protocols.

- Meticulous Record Keeping: Every step is documented, from raw material lot numbers to final batch records, ensuring full traceability.

Being an FDA-registered facility means the manufacturer is subject to unannounced inspections. This registration adds a layer of accountability, giving you peace of mind that your partner operates under federal oversight.

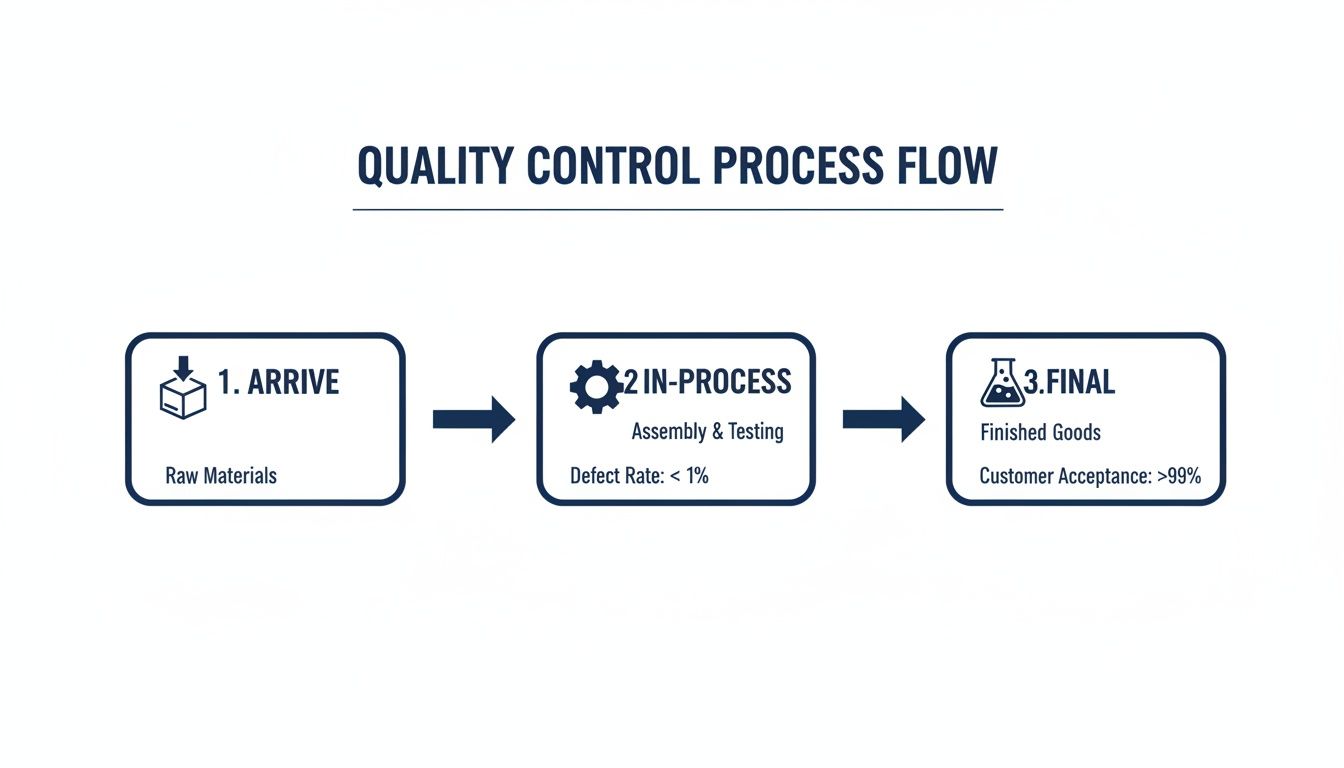

Key Quality Checkpoints in the Production Journey

A reliable manufacturer builds quality into every phase of production. This proactive approach catches potential issues early, saving you from expensive mistakes and protecting your customers.

Here's what that looks like in practice:

- Raw Material Quarantine and Testing: No ingredient enters the production line until it's been rigorously tested for identity, purity, and potential contaminants, starting with verifying the supplier's Certificate of Analysis (COA).

- In-Process Testing: Quality checks happen at critical points during production, such as testing pH levels or viscosity to ensure every drop of a liquid supplement is consistent.

- Microbial Screening: Before bottling, samples are tested for any harmful bacteria, yeast, or mold. This is a non-negotiable safety step.

A manufacturer’s quality process reflects their respect for your brand. If they can't walk you through their specific testing protocols for each production stage, that’s a significant warning sign.

This multi-step validation ensures the product in the bottle perfectly matches the formula on paper. We take this so seriously that we've broken down our entire process in our guide to comprehensive supplement quality control.

The Power of Independent Third-Party Testing

While in-house testing is critical, the gold standard for trust is independent, third-party lab testing. This final step delivers an unbiased verdict on your product's potency and purity. Any top-tier manufacturer will automatically send a sample from your finished batch to an accredited lab for analysis.

This independent lab checks two main things:

- Potency: Does the bottle contain the exact amount of active ingredients listed on your label?

- Purity: Is the product free from contaminants like heavy metals, pesticides, or solvents?

The resulting COA is one of your most valuable assets. It's objective proof that your product is exactly what you claim it is—essential for building consumer trust and often a requirement for selling on major platforms like Amazon.

The entire nutraceutical market is built on this foundation of trust. The numbers don't lie—the broader nutraceutical contract manufacturing services market is projected to be worth USD 187.6 billion in 2025 and is forecasted to hit an incredible USD 585.2 billion by 2035. That explosive growth is driven by brands that prioritize and prove their commitment to quality.

From Pilot Runs to Full-Scale Production

Once your custom formula is approved, the action begins. This is where we turn a crafted recipe into a physical, market-ready product. Going from a single lab sample to pallets of thousands of units requires military precision. As a brand founder, understanding this playbook is what separates a smooth launch from a stressful one.

A top-tier contract manufacturer for nutritional supplements will guide you through a structured production timeline built for quality, consistency, and scale. This is the kind of reliability you need to build your business with confidence.

The Critical Role of the Pilot Run

Before committing to a full-scale run, any smart manufacturer will insist on a pilot run. This is a small, controlled batch (usually a few hundred units) that serves as the ultimate real-world test for your formula. It is an essential step that removes a massive amount of risk.

The pilot batch accomplishes several critical things:

- Verifies Consistency at Scale: It proves the formula behaves the same in large-scale equipment as it did in the R&D lab, ensuring consistent taste, color, and texture.

- Confirms Stability: Samples are pulled for final stability testing, guaranteeing the product holds its quality and potency throughout its shelf life.

- Finalizes Sensory Profile: This is your last chance to taste and approve the final product before hitting "go" on the main production.

Think of the pilot run as the final dress rehearsal. It catches any tiny issues before they become expensive headaches, ensuring a rapid and reliable turnaround for your full launch.

Navigating Minimum Order Quantities

One of the first conversations you'll have with a partner revolves around the Minimum Order Quantity (MOQ)—the smallest number of units they’ll produce at once. For new brands, the MOQ can be a make-or-break factor for your budget.

MOQs exist because setting up production lines has a fixed cost. Spreading that cost over more units lowers the price per unit. However, a high MOQ means a larger upfront investment and more inventory to manage.

A true partner gets the startup grind. They’ll offer flexible MOQs that let you launch with a manageable pilot run and then scale up smoothly as sales take off. This approach keeps your initial risk low while giving you a clear runway for growth.

Be upfront about your sales forecasts. A manufacturer who believes in your vision is more likely to find a starting point that works for your budget, because they plan to grow alongside you.

Packaging Sourcing and Label Compliance

Your product’s bottle, cap, and label are as vital as the liquid inside. Your manufacturer should guide you through these final steps, ensuring everything is functional, looks great, and is 100% compliant.

Label compliance is non-negotiable. The FDA has strict rules for what must appear on a supplement label, including:

- Statement of identity (what the product is)

- Net quantity of contents

- Supplement Facts panel

- A full list of ingredients

- Name and place of business of the manufacturer or distributor

A good contract manufacturer will have an expert review your label design to flag potential red flags before printing. This proactive step can save you from major regulatory nightmares and ensures your product is ready for demanding platforms like Amazon.

The entire production journey is a multi-stage process with quality control baked in at every step.

Quality isn't just a final check. It's a continuous process that ensures a reliable, on-time delivery you can count on. From the pilot run to the final packaged product, a dependable partner provides transparent timelines and clear communication, turning your vision into a product you can be proud to sell.

Getting Your Product Ready for Prime Time: Retail and E-Commerce

Your product is finally manufactured—a huge milestone. Now it’s time for the final lap: getting those finished goods from the factory floor to a successful launch. This is where a true manufacturing partner proves their worth.

Retailers and e-commerce giants don't compromise on compliance. A top-tier contract manufacturer for nutritional supplements will have all essential paperwork ready, including cGMP certificates and a Certificate of Analysis (COA) for every batch. This is the proof they need that your product is safe, high-quality, and ready for customers.

Nailing the Logistics and Inventory Handoff

With documentation squared away, it’s time to get your product to customers. Your manufacturing partner should make the logistics process feel effortless. Whether you’re shipping a full freight load to an Amazon FBA warehouse or coordinating with your own third-party logistics (3PL) provider, their experience is invaluable for a smooth handoff.

A proactive partner doesn't just ship your order and disappear. They work with you to establish smart reorder points, so you don't run into dreaded stockouts that crush sales momentum and tank search rankings.

This partnership mindset extends to other crucial areas, like packaging. As you gear up for launch, what your product looks like is almost as important as what's inside. For a deep dive, check out this comprehensive guide to effective packaging strategies for supplements to make sure your product stands out while maintaining its integrity.

Ultimately, this last stage separates a mere supplier from a genuine, long-term collaborator. They become invested in your growth, offering the operational backbone you need to thrive. That reliable support frees you up to do what you do best: marketing your product and scaling your business.

Common Questions from New Supplement Brands

When you're diving into supplement manufacturing, a few key questions always come up. Let's tackle the big ones—budget and timeline—to give you a clear picture of what to expect when looking for the right contract manufacturer for nutritional supplements.

What's a Realistic Budget for a First Production Run?

The honest answer is: it depends. Your formula's complexity, ingredient costs, packaging, and your manufacturer's Minimum Order Quantity (MOQ) all play a role.

That said, for a relatively straightforward liquid herbal supplement, a new brand should be prepared for an initial investment between $10,000 and $25,000.

What does that initial investment typically cover?

- R&D and custom formulation.

- Sourcing and testing of all raw materials.

- A small but crucial pilot batch for final approval.

- Your first full production run, often in the 1,500-3,000 unit range.

- Packaging components and essential third-party lab testing.

My best advice? Always demand a detailed, line-item quote from any potential partner. This prevents surprise fees and signals you're dealing with a transparent, reliable manufacturer.

How Long Does It Take to Go from Concept to Finished Product?

Patience is key. The average timeline from idea to a market-ready supplement is about 4 to 6 months. This is a solid benchmark for planning your launch.

The journey usually breaks down like this:

- Formulation & R&D: 4-8 weeks

- Ingredient Sourcing & Testing: 3-6 weeks

- Pilot Batch & Stability Testing: 4-8 weeks

- Full Production Run & Final QC: 4-6 weeks

This timeline can be faster if you're using a pre-existing base formula, or longer if your product requires rare botanical extracts or hits complex development hurdles. A partner focused on speed and reliability will provide a transparent timeline and stick to it.

Key Takeaway: Formula ownership is non-negotiable. If you are paying for custom development, ensure the intellectual property (IP) belongs to you. This must be spelled out clearly in your manufacturing contract.

If you opt for a manufacturer's stock "private label" formula, they own that IP. Clarify this in writing before any money is spent. Your formula is your brand's most valuable asset—protect it.

Once your product is made, the real work of selling it begins. A successful launch requires a smart sales and marketing engine. It's worth exploring effective marketing automation strategies for e-commerce to maximize your reach and drive sales from day one.

Ready to turn your vision for a liquid herbal supplement into a market-ready reality? The expert team at Triton Nutra Group is your dedicated R&D partner, offering transparent timelines, flexible run sizes from pilot to full scale, and unparalleled quality control.