Your Partner in Bayberry Root Bark Private Label Manufacturing

Partner with the leading Bayberry Root Bark private label contract manufacturer for quality and reliable private labeling solutions. Get started today!

Get a Free Quote Today!

Get a Free Quote Today!Choosing your Bayberry Root Bark private label contract manufacturer is a foundational decision for your brand. This isn't just sourcing a product; it's about finding a true partner who understands the nuances of botanical extracts and has the advanced systems to scale with you. Get this right, and you launch with an unshakeable commitment to quality and innovation.

Finding Your Ideal Manufacturing Partner

Let's be clear: selecting a manufacturer is one of the most critical moves you'll make. You aren't just looking for someone to fill bottles. You need a long-term collaborator who acts as an extension of your team—a partner equipped to handle the unique challenges of niche botanicals like Bayberry Root Bark.

For e-commerce founders and brand managers, the vetting process must start with a list of non-negotiables. These are the absolute must-haves that separate a top-tier, reliable operation from a potential liability.

Starting Your Search with Core Qualifications

Before discussing formulas or pricing, your first pass should focus on the fundamentals: compliance and certifications. Think of these as the gatekeepers of quality and trust.

Your initial vetting checklist should include:

- cGMP Certification: Current Good Manufacturing Practices are the bedrock of safety in the supplement industry. A cGMP-certified facility proves they have robust processes to guarantee your product's identity, strength, and purity. This is non-negotiable.

- FDA-Registered Facility: This is table stakes. It confirms the facility is known to the FDA and subject to inspection, adding a crucial layer of accountability.

- Third-Party Testing: A great partner doesn’t just grade their own work. They provide independent, third-party lab testing to verify the potency and purity of your Bayberry Root Bark extract, ensuring it's free from heavy metals, microbes, and other contaminants.

The demand for high-quality botanicals has exploded. The best manufacturers have leaned into this by integrating rigorous safety and efficacy testing that meets and exceeds FDA regulations. This commitment is what keeps niche ingredients safe and builds consumer confidence in specialty products like yours.

A true partner doesn't just take your order. They build the quality and compliance framework that gives you the peace of mind to grow your brand with confidence.

To streamline your initial screening, use this quick-reference checklist.

Initial Manufacturer Vetting Checklist

This table breaks down the non-negotiable criteria for any potential partner. If a manufacturer can't tick all these boxes, move on.

| Core Requirement | Why It Matters | What to Ask For |

|---|---|---|

| cGMP Certification | This is the gold standard for quality control, ensuring every batch is consistent, pure, and safe. | A copy of their current cGMP certificate from a reputable third-party auditor (like UL or NSF). |

| FDA Registration | A legal requirement for any facility producing supplements for the US market. | Their FDA registration number and proof of current registration. |

| Third-Party Lab Testing | Provides unbiased verification of your product's potency and purity, building consumer trust. | Examples of Certificates of Analysis (CoAs) from their third-party lab partners. |

| Botanical Expertise | Experience with botanicals ensures they understand proper handling, advanced extraction, and formulation. | Ask about other botanical products they've manufactured and their experience with liquid supplement stability. |

Using this checklist will save you significant time and help you quickly filter out operations that don't meet the baseline standards for a premium botanical product.

Finding a manufacturer that meets these technical requirements is just the first step. The next is determining if they are the right strategic fit for your brand. That alignment is what turns a supplier relationship into a true partnership. For a deeper dive, check out our complete guide on choosing the right manufacturer.

Decoding Quality and Compliance Standards

In the wellness industry, "quality" isn't a vague marketing term; it's the foundation of your brand's reputation. For a niche product like a Bayberry Root Bark liquid supplement, demonstrating your commitment to safety and efficacy is non-negotiable. This means you must look past buzzwords for tangible, verifiable proof of a manufacturer's compliance systems.

When you evaluate a potential Bayberry Root Bark private label contract manufacturer, you need to speak their language. Asking sharp, specific questions about quality protocols is what separates a prepared brand founder from an amateur.

The Non-Negotiable Trio: cGMP, FDA, and UL

Think of these credentials as the unshakable pillars of a trustworthy manufacturing operation. They represent a serious, ongoing investment in excellence and safety.

-

cGMP Certified: This is your absolute baseline. Current Good Manufacturing Practices are federally enforced standards ensuring products are consistently produced and controlled. A cGMP-certified facility proves they have documented procedures for everything, from raw material quarantine to final product release.

-

FDA Registered: This confirms the manufacturer is on the Food and Drug Administration's radar. It means they are subject to inspections and must adhere to federal regulations, adding a critical layer of oversight.

-

UL Certified: While cGMP is the standard, a UL certification (or a similar audit from NSF) provides an extra layer of assurance. It shows an independent body has audited the facility's processes and verified they meet specific, high-level quality and safety standards, showcasing a commitment that goes above and beyond.

A partner’s investment in these certifications is a direct investment in your brand's safety and credibility. It’s the difference between hoping your product is compliant and knowing it is.

Beyond the Certificate: Raw Material Verification

Certificates are vital, but an elite partner demonstrates their commitment to quality long before the first ingredient is mixed. For a botanical like Bayberry Root Bark, this process begins with rigorous raw material sourcing and verification.

Bayberry root bark, from the Morella cerifera plant, has a rich history in traditional herbalism. Its use demands precise formulation and testing to ensure safety and efficacy.

This is why you must pin down potential partners with specific questions about their supply chain integrity:

- Sourcing & CoA: How do you vet your raw material suppliers? Is a Certificate of Analysis (CoA) required with every shipment?

- Identity Testing: What methods do you use to confirm the botanical identity of the raw Bayberry Root Bark? Do you use modern techniques like HPTLC?

- Purity Screening: How do you screen for contaminants like heavy metals, pesticides, and microbial pathogens?

A confident, detailed answer—backed by documentation—is a clear sign you’ve found a manufacturer who takes ingredient integrity as seriously as you do. This proactive approach is a hallmark of a top-tier partner and a key component of the essential dietary supplement manufacturing requirements that protect your brand and your customers.

How Customization Sets Your Brand Apart

The wellness market is crowded. A generic product won't cut it—it will get lost in the noise. Your brand’s unique identity is its most powerful asset, and a true manufacturing partner acts as a collaborator to amplify it. This is where customization becomes your core strategic advantage.

When you work with the right Bayberry Root Bark private label contract manufacturer, you get a partner who helps you build a product from the ground up. Think of us as your R&D partner, turning your vision into a tangible, market-ready liquid supplement that stands out.

Beyond the Base Formula

The most exciting layer of customization is the formula itself. While Bayberry Root Bark is the star, the opportunities to create a unique product are nearly endless. A skilled formulation partner works with you to dial in every detail.

This includes:

- Potency Adjustments: Do you need a standard-strength formula for daily use or something more potent for a specific consumer? We precisely adjust the concentration to match your product strategy.

- Synergistic Blends: Bayberry Root Bark pairs well with other botanicals. We can suggest ingredients like Black Pepper extract to enhance absorption or Ginger for its complementary soothing properties, creating a more effective and marketable product.

- Flavor Profiling: Herbal extracts can have a strong taste. Our flavor chemists can develop a unique profile—from subtle citrus notes to warm spice blends—that makes your supplement not just effective, but enjoyable.

A partner’s job isn’t to sell you a pre-made formula. It’s to provide the R&D expertise to build your dream formula, ensuring it's stable, effective, and uniquely yours.

Packaging and Production That Fits Your Brand

The customization journey continues after the formula is perfected. The physical product and production scale must align with your brand’s ethos and operational needs. We help you match your formula with packaging that tells your story, from eco-friendly glass bottles to specific dropper styles.

Just as important is flexibility in production. You shouldn't have to commit to a massive run to test a new idea. Our commitment to flexible run sizes is a core part of our partnership mindset.

- Pilot Batches: Validate your concept with a small run. Gather real customer feedback and test the market without a huge upfront investment.

- Scaling Production: Once you have proof of concept, we seamlessly scale to full production to meet growing demand, ensuring a reliable supply chain.

This agility allows you to innovate quickly and grow with confidence. By combining deep formula customization with flexible production, you get a product that isn't just different—it's authentically better and perfectly positioned for your audience.

Mapping Your Product Development Timeline

For ambitious e-commerce brands, speed to market is everything. A fast, well-executed launch grabs customer attention and builds crucial momentum. That's why you need a realistic roadmap for taking your Bayberry Root Bark supplement from concept to customer.

A transparent partnership with your manufacturer makes this timeline work. This isn’t a black box where you place an order and wait. It’s a collaborative project with clear phases, and a great partner keeps you in the loop every step of the way, ensuring reliable, on-time delivery.

From Concept to Pilot Batch

The journey begins the moment you approve your custom formula. From there, a series of carefully planned stages kicks off to lay a solid foundation for a smooth production run.

- Raw Material Sourcing & Verification (2-3 weeks): This is the most critical first step. As your Bayberry Root Bark private label contract manufacturer, we immediately source the botanical from our vetted supplier network. Upon arrival, the material is quarantined and sent for third-party testing to confirm its identity, purity, and potency. Only after it passes is it released into our inventory.

- Pilot Batch & Flavoring (1-2 weeks): With the approved raw material, we create a small-scale pilot batch. This is your chance to test the sensory aspects, like taste and mouthfeel, and provide feedback. It’s the perfect time for final tweaks before scaling up.

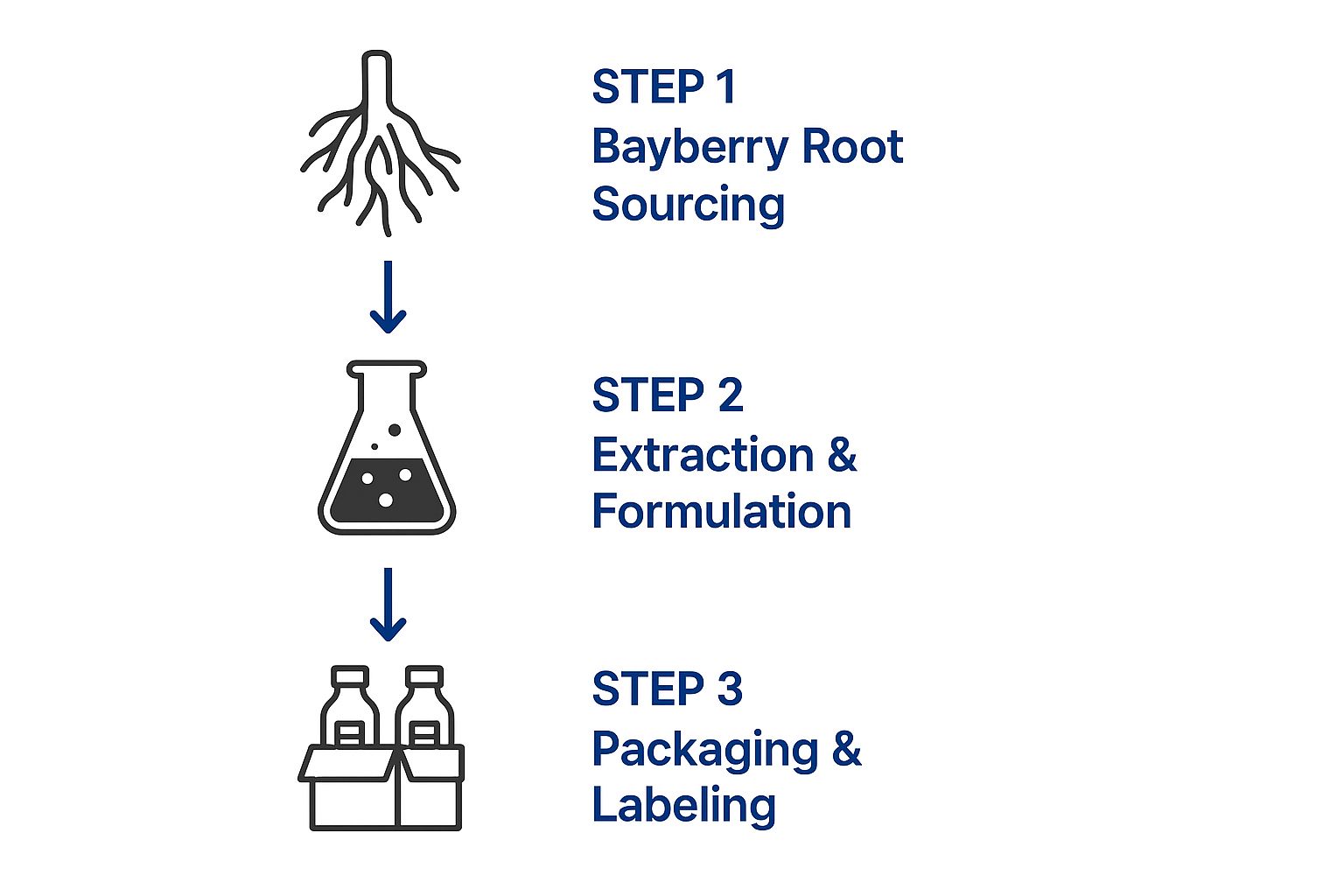

This infographic breaks down the core manufacturing journey into three main stages.

This illustrates how each step builds on the last, from securing quality botanicals all the way to final delivery.

Stability, Production, and Launch

With your approval on the pilot batch, the project moves into the home stretch. Open communication here is essential for staying on schedule.

Here’s what happens next:

- Stability Testing (Timeline varies): While other steps are in motion, we initiate stability testing. This ensures your product maintains its quality and potency throughout its shelf life. Initial data points, which take about 4-6 weeks, are enough to confirm stability for launch.

- Full-Scale Production (3-4 weeks): After your final sign-off, we begin full-scale manufacturing. Your custom Bayberry Root Bark liquid supplement is blended, bottled, and packaged under strict cGMP protocols. We provide transparent updates as we hit key production milestones.

- Final Quality Control & Release (1 week): Before shipment, the finished product undergoes one last round of quality assurance checks. Once cleared, it’s officially released.

A proactive manufacturer anticipates roadblocks. We build in buffer time and maintain open communication, turning potential delays into manageable checkpoints. This is how we ensure on-time delivery.

From formula approval, a realistic lead time is typically 8-12 weeks. A clear timeline managed by a dedicated partner empowers you to plan your marketing campaigns and prepare for a successful, high-impact launch.

Why You Need a Partner, Not Just a Supplier

The most successful brands didn’t get there by simply finding a supplier to fill an order. They found a strategic partner. It’s a crucial difference.

A supplier takes your PO, makes your product, and sends a bill. A partner is in the trenches with you. They are as invested in your success as you are, from the first pilot batch to scaling up for massive growth.

When choosing a Bayberry Root Bark private label contract manufacturer, you’re really looking for an ally. You need someone who brings solutions before you even know there’s a problem. A supplier might tell you a raw material is delayed. A partner sees that risk weeks in advance and comes to you with a pre-vetted alternative source or a smart adjustment to the production schedule. That’s the game-changer.

Your R&D Partner from Concept Through Launch

What does this partnership look like? It feels like having an expert R&D team on your payroll, without the overhead. A real partner doesn’t just ask for specs; they dig deeper to understand your goals.

They might suggest adding Black Pepper extract to your Bayberry formula, not as an upsell, but because they know from experience that it can boost bioavailability—a massive selling point for savvy customers.

This collaborative spirit gives you access to incredible market intelligence. An experienced manufacturer has a bird's-eye view of the industry. They see what’s working, what’s not, and what’s next.

A true partner brings ideas to the table you hadn't even considered. They'll say, "We're seeing a huge consumer shift toward alcohol-free tinctures. Our innovative cold-fill technology would be perfect for preserving the delicate compounds in your Bayberry Root Bark. Have you considered that for your line?"

This proactive advice is invaluable. It helps you innovate, stay ahead of the competition, and build a product line with staying power.

Listening for a Collaborative Spirit

You can tell the difference between a supplier and a partner from the first call. A supplier’s conversation is about logistics: MOQs, pricing, lead times. A partner’s conversation starts with your vision.

They’ll ask questions like:

- What's the long-term plan for this product? Are you envisioning a full line?

- Tell me about your ideal customer. What problem are you solving for them?

- How can we ensure this product perfectly tells your brand's story?

This approach is everything. When your manufacturer understands the "why" behind your brand, they are infinitely better at executing the "how." For any e-commerce founder or brand manager, finding that alignment is the key to building a resilient, scalable, and wildly successful business.

Common Questions About Bayberry Root Bark Manufacturing

When you're diving into botanical supplements, especially something as specific as Bayberry Root Bark, questions are a good sign. They show you're serious about getting it right. We’ve found that brand founders—seasoned pros and first-timers alike—tend to ask the same crucial questions.

Let’s get right to the answers you need when partnering with a Bayberry Root Bark private label contract manufacturer.

What's a Realistic Minimum Order Quantity (MOQ)?

This is often the first question, and for good reason—it impacts your budget and inventory risk. The answer separates manufacturers who want to grow with you from those seeking large orders. Some large players won't talk to you unless you commit to 5,000 units or more. That’s a huge gamble for a new product.

A partner invested in your success thinks differently. We find a starting point of 1,500 to 2,500 units is the sweet spot. It's large enough for efficient production but small enough that you don’t tie up all your capital. This flexible approach lets you launch your custom formula, gather customer feedback, and then scale confidently.

A true manufacturing partner offers manageable MOQs that let you test, learn, and then scale up when you're ready for explosive growth, acting as your partner from pilot to full-scale production.

How Do You Guarantee Potency and Purity?

For a botanical product, this is everything. Quality is a non-negotiable process that begins long before ingredients enter the mixing tank.

First, it comes down to sourcing. We work only with a select group of vetted suppliers, and every raw material batch must arrive with a detailed Certificate of Analysis (CoA). But we don't just take their word for it. The moment that raw Bayberry Root Bark arrives, it's quarantined.

Our in-house quality team then sends samples for third-party lab verification, using methods like HPLC to confirm the phytochemical profile and potency. It must match our specifications.

On top of that, we screen aggressively for anything that shouldn’t be there:

- Heavy metals (lead, arsenic, mercury)

- Microbes (E. coli, salmonella)

- Pesticides and other residual toxins

This isn't just about ticking boxes. It's about ensuring the product you sell is safe, pure, and delivers exactly what your label promises, backed by our cGMP and UL certifications.

What's the Average Lead Time From Formula to Delivery?

Knowing your timeline is critical for a successful launch. For a new custom product, you should realistically budget 8-12 weeks from final formula and packaging approval. Our commitment to reliability means we provide rapid, transparent timelines.

A typical project flows like this:

- Sourcing & Raw Material Testing: 2–3 weeks

- Pilot Batch Run (if required): 1–2 weeks

- Full-Scale Production & Quality Control: 4–6 weeks

- Final Lab Release & Shipping: 1 week

This timeline integrates the meticulous quality checks that protect your brand. The key is communication. As your partner, we report any potential delay the second we see it and come to you with a solution already in mind, ensuring an on-time delivery record you can count on.

Can You Help with Label Design and FDA Compliance?

Absolutely. This is one of the most valuable services a great manufacturing partner provides. While we are not a design firm, we are your regulatory guardrail. Your label is a marketing tool, but in the eyes of the law, it's a legal document that must be perfect.

Our compliance team lives and breathes FDA regulations. Before you print, we will review your entire label design. We check for the proper format of the Supplement Facts panel, ensure all allergen statements are present, and—most importantly—flag any marketing claims that could create regulatory risk.

Think of it as an insurance policy. This collaborative review protects you from costly reprints or, worse, legal trouble down the line. It's a core part of our partnership mindset.

Are you ready to turn your vision for a premium Bayberry Root Bark liquid supplement into a market-ready success? At Triton Nutra Group, we are your dedicated R&D and manufacturing partner, providing the expertise, quality, and flexibility you need to grow your brand.