Partnering with the Right Astragalus Root Private Label Contract Manufacturer

Partner with a reliable Astragalus Root private label contract manufacturer to elevate your brand. Expert quality and custom solutions available.

Get a Free Quote Today!

Get a Free Quote Today!Choosing the right Astragalus Root private label contract manufacturer isn't just a box to check—it's the single most important decision you'll make when launching your supplement. Think of it less like finding a supplier and more like securing a strategic partner who can accelerate your launch, slash massive R&D costs, and give you day-one industry expertise.

Finding Your Astragalus Supplement Launch Partner

The demand for high-quality herbal supplements like Astragalus Root is booming. For e-commerce founders and wellness entrepreneurs, the opportunity is huge. But turning that great idea into a real, market-ready product means navigating a tricky landscape of formulation, compliance, and production.

This is exactly where a partnership-focused manufacturer becomes your biggest asset. We act as an extension of your team, bringing deep expertise in botanical extraction, regulatory compliance, and supply chain management. This lets you focus on what you do best: building your brand and connecting with your customers.

The Strategic Edge of Private Labeling

Going the private label route gives you serious advantages that de-risk your launch and boost your chances of success.

- Speed & Reliability: Bypass the long R&D phase by starting with a proven base formula. Our transparent timelines can take you from concept to a finished product in as little as 8-12 weeks.

- Cost Efficiency: Forget the multimillion-dollar investment in equipment and staff. You get immediate access to our cGMP, UL certified, and FDA-registered facility.

- Built-in Expertise: You immediately tap into our team's knowledge of sourcing high-potency raw materials, ensuring product stability, and meeting tough quality standards.

This approach is especially powerful in a growing market. The global astragalus root extract market is projected to hit an estimated US$ 777.3 million by 2033, growing at a compound annual rate of about 3.9%. Tapping into that growth requires moving quickly and efficiently.

Before we dive deeper, it's worth taking a moment to clarify the difference between private labeling and creating a fully custom formula from the ground up. While they might seem similar, they serve very different needs and timelines.

Private Labeling vs Custom Formulation

| Factor | Private Labeling | Full Custom Formulation |

|---|---|---|

| Speed to Market | Very Fast (8-12 weeks) | Slow (6-12+ months) |

| Upfront Cost | Low | Very High |

| Minimum Orders | Low | High |

| Formula Control | Limited (customizations on a base) | Full Control |

| R&D Required | None | Extensive |

| Best For | New brands, fast launches, market testing | Established brands, unique IP |

As you can see, private labeling is the ideal path for entrepreneurs who want to get a high-quality product to market without the massive initial investment and long lead times of a custom formulation.

Your manufacturer shouldn't just be an order-taker. We are your R&D partner from concept through launch. This collaborative mindset is the difference between simply making a product and building a successful brand.

Once your Astragalus supplement is professionally manufactured and ready to go, the focus shifts to marketing and getting the word out. Smart brands know that a great product is only half the battle; for instance, many in the wellness space focus on strategies like building a killer beauty PR list to create buzz and connect with the right people.

In this guide, we'll walk you through exactly what to look for in a manufacturing partner—from the non-negotiable compliance and customization options to their ability to scale with you—so you can build a standout product backed by a reliable, expert-driven process.

Vetting Partners for Quality and Compliance

Let's be blunt: your brand’s reputation isn't built on slick marketing. It's built on the quality and safety of the supplement your customers take every day. When you sign on with an Astragalus Root private label contract manufacturer, you’re putting your brand's integrity in their hands.

This makes the vetting process the single most critical stage of your launch.

It’s easy to get distracted by flashy sales pitches about fast turnarounds and rock-bottom costs. But a truly reliable partner leads with verifiable proof of their commitment to quality. The non-negotiables are what separate a professional operation from a potential disaster.

Decoding cGMP Compliance

You’ll see cGMP (Current Good Manufacturing Practices) on every legitimate manufacturer's website. But what does it actually mean? It’s not just a certificate on the wall; it’s a living system governing every aspect of production.

A truly cGMP-compliant facility can show you:

- Meticulous Documentation: Every step, from when raw Astragalus root arrives to when the finished bottle ships, is logged in detailed batch records. Nothing is left to chance.

- Strict Process Controls: We live by our Standard Operating Procedures (SOPs) for everything from cleaning equipment to training staff, all designed to prevent cross-contamination.

- Environmental Monitoring: The facility itself is controlled, maintaining specific standards for air quality, temperature, and humidity to ensure your product remains stable and pure.

When you're talking to a potential partner, ask them to walk you through their batch record process. Their ability to explain it clearly is a dead giveaway of how seriously they take cGMP.

The Power of Third-Party Verification

While cGMP is the foundation, independent certifications are your extra layer of armor. Look for partners who have invested in being audited by respected third-party organizations.

An FDA-registered facility is the bare minimum—no exceptions. This simply means they're on the FDA's radar and subject to inspection. But the best manufacturers, like us, go further. An approval from an organization like UL proves that an independent body has audited our facility and confirmed our processes meet or exceed established safety and quality standards.

A partner’s investment in third-party audits is a direct investment in your brand's safety. It proves they are willing to be held accountable by objective, external experts, giving you and your customers ultimate peace of mind.

Given the rising global demand and concerns over adulteration, quality control within the astragalus root supply chain has become more critical than ever. The best manufacturers have adapted with tighter stakeholder coordination, allowing for strict traceability and quality management from field to bottle.

Raw Material Sourcing and Testing

The final quality of your supplement is 100% dependent on the quality of the raw Astragalus root they start with. A premier manufacturer has an ironclad system for sourcing and validating every ingredient.

Your vetting questions should be direct and specific:

- Supplier Qualification: "Walk me through your process for vetting and approving new raw material suppliers."

- Quarantine and Testing: "Do you quarantine all incoming materials? What specific tests do you run before releasing them into production?"

- Identity and Potency: "How do you verify the identity—that it is Astragalus membranaceus—and the potency of the root?"

A confident partner will welcome these questions. They should be able to tell you about their use of methods like High-Performance Liquid Chromatography (HPLC) to confirm the concentration of active compounds, proving you’re getting exactly what you're paying for.

Beyond these initial checks, remember that this is about building a relationship. Understanding solid vendor relationship management best practices is key to ensuring consistent quality for years to come. For more tips, our guide on finding a reputable supplement manufacturer digs even deeper. This commitment to transparency and verifiable quality is the bedrock of a partnership that will help you grow.

Customizing Your Astragalus Root Formula

This is where your vision becomes tangible. A great Astragalus Root private label contract manufacturer isn't just an order-taker; we are an extension of your R&D team, helping you nail a formula that stands out.

Think of this process less like picking from a catalog and more like a collaborative workshop. It’s all about translating your brand's unique concept into a high-quality, effective supplement that your target customer will love.

Choosing the Right Delivery Format

One of the first big decisions is the delivery format. This choice impacts everything—from the customer's daily experience and perceived effectiveness to manufacturing complexity and your final cost per unit.

While powdered extracts have traditionally held a strong position—about 43% of the market—liquid tinctures are gaining momentum. We're seeing this trend firsthand, driven by a growing consumer desire for faster absorption and ease of use. You can dig into some of the market data and see exactly how product form influences consumer choice.

Let's quickly compare the most common options for an Astragalus supplement.

Comparing Astragalus Supplement Formats

The way you deliver your formula is just as important as the formula itself. Each format has its own set of pros and cons, both for your brand and for the end consumer.

| Format | Key Advantages | Manufacturing Considerations |

|---|---|---|

| Liquid Tinctures | Faster absorption, precise dosing, alcohol-free glycerin options available. | Requires expertise in botanical extraction, flavoring to ensure palatability, and specialized bottling equipment. |

| Powders | Highly versatile for use in smoothies or drinks, cost-effective at higher doses. | Needs careful blending for homogeneity, potential for clumping if not processed correctly, and packaging must prevent moisture. |

| Capsules | Tasteless, convenient, and offers a precise pre-measured dose. | Encapsulation machine speeds can affect cost, and requires excipients (fillers) to ensure proper fill volume. |

For a brand that wants to convey "purity" and "fast-acting," a liquid tincture is often the best choice. Specifically, one using a glycerin-based, alcohol-free extraction process can preserve the delicate compounds of the Astragalus root while also being pleasant to take.

Creating a Synergistic Ingredient Profile

Your Astragalus supplement doesn’t have to fly solo. A massive opportunity for customization lies in creating a synergistic blend that targets a specific health benefit, whether it’s immune support, stress reduction, or respiratory health. This is where your manufacturer’s formulation expertise becomes invaluable.

Let’s say you’re creating an "Immune Resilience" tincture. A good formulator can help you pair Astragalus with other well-researched botanicals to amplify its effects.

- For Immune Support: Combining Astragalus with Elderberry and Echinacea can create a powerhouse, multi-faceted immune-boosting formula.

- For Adaptogenic Benefits: Pairing it with Ashwagandha or Rhodiola can lean into its stress-adapting properties, making it a perfect fit for consumers looking for mood and energy balance.

- For Enhanced Absorption: Adding a small amount of Black Pepper Extract (Piperine) is a smart, science-backed move to potentially increase the bioavailability of the active compounds.

Your contract manufacturer should be more than a supplier—they are your formulation consultant. They should have the scientific know-how to recommend ingredients that not only work well together but also align with your brand story and the claims you want to make.

Perfecting Flavor and Packaging

Especially in the liquid supplement world, taste isn't an afterthought—it’s a dealbreaker for customer retention. If it tastes awful, people won't re-purchase. An experienced partner will have a library of natural flavors and sweeteners to help you craft a profile that is both delicious and clean-label.

This part of the process usually involves a few rounds of sampling to get it perfect. Whether you're going for a subtle earthy-sweet flavor or something with a bright citrus pop, your manufacturer should guide you.

Finally, the packaging is what brings your brand to life. A flexible manufacturing partner offers a full suite of packaging solutions to match your brand's vibe and functional needs.

Packaging Customization Options:

- Bottle Type: Amber glass is classic for UV protection, but sleek PET plastics have their place, too.

- Closure: Dropper caps for tinctures, pump tops, or simple screw caps.

- Labeling: Full-color labels with different finishes (matte, gloss) and crucial tamper-evident seals.

- Secondary Packaging: Custom-printed boxes can give you that premium, ready-for-retail look.

From the first ingredient to the final sealed bottle, customization is all about making smart choices that build a product customers will love. The right manufacturing partner makes this complex process feel seamless.

From Lab Bench to Production Floor

Once your custom Astragalus formula gets the green light, the action moves from R&D to the production floor. This is where your vision takes shape, and a seasoned Astragalus Root private label contract manufacturer kicks into gear, focusing on delivering a consistent, high-quality product, on schedule. Seeing how this comes together demystifies the process and gives you the confidence to plan your launch.

Think of the manufacturing workflow as a carefully choreographed dance. Every step is governed by strict protocols. You should expect total transparency from your manufacturing partner here—a clear view of what’s happening at every stage is non-negotiable.

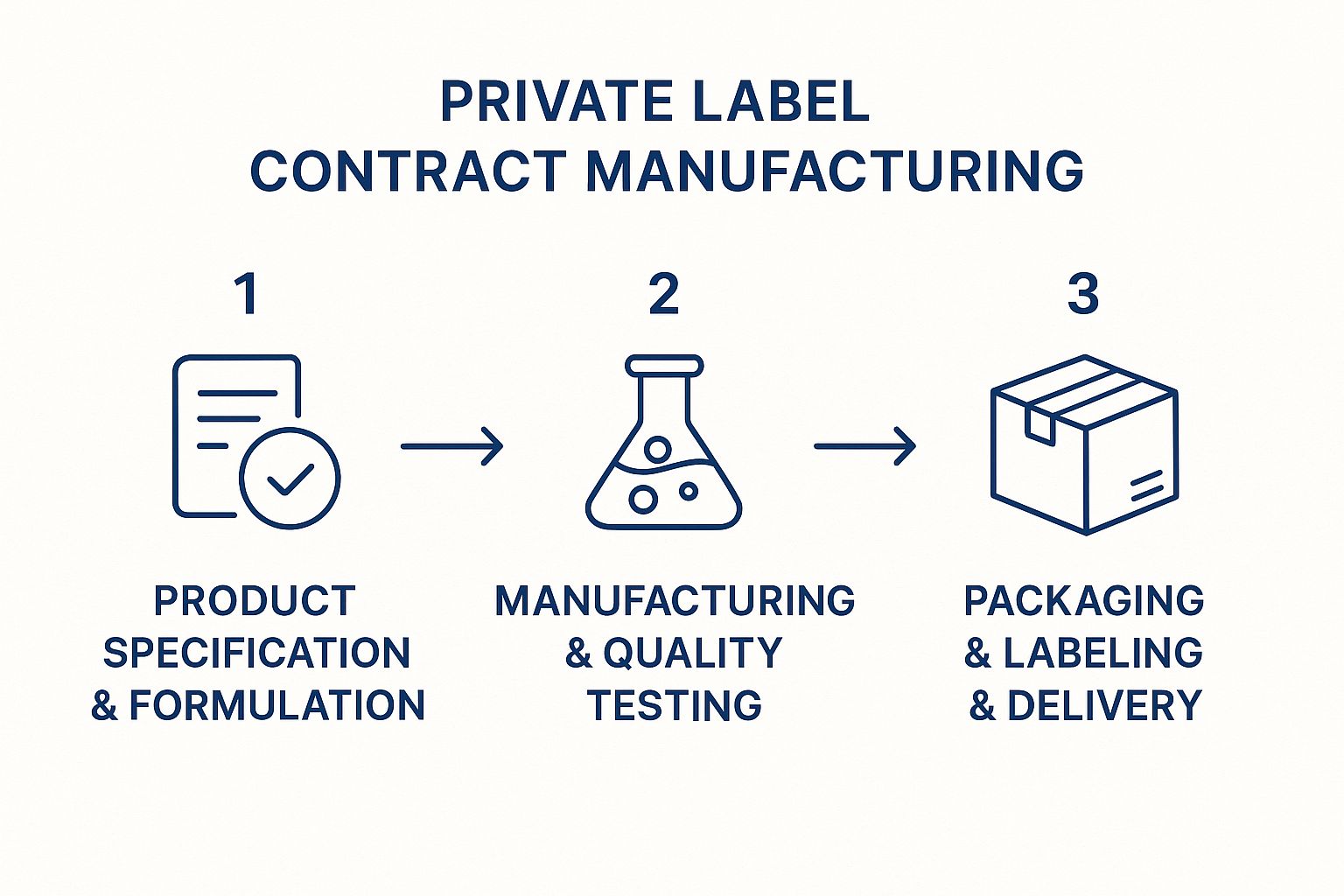

This graphic gives you a bird's-eye view of how we move a product from an idea to a reality.

As you can see, it's a linear path, but each stage is deeply connected. Notice how quality testing is woven throughout? That’s deliberate. It ensures your final product is absolutely perfect before it ever reaches your customers.

Keeping the Good Stuff Potent with Advanced Tech

What makes Astragalus root so effective are its delicate bioactive compounds. The catch? They’re sensitive to heat. Old-school hot-extraction methods can cook away these vital compounds, watering down the potency of the final product. This is where forward-thinking technology makes all the difference.

We utilize innovative cold-fill technology and advanced botanical extraction methods. These processes use precisely controlled, lower temperatures to gently pull the active constituents from the plant material without damaging them. The result is a more potent, stable, and great-tasting tincture that preserves the full spectrum of the herb.

If you're curious about the pros and cons of different formats, we've got a deep dive into the world of liquid supplements that breaks it all down.

Your Production Timeline, Unpacked

While no two projects are identical, a typical production run follows a predictable and transparent timeline. Understanding these milestones helps you sync up your marketing, sales, and launch plans with a delivery date you can count on.

Here's how it generally plays out:

- Weeks 1-2: Sourcing Raw Materials. We tap into our network of vetted suppliers to get our hands on the highest quality Astragalus membranaceus root and any other ingredients your formula needs.

- Weeks 3-4: Inbound QC & Testing. Every raw material that comes through our doors is quarantined. It then goes through a battery of tests for identity, purity, and potency before it’s even allowed near the production line.

- Weeks 5-7: Blending & Manufacturing. This is where the magic happens. Your formula is precisely blended in our cGMP-compliant facility, using our cold-fill tech to protect every last drop of potency.

- Weeks 8-10: Bottling, Labeling & Final QA. The finished liquid is bottled, sealed, and labeled. We then send samples from the completed batch for third-party testing to double-check that the final product meets every single one of our quality specs.

This standard 8-10 week timeline is built on a foundation of reliability, which means you can build your business forecasts around your inventory schedule with confidence.

Why a Rock-Solid Supply Chain is Everything

A manufacturer’s fancy equipment means nothing if they can't get the raw materials. A delay in sourcing can grind the entire operation to a halt, putting your launch at risk. That's exactly why we’ve spent decades building bulletproof relationships with trusted growers and suppliers all over the world.

This global network is more critical now than ever. Take India, for example. It's becoming a major powerhouse in the astragalus root market, with a forecasted CAGR of 5.8% from 2025 to 2035—blowing past the global average. This boom is driven by a modernizing herbal industry and government support for exports. Having solid partnerships in key regions like this ensures we can maintain a steady stream of top-quality raw materials, no matter what the market throws at us.

A reliable supply chain is your insurance policy against disruption. It ensures that the Astragalus root in your 100th batch is just as pure and potent as it was in your first, guaranteeing the consistency your brand depends on.

More Than a Supplier: Building a Partnership for Long-Term Growth

Choosing your Astragalus Root private label contract manufacturer is a critical decision. This isn't just about placing an order; it’s about starting a strategic relationship that can either launch your brand into the stratosphere or anchor it to the ground. You're not just buying a supplement; you're entrusting a collaborator with your brand's future.

The best partners in this space play the long game. They think beyond the current purchase order because they understand that your success is their success. You should stop thinking of them as a simple supplier and start seeing them as an extension of your own team.

Communication is Everything

Clear, proactive communication is the bedrock of a healthy manufacturing partnership. You can't make smart moves for your business when you're left guessing about production timelines or potential supply chain snags. A true partner sets up solid communication channels from the start.

This usually looks like a dedicated project manager—one person who becomes your go-to, who knows your product inside and out, and understands your brand's goals.

Here’s what that actually looks like in practice:

- A Dedicated Point of Contact: You shouldn't be bounced between departments. Having one person who owns your project means accountability and clarity.

- Proactive Updates: They should be telling you about progress before you even think to ask. Regular check-ins on milestones, from raw material arrival to final QC, are the sign of a pro operation.

- A Clear Escalation Path: Problems happen. But what's their process for fixing them? A great partner has a plan to tackle issues quickly and transparently.

Think about it this way: a key synergistic ingredient for your formula has a crop failure. A reactive manufacturer might not say a word until it delays your order. A proactive partner, on the other hand, calls you immediately. Better yet, they come to the table with pre-vetted alternative suppliers to keep your production moving. That's the difference.

Can They Grow With You?

Your brand's journey will hopefully involve serious growth. Your manufacturer must be ready to scale right alongside you. The ability to go from small test runs to massive orders without sacrificing quality is the hallmark of a top-tier operation.

This customization and flexibility are essential in the early days. Kicking things off with a smaller pilot run—maybe 500 to 1,500 units—is the smart way to test the market. It lets you get real customer feedback and validate your concept without sinking a ton of cash into inventory.

But once your Astragalus supplement takes off, you need a partner who can crank up production to 10,000, 50,000, or even 100,000 units per run. That takes serious infrastructure, quality systems that don't crack under pressure, and deep supplier relationships that can handle high-volume orders.

The question isn't just, "Can you make my product today?" It's, "Can you support my brand when we're five times bigger?" A partner who is truly built for the long haul will have solid answers and the track record to prove it.

A Partner in Innovation, Not Just Production

The supplement market is constantly changing, and your product line can't afford to stand still. A forward-thinking manufacturer acts as your eyes and ears on the ground, bringing fresh ideas and new opportunities to the table. They should be more than a factory; they should be a source of innovation.

This kind of collaborative spirit shows up in a few key ways:

- Suggesting New Ingredients: "We're seeing a lot of demand for formulas that combine Astragalus with Reishi mushroom for extra immune support. Have you thought about that for a line extension?"

- Highlighting Market Trends: "There's a big consumer shift toward glycerin-based tinctures because they taste better and are alcohol-free. That could be a great new angle for your brand."

- Improving Existing Formulas: "Our R&D team just found an extraction method that could boost the polysaccharide concentration in your current formula by 10%."

This innovative drive is directly linked to their own operational excellence. They're constantly improving their supply chain and working on sustainable cultivation practices to secure long-term ingredient availability. These aren't just buzzwords; these advances are critical for producing high-quality private label astragalus products, because quality assurance directly impacts your revenue and reputation. You can explore more about these market dynamics and see how a relentless focus on quality protects your brand.

In the end, you're looking for a collaborator who is just as invested in building your brand as you are. Their success is tied directly to yours, and that alignment creates the trust, reliability, and growth that defines a truly great partnership.

Answering Your Top Private Labeling Questions

Stepping into private labeling can bring up a lot of questions. As an Astragalus Root private label contract manufacturer, we’ve heard them all. Founders often wrestle with the same core uncertainties, and getting clear, honest answers is the first step toward building a successful brand.

We’ve compiled the most common questions we get from entrepreneurs just like you. The goal here is to cut through the jargon and give you the practical knowledge you need to move forward with confidence.

What Are Typical MOQs for a Liquid Astragalus Supplement?

Minimum order quantities, or MOQs, are always a hot topic, especially for new brands managing cash flow. They can vary between manufacturers, but for a liquid herbal supplement like Astragalus root, a typical starting point is between 1,000 to 2,500 units.

But a good partner knows that you need to test the market first. That's why you should look for manufacturers flexible enough to offer pilot programs with MOQs as low as 500 units. This is a game-changer for new brands, letting you get real customer feedback before you commit to a larger investment.

How Long Does the Private Label Process Take?

From our initial chat to your finished product shipping out the door, a realistic timeframe is about 8 to 12 weeks. This window allows us to handle every step with precision, never cutting corners on quality.

Here’s what that timeline usually looks like:

- Weeks 1-2: The discovery phase—initial consultation, finalizing your formula, and approving the quote.

- Weeks 2-4: We source and send all raw materials for third-party testing. No exceptions.

- Weeks 4-8: Your product comes to life. Production, blending, and bottling happens in our cGMP facility.

- Weeks 8-12: The final stretch includes quality assurance checks, labeling, and preparing your product for shipment.

Any transparent partner will give you a detailed project schedule at the start, so you're never left guessing. We cover this entire process in much more detail in our https://tritonnutragroup.com/private-label-liquid-supplements-a-comprehensive-guide-for-starting-your-own-brand.

Can I Supply My Own Ingredients or Packaging?

This question comes up a lot, but the answer is almost always no—for an important reason. To maintain strict cGMP compliance and guarantee full traceability from source to bottle, top-tier manufacturers work with a network of vetted, pre-qualified suppliers. Bringing in outside materials would trigger a long and expensive quarantine-and-testing process to meet our quality standards.

The same logic applies to packaging. Our bottling and labeling equipment is finely calibrated for specific types of bottles, caps, and labels to ensure a perfect, tamper-proof seal every time. Using our in-house options guarantees compatibility and keeps production running smoothly.

It's crucial to know the difference: 'White Label' is a generic, one-size-fits-all product. 'Private Label' is your unique vision brought to life by customizing a proven base formula, giving you a much stronger edge in the market.

Getting a handle on the financial side is also critical. Understanding the fundamentals of calculating wholesale prices is key to ensuring your Astragalus supplement is profitable and successful for the long haul.